3PL vs. 4PL: Key Differences, How To Choose [+ Infographics]

The global 3PL market topped $1 trillion in 2023, and it’s on track to nearly double by 2030, hitting close to $1.9 trillion. That kind of growth shows just how essential outsourced logistics has become for modern businesses.

As you start exploring fulfillment providers, you’ll likely come across two key models: 3PL and 4PL.

While 3PLs are more common partners for fulfillment, 4PLs offer a higher level of strategic oversight.

If you’re planning to hand off your logistics to an external partner, the next step is figuring out which model fits best: a third-party logistics (3PL) provider or a fourth-party logistics (4PL) partner.

To help you decide, this article covers:

- The key differences in the 3PL vs. 4PL modelsHow each model works

- How to choose the right logistics partner based on your stage of growth and operational needs

What Is a Third-Party Logistics Provider (3PL)?

A third-party logistics (3PL) provider is a company that handles logistics operations on behalf of a business. They own the warehouses, the forklifts, and the staff. This includes services like:

- Warehousing: Storing your inventory in their facility.

- Inventory management: Tracking stock levels in real-time and syncing data with your sales channels.

- Order fulfillment: Picking, packing, and labeling orders.

- Shipping: Negotiating rates with carriers (UPS, FedEx, and DHL) and managing delivery.

- Returns (Reverse Logistics): Processing items sent back by customers.

In essence, a 3PL acts as the middleman between your business and the carriers that deliver your products to customers.

What Is a Fourth-Party Logistics Provider (4PL)?

The global 4PL market is on the rise, valued at about $62 billion in 2023 and expected to nearly double to $121 billion by 2033. That growth reflects a shift in how businesses manage logistics.

Unlike a 3PL, which handles the day-to-day execution, a fourth-party logistics (4PL) provider takes it a step further, overseeing the entire supply chain from a strategic, top-down level. They typically don’t own warehouses or trucks.

This includes:

- Managing one or more 3PLs

- Coordinating operations across different regions and vendors

- Integrating logistics technologies to provide a single view of data

- Delivering a complete, end-to-end solution for your supply chain strategy

Instead, they focus on strategy, optimization, and orchestration, making sure all logistics partners and systems work together seamlessly across the supply chain.

3PL vs. 4PL Difference

The main difference lies in control and assets. A 3PL focuses on execution (moving goods), while a 4PL focuses on strategy (managing the network).

E-commerce businesses often outsource fulfillment to a third-party logistics provider (3PL), which handles storage, picking, packing, and shipping.

This frees internal teams to focus on sales, marketing, and customer service, without the cost or complexity of managing a warehouse.

A single 3PL partnership optimizes operations and supports scalable growth, especially for fast-moving brands.

In contrast, a fourth-party logistics provider (4PL) acts as a supply chain strategist.

Rather than executing fulfillment, a 4PL manages relationships with multiple 3PLs, overseeing logistics performance, vendor coordination, and overall supply chain optimization.

| Feature | 3PL (Third-Party Logistics) | 4PL (Fourth-Party Logistics) |

|---|---|---|

| Primary role | Execution: Manages day-to-day order fulfillment | Strategy: Manages and optimizes the entire supply chain |

| Assets | Owns warehouses, trucks, and equipment. | Non-asset based; owns the data and strategy. |

| Vendor relationships | Direct operational partner. | Strategic partner managing other vendors. |

| Level of control | Direct involvement in day-to-day logistics | Oversees logistics providers without handling goods directly |

| Technology focus | Operational systems (think WMS and TMS) | End-to-end integration, analytics, and visibility tools |

| Costs | Typically more cost-effective | Adds a layer between you and the 3PL, often taking a cut that can increase costs |

| Scalability support | Supports growth by handling increased order volume | Builds scalable, coordinated supply chain infrastructure |

| Cost structure | Pay-per-service (storage, pick/pack, and shipping) | Strategic service fee, often project- or performance-based |

| Ideal for | Growing brands needing hands-on fulfillment | Large Enterprises managing multiple logistics partners |

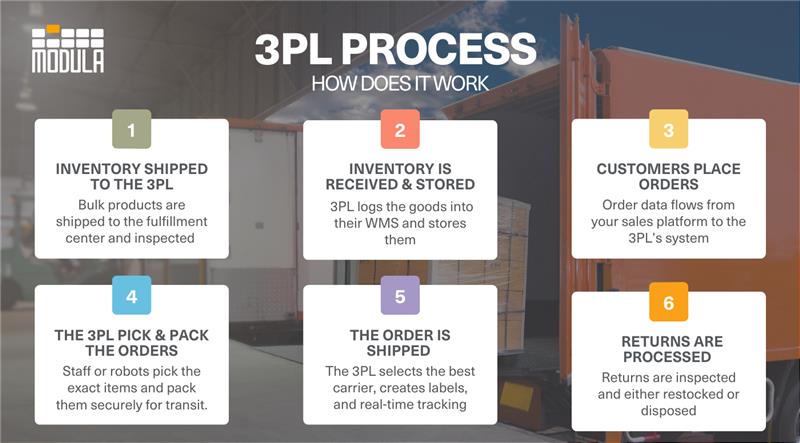

How the 3PL Process Works

So, how does a 3PL handle your orders? Here’s what the process actually looks like.

Step 1: Inventory Is Shipped to the 3PL Warehouse

Your business ships its products in bulk to the 3PL’s fulfillment center. The receiving team inspects the cargo to ensure it matches the advanced shipping notice (ASN).

Step 2: Inventory Is Received and Stored

The 3PL receives the goods, logs them into its system, and stores them in a designated location, often using warehouse management software (WMS) for tracking.

Modula Insight: To improve warehouse efficiency, many 3PLs use automation systems like Modula’s vertical lift modules (VLMs). These systems optimize space, speed up order picking, and integrate with WMS platforms to provide real-time inventory visibility, key to scaling without added labor or square footage.

Step 3: Customers Place Orders

When a customer places an order on your website or sales platform, the order data is automatically sent to the 3PL’s system.

Step 4: The 3PL Picks and Packs the Order

Warehouse staff, or automated warehouse solutions like robotic pickers, grab the right items, double-check the order for accuracy, pack everything securely using the best materials, and get it ready for shipping.

Modula Insight: Accuracy is critical here. 3PLs equipped with Modula automated picking solutions can guide operators to the exact item using laser pointers, achieving 99.9% picking accuracy and virtually eliminating shipping errors.

Step 5: The Order Is Shipped to the Customer

The 3PL selects the most cost-effective carrier, generates a shipping label, and sends the package directly to the customer, often providing tracking information in real time.

Step 6: Returns Are Processed

If a customer sends an item back, the 3PL handles returns, inspects products, and restocks or disposes of them based on client instructions.

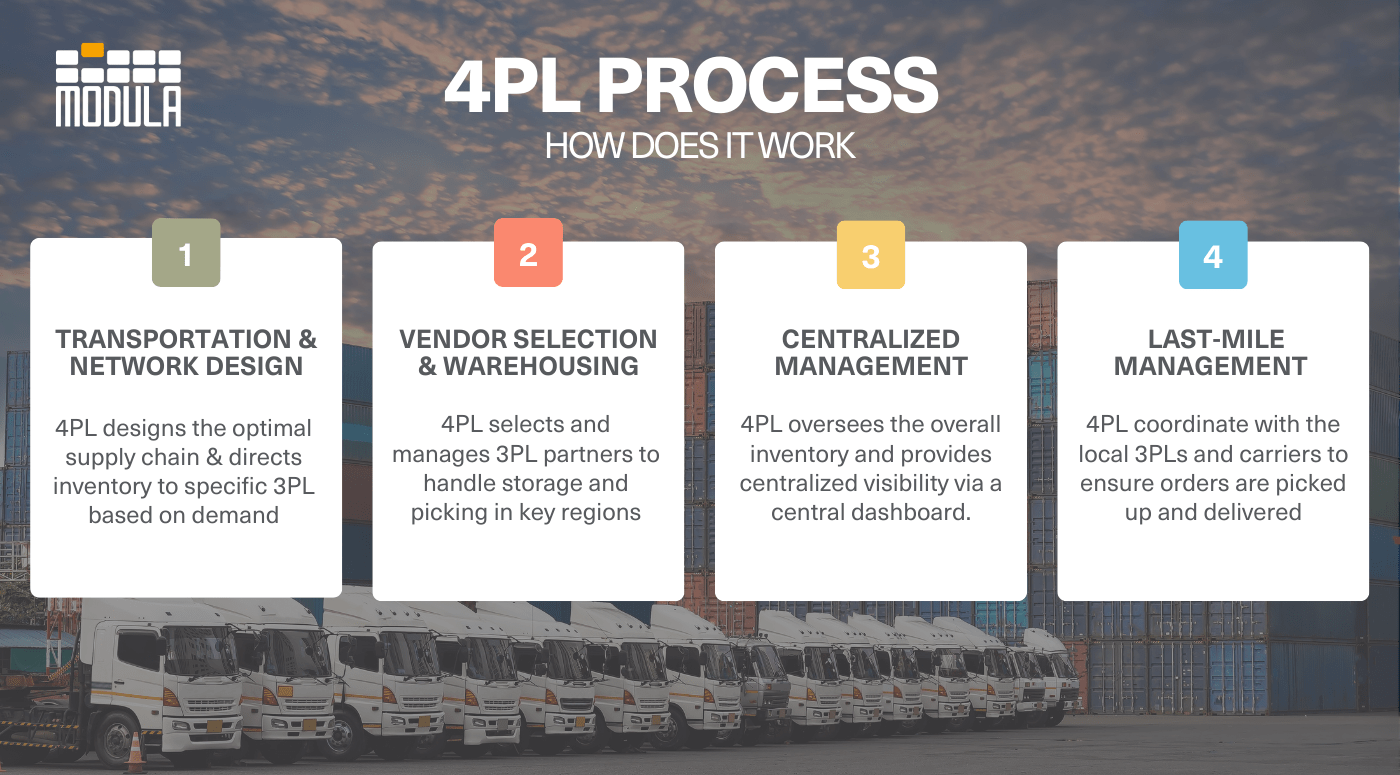

How the 4PL Process Works

A 4PL’s main job is to take the stress of supply chain management off the merchant’s plate. They act as the “control tower.” Here is how they operate.

Step 1: Transportation & Network Design

The 4PL designs the optimal supply chain network.

They coordinate the transportation of finished goods from the manufacturer, directing shipments to specific 3PL nodes based on demand forecasts (for instance, “Send 40% to the West Coast node, 60% to the East Coast”).

Step 2: Vendor Selection & Warehousing

The 4PL doesn’t own the warehouses, but they choose who does. They select 3PL partners to handle storage and picking in key regions.

Modula Insight: Smart 4PLs prioritize vendors that use automation like Modula VLMs. Why? Because automation guarantees a standardized level of performance, security, and speed across the entire network, regardless of where the warehouse is located.

Step 3: Centralized Inventory Management

The 4PL oversees inventory management by providing centralized visibility through integrated software.

Merchants can monitor inventory levels across all warehouse locations in real time from a single dashboard.

Modula Insight: Integration is key here. Warehouses using Modula IoT (Cloud) can transmit real-time stock data and machine status directly to the 4PL’s central dashboard. This eliminates manual reporting errors and gives the 4PL total visibility into inventory health globally.

Step 4: Shipping & Last-Mile Management

In the final stage, the 4PL optimizes the last-mile delivery.

They coordinate with the local 3PLs and carriers to ensure orders are picked up and delivered to the end customer on time, managing any exceptions or delays centrally.

3PL vs. 4PL Logistics: How to Pick the Best Model for Your Operations

Wondering whether a 3PL or 4PL makes more sense for your brand? Here are some situations where each model might be the better fit.

Just Getting Started? A 3PL Can Still Be the Right Move

Many new businesses assume they need to handle fulfillment themselves in the beginning, but starting with a 3PL can actually set you up for faster, more sustainable growth.

Instead of investing capital in forklifts, racking, and warehouse leases, you can hand off logistics to a 3PL that manages storage, picking, packing, and shipping for you.

This frees you up to focus on what matters most early on, such as developing your product, building your brand, and growing your customer base.

Your Business Is Growing Fast: 3PL Is a Good Fit

As your business gains momentum, you risk hitting a “growth ceiling”; running out of storage space or falling behind on order volume.

Outsourcing to a 3PL solves the space issue, but volume requires technology. A report points to rising demand and limited warehouse space as key drivers for 3PL adoption. However, not all 3PLs are created equal.

Pro Tip: Don’t just look for empty shelf space. Look for a partner that uses automation. Whichever logistics partner you choose, their ability to scale depends on the technology they use.

Modula’s smart warehousing solutions empower top-tier 3PLs by:

- Streamlining repetitive tasks to handle sudden spikes in order volume.

- Maximizing storage efficiency to keep your storage costs low.

- Integrating with systems for real-time inventory visibility.

You’re Hitting Enterprise Scale: 4PL Might Make Sense

If you’re reaching a point where managing the entire supply chain feels overwhelming, a 4PL could be worth considering.

Unlike a 3PL, a 4PL oversees everything for you, including coordination between multiple logistics partners. That being said, working with a 4PL means giving up some control.

For this reason, many fast-growing eCommerce brands stick with a tech-forward 3PL they can grow with, one that offers both flexibility and visibility as operations expand.

3PL vs. 4PL: Can They Work Together?

Yes, and they often do. A 4PL acts as the strategic lead, overseeing the full supply chain and coordinating the logistics operations carried out by 3PLs.

With modern logistics technology, like shared data platforms and real-time dashboards, 4PLs can seamlessly manage multiple 3PL partners across regions, maintaining centralized visibility and control.

The 3PL focuses on execution, while the 4PL keeps the big-picture strategy on track.

3PL vs. 4PL Explained: Key Takeaways

- Execution vs. Strategy: 3PL providers act as your operational partner, handling physical tasks like storage, picking, and shipping. 4PL providers act as your strategic partner, overseeing the entire supply chain and managing multiple vendors.

- Scalability: Fast-growing businesses typically benefit from 3PLs for cost-effective, hands-on fulfillment support. Large enterprises with complex, multi-region networks often require the centralized oversight of a 4PL.

- The Technology Factor: Whether you choose a 3PL or a 4PL, success depends on the technology they use. Providers equipped with automated storage and picking systems (like Modula VLMs) offer superior accuracy, density, and speed compared to manual warehouses.

3PL vs. 4PL Logistics: FAQs

3PL vs. 4PL vs. 5PL

- Third-Party Logistics (3PL): Handles specific logistics functions like warehousing, picking, packing, and shipping. It’s hands-on fulfillment support for businesses.

- Fourth-Party Logistics (4PL): Manages the entire supply chain, including multiple 3PLs. Focuses on strategy, technology integration, and end-to-end coordination.

- Fifth-Party Logistics (5PL): Takes a broader approach, managing entire supply networks with a focus on digital optimization, automation, and large-scale logistics across multiple clients.

Can a 3PL become a 4PL?

Some 3PLs offer added services like tech integration or analytics, but a true 4PL operates independently, managing multiple 3PLs and overseeing the entire supply chain from a strategic level.

When should a business switch from 3PL to 4PL?

Consider moving to a 4PL when you’re juggling multiple logistics vendors, expanding globally, or need centralized control over supply chain strategy, performance, and tech integration.

Is a 4PL more expensive than a 3PL?

Yes. Working directly with a 3PL is usually more affordable, especially if you take the time to compare quotes from multiple providers.

With a 4PL, you’re matched with 3PLs through a managed network, but the 4PL takes a cut of the transaction.

That added layer can drive up costs and may limit how competitive the 3PL’s pricing can be.