How To Reduce Warehouse Costs in 2025

Whether there’s another global pandemic or a nationwide recession on the horizon, it’s essential to cut current warehouse costs to help recession-proof your operations against economic downturns.

In this article, we’ll explore warehousing forecasts for 2025 and reveal strategies focused on automation that can help decrease warehouse costs.

We’ll also demonstrate how Modula’s automated solutions can cut your operating expenses and position your warehouse for profitability in 2025 and beyond.

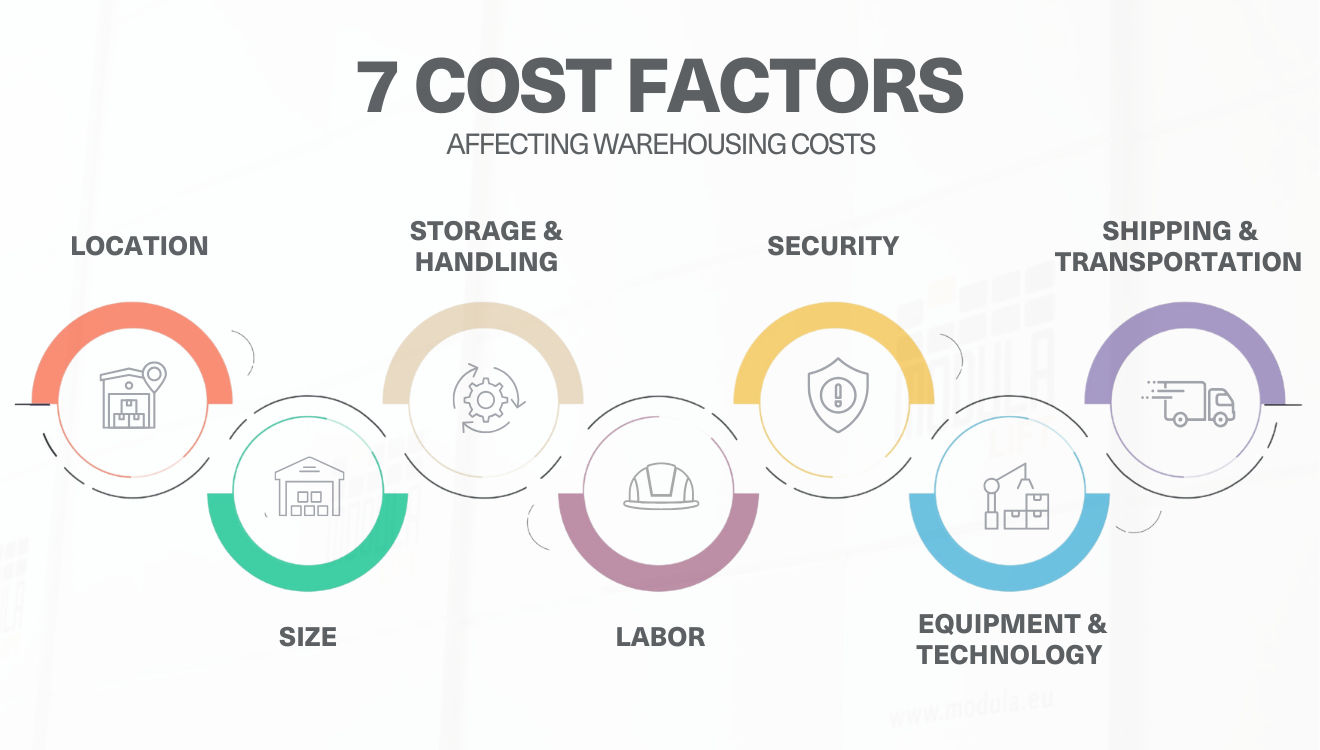

Factors That Affect Warehouse Cost

Warehousing costs refer to the expenses of operating a warehouse.

These expenses may include rent, utilities, labor, insurance, maintenance, taxes, inventory control and order fulfillment.

Factors That Affect Warehousing Costs

Running an efficient warehouse involves various costs influenced by location, size and storage practices.

Understanding each contributing factor can help you take a deeper look at your warehouse costs to identify overspending and find methods to reduce your overhead.

Location

Location has a significant impact on cost, due to the direct correlation of transportation expenses, accessibility to suppliers and customers, and regional variations in taxes, land prices and labor rates.

For example, warehouses closer to distribution channels can help reduce transportation costs, but may have higher land or lease costs.

High-demand areas, like those near major transportation hubs, usually have higher real estate prices, as businesses compete for the logistical benefits these areas offer, such as accessibility.

Size

The bigger the warehouse, the higher the initial construction or lease costs.

Most bigger warehouses require more extensive infrastructure, such as complex electrical systems or plumbing, driving the initial setup expenses. Moreover, larger warehouses incur greater ongoing operational expenses, including electricity, personnel, and maintenance costs.

Storage and Handling

Specialized storage solutions can further affect operating costs, as they are equipped with advanced technology.

For example, a warehouse with climate-controlled storage will require heating cooling features, leading to higher energy consumption.

Labor

Wages and salaries account for a significant portion of operational expenses. States with higher minimum wages such as the District of Columbia, or greater labor demands, may increase labor costs. Additionally, factors such as employee training also contribute to these expenses.

Security

Implementing surveillance cameras and alarm systems or hiring security personnel, are vital for facility protection but entail significant costs.

These expenses vary based on the sophistication of the security technology and expertise of the security personnel.

For instance, advanced cameras with night vision or motion detection capabilities typically cost more than basic models without these features.

Likewise, high-tech alarm systems that incorporate facial recognition software or mobile device integration can substantially increase expenses compared to more basic setups.

Equipment and Technology Costs

Investing in essential warehouse equipment and technology is crucial for efficient warehouse operations. However, it comes with significant costs.

These include purchasing, maintaining, and upgrading material handling equipment like forklifts, conveyor belts, and automated storage and retrieval systems (ASRS), as well as implementing warehouse management systems (WMS).

To paint a better picture, the cost of a vertical lift module (VLM) varies based on the system’s size, capacity, customization level and technology.

A new system typically costs between $60,000 and $100,000. Alternatively, used models are available for $30,000 to $40,000, though they may feature outdated technology and require more maintenance.

Shipping and Transportation Costs

Shipping and transportation significantly influence overall warehouse costs. These expenses fluctuate with changes in fuel prices, delivery distances, carrier fees and the size and weight of shipments.

To manage these costs effectively, optimize delivery routes, consolidate shipments and negotiate better carrier rates.

How To Calculate Warehouse Costs

You can typically rent warehouses on a monthly or annual basis, with rental prices based either on square footage or inventory size.

If you store small parts or inventory, you’ll likely based on the number of items stored. However, for large inventory items, charges may be based on the storage space required.

When calculating total costs, consider the rental rate and the NNN/CAM charges. NNN charges, also known as triple net lease, includes the tenant’s share of three additional expenses — property taxes, insurance and property maintenance.

Alternatively, common area maintenance (CAM) charges cover expenses associated with maintaining shared spaces in a commercial property. These typically include maintenance, repairs, landscaping, security, utilities and snow removal.

The rental rate covers the basic cost of renting the space but doesn’t include utilities or taxes. NNN/CAM charges cover additional occupancy expenses.

If the landlord includes utilities in the warehouse space quote, they fall under NNN/CAM charges. Otherwise, utilities are an additional expense beyond the rental rate and NNN/CAM charges.

How To Reduce Warehouse Costs in 2025

Get a head start and implement the cost-saving tactics below for profitability in 2025.

1. Analyze Your Warehouse Operations

Analyzing your warehouse operations can help you pinpoint inefficiencies and optimize your resource allocation and processes, leading to substantial cost savings.

Assess your warehouse operations by conducting regular audits, utilizing data-driven performance metrics, implementing a warehouse management system (WMS) and getting feedback from your employees.

2. Evaluate Your Transportation Costs

Gauging your transportation practices can help reduce warehouse costs, as you can negotiate better rates with freight carriers, or optimize routing and delivery schedules.

Evaluate your transportation costs by analyzing your historical shipping data, reviewing current contracts with freight carriers and tracking the frequency and accuracy of deliveries.

3. Maximize Space

Optimizing your warehouse space can help reduce warehouse costs, as efficient utilization reduces the need for a bigger facility and minimizes energy expenses.

Maximize space in your facility by implementing efficient warehouse storage solutions, such as vertical lift modules (VLMs), and integrating a WMS for strategic product placement — for example, placing high-turnover items closer to shipping areas to minimize retrieval times.

4. Practice Cross Docking

Cross docking is the practice of moving products directly from a manufacturer or supplier to a retail chain or customer. Using inbound and outbound docks, products are received, then immediately transferred to trucks for delivery.

Cross docking can help reduce warehouse costs, as it eliminates the middleman and in turn, minimizes the need for extra storage space and reduces the handling of goods.

To practice cross docking, utilize logistics software to track shipments in real-time and predict arrival and departure schedules. Then, designate specific zones within your warehouse for inbound and outbound activities to optimize the flow of goods.

5. Buy Used Containers

When it comes to shipping or storing your inventory, opt for used containers. Whether pallets, bins, baskets, trays, totes or others, this may be one of the easiest cost-saving tips in the warehousing industry.

6. Utilize the Benchmarking Technique

Benchmarking is a technique used to compare your key performance indicators (KPIs) against other warehouses in your industry, to determine how you can improve warehouse management in your facility.

To utilize the benchmarking technique, identify warehouse KPIs, such as inventory turnover and order accuracy, that are most relevant to your warehouse operations.

Then, collect data from warehouses in your industry through industry reports or surveys and analyze the differences and similarities between your warehouse’s performance and the benchmarks.

7. Protect Your Inventory

Key factors in financial loss when it comes to inventory include stock damage and theft — both internal or external.

If you’re not actively protecting your inventory, you’re risking financial loss.

Hire security guards, install cameras and restrict access to areas that hold your most valuable inventory. In addition, train your employees to properly handle inventory to help reduce accidental inventory damage.

8. Maximize Your Equipment

Maximizing your equipment means making sure it is running at 100% utilization.

To make the most of your equipment:

- Use predictive maintenance to monitor your equipment

- Track how long each machine is in use or idle to reduce unnecessary wear and tear

- Set up a maintenance schedule for each piece of equipment based on its age and condition so that it is serviced at least once a year

9. Cut Down on Energy Costs

Whether for electricity, gas or heat, the total cost of energy can be substantial.

To cut down on your energy costs, improve your warehouse insulation, install solar panels and upgrade older equipment with newer models that consume less power — for example, use VLMs instead of outdated vertical carousels.

Identify the methods that will prove most cost-effective for your warehouse, and make the changes needed to reap the benefits down the road.

10. Implement Warehouse Automation

Warehouse automation can help reduce warehouse costs in the long term, as it minimizes human error, increases efficiency and reduces costly product damage.

Implement automated warehouse solutions such as conveyor belts, warehouse robotics and automated storage and retrieval systems (AS/RS) to reduce your warehouse costs for 2024.

The Benefits of Reducing Warehouse Costs Through Automation

Automated solutions can help drastically reduce your warehouse costs. The benefits of automation include:

Reduce Your Warehouse Costs with Modula’s Automated Solutions

As the leading provider of advanced storage solutions and inventory management systems, we offer state-of-the-art innovations to help you reduce warehouse costs and set up your business profitability for years to come.

Our automated solutions at Modula include:

1. Modula Vertical Lift Modules

Make use of your existing warehouse space by utilizing every inch of your available ceiling height.

Modula vertical lift modules come in three models:

- Modula Lift: Boost efficiency, picking speeds and accuracy by up to 90% with our most popular vertical lift module.

- Modula Slim: Leverage the same innovation as the Modula Lift, but in a more compact design. Ideal for smaller warehouses.

- Modula Next: Combines the space-saving and efficiency of Vertical Lift Modules (VLMs) with all the precision and control of industrial vending machines.

- Modula Pallet: Safely handle pallets directly from the ground, eliminating the need for forklifts.

2. Modula Horizontal Carousel

Working with limited ceiling height? You can count on our Modula horizontal carousels.

The Modula HC allows you to save space, boost throughput, reduce labor costs, and store and retrieve items as needed with minimal labor.

The horizontal carousel consists of carriers (bins), which are mounted on an oval track that rotates horizontally and delivers stored goods to the picker.

Each shelf can be divided into totes, bins, and partitions to create an efficient and well-organized storage space. Modula HCs are commonly used in warehouses and distribution centers for their ability to quickly handle large quantities of inventory.

When seasonal demands arise, you can boost your picking accuracy by up to 99% with barcode readers and Put to Light Systems (more on this below!)

Check out our horizontal carousel in action in the video below!

MODULA HC: the New Horizontal Carousel for Efficient Picking

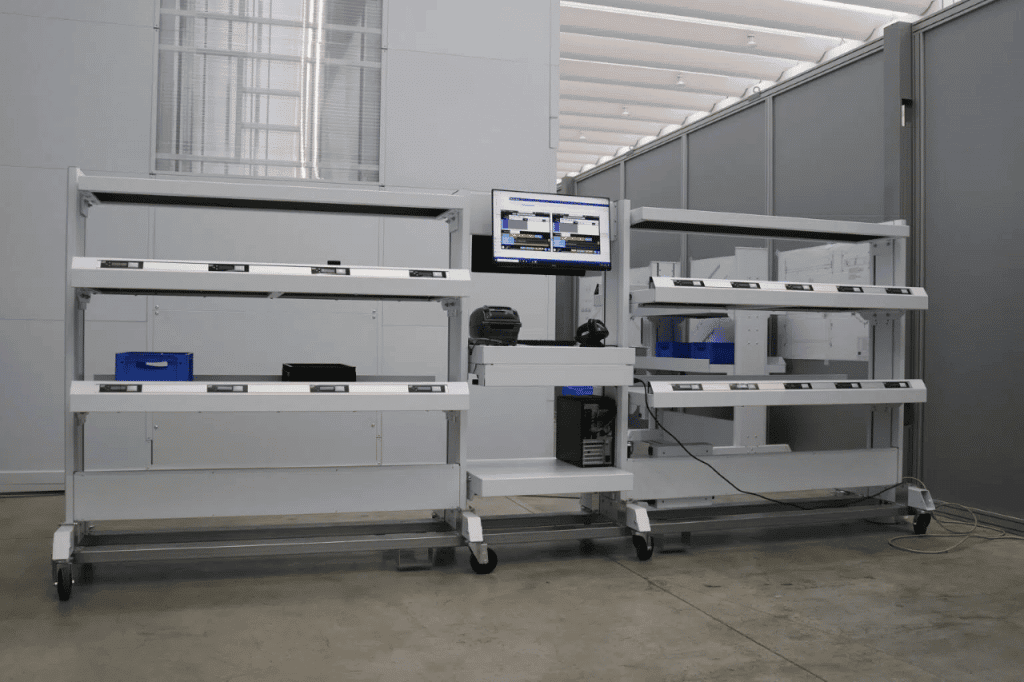

3. Modula Order Picking Solutions

Are your picking operations quick enough to meet challenging consumer demands? Save time and money with Modula order picking solutions.

Our automated warehouse picking solutions allow your operators to simultaneously fulfill multiple orders.

Our automated warehouse picking solutions allow your operators to simultaneously fulfill multiple orders.

Our Modula Warehouse Order Picking Solutions include:

- Mobile Picking Station: Process large volume orders quickly

- Modula Picking Cart: Move inventory to and from different areas within your warehouse

- Modula Put to Light: Direct your warehouse pickers to the correct picking zone

- Modula Mobile Picking App: Manage your picking operations whether on-site or on the go

4. Autonomous Mobile Robots

Need an extra hand with order fulfillment when demand spikes? Look no further than Modula autonomous mobile robots (AMRs).

Check out our AMRs in action in the video below!

Modula & MiR: automatic storage systems and autonomous mobile robots. How do they work together?

Autonomous mobile robots allow you to:

- Automate time-consuming tasks so your warehouse operators can focus on more value-added work that requires human intervention

- Increase accuracy and productivity to fulfill more orders in less time

- Balance the uptick in demand during fluctuating and peak seasons

- Adapt to evolving needs without requiring structural modifications

- Optimize inventory management when integrated with Modula’s warehouse management system

(Interested in learning more about AMRs? Check out our guide to autonomous mobile robots!)

5. Modula Warehouse Management Systems

Gain inventory control and visibility to prevent dead stock and overstock with Modula warehouse management systems.

Modula WMS is a comprehensive warehouse management software that improves the accuracy, efficiency, and visibility of all operations.

It integrates with Modula vertical lift modules and any local ERP systems to provide a complete warehouse solution.

This allows you to store and manage your data in a centrally located, easy-to-manage system. Thanks to its scalability, it can grow with your business as your warehousing needs change over time.

Modula warehouse management solutions allow you to:

- Accurately pick and replenish your warehouse inventory

- Gain better control over inventory management, preventive maintenance and material handling

- Prevent potential employee theft and unauthorized access with next-level security and identity systems

- Operate in batch and multi-order modes

In Conclusion

Reducing your warehouse costs through automation can help you prepare for even the most unexpected situations that might lie ahead.

At Modula, our automated solutions are designed to help you streamline operations and reduce costs throughout the warehouse, from storage to picking and beyond.