A Complete Guide to Warehouse Automation ROI

As warehouse space tightens and labor costs climb, automation has become the competitive edge. But the true return on investment from automation goes far beyond just space and labor.

Modern automated warehouse systems deliver value across four key pillars: space efficiency, labor productivity, inventory control, and data intelligence. Understanding how each of these pillars contributes to your bottom line is essential for making a smart investment.

Automated systems, like Modula’s vertical lift modules (VLMs), make it easier to free up floor space, cut down on manual labor and boost overall efficiency.

The best part? Most companies see a full return on investment in just six to 18 months. Let’s take a closer look at how automation delivers real, measurable ROI by optimizing both space and labor.

Here’s what you’ll take away from this guide:

- How to quantify the gains from space, labor, security, and data.

- The key factors that drive overall productivity and profitability.

- Which automated systems are best suited to deliver these comprehensive results.

How Automation Maximizes Space Efficiency

One of the most immediate and measurable benefits of warehouse automation is how effectively it uses space, especially in facilities where every square foot counts.

Vertical Storage Solutions

Vertical lift modules make full use of your facility’s height by storing items in stacked trays that move automatically.

Instead of spreading out across the floor, inventory is stacked vertically, freeing up to 90% of your usable space and leaving room for other operations like packing or kitting.

A recent study found that simply rethinking how items are stored can boost warehouse capacity by 54%, all without adding a single square foot.

Reduced Need for Wide Aisles

In a traditional warehouse, aisles need to be wide enough for forklifts to turn and for workers to move safely, which takes up a lot of floor space.

But automated systems don’t need that much room.

Technologies like VLMs can operate in aisle widths as narrow as three to five feet, compared to the 12-foot standard for forklift lanes.

That means less space wasted on movement and more square footage dedicated to actual storage, or better yet, for activities that drive revenue, like warehouse consolidation.

Storage and Process Consolidation

Many warehouses have inventory scattered across different areas: bulk storage, forward picking zones, and special handling sections. Automated warehouse systems allow you to consolidate these disparate zones into a single, high-density unit. This not only saves space but also streamlines inventory management, as all items are tracked within one system, improving visibility and control.

How Automation Reduces Labor Costs and Boosts Productivity

Labor is one of the biggest costs in any warehouse, often making up 50 to 70% of total operating costs.

Automated systems help bring that number down by speeding up repetitive tasks, minimizing errors, and letting your team focus on higher-value work, like QA checks.

Fewer Manual Touchpoints with Goods-to-Person Systems

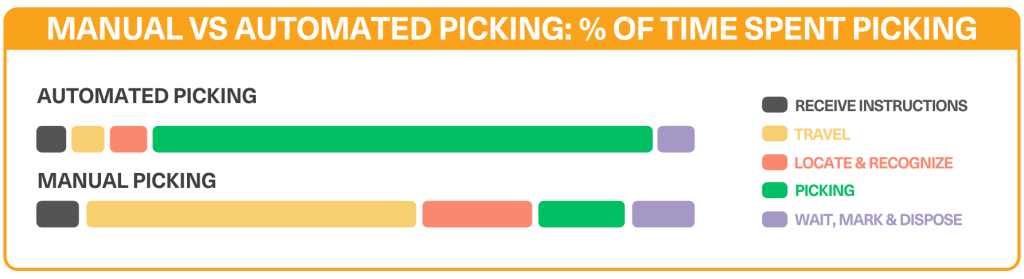

In a typical warehouse, up to 70% of a picker’s time is spent walking and searching for items. Automated warehouse systems flip this model on its head with a “goods-to-person” principle. Instead of workers traveling to the inventory, systems like VLMs and horizontal carousels retrieve the correct items and deliver them directly to an operator at a fixed station. This simple change eliminates unproductive travel time, drastically reduces handling, and lowers the risk of mispicks.

Improved Ergonomics and Safety

Walking, bending, reaching, and lifting heavy items all contribute to worker fatigue and injuries, leading to downtime, high turnover, and increased insurance costs. Goods-to-person automation delivers all items at an optimal ergonomic height, eliminating these risky movements. This creates a safer work environment, which is a significant, if often overlooked, component of automation ROI.

Faster Picking and Packing

Automated picking systems are fast, managing up to 550 lines per hour, compared to the 60 to 80 lines a manual picker typically operates.

By pulling SKUs in the right sequence and delivering them straight to the employee, these systems streamline the entire order fulfillment process.

The Modula Horizontal Carousel (HC) is built for exactly this kind of speed and efficiency. It’s an ideal solution for facilities with lower ceilings with demand high-volume picking.

Less Training Time

Training a new forklift driver or picker in a traditional warehouse can take two to four weeks.

With automation, it’s a different story. Systems like VLMs are intuitive to use and come with touchscreen controls, so most employees can be fully trained in just a day or two.

Curious how automation could improve your ROI?

How Automation Enhances Inventory Security and Accuracy for ROI

A major, often underestimated, component of automation ROI comes from gaining total control over your inventory.

- Drastically Reduced Shrinkage: Enclosed automated systems like VLMs function like secure vaults. Access can be restricted by user, and every transaction is tracked. This drastically reduces shrinkage from theft, damage, or misplacement, which is a direct financial gain.

- Near-Perfect Accuracy: The combination of software control and picking aids (like light pointers and LED bars) drives inventory accuracy rates to over 99%. This eliminates the high costs associated with stock write-offs, excessive safety stock, and emergency re-orders for items you mistakenly thought you had in stock.

How Automation Delivers Value with Software and Data Intelligence

Automation hardware handles the physical work, but it’s the software that drives strategy and long-term value.

- System Optimization: Software like a Warehouse Management System (WMS) or Warehouse Execution System (WES) acts as a force multiplier. It optimizes all automated equipment, ensuring it works on the highest-priority tasks in the most efficient sequence.

- Data as a Strategic Asset: Automated warehouse systems are incredible data-gathering engines. Every pick, machine movement, and stock level change is tracked. This operational data can be analyzed to identify hidden bottlenecks, predict maintenance needs, and drive continuous process improvement, turning the warehouse from a cost center into a source of business intelligence.

How Do You Calculate the ROI of Warehouse Automation?

Before investing, most companies ask the same thing: What’s the ROI and how long will it take to see results?

There’s no universal answer, but there is a straightforward way to figure it out.

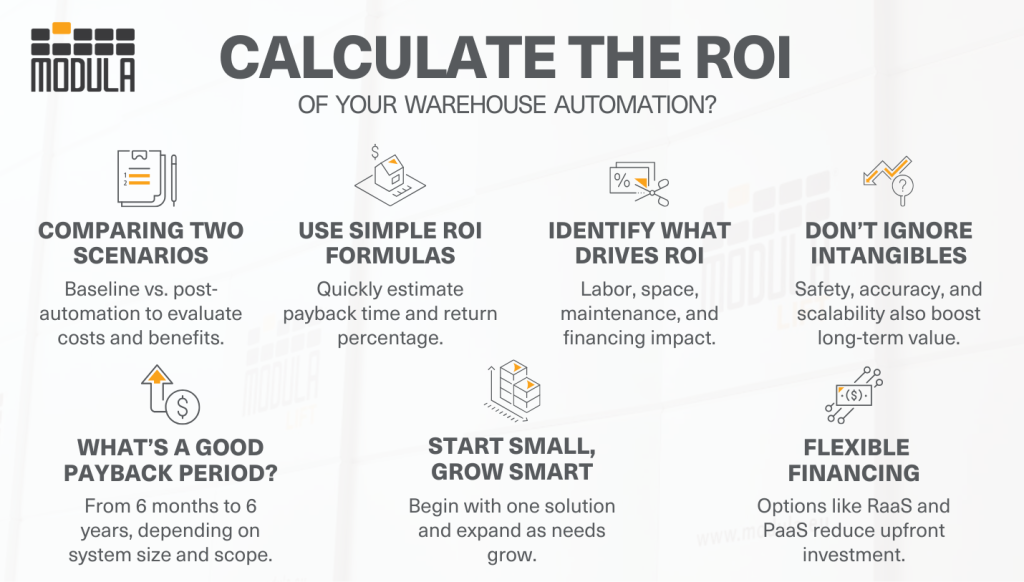

Start by Comparing Two Scenarios

To get a real handle on ROI, you’ll need to build out two scenarios:

- Scenario one is your baseline or how your operations run without automation. This includes current labor costs, layout limitations, and projected growth.

- Scenario two shows what your operations could look like post-automation, with all the related costs: equipment, software, integration, maintenance, and training.

Once you’ve got both models, you can compare costs and benefits side by side.

Use a Simple Formula to Start

While a full analysis is complex, you can start with two basic formulas:

- Payback Period = Initial Investment / Annual Savings. This tells you how long it will take to recoup your initial cost.

- Simple ROI = (Annual Savings – Initial Investment) / Initial Investment. This gives you a percentage return.

“Annual Savings” should include direct labor cost reductions, space savings (calculated as rent saved per square foot), and gains from increased accuracy and throughput.

Identify What Drives ROI?

A few big factors usually tip the scale:

- Labor savings are the most obvious. Automation minimizes the need for manual handling, which is especially valuable in a tight labor market.

- Maintenance and parts matter too. Some systems are low-maintenance, while others require ongoing service.

- Space efficiency is a hidden gem. Vertical systems and compact racking often free up 40–90% of your floor space.

- Energy use might increase a bit, but it’s usually offset by labor and space savings.

- Financing should be factored in using tools like WACC to reflect the cost of capital over time.

Don’t Ignore the Intangibles

Automation also brings big but less tangible wins, such as safer work environments, fewer picking errors, and the ability to scale more easily.

These benefits might not show up in a spreadsheet, but they reduce returns, lower injury-related downtime and help you adapt faster to demand shifts, all of which directly impact profitability.

What’s a “Good” Payback Period?

It depends. For third-party logistics (3PL) providers, the system could pay for itself within two to three years, or even sooner, depending on client contract terms.

For larger, more complex systems, a four- to six-year payback is common. The good news? Payback timelines are getting shorter as automation becomes more affordable.

At Modula, it’s common for prospective clients to ask how long it takes to see a return on investment with a vertical lift module (VLM) or horizontal carousel (HC). The answer usually exceeds expectations: most customers reach ROI within six to 18 months.

Though the upfront cost might be high, Modula systems quickly pay off by cutting labor, reclaiming space and lowering inventory costs.

These efficiencies add up fast, making the investment well worth it!

Start Small, Grow Smart

You don’t have to go all-in on day one. Many operations begin with a single VLM, AMR, or semi-automated station to solve a specific problem.

A modular approach lets you scale as demand grows, diminishing risk, preserving capital and avoiding operational disruption.

Consider Flexible Financing

Buying equipment outright isn’t your only option. Models like Robot-as-a-Service (RaaS) or Picking-as-a-Service (PaaS) let you pay as you go, turning a big capital expense into a manageable monthly cost.

That makes automation more accessible, especially for growing businesses.

How To Get Started With Warehouse Automation

Getting started with warehouse automation can feel like a big step, but with the right strategy, it’s one of the most practical upgrades you can make to improve efficiency, bring down costs and future-proof your operations.

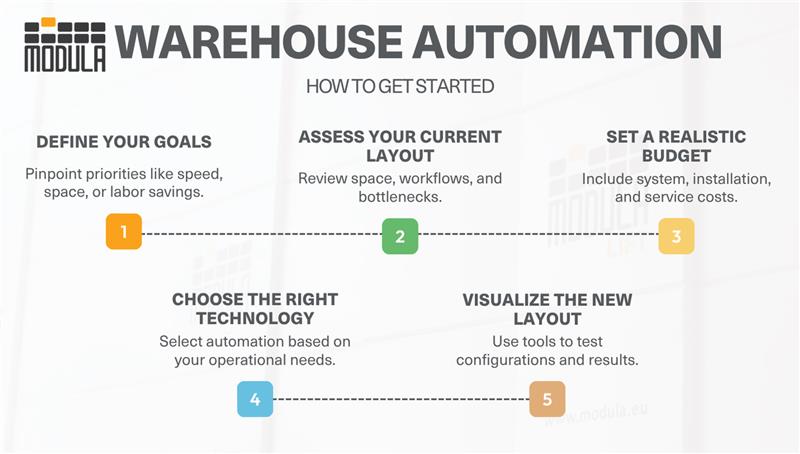

Define Your Goals

Begin by identifying what you want to improve.

- Is your main focus faster order fulfillment?

- Saving space?

- Decreasing labor costs?

Maybe all three. Knowing your priorities upfront will help you choose the best-fit technologies.

Assess Your Current Layout

Take a close look at your warehouse setup. This means your available space, workflows, ceiling height and how your picking zones are organized.

Spot the problem areas where automation could make the biggest impact.

Set a Realistic Budget

Automation can be scaled to fit your operation, but it’s still an investment.

For a brand-new system, you’re typically looking at $80,000 to $120,000. If you’re considering a used model, prices usually fall between $60,000 and $80,000. But keep in mind, older systems may come with outdated tech and higher maintenance needs.

And remember, those numbers don’t include installation or ongoing service costs, which can add up quickly.

Choose the Right Technology

Match your needs to the right tools. Vertical lift modules, horizontal carousels and AMRs each solve different problems, whether it’s saving floor space, boosting picking speed, or improving inventory accuracy.

Visualize the New Layout

Leverage a warehouse design tool to map out your space and simulate how automation would fit.

The Modula Plant Designer lets you test different configurations, optimize workflows and forecast performance improvements before making any physical changes.

Do you want to get an ROI estimate for your operation?

How Automated Warehouse Systems Improve Space and Labor ROI: Key Takeaways

- The full automation ROI is built on four pillars: space efficiency, labor productivity, inventory control, and data intelligence.

- Significant savings from all four pillars are what drive fast and compelling payback periods.

- Scalable and flexible automation lowers risk and improves long-term efficiency

How Automated Warehouse Systems Improve Space and Labor ROI: FAQs

How does automation actually help save space in a warehouse?

Automated systems like vertical lift modules (VLMs) take advantage of your building’s height, storing items in stacked trays instead of spreading them across the floor.

That means you can store more inventory without needing more square footage.

Can automation really decrease labor costs that much?

Yes. And often more than people expect. By cutting down on walking, searching and manual handling, automation helps teams work faster and more efficiently.

Depending on your setup, you could bring down labor hours by 30 to 70%, while also improving accuracy and eliminating strain on employees.

How can I estimate the ROI for my warehouse?

It’s easy. Just use our ROI calculator to get a quick, customized estimate based on your operation’s needs.

Matching the System to Your Goal

While many systems offer overlapping benefits, certain technologies excel at solving specific problems. Here’s a more detailed guide to which automated systems are best suited to deliver comprehensive results based on your primary objective.

For General-Purpose Space Saving & Security

This is the core strength of Vertical Lift Modules (VLMs). Solutions range from the highly versatile Modula Lift for mixed-sized inventory to the compact Modula Slim for facilities where every square foot is critical.

- Primary ROI Driver: Reclaiming up to 90% of floor space, which directly translates to reduced real estate costs or deferred facility expansion.

For High-Speed, High-Volume Picking

When throughput is the top priority, Horizontal Carousels (HCs) are a premier choice. For operations handling high volumes of small items in standardized bins, specialized VLMs like the Modula Flexibox are also engineered for maximum speed.

- Primary ROI Driver: Drastically increased order fulfillment speed and labor throughput, allowing you to process more orders with the same headcount.

For Enhanced Security & Access Control

For high-value items requiring precise tracking and controlled access, the Modula Next offers advanced, vending-machine-like dispensing for ultimate inventory control.

- Primary ROI Driver: Eliminating shrinkage from theft or damage and improving the accuracy of high-value inventory.

For Heavy Loads & Pallet Handling

To improve safety and efficiency when storing heavy materials or pallets, the Modula Pallet is the ideal solution. It retrieves pallets and brings them to the operator, eliminating the need for forklifts in the storage aisle.

- Primary ROI Driver: A twofold return from improved workplace safety when dealing with heavy materials and pallets (reducing injury-related costs) and increased operational efficiency

For Boosting Picker Accuracy & Efficiency

To get the most out of any storage unit, Modula Picking Solutions are essential. Tools like Put-to-Light systems, mobile Picking Carts, and operator display consoles guide workers, dramatically increasing accuracy and enabling efficient multi-order (batch) picking.

- Primary ROI Driver: Increasing picking accuracy to over 99% (reducing costly errors) and maximizing the number of orders each operator can fulfill per hour.

For Specialized and Controlled Environments

For industries like electronics, pharmaceuticals, or food storage, Modula Storage Solutions for Controlled Environments are required. This includes systems designed for Clean Rooms, temperature-controlled storage (Climate Control), and low-humidity environments (Dry).

- Primary ROI Driver: Protecting products from contamination or degradation, which prevents costly spoilage and ensures regulatory compliance.

For Overall Intelligence & Optimization

A robust Warehouse Management System (WMS) is the essential software layer that directs all hardware and unlocks the data needed for continuous improvement.

- Primary ROI Driver: Optimizing the entire operation by providing the data needed for continuous improvement and maximizing the efficiency of every hardware component.