Modula Next

Modula Next is an innovative automated storage and retrieval solution, that combines the space-saving and efficiency of Vertical Lift Modules (VLMs) with all the precision and control of industrial vending machines.

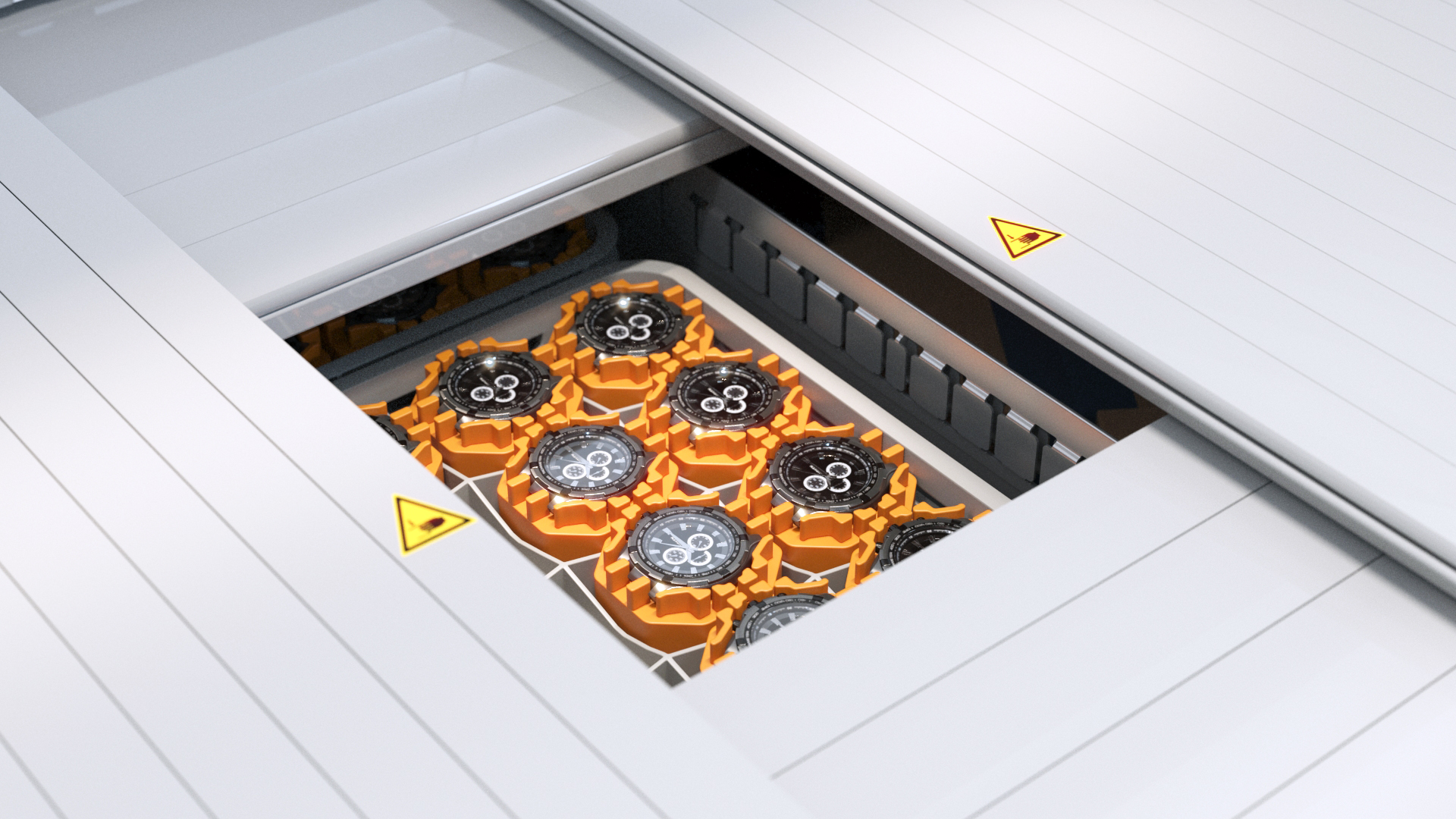

When an item is requested, the unit retrieves the specific tray where the item is stored and brings it to the picking bay at an ergonomic height. Unlike conventional Vertical Lift Modules, Modula Next’s shuttering door system only opens the compartment containing the requested item. This ensures unmatched precision in picking and replenishment operations.

Why Choose Modula Next

Smart System Combination

Combines the precision of industrial vending machines with the capacity of Vertical Lift Modules.

Innovative Design

The Sliding shutter doors provides access only to a specific item, an individual compartment at a time.

Flexibility and Customization

Adjustable compartments on the fly make it versatile for various industrial needs, and diverse item sizes.

Versatility Across Industries

Ideal for healthcare, retail, aerospace, automotive, MRO, and any Industries handling sensitive or high-value items.

Modula Next – How Does It Work?

The Right Part to the Right Person.

Modula Next operates on a goods-to-person principle.

When an item is requested, the unit retrieves the specific tray where the item is stored and brings it to the picking bay at an ergonomic height.

Unlike conventional Vertical Lift Modules, Modula Next’s shuttering door system opens only the compartment containing the requested item. The targeted access mechanism ensures that operators can only access the designated item.

This is especially crucial when managing costly or sensitive materials, or in applications where picking accuracy is paramount.

Safety For Your Products & Operators

1. Safety with User identification

Every unit is password protected, allowing access only to authorized operators with a badge or access code. All picking operations and logins are monitored even down to specific trays, depending on the chosen level of security.

2. Safety Light Barriers

Every unit is password protected, allowing access only to authorized operators with a badge or access code. All picking operations and logins are monitored, even down to specific trays, depending on the chosen level of security.

3. Emergency Stop Button

Every unit is password protected, allowing access only to authorized operators with a badge or access code. All picking operations and logins are monitored even down to specific trays, depending on the chosen level of security.

Modula Next – Technical Highlights

Modula Next – Special Applications

Consignment Inventory

For suppliers, it translates into efficient consignment inventory service, enhancing their value proposition. Clients benefit from having the right tools at the right time.

Personal Protective Equipment

By consolidating all PPE into one accessible location, it ensures that essential safety gear is available, properly managed and secured, and compliant with regulations.

Dispensing Kitted Components

Significantly improves the management of kits. Unlike vertical lift modules, this solution adds a layer of security with access to only one compartment at a time.

Handling High-Value or Sensitive Items

Modula Next is perfect in industries like jewelry, electronics, pharmaceuticals, and aerospace, where protecting high-value items is critical.