E-Commerce Micro-Fulfillment: Space and Flexibility Reimagined

A successful e-commerce micro-fulfillment operation integrates carefully planned processes, optimized space utilization, scalable operations, and highly-efficient automation to address challenges at the individual store level.

The latest generation of vertical lift modules and horizontal carousels fill this need. Capable of handling thousands of SKUs, these systems maximize cubic storage density while minimizing the needed footprint. This allows inventory to be stored, picked, packed, and shipped with a very high level of efficiency, optimized labor usage, and minimized operational costs

The fulfillment aspect of online retailing is commanding considerable attention from retailers, particularly with the advent of Covid-19 as consumers have evolved to more fully rely on online shopping. Fulfillment is the decisive moment with the customer, and where the real e-commerce profit is derived. The retailer can catch its revenue on the front end with an attractive and easy-to-navigate website, and an easy-to-use shopping cart and credit card capturing system in place.

However, if the customer cannot get the product when and where they want it, the retailer risks alienating and ultimately losing the customer.

Today’s consumer is in a power position. They want flexibility and options. They are requesting different service levels. Same-day delivery and immediate local-store pick-up are no longer perks for e-commerce consumers; they are expectations.

The typical e-commerce consumer expects cross-channel services like click-and-collect and order-to-delivery, wider online SKU offerings, order accuracy, fast and free delivery, free returns, mobile and social media retail sites, and consistent brand experiences across brick-and-mortar, online and social media storefronts.

Of these expectations, consumer demand for fast and free delivery is causing retail supply chain executives the biggest challenge to remaining competitive and profitable.

Essentially, e-commerce fulfillment is a delivery proposition. If a customer wants it, and the retailer has it, the retailer needs to get that item to the customer in the fastest and most efficient way possible to meet the expectations of the customer. E-commerce consumers are willing to change brand allegiance to get better value and service.

To remain competitive, every step in the fulfillment process must be handled accurately, efficiently, and quickly to maintain a positive customer experience.

In-Store e-Commerce Fulfillment

Conventional models for retail distribution utilize central distribution centers (CDCs) to ship inventory out to stores, and separate centralized eFulfillment centers to ship direct to consumers. Managing retail e-commerce from these eFulfillment centers, however, cannot accommodate today’s customized needs of consumers who are pushing retailers for more engaging in-store experiences with their e-commerce orders.

However, localized in-store micro-fulfillment and nano-fulfillment can do so, along with the capacity of delivering orders more cost-efficiently than centralized e-Fulfillment centers. Nano-fulfillment centers (also known as dark stores), smaller than micro-fulfillment locations, are typically plug-and-play robotic solutions located within urban centers and carry a fraction of the SKUs of full-size DCs.

To achieve a faster and more flexible level of fulfillment for e-Commerce orders, a streamlined, interconnected micro-fulfillment distribution system is needed. One where local retail store channels are utilized to pick, pack and deliver small orders directly to consumers.

A strategy of utilizing system-wide inventory, combined with local retail stores to fulfill customer orders across all channels, can provide an enhanced customer experience. This includes capturing sales that otherwise would be lost, gaining a better price point and improving margins, all while reducing the investment and operating costs of centralized DCs.

A retailer fulfilling an order placed online through a central fulfillment facility in Omaha, Nebraska for delivery to a consumer in San Francisco, California must factor the cost of packing and shipping to that customer across the country. Compare this to having that same item sitting in the retailer’s store in San Francisco, where it can be picked from the floor and delivered in a two to three-hour time window to the customer.

Or, if the customer prefers, it can be picked-up from the store location in a matter of hours. Not only does the customer get the item faster, but the retailer saves on the cost of order packing and transportation. Because the retailer could make the item available at a local store, it prevented the customer from looking at another retailer that might have it available locally.

This approach supports a highly-efficient inventory strategy of fulfilling eCommerce orders for faster-moving SKUs from retailers’ stores, while making slower-moving SKUs available from central fulfillment centers.

An additional benefit is the fact that the item from the retail store is sold at full price. By making the retailer’s inventory more universally accessible to the consumer, the incidence of excess inventory that would eventually have to be marked down can be significantly reduced. Utilizing any and all inventory to fill every order is intended to maximize top-line revenue, while optimizing fulfillment costs to leverage as much margin as possible.

By implementing this strategy of in-store fulfillment – moving much of the pick, pack and delivery operations into stores, enabling those stores to receive online orders and fulfill them – retailers can markedly reduce the fulfillment space required in their distribution centers, or even reduce the number of distribution centers in their network.

Within a geographic area, where multiple stores in a chain are located, one store might be designated as an alpha-store, say within a group of three stores. This store would be stocked from the distribution center with a higher volume of faster-moving and seasonal SKUs, and could replenish the other two stores within its area quickly as demand needed. In a very populated area where several stores are in close proximity, the alpha-store might be designated as the sole pick, pack and ship location for the group of stores.

To facilitate this precision level of fulfillment, the retailer must have visibility to what inventory it has on its retail store floors and back rooms, in-transit and on order, as well as the stock in its centralized eCommerce fulfillment centers. This determines the most timely and cost-effective fulfillment solution to meet the customer’s service requirements.

The benefits to retailers of implementing an in-store fulfillment strategy are considerable:

- if a store has an item in stock it can be sold to a customer to fulfill an online order. Or, a slow-moving item from another story can be redirected to fill the order;

- if the item can be fulfilled from a store that is closer to the customer than the distribution center, the customer will receive the item faster;

- coming from a local store, compared to a distant distribution center, the shipping cost will be less;

- in-store fulfillment can improve store employee utilization, particularly with back-of-store fulfillment, reducing the amount of in-store picking required to fill orders.

Space and Flexibility for e-commerce micro-fulfillment

Space utilization within retail stores and e-Commerce fulfillment warehouses is at a premium.

The continuous increase in the cost of land, construction, labor, and facilities has put a heightened demand on more efficient space utilization within these operations. Many e-Commerce fulfillment operations have completely outgrown their warehouse space, forcing them to rely on leased off-site facilities and 3PLs.

However, this presents a new set of issues – increased rental and transportation costs, and loss of last-touch product control which can result in increased product damage and returns, particularly troublesome in food and beverage, and pharmaceutical environments.

Consequently, retail stores and e-Commerce fulfillment centers are more closely looking at how they can optimally balance their inventory against fulfillment and delivery.

A successful e-Commerce fulfillment implementation requires carefully planned processes, optimized space utilization, scalable operations and highly-efficient automated systems to address the speed of throughput and space challenges at the individual store level.

For retailers, space utilization is a prime consideration. The tipping point for in-store micro-fulfillment centers is being able to store more SKUs within a limited space. Supporting this is the flexibility of an in-store micro-fulfillment solution, easily configured to fit different store space models, accommodating for variations in ceiling heights and obstacles, yet having the scalability to expand or contract as the store’s eCommerce needs require.

Expanding SKUs, fluctuations in throughput volume and potential reduction of SKUs need to be factored in. Seasonal influences and the rise and fall of the popularity of items offered online, necessitate the need for highly flexible and scalable requirements in an e-commerce micro-fulfillment system.

Those e-commerce micro-fulfillment solutions that are highly efficient have achieved high-density cubic space utilization, coupled with a low footprint, for storage of single-item and small-case SKUs.

Essentially, they have a space configuration that allows for the maximum number of SKU positions to fit into the system and utilize both the footprint and the facility height optimally.

Automating E-commerce Micro-Fulfillment

Where once considered acceptable for a picker to spend 60 percent of the time traveling and 40 percent of the time picking, as is typical in a person-to-goods fulfillment model, e-Commerce executives are increasingly looking for more efficient solutions to minimize the amount of wasted time between picks and increase the number of eCommerce orders processed per picker.

Manual picking is a highly labor-intensive function and can provide significant cost savings when automated.

As a company’s e-Commerce needs fluctuate, its pick, pack and delivery model should be able to accommodate these changes. Flexibility and scalability with online fulfillment is critical. Making improvements in stationary rack storage locations can be stretched only so far. The correct solution in most circumstances is to automate the fulfillment operation, by implementing the right automated system for that application, one that can support the fluidity that its eCommerce fulfillment demands.

The right micro-fulfillment automation facilitates the minimization of manual touches, resulting in more accurate orders, improved ergonomics, lower labor costs and travel time, lessened returns and saves space by operating in a smaller footprint.

In an automated goods-to-person micro-fulfillment concept, incoming goods or cartons are placed into totes or trays, which are stored in high-density automated storage and retrieval systems. As orders are required to be fulfilled, SKUs are automatically retrieved from storage and brought to the picker at a pick/pack station.

Since the picker does not have to travel, the focus at the pick/pack station is on ergonomics and high productivity, eliminating the significant travel element inherent in traditional person-to-goods picking operations.

Such automation should generate:

- improved results in throughput, productivity and accuracy;

- it should be capable of becoming operational quickly with minimal disruption to throughput;

- it needs to be an affordable capital investment while realizing a short-term ROI;

- it should have location flexibility and a high density of space utilization with a minimal footprint.

Over the past decade, highly-automated goods-to-person systems for efficient single-item/small-order fulfillment in eCommerce have made considerable advancements towards realizing these objectives.

Automated e-commerce micro-fulfillment solutions come in a variety of forms and configurations. They can incorporate high-density storage systems, pallet-based or tote/carton-based systems, horizontal and vertical carousels, robots and vertical lift modules. The solution selected needs to fully embrace the needs of the eCommerce fulfillment operation.

An increasing number of e-Commerce executives are embracing a goods-to-person fulfillment approach based on vertical lift modules and horizontal carousels as a solution to achieve more efficiency in their e-commerce micro-fulfillment storage and picking processes. This enables the inventory to be moved to the picker, who is comparatively more stationary, utilizing advanced technology to facilitate the inventory storage and movement.

Latest-Generation Vertical Lift Modules and Horizontal Carousels Support E-commerce Micro-Fulfillment

Two of the latest-generation systems released for high-density, low-footprint automated storage and retrieval for e-commerce micro-fulfillment are the Vertical Lift Module (VLM) and Horizontal Carousel (HC), from Modula, which designs and manufactures automated storage solutions for manufacturing and distribution.

Capable of handling thousands of different SKUs, these systems allow inventory to be stored, picked, packed and shipped with a very high level of efficiency, optimized labor usage and minimized operational costs. These systems provide an excellent example of the latest state-of-the-art technologies and system capabilities for micro-fulfillment.

The modular, scalable design of these latest-generation VLMs and HCs allows them to be easily installed and implemented in any existing or greenfield retail store, warehouse, manufacturing facility or distribution center. They function for both high and low-ceiling height applications, and facilities with unusual configurations.

Designed for high throughput, these systems permit the flexibility to easily be extended or contracted as needed to accommodate changes in SKU counts and throughput volumes, including for storage of temperature-controlled products between 35.6° F and 77° F.

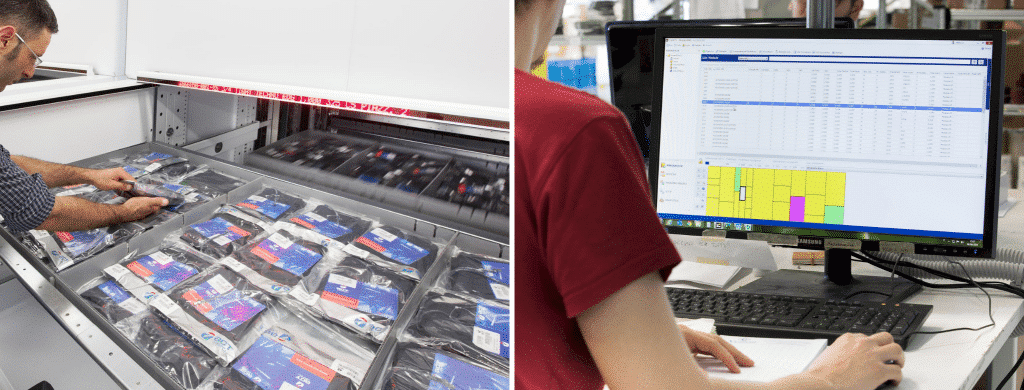

The goods-to-person concept embodied within these two systems is simple: Incoming goods are inventoried into the high-density, automated-storage VLM or HC. As e-Commerce orders are required to be filled, the items are automatically retrieved from the storage system and brought to the picker at an ergonomic receipt station, where items are then picked from partitioned trays.

Since the picker does not have to walk, the focus at the pick station is on ergonomics and high productivity.

Goods are automatically delivered to the operator with a simple touch of a user-friendly HMI copilot controller or the scan of a barcode. This feature eliminates the need to search for items and ensures that the right item is delivered with the order, significantly reducing picking errors, and increasing productivity and efficiency.

They allow for a large inventory of goods to be quickly accessible while being stored in a safe and secure environment, permitting user authentication with badge, EKS and RFID readers.

Modula’s VLMs and HCs incorporate a WMS that provides complete inventory management, seamlessly integrating with an eCommerce company’s ERP or DMS. Automatic tracking of picking operations records inventory levels in real-time.

Latest-Generation Vertical Lift Modules

The Modula VLM takes up a minimum footprint by utilizing the ceiling height available. It has a capability to hold thousands of SKUs, positioned in trays located within the VLM. Depending on the VLM design, each tray can have a payload capacity of up to 2,200 pounds. The VLM is capable of delivering up to 130 trays per hour to the operator, with picking speeds of up to 300 lines per hour.

The VLM is capable of presenting trays internally or externally. Internal bays are best for limited floor space applications. External bays offer optimum ergonomics for operators, as well as adapting picking aids, like cranes or mechanical manipulator interfaces such as anthropomorphous robots.

The system can be set up for single or dual-tray delivery. Single-tray delivery is suitable for situations with less stringent throughput requirements or quick picking time. Dual-tray delivery reduces wait time for the next tray, enhancing productivity.

With simple visual picking aids, operators can quickly and easily identify the items needed to be picked or replenished. These include X-axis LED bars, alphanumeric pointers, laser pointers, put-to-light and external picking monitors.

This latest-generation VLM also makes available an energy recuperation capability. A specially designed inverter generates energy from the VLM’s movement. It converts kinetic energy produced by the descending elevator into electricity, feeding it back into the grid and supporting the VLM’s environmental sustainability. This functionality results in saving up to 40 percent on energy used by the VLM.

Latest-Generation Horizontal Carousels

Where ceiling height is limited, such as in an existing brownfield facility, and a VLM would not be an efficient option, the Modula HC is designed for use in these operations.

Each of the system’s trays has a payload capacity of 1,200 pounds, and capable of picking speeds of up to 550 lines per hour. The HC’s put-to-light system enables fast, nearly error-free picking operations.

Multiple horizontal carousels can be combined to achieve higher picking performance, using Modula’s WMS to create a batch of orders that can be filled at the same time. Operators select the total quantity of each SKU for all orders, and picking aids such as batch picking lights, direct the operator to select and place the correct items in the correct orders.

Operators only visit each SKU location once during each batch, increasing accuracy, reducing picking times and increasing productivity by as much as 65 percent.

E-Commerce Micro-Fulfillment Optimized

Many retailers and smaller eCommerce companies are faced with the challenge of scaling up the efficiency of their storage, picking and fulfillment operations. Until recently, these eBusinesses were forced to invest in expensive, complex systems for what they could only project they might need well into the future.

The latest generation of vertical lift and horizontal carousel systems, like those systems from Modula, present extremely optimized solutions for high-density, low-footprint, highly scalable, and cost-efficient micro-fulfillment automation for retailers, and for virtually all e-commerce fulfillment requirements.