Best Automated Warehouses for eCommerce Fulfillment [+ FAQs]

Same-day delivery and artificial intelligence are continuously shaping the logistics industry. To meet growing customer expectations, eCommerce businesses need automated warehouse solutions that are faster, smarter and more flexible.

The numbers prove just how important this is: The global same-day delivery market is expected to grow from $9.90 billion in 2024 to $29.82 billion by 2030.

To stay competitive, it’s essential to understand which automation technologies deliver real value.

By the end of this guide, you will:

- Understand why automating the order fulfillment process is a good investment

- Recognize typical challenges when implementing warehouse automation

- Learn the key automated systems and technologies best suited for automated eCommerce

Why Invest in an Automated Warehouse for eCommerce Fulfillment?

Automating your eCommerce fulfillment process is a strategic investment that delivers measurable returns.

As customer expectations for delivery speed and order accuracy grow, manual processes often struggle to keep pace.

Automated fulfillment systems help bridge that gap by improving efficiency, accuracy, and scalability across every step of the order lifecycle.

Here are five ways it delivers measurable value:

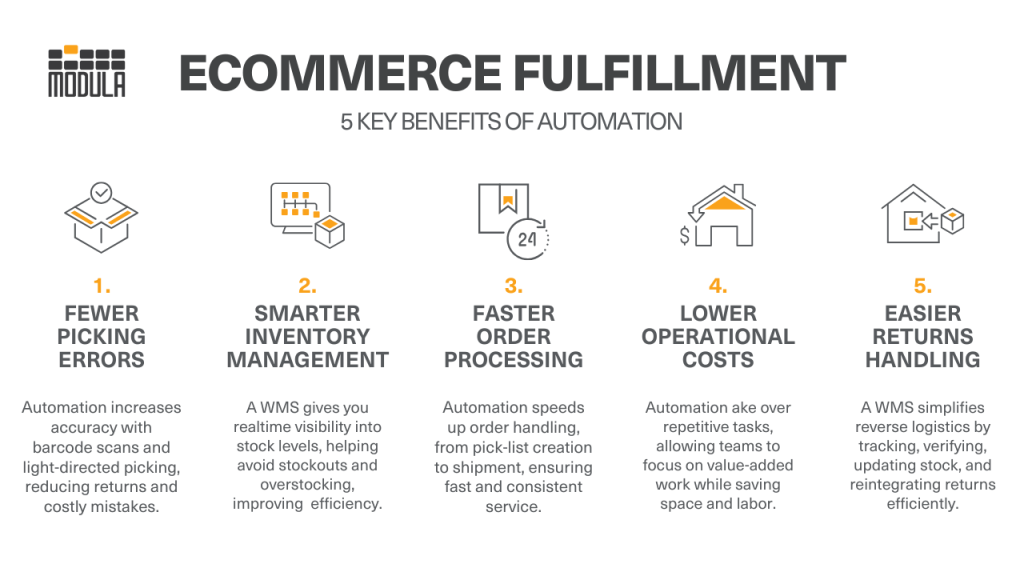

1. Minimizes Costly Picking Errors

Manual order picking is prone to human error, and a single mis-pick can lead to expensive returns, reverse logistics costs, and a poor customer experience.

Automated ecommerce systems use light-directed picking, barcode scanning, and software verification to drive picking accuracy rates to over 99%, protecting your bottom line and brand reputation.

2. Improves Inventory Management With Real-Time Data

Effective eCommerce fulfillment relies on having a clear understanding of your stock levels and their locations.

An integrated Warehouse Management System (WMS) provides a precise, real-time view of stock levels. This prevents stockouts of popular items and avoids overstocking slow-movers, optimizing cash flow and warehouse space.

3. Achieves Faster, More Reliable Order Processing

Online shoppers now expect near-instant order processing. Automation eliminates manual bottlenecks.

The system can quickly allocate inventory, generate a pick list, and guide operators the moment an order is placed, ensuring that orders are processed and shipped much faster than manual methods.

This speed and reliability increases customer trust.

4. Reduces Operational and Labor Costs

Automation directly addresses rising labor costs and shortages.

By allowing systems to manage repetitive tasks such as walking, searching, and lifting, you can redeploy your team to focus on more complex and value-added work.

Additionally, high-density storage solutions can reduce your facility’s physical footprint, saving on expensive real estate costs.

5. Streamlines Returns Processing (Reverse Logistics)

A complicated returns process can turn a customer away for good.

Automated warehouses streamline reverse logistics by using a Warehouse Management System (WMS) to:

- Quickly track returned items

- Verify their condition

- Update inventory counts in real time

- Direct the items to the appropriate storage location for resale or disposal

Inside the Best Automated Warehouses for eCommerce Fulfillment

The best automated warehouses rely on a combination of technologies. These systems work together to manage the entire fulfillment process.

From receiving to storage, picking, packing, and shipping, automation ensures speed, accuracy, and control.

Below is an overview of the main technologies used in modern automated eCommerce operations.

High-Density Storage and Retrieval (ASRS)

Automated Storage and Retrieval Systems (ASRS) enable you to store more in less space. They use vertical or horizontal configurations to deliver items directly to the operator which reduces walking time and improves accuracy.

Vertical Lift Modules (VLMs)

Vertical lift modules (VLMs) are enclosed systems with vertically arranged trays that automatically deliver stored items to an access bay at an ergonomic height.

They’re ideal for managing a wide mix of SKUs in a minimal footprint. Solutions like the Modula Lift and Modula Slim are well-suited to facilities that need flexibility, security, and floor space savings.

Horizontal Carousels (HCs)

Horizontal carousels feature rotating bins on an oval track, making them ideal for low-ceiling environments and high-throughput picking zones.

Systems like the Modula HC provide fast access to stored items and are often used for order consolidation or batch picking.

Shuttle Systems

Shuttle-based ASRS use robotic shuttles that travel on tracks across storage aisles to retrieve totes or bins.

These systems offer high throughput and are ideal for operations with a large number of SKUs and frequent order changes.

Mini load ASRS

Miniload systems use small, automated cranes to handle totes or trays in narrow aisles.

They’re commonly used in eCommerce and retail fulfillment for storing small parts and managing high-volume order picking.

Unit Load ASRS

These systems are designed for handling full pallets or heavy loads. Automated cranes retrieve and store items on racking systems that extend vertically.

They’re typically used in distribution centers or for buffering inventory between production and shipping.

Mobile Robotics and Conveyors

Storing inventory efficiently is just one part of fulfillment. Moving products quickly between areas is just as important. For this reason, mobile robots and conveyors are used to transport items across the warehouse.

Autonomous Mobile Robots (AMRs)

AMRs are increasingly common in fulfillment centers thanks to their flexibility.

They use sensors, cameras, and navigation software to move independently through dynamic environments, avoiding obstacles and adapting their paths in real time.

Typical AMR use cases in eCommerce include:

- Goods-to-Person Picking: AMRs retrieve totes or bins from storage and deliver them to an operator, reducing walking time and speeding up the picking process.

- Zone-to-Zone Transfers: AMRs transport goods between key warehouse areas. For example, from receiving to the ASRS induction point or from picking to packing.

Automated Guided Vehicles (AGVs)

AGVs follow fixed paths and are used for repetitive tasks. For example, they can transport pallets between storage areas and shipping docks. While less flexible than AMRs, they are reliable in consistent workflows.

Conveyor Systems

Conveyors are one of the oldest and most reliable forms of automated transport.

They are ideal for moving items over long distances within the warehouse, especially when there is a high volume of bins, trays, or packages to process.

Conveyors are often used to connect picking areas with packing stations or sortation zones, ensuring a steady flow of goods.

When integrated with control software, conveyors can automatically direct items to different destinations based on order data, reducing the need for manual sorting.

What makes these technologies especially effective is their ability to integrate with automated storage systems.

For instance, Modula’s vertical lift modules can be configured with access points that allow AMRs to load and unload trays directly.

This type of integration supports a more continuous and hands-free material flow, speeding up the overall fulfillment process.

Picking and Verification Technologies

In eCommerce fulfillment, picking errors are costly. They impact not just returns, but also customer satisfaction.

That’s why accuracy is just as important as speed. Modern warehouses rely on a mix of visual guidance tools and robotic systems to ensure each item is picked correctly.

Light-Directed Systems

Pick-to-Light and Put-to-Light systems use lights to guide operators during the picking process.

Each light indicates the exact location and quantity to pick or place.

This reduces confusion and helps prevent mistakes and is especially useful for batch picking.

Light-directed technologies come in different formats:

- Fixed systems, such as the Modula Picking Station, are installed at dedicated workstations.

- Mobile systems, like the Modula Picking Cart, can move across different zones, supporting more flexible workflows.

Robotic Piece-Picking

For higher levels of automation, robotic arms equipped with vision systems can identify, pick and place individual items into order containers.

These systems are especially effective for handling high volumes of small items with repetitive picking requirements. As the technology evolves, robotic picking is becoming more accurate and versatile.

Automated Packing and Sortation Systems

After picking, orders must be packed and sent to the right shipping lane. These processes can often cause major bottlenecks.

- Automated Packaging: To minimize shipping costs and material waste, on-demand packaging systems create custom-fit boxes or bags for each specific order. This is a cost-saving measure in high-volume eCommerce.

- High-Speed Sortation: Automated sorters (such as tilt-tray or cross-belt systems) can process thousands of packages per hour, routing them to the correct shipping lane with minimal human intervention.

The Digital Layer: WMS, WES, and IoT

Behind every successful automated warehouse is a strong software layer. These tools connect systems, manage tasks, and provide visibility across the operation.

Warehouse Management System (WMS)

A WMS is the central database for all inventory and order data. It handles product locations, stock levels, and task assignments.

Modula WMS, for example, integrates seamlessly with ASRS systems and external ERPs, offering real-time inventory control and support for various picking strategies.

Warehouse Execution System (WES)

While the WMS manages the big picture, a WES focuses on real-time operations.

It connects software to automation hardware, such as ASRS units, mobile robots, or conveyors, and dynamically adjusts task flow to prevent congestion or downtime.

This orchestration ensures that picking, packing, and replenishment stay balanced and efficient.

Internet of Things (IoT)

IoT platforms add another layer of insight. Sensors placed on equipment monitor performance, usage, and potential issues.

Solutions like Modula IoT enable proactive maintenance and system monitoring, giving managers full visibility of the operation from any connected device.

How To Choose the Right Automation Technology

Not all eCommerce fulfillment operations are the same. The best automated warehouses use technologies that match their specific business model, order volume, and space constraints.

Defining your eCommerce fulfillment profile is the first step toward smarter automation.

By examining aspects like your order profile, picking priorities, and shipping requirements, you can identify the right solutions for your business. Consider the following:

1. What Is Your Order Profile?

WHY IT MATTERS: The way your orders are structured influences how you should prioritize your picking process. Is speed more important, or accuracy?

SCENARIO A: HIGH VOLUME, FEW ITEMS PER ORDER

You ship many orders every day. Most contain only one or two items.

Example: A direct-to-consumer fashion brand or a business with a best-selling product.

YOUR CHALLENGE: Maximize throughput. The bottleneck is the speed at which your team can pick, pack, and ship many small, repetitive orders.

SCENARIO B: LOW VOLUME, MANY ITEMS PER ORDER

Your orders include many different SKUs.

Example: B2B distribution, a hobbyist eCommerce store, or an auto parts supplier.

YOUR CHALLENGE: Maximize accuracy. These orders are complex. A single mistake leads to costly returns and poor customer satisfaction. The focus should be on guided picking and clear instructions.

2. What Is Your SKU Profile?

WHY IT MATTERS: The number, shape, and turnover rate of your products influence the best storage and picking systems.

SCENARIO A: FEW HIGH-TURNOVER SKUS (THE 80/20 RULE)

A small number of products drive most of your revenue.

YOUR CHALLENGE: To stay ahead, fast movers must always be in stock and within easy reach. Streamlined replenishment is critical to avoid disruptions and lost sales

SCENARIO B: THOUSANDS OF DIVERSE SKUS

You carry a large, varied catalog. Many items sell slowly.

Your challenge: Optimize storage density. You need to keep all items accessible, without wasting space or time searching for them.

3. How Are You Using Your Warehouse Footprint?

WHY IT MATTERS: Space is expensive. You need to use every cubic foot, not just every square foot.

SCENARIO A: HIGH CEILINGS, LIMITED FLOOR SPACE

Your facility is in a high-cost area. Expanding horizontally isn’t an option.

YOUR CHALLENGE: Increase capacity without expanding your footprint. The best approach is to build upward with vertical systems like VLMs.

SCENARIO B: LOW CEILINGS, WIDE AREA

You work in an older facility or mezzanine level. Horizontal space is available.

YOUR CHALLENGE: Reduce walking. Your team spends too much time traveling between zones. You need solutions that bring goods to the operator.

4. What Is Your Primary Operational Bottleneck?

WHY IT MATTERS: Automation should fix a real problem. Knowing your weakest point helps you focus your investment where it counts.

SYMPTOM 1: EXCESSIVE PICKING TIME

Your operators spend more time walking than picking.

WHAT YOU NEED: A goods-to-person solution. Items should come to the operator automatically.

SYMPTOM 2: FREQUENT PICKING ERRORS

You often ship the wrong item or quantity.

WHAT YOU NEED: Picking assistance tools, such as light-directed systems or scanners, to reduce human error.

SYMPTOM 3: LACK OF STORAGE SPACE

You constantly run out of room and your layout feels disorganized.

WHAT YOU NEED: A high-density storage system to compress your inventory and free up floor space.

SYMPTOM 4: POOR INVENTORY VISIBILITY

Your system says an item is in stock, but your team can’t find it.

WHAT YOU NEED: A real-time warehouse management system (WMS) integrated with your hardware.

| DIMENSION | SCENARIO | YOUR CHALLENGE | SUGGESTED FOCUS |

|---|---|---|---|

| Order Profile | High volume, few items per order (e.g., DTC fashion, single-product brands) | Maximize throughput | Fast goods-to-person picking systems that minimize walking |

| Low volume, many items per order (e.g., B2B, auto parts, hobby stores) | Maximize accuracy | Light-directed picking, barcode scanning, strong WMS integration | |

| SKU Profile | Few fast-moving SKUs (80/20 rule) | Keep high-demand items always available | Fast replenishment, easy access storage zones |

| Thousands of slow-moving SKUs (long tail) | Save space while keeping everything accessible | High-density storage like VLMs or Mini load ASRS | |

| Warehouse Footprint | High ceilings, limited floor space | Use vertical space | Vertical Lift Modules (VLMs), vertical ASRS systems |

| Low ceilings, wide layout | Reduce walking time | Horizontal carousels, AMRs, mobile picking stations | |

| Main Bottlenecks | Excessive walking and long picking times | Low productivity and fatigue | Goods-to-person automation, conveyors or AMRs |

| Frequent picking errors | Costly returns and bad CX | Pick-to-light, put-to-light, barcode validation systems | |

| Lack of storage space | Inventory overflow, chaos | Compact ASRS systems, better slotting strategies | |

| Poor inventory visibility | Lost items, delays, backorders | Real-time WMS with location tracking |

Once you’ve answered these questions, you’ll be in a stronger position to identify the right automation solution. In some cases, the next step might be building your own system.

In others, outsourcing fulfillment to a third-party logistics provider (3PL) with automation already in place could be the smarter choice.

Let’s explore that option next.

Build or Outsource? In-House Automation vs. a 3PL Partner

Before deciding which automation technology to buy, ask yourself a more strategic question: Should you manage automation yourself at all?

For many eCommerce businesses, especially growing small and mid-sized brands, the answer might be no.

A third-party logistics (3PL) partner that already uses automated warehouse technologies offers an alternative path.

Instead of building your own system, you can rely on an external provider for storage, picking, packing, and shipping.

Automated 3PL

What it is: You outsource your eCommerce fulfillment to a 3PL that uses its own automation systems. These may include ASRS units, conveyors, robotic picking, or advanced WMS platforms.

Why it works:

- No upfront investment: You avoid capital expenditure. Instead, you pay a service fee that becomes part of your operating costs.

- Faster implementation: You can go live in weeks, not months or years.

- Built-in scalability: As your order volume grows, the 3PL handles peaks without changes to your own infrastructure.

This makes automated 3PLs a smart option for companies that need speed, flexibility, and lower risk.

In-House Automation

What it is: You invest in your own warehouse automation systems and manage all operations directly.

When it makes sense:

- At high volumes: Once you reach a certain order threshold, 3PL fees can become more expensive than owning and operating your own automated warehouse.

- For full control: You manage every part of the process, including packaging, quality checks, and returns.

- For specialized needs: If you handle fragile, regulated, or high-value items, a standard 3PL may not offer the control or flexibility you need.

- As a competitive advantage: For some companies, fulfillment is a core part of the customer experience. Owning your automation systems can help deliver faster service, better packaging, and more visibility.

| FACTOR | IN-HOUSE AUTOMATION | AUTOMATED 3PL PARTNER |

| Initial investment | High (Significant Capital Expenditure – CapEx) | Low to None (Operating Expenditure – OpEx Model) |

| Long-term cost | Lower Total Cost of Ownership (TCO) at high volumes. | Variable costs that scale with volume; can become more expensive long-term. |

| Control | Full control over processes, quality, and branding (e.g., unboxing experience). | Shared control; you must adapt to the partner’s standard procedures. |

| Implementation speed | Slower (months to over a year for planning and deployment). | Fast (can be operational in a matter of weeks). |

| Scalability | Strategic and planned. Scaling up requires forecasting and further investment. | Highly flexible. Easy to scale up or down to meet seasonal demand. |

| Customization | Fully customizable to your unique product needs and specific workflows. | Limited customization; based on the provider’s standardized offerings. |

Choosing between a 3PL and in-house automation depends on your current stage and long-term goals.

Many eCommerce companies start with a 3PL to scale quickly. Later, when volumes grow and needs become more complex, building a proprietary automated warehouse becomes the next step.

Top Challenges When Automating Your eCommerce Fulfillment Warehouse

Automating your eCommerce warehouse unlocks major benefits, but even the best systems face hurdles along the way.

The top challenges to keep in mind include:

1. Cost and ROI

Let’s face it, warehouse automation isn’t cheap. That’s why it’s important to think beyond labor savings when you calculate ROI, especially in high-volume eCommerce fulfillment environments.

The true financial return comes from a combination of factors:

- Reduced picking errors and the associated costs of returns.

- Increased throughput, allowing you to process more orders with the same resources.

- Space optimization which can delay or eliminate the need to rent or build new warehouse space.

The key to managing the upfront investment is a modular and scalable approach. You don’t have to automate your entire warehouse at once.

With solutions like Modula’s, you can start with a targeted implementation, such as a single Vertical Lift Module (VLM) to handle your most critical or high-value SKUs and a robust Warehouse Management System.

This “start small and scale” approach delivers an immediate impact and allows you to expand the system as your business grows.

This is how our customers typically achieve a return on investment in just 6 to 18 months, turning a capital expense into a measurable engine of efficiency.

2. System Integration

Even the best automated warehouses rely on seamless system communication. Your new solution will need to connect perfectly with your:

- Enterprise Resource Planning (ERP) platform

- Existing Warehouse Management System (WMS), if you have one

- eCommerce platform (for instance, Shopify and Magento)

Before committing to a vendor, it’s crucial to verify their track record with integration. A well-designed integration, like that provided by Modula WMS software, acts as the central nervous system for your warehouse, synchronizing inventory, orders, and physical operations in real time.

Sorting this out early saves time, reduces disruptions, and keeps your automation rollout on track.

3. Training and Team Readiness

Many people assume automation leads to job cuts. That’s a common concern: 32% of U.S. workers believe AI will reduce future job opportunities.

What we’re seeing so far is the opposite. Automation often drives business growth, which can lead to more hiring, not layoffs.

That said, roles can shift. As technology takes over repetitive tasks, it’s important to support your team through the transition and help them adapt to new responsibilities.

To ensure a successful transition, it’s essential to communicate clearly and support your team:

- Explain the “why”: Show how automation will improve their daily work by reducing physical strain and errors.

- Outline the changes: Be transparent about how their responsibilities will evolve.

- Provide training: Ensure your team is supported before, during, and after the transition.

This is why Modula systems are designed with intuitive, user-friendly interfaces, to minimize training time and empower your team to be confident and productive from day one.

Best Automated Warehouses for eCommerce Fulfillment: Key Takeaways

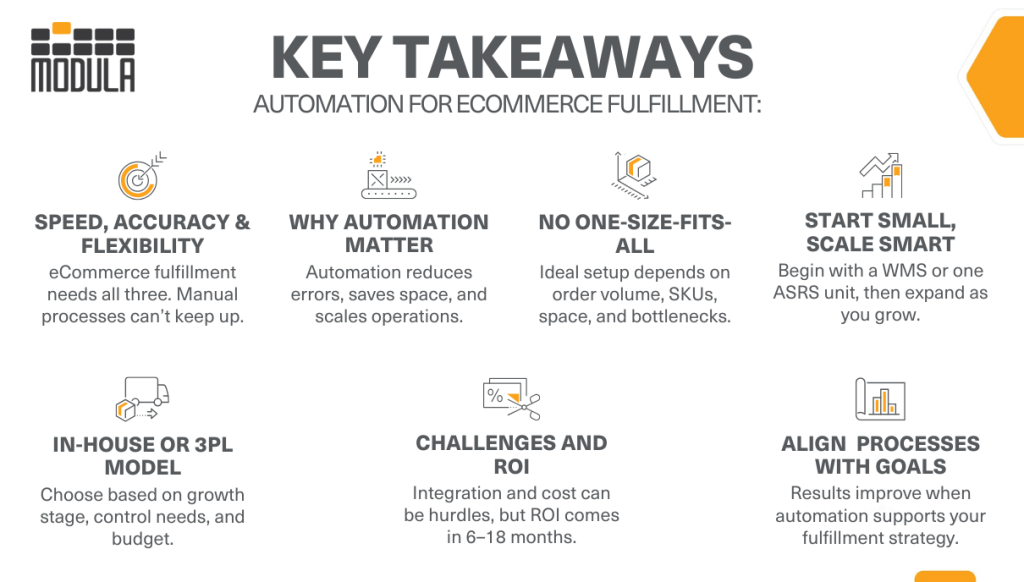

Warehouse automation is no longer optional for growing eCommerce businesses. It’s a key strategy to stay competitive, scale operations, and meet rising customer expectations.

Success doesn’t mean adopting every new system. It means choosing automation that fits your operation, based on what you ship, how you store it, and where your process slows down.

Here’s what to keep in mind as you move forward:

- eCommerce fulfillment demands speed, accuracy, and flexibility. Manual processes often can’t keep up.

- Automated warehouses help reduce errors, save space, and scale operations efficiently.

- There’s no one-size-fits-all solution. The right automation strategy depends on your order volume, SKU profile, space, and bottlenecks.

- Starting small is smart. Many companies begin with a WMS or a single ASRS unit, then expand over time.

- Choosing between in-house automation and an automated 3PL depends on your growth stage, control needs, and budget.

- The most common challenges include cost, integration, and team readiness—but with the right plan, they’re manageable.

- Most businesses see ROI within 6 to 18 months, especially when automation is aligned with fulfillment goals

Best Automated Warehouses for eCommerce Fulfillment: FAQs

What are fully automated warehouses?

Fully automated warehouses leverage machines, software and robotics to manage nearly every aspect of material handling with minimal human input.

They’re built to boost speed, accuracy and efficiency while cutting labor costs and reducing errors.

What does an automated warehouse look like?

An automated warehouse is a coordinated system of robots, conveyors, and software that handle storage, sorting, picking, packing, and shipping with little to no human input, delivering fast, efficient, high-throughput operations.

Does warehouse automation replace human employees?

No, but it does reduce the need for manual, repetitive tasks, freeing up your team to focus on higher-value work like quality control, exception handling, and process improvement.

What is the ROI of warehouse automation?

ROI depends on your current challenges and fulfillment volume. Most companies see savings in labor, space, and order accuracy. For many, the investment pays off in less than two years.

Can I automate a small warehouse?

Yes. Automation isn’t just for large facilities. Many scalable solutions are designed for small to mid-sized warehouses, including vertical storage systems, smart carts, and modular WMS tools.

Is it better to automate or use a 3PL?

It depends. Using a 3PL with automated infrastructure can speed up your launch and reduce CapEx.

In-house automation gives you more control and can reduce long-term costs. Many businesses start with a 3PL, then move to their own systems as they grow.