Best Practices for Warehouse Inventory Management in 2025

From reducing manual labor with warehouse automation to collaborating with your suppliers, we’ll cover top warehouse inventory management strategies for 2025.

We’ll also introduce Modula’s automated warehouse inventory management system that can help streamline your operations, enhance accuracy in inventory tracking and reduce overhead costs.

Regular cycle counting is a best practice that involves frequent, systematic counting of a portion of inventory to ensure accuracy and maintain inventory records. Unlike annual physical inventory counts, cycle counting provides continuous monitoring and validation of stock levels, leading to more accurate inventory management.

What Is Warehouse Inventory Management?

Warehouse inventory management is the process of receiving, tracking, auditing, and managing goods in your warehouse.

Efficient warehouse inventory management allows you to meet consumer demand while minimizing storage costs and reducing the risk of stockouts or overstocks.

Inventory Management vs. Warehouse Management

Inventory management is the process of forecasting, ordering, receiving and allocating stock through rigorous evaluation and planning.

A purchasing manager, for example, uses seasonality and historical sales data to forecast demand, covering raw materials, components and finished products.

Inventory management aims to maintain optimal inventory levels to meet demand without excessive costs or stockouts.

In contrast, warehouse management focuses on running an efficient warehouse as a whole.

It concentrates on your warehouse’s operational aspects, such as storing, retrieving and transporting goods, to enhance efficiency, reduce costs and improve customer satisfaction.

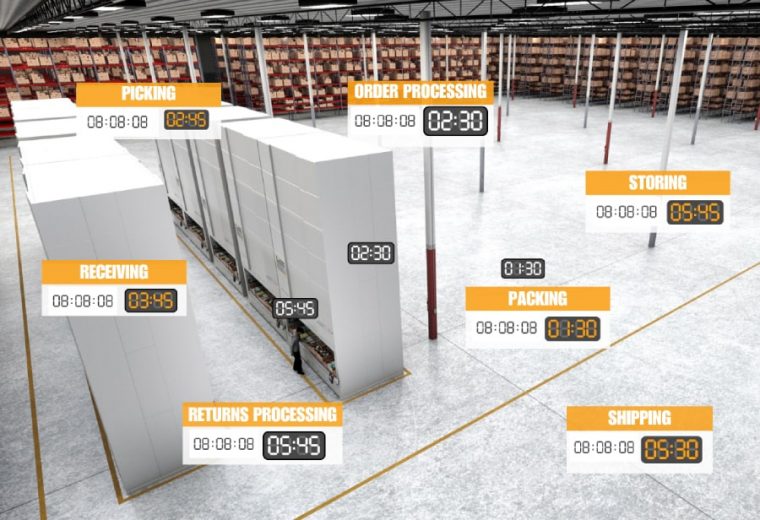

Warehouse Inventory Management Processes

Warehouse inventory management involves six core processes, including:

- Receiving: First, inventory is checked in and logged to ensure items are in good condition and in the correct quantity.

- Put-away and storage: In this step, the inventory is put away and properly stored in their designated warehouse location. For example, fast-moving items are stored near the shipping area for easier access.

- Order processing: Next, the customer places an order, which can be verified in person, via email, telephone, or online.

- Picking: Then, the correct product and quantity are picked. Picking aids, such as voice picking technology, put to light systems or laser pointers, are utilized to ensure accurate picks.

- Packing: In the packing step, the picked items are prepared for shipment. Orders are safely packed in bubble wrap or other protective material to reduce the risk of damage. Then, the package is sealed and marked with a shipping label that displays key information, such as the tracking code and the customer’s name and address.

- Shipping: Finally, orders are documented and shipped out to the right customer at the right time.

- Returns: Returned items are inspected for damage and resellability. If resellable, the item is added back to inventory and a refund or exchange is issued to the customer.

Implementing Lean Warehousing Principles

Adopting lean warehousing principles can significantly enhance efficiency and reduce waste in warehouse operations. By focusing on continuous improvement and eliminating non-value-added activities, warehouses can streamline processes and improve overall productivity. Key lean practices include:

- Sort (Seiri): Eliminate unnecessary items from the workspace to reduce clutter and improve organization.

- Set in Order (Seiton): Arrange necessary items systematically for easy access and efficient workflow.

- Shine (Seiso): Maintain cleanliness to identify and address issues promptly.

- Standardize (Seiketsu): Establish standardized procedures to maintain consistency and quality.

- Sustain (Shitsuke): Cultivate discipline to adhere to established processes and continuously seek improvement.

Implementing these 5S principles fosters a culture of efficiency and continuous improvement, leading to optimized warehouse operations.

Utilizing Warehouse Management Systems (WMS)

Implementing a Warehouse Management System (WMS) is essential for modern warehouse operations. A WMS offers comprehensive tools to manage inventory, optimize storage allocation, and ensure timely order fulfillment. Key benefits of a WMS include:

- Improved Inventory Accuracy: Real-time tracking of stock levels reduces discrepancies and enhances inventory control.

- Optimized Storage Utilization: Efficient space management leads to better organization and increased storage capacity.

- Enhanced Order Processing: Streamlined workflows result in faster and more accurate order fulfillment.

By leveraging a WMS, warehouses can significantly boost productivity and maintain a competitive edge in the industry.

Adopting Advanced Warehouse Technologies (Added)

Incorporating advanced technologies into warehouse operations can significantly enhance efficiency and accuracy. Technologies such as automated storage and retrieval systems (AS/RS), autonomous mobile robots (AMRs), and barcode scanning systems streamline various processes, from inventory management to order fulfillment. For instance, AS/RS can automate the storage and retrieval of goods, reducing labor costs and minimizing errors. Similarly, AMRs can transport items within the warehouse, optimizing material handling and increasing throughput. By adopting these technologies, warehouses can improve productivity and maintain a competitive advantage in the market.

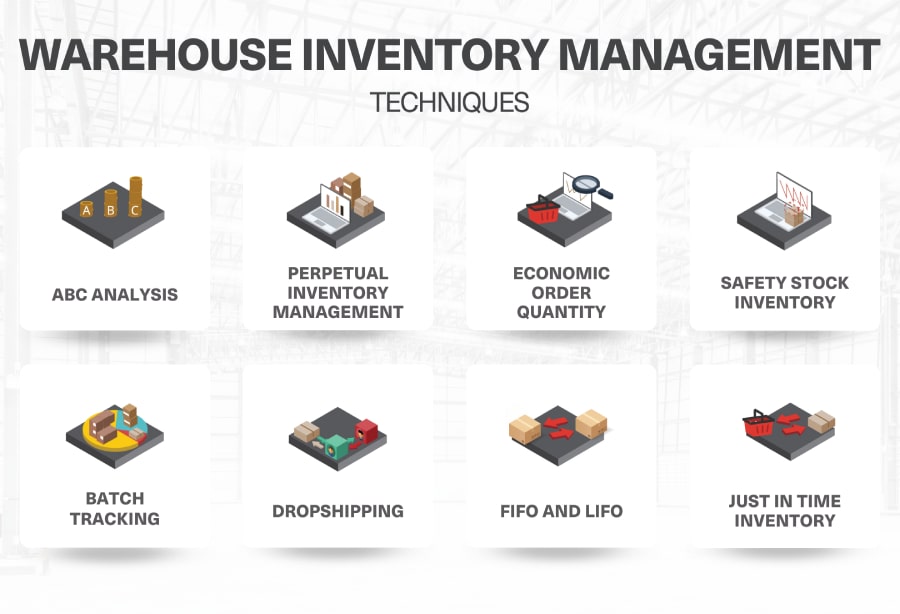

Warehouse Inventory Management Techniques

From identifying popular inventory to shipping products directly from your third-party supplier, here are eight techniques to optimize your warehouse inventory management.

ABC Analysis

ABC analysis is an inventory management technique that allows you to identify the value of your inventory based on its popularity.

This technique can help you identify fast-moving (popular) items, so you can consistently meet consumer demands.

ABC analysis works by grouping products into A, B and C categories.

Your most valuable products are labeled Category A, your next most valuable products are labeled Category B, and Category C products are the least valuable.

Perpetual Inventory Management

Perpetual inventory management is a technique in which you count your inventory as soon as it arrives using radio-frequency identification (RFID) and point-of-sale (POS) systems, to maintain around-the-clock visibility over your inventory levels.

Economic Order Quantity

Economic order quantity (EOQ) is an inventory management technique that allows you to determine the optimal quantity of goods to order so you can meet customer demands and cut inventory costs.

Inventory costs include:

- Shortage costs: Costs when your inventory runs out of stock

- Order costs: Costs when you place an order to restock inventory

- Holding costs: Costs when you maintain inventory

This technique works by calculating the costs of holding inventory and the costs of ordering inventory.

Here is the basic formula for EOQ: EOQ = √((2DS)/H)

In this formula,

- D = annual demand for the product (in units)

- S = cost to place an order (per order)

- H = cost to hold one unit of inventory for a year (also known as the carrying cost)

- EOQ = the optimal order quantity (in units)

By using the EOQ formula, you can find the optimal order quantity that minimizes total inventory costs.

Safety Stock Inventory

Safety stock inventory is an inventory management technique that allows you to meet customer demand despite supply chain disruptions and unexpected fluctuations in demand.

Safety stock is additional goods that you store in your warehouse in case supply shortages or transportation delays occur. Think of it as your cushion to prevent an out-of-stock situation.

You can utilize this technique when your supplier can’t deliver more of your inventory or when there’s a shift in customer demand.

To implement the safety stock inventory technique:

- Determine the level of safety stock you need — typically about 50% more of your average inventory quantity

- Monitor inventory levels using a warehouse management system

- Reorder goods when your inventory levels fall below the safety stock level

Batch Tracking

Batch tracking is an inventory management technique that allows you to monitor inventory expiration dates or track defective items back to their original batch to help you ensure quality control and seamless product recalls.

This is particularly important in industries such as food, pharmaceuticals, and cosmetics, where it is essential to ensure that products are safe and meet regulatory requirements.

This technique works by assigning a unique batch or lot number to a specific inventory group, to track production and expiration dates, along with storage and handling conditions.

Dropshipping

Dropshipping is an inventory management technique that allows you to ship products directly from your third-party supplier or manufacturer, rather than storing inventory in your own facility.

To implement dropshipping, you purchase items from a third-party supplier, who then ships them directly to your customers.

The biggest benefit of this model is that you don’t need to store inventory, avoiding storage costs. This makes it popular among online businesses, allowing them to offer a wide variety of products without major overhead costs.

FIFO and LIFO

FIFO, or first in, first out, is an inventory management technique in which you sell your older inventory first, making way for newer items to keep your inventory fresh.

On the other hand, LIFO or last in, first out, is a technique in which you sell your latest inventory first, allowing you to save on taxes by increasing the cost of goods sold (COGS).

Just-in-time Inventory Management

Just-in-time (JIT) inventory management is a technique that allows you to prevent dead stock, or unsold inventory, by only ordering and receiving items when needed.

Ultimately, your supplier only delivers inventory to your warehouse once a customer places their order. As a result, you don’t have to store inventory that might end up as dead stock.

Warehouse Inventory Management Best Practices

From maintaining strong relationships with your supplier to warehouse automation, here are 13 best practices for warehouse inventory management in 2025.

Minimize Manual Input

Manual tasks are often time-consuming and prone to human error.

Instead of manually counting your inventory, you can utilize automated solutions like warehouse drones, sensors, wearable devices and RFID tags to help you track and manage your warehouse inventory.

Implement Cycle Counting

Using cycle counting, you can calculate your inventory items in sections, allowing you to evaluate inconsistencies. The cycle length will depend on your inventory’s product group or type and warehouse zone or section.

For example, higher-valued items should be counted more frequently.

While there are different ways to perform a cycle count, here’s an example of a cycle counting process using ABC classification:

- Categorize inventory items: Use the ABC analysis to categorize inventory items into groups based on their value or importance to your business. For example, category A can include high-value items that represent 80% of the inventory value, category B can include moderate-valued items that represent 15% of the inventory value, and category C might include least-valued items that represent 5% of the inventory value.

- Determine cycle counting frequency: Determine how frequent you want to cycle count each category of inventory. For example, you can count category A items once a month, while you can count category C items every six months.

- Conduct cycle counting: Conduct cycle counting activities according to the schedule. Count a small portion of inventory each time and compare the results to your inventory records to identify any discrepancies.

- Adjust inventory records: Adjust your inventory records based on the results of your cycle counting. Any discrepancies should be investigated and resolved, and inventory records should be updated.

Ensure Popular Products Are Easy To Reach

You can identify your best-selling products by tracking your orders or by performing an ABC analysis.

After distinguishing which items are most popular — your category A products — move your fast-moving stock closer to the shipping and packing areas in your warehouse for easy access.

Of course, there’s an even easier, no-fuss way of ensuring your products are easy to reach.

Modula’s Vertical Lift Modules (VLM) and Horizontal Carousels (HC) are automated solutions that allow a large inventory of goods to be quickly accessible while being stored in a safe and secure environment.

With a simple touch of the user-friendly Copilot or a barcode scan, products are automatically delivered to your operators.

Organize Your Floor Plan

Organizing your floor plan allows you to maximize your current warehouse space.

Utilize vertical space by installing taller storage units and use clear labeling and signage to improve navigation.

For example, you can implement a multi-tier racking system that lets you stack pallets or bins vertically, effectively doubling or even tripling your storage capacity without increasing the footprint.

In addition, you can place color-coded signs at each aisle and section to guide your employees to the right location, reducing the time they spend searching for items.

To make the most of your existing floor plan, you can also take advantage of your available ceiling height and width with Modula’s VLMs and HC. You don’t need the largest warehouse to operate — you just need the smartest layout.

Hire a Warehouse Manager

A warehouse manager is responsible for overseeing the day-to-day operations of your warehouse, such as managing inventory, ensuring efficient use of warehouse space and managing warehouse employees.

Hire a warehouse manager to ensure that inventory levels in your warehouse meet consumer demand and goods are received and shipped according to schedule.

Utilize Demand Forecasting

Demand forecasting is the process of using historical data to predict upcoming demand and ensure your inventory doesn’t run out.

It involves analyzing trends, patterns and factors that influence consumer demand to make informed predictions.

For example, seasonality can cause SKU velocity (how often each SKU is picked during a specific period) to fluctuate.

So, you can expect an uptick in demand for beach hats in the summer or hotdogs when the 4th of July rolls around the corner.

Keep a Close Eye on Expiration Dates

By monitoring product expiration dates, you can clear out inventory before it expires by lowering prices or offering special deals.

For example, you can run promotions like “Buy One, Get One Free” on these products or set up a clearance section for items nearing their expiration date, offering discounts of 20% to 50% to encourage quick sales.

Implement Quality Control

Conduct regular quality inspections for incoming and outgoing goods to maintain product quality and reduce returns and defects.

For example, implement a standardized checklist your warehouse staff must complete upon the arrival of new shipments.

This checklist should include tasks such as verifying the number and condition of items, checking for any visible damage and confirming that the goods match the specifications and quantities outlined in the purchase order.

Train Your Staff

Develop detailed training modules that cover all aspects of inventory management, including the use of inventory management systems (IMS) or enterprise resource planning (ERP) software.

For example, train staff on how to use barcode scanners and RFID technology to track inventory accurately.

Encourage feedback and suggestions from your staff on how to improve inventory management processes.

Use a Warehouse Management System

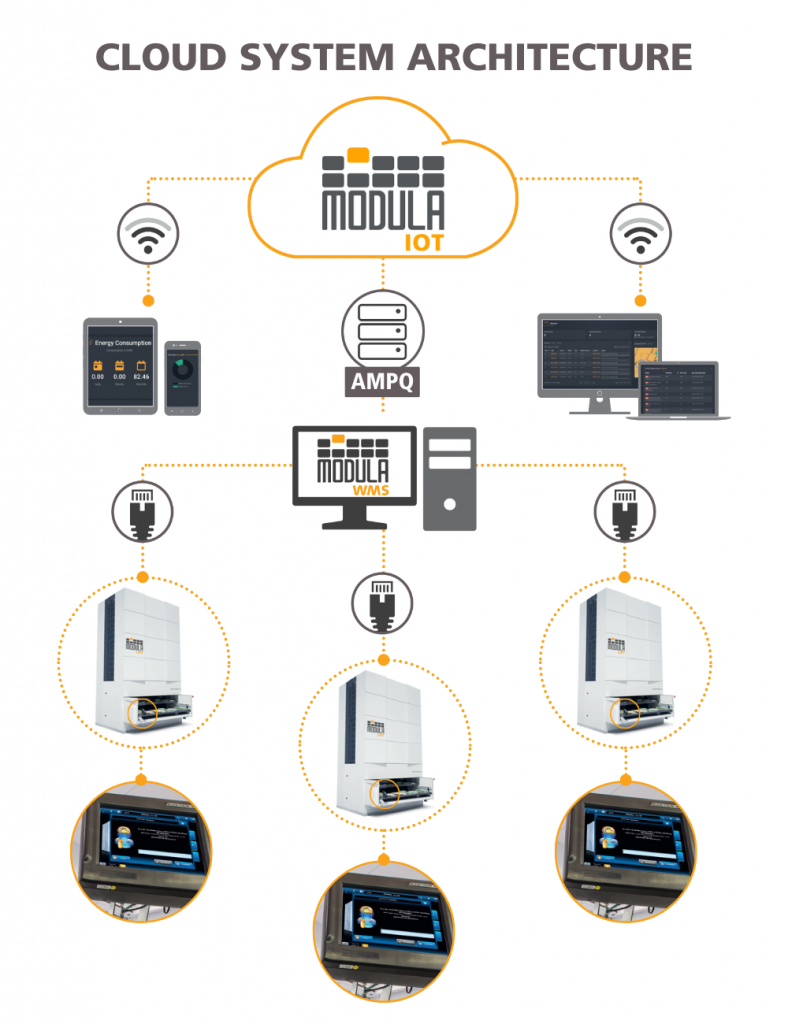

A warehouse management system can provide support, monitor your warehouse and collect real-time data from your automated storage and retrieval systems, regardless of the location.

With Modula’s Warehouse Management System, you can accurately manage and track individual items, from stock levels to product movement and beyond — more on that below!

Know Your Inventory

Effective inventory control begins by understanding your stock levels, inventory performance and replenishment needs.

To better grasp your inventory, review your products to determine what you have, their value, and how they’re used. Inventory management software can simplify this process.

Then, maintain accurate records for each item and ensure your system updates with every inventory change.

Understand Your Priorities

Different businesses have different needs, so identify your goals for an inventory management system.

If reducing storage costs is your priority, consider just-in-time (JIT) or dropshipping methods. If stockouts are frequent, consider maintaining safety stock or switching suppliers.

Align With Your Suppliers

Regular communication helps you negotiate better deals and receive early warnings about supply chain delays, allowing you to find alternatives.

Strengthen relationships with your suppliers by seeking their feedback, collaborating on improvements and consistently paying on time.

How to Automate Warehouse Inventory Management with Modula Solutions

Modula is a leading manufacturer of innovative automated storage solutions and inventory management systems.

Whether you’re in the automotive, retail or transportation, or another industry entirely, we provide automated storage and inventory management solutions that can help you increase productivity, improve picking accuracy and cut costs.

Modula Warehouse Management System

Our Modula software integrations are proven and tested. Our commitment to our customers has paved the way for us to develop and deliver standard-setting integration options that bind today’s warehouse operations with your ERP or DMS of choice.

At Modula, we offer two Warehouse Management System solutions:

- Module WMS Base: Perfect for small or scalable warehouse footprints

- Modula WMS Premium: End-to-end inventory and warehouse management solutions

Regardless of the package you choose, our warehouse management system allows you to:

- Gain complete inventory visibility and control

- Achieve exceptional picking and replenishment accuracy and efficiency

- Reduce cumbersome, time-consuming paper and manual processes

Modula Web Analytics

Modula Web Analytics is an all-in-one solution for your remote management, support, and analytics needs, whenever and wherever you need it.

Built-in and always running, the Modula Web Analytics platform captures all data in an easy-to-navigate online portal where you can securely monitor and manage your operations, from any device, anywhere.

Modula Web Analytics allows you to:

- Monitor your advanced Modula storage systems

- Gather statistical data from all your automated storage and retrieval systems, regardless of where they are located

- Implement preventive warehouse maintenance

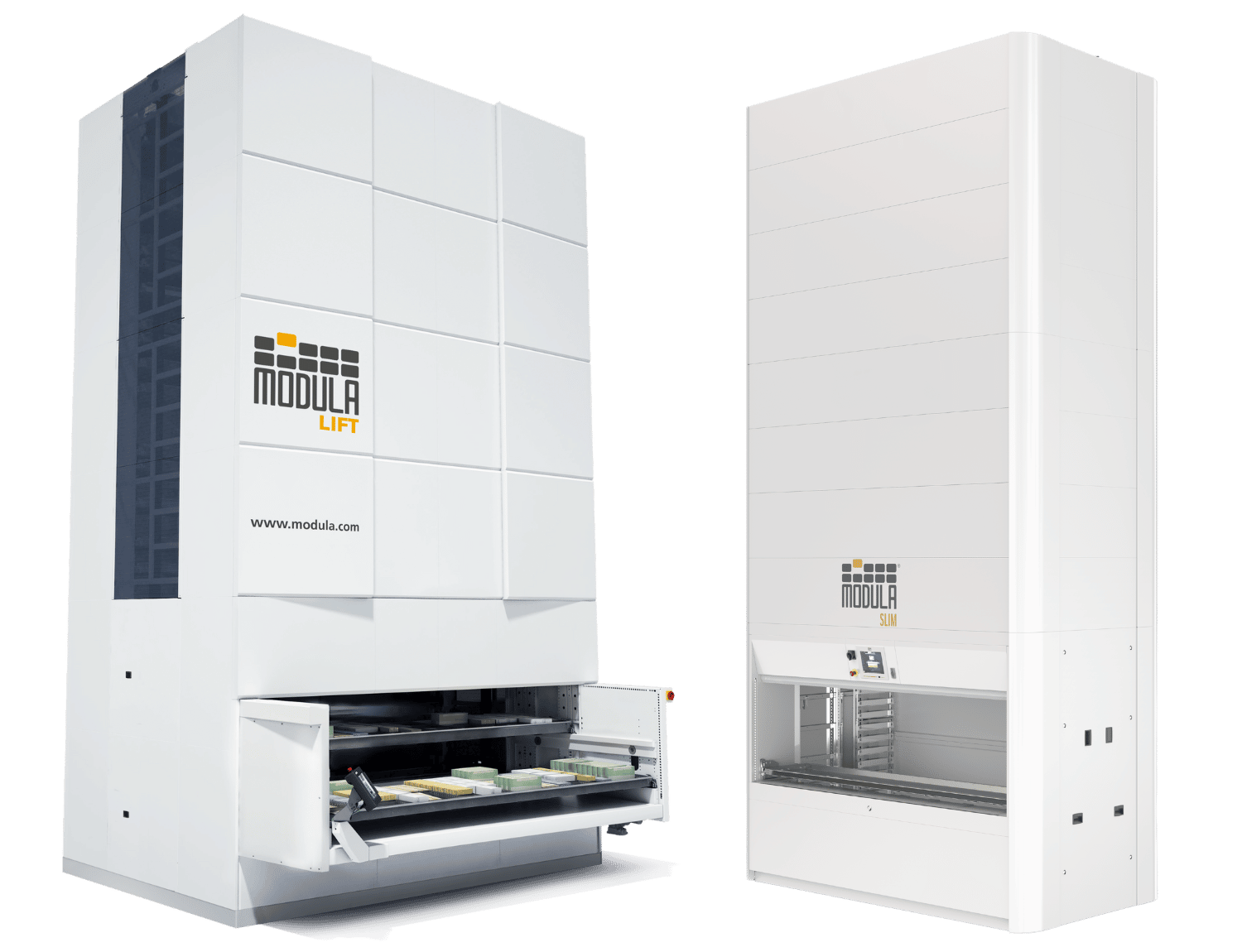

Modula Vertical Lift Modules

Need to optimize your storage space?

Modula’s VLMs are state-of-the-art, fully automated vertical storage systems, designed to minimize warehouse footprint by taking advantage of your warehouse’s existing ceiling height.

Select from two models: Modula Lift and Modula Slim.

Modula VLMS allow you to:

- Save up to 90% of floor space compared to traditional warehouse storage solutions

- Automatically receive items with the Copilot console or a scan of a barcode

- Process complex orders in the shortest possible time without sacrificing quality

- Reduce travel time by up to 90% compared to static shelving

- Keep your workers’ safety and ergonomics in mind

- Restrict access to unauthorized employees thanks to access codes and passwords

- Monitor picking operations and log-ins even down to its specific tray

Modula Horizontal Carousel

If you don’t have towering high ceilings in your warehouse, we’ve got you covered with the Modula HC.

Modula HC allows you to:

- Reach picking rates of up to 550 lines per hour for each employee

- Achieve up to 99% picking accuracy

- Store more items thanks to compact and high-density storage areas

- Experience a safer working environment by reducing physical strain and eliminating wasteful travel around the warehouse

- Protect your operators from moving parts, thanks to fast, automatic safety doors

Wrapping Up on Warehouse Inventory Management

Implementing warehouse inventory management strategies can help you run a more efficient warehouse by following best practices, such as organizing your floor plan, implementing cycle counting and minimizing manual input.

Warehouse software solutions are one way to help reduce human error, increase profitability and improve customer satisfaction.

Modula’s wide range of advanced warehouse management solutions help ensure that you get real-time data whenever and wherever you need it, while meeting growing customer demands in a cost-effective and productive operation.