Automated vs. Manual Warehouse Storage: What’s Better for SMBs?

When space gets tight and operations start to slow down, small and mid-sized businesses often find themselves asking the same question: is it time to automate?

As businesses scale, manual warehouse processes can quickly become a bottleneck.

That’s why many SMBs are turning to automated warehouse systems to improve inventory control, reduce picking errors, and maximize storage space.

According to the MHI’s 2025 Annual Industry Report, 41% of companies are already using warehouse automation, and that number is expected to jump to 83% within the next five years.

It’s more than just a technological upgrade, it’s a shift in how products move from manufacturers and distributors to customers.

Automated warehouse systems like Modula vertical lift modules minimize walking time, speed up order fulfillment, and cut storage footprints by up to 90%.

And while the upfront investment is higher than manual setups, many businesses see ROI in just 6 to 18 months through labor savings, improved throughput, and fewer errors.

In this guide, we will:

- Understand the key differences between manual and automated storage systems

- Discover when an SMB should consider automation

- Share the path to transition from manual to automated systems

- Explore Modula’s automated warehouse storage solutions

Key Differences Between Manual and Automated Storage Systems

Manual and automated storage systems share the same goal: keeping inventory organized and accessible, but they get the job done in very different ways.

For small and midsize businesses, understanding these differences can help you choose the right solution.

Here’s what sets them apart:

Labor Demand

Manual storage systems rely on employees to handle every task, including walking the aisles, picking items, scanning and shelving.

In contrast, automated warehouse systems like Modula VLMs deliver items directly to operators via vertical lifts, touchscreens and guided picking, cutting walking time and helping small teams work faster with less strain.

Picking Speed and Accuracy

Manual storage often relies on visual searches and handheld scanners, a slow process that’s prone to picking errors, especially during peak periods, such as:

- Holiday order surges

- Seasonal inventory changes

- End-of-quarter fulfillment rushes

Automated warehouse systems offer guided picking like laser pointers, LED indicators or barcode validation, helping reduce mispicks and speeding up order processing.

Space Utilization

A CBRE-backed report found that nearly 60% of 3PL facilities are operating at over 90% capacity, while another 28% run at 80–89%. With such tight capacity, especially amid rising inventory demand, many facilities have little room to grow.

One reason is that manual shelving consumes valuable floor space and often leaves overhead areas unused, eventually forcing costly expansions or the need for off-site storage.

Automated warehouse systems solve this by making full use of ceiling height and consolidating inventory into a compact footprint.

For example, a Modula VLM can reduce your storage footprint by up to 90%, creating valuable floor space for production, packing, or other revenue-generating activities.

Inventory Visibility

Manual systems often rely on spreadsheets or occasional cycle counts, which can cause:

- Inaccurate stock levels

- Costly stockouts

- Excess inventory and wasted space

Automated systems integrate with WMS platforms, giving you real-time inventory tracking, audit trails and automated reorder alerts, all essential for just-in-time or high-turnover operations.

Scalability

Manual systems are difficult to scale without adding warehouse space, storage racking and additional employees for picking, packing, and inventory control.

As order volumes rise, these limitations often lead to longer fulfillment times, higher labor costs and frequent bottlenecks.

Automated solutions expand with your business needs.

Whether you’re increasing SKUs, adding new product lines or launching additional distribution centers, automation can:

- Handle higher demand

- Maintain accuracy

- Increase throughput without a costly redesign of your entire operation

Workplace Safety and Ergonomics

Manual processes that involve repetitive lifting, bending, and reaching put employees at risk for costly workplace injuries.

Automated goods-to-person systems deliver items at an optimal, ergonomic height, protecting your team from strain and creating a safer, more comfortable work environment

Cost and ROI

Manual systems cost less upfront, making them attractive to SMBs with tight budgets. However, long-term expenses from excess labor and poor space utilization can add up quickly.

Automated warehouse systems require a higher initial investment, and prospective customers often ask about the typical ROI timeline for a Modula vertical lift module (VLM) or horizontal carousel (HC).

Most are surprised to learn that the payback period usually ranges from just six to 18 months. Try our ROI calculator to estimate your payback time.

Not sure if manual or automated storage is right for you? This side-by-side comparison shows how they stack up.

| Category | Manual Storage | Automated Storage |

| Labor requirements | Relies on employees for all material handling | Reduces walking and boost efficiency by up to 70% using vertical lifts, touchscreens, and guided picking |

| Space efficiency | Leverages floor space inefficiently, leaving vertical space unused and causing costly expansions or off-site storage | Maximizes vertical space, freeing up floor area for other operations |

| Picking speed and accuracy | Relies on visual searches and scanners, making it slower and more error-prone, especially during peaks | Guided picking with lasers, LEDs or barcode validation cuts mispicks by up to 99% and speeds order processing |

| Inventory visibility | Uses spreadsheets or periodic counts, causing inaccurate data, stockouts or overstock | Integrates with WMS for real-time tracking, audit trails, and auto-reorder alerts, ideal for JIT or high-turnover operations |

| Cost and ROI | Lower upfront cost for SMBs, but long-term labor and space inefficiencies raise expenses | Higher upfront cost, but payback in 6-18 months via labor savings, higher throughput and better inventory control |

| Workplace safety and ergonomics | Requires frequent bending, lifting, and reaching, higher injury risk | Goods-to-person systems deliver items at ergonomic height, reducing strain and improving safety |

| Scalability | Limited without more space or staff, causing bottlenecks as orders grow | Easily scales with growth. More SKUs, new lines, or added locations without major changes |

| Ideal for | Smaller operations with low order volumes, limited budgets or minimal SKU variety | Growing SMBs or high-volume operations seeking better space utilization, faster fulfillment and better accuracy |

When Should an SMB Consider Automated Warehouse Systems?

Small and midsize businesses should consider warehouse automation when:

- Labor costs are rising and it’s difficult to find or retain skilled workers

- Space is running out and expanding the facility or adding off-site storage would be costly

- Order volumes are growing and current processes can’t keep up without adding more staff

- Picking errors are increasing, leading to returns, rework, and reduced customer satisfaction

- Peak seasons cause major bottlenecks, slowing fulfillment and impacting delivery times

- Inventory visibility is limited, making it hard to track stock instantly

- Scalability is a priority and the business needs a system that can handle growth without major operational overhauls

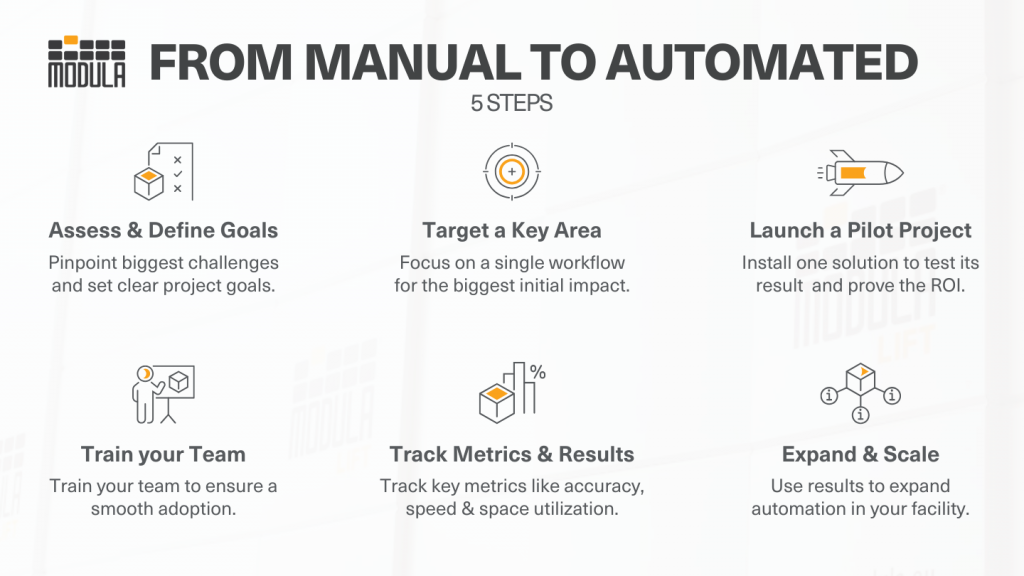

How To Transition from Manual to Automated Warehouse Systems

Switching from manual to automated storage starts with understanding your current challenges and setting clear goals.

Step 1: Identify Challenges and Set Goals

Evaluate your current operation to pinpoint pain points. Review space utilization, labor costs, inventory accuracy and order volumes.

Define clear goals, such as reducing errors, reclaiming floor space, or speeding up fulfillment.

Step 2: Prioritize Workflows for Automation

You don’t have to automate everything at once. Identify the processes causing the most delays, errors and costs. This could be slow picking zones, congested storage areas or high-error order lines.

Step 3: Start With a Pilot Project

Test automation in a high-impact area, like installing a Modula Vertical Lift Module (VLM) for your most frequently picked items.

Step 4: Train Your Team

Introduce training early, during the pilot project. This allows your employees to learn how to operate the new system, interpret data and adjust to new workflows with confidence.

Step 5: Measure Results

Track metrics such as time saved, picking accuracy, error reduction and space reclaimed to determine the system’s ROI.

Step 6: Expand Implementation

Once the pilot project has delivered clear results and your team is confident with the new technology, you can roll out automation to other areas or facilities to maximize efficiency gains.

Is Automation Too Complex for an SMB?

One concern many SMBs have when exploring automation is the perceived complexity of maintaining and operating new equipment.

In reality, modern automated storage systems are designed for ease of use and minimal upkeep, making the transition far simpler than you might think.

- Low maintenance requirements: Routine maintenance often involves basic cleaning, occasional inspections, and software updates, many of which can be scheduled around normal operations to avoid downtime.

- User-friendly interfaces: Touchscreen controls, guided picking aids, and intuitive software make it easy for new operators to get up to speed quickly.

- Training support: Most suppliers offer onboarding sessions, training materials, and ongoing support, so teams can adapt without disrupting workflows.

Common Misconceptions About Warehouse Automation

Despite its growing adoption, warehouse automation is still surrounded by myths that can hold businesses back from exploring its benefits.

Myth 1: Automation Replaces Workers

Did you know that 32% of U.S. workers believe AI will reduce their future job opportunities? In reality, automation is designed to support your team, not replace it.

By handling repetitive and physically demanding tasks, it frees employees to focus on higher-value work such as quality control, process improvements, and customer service.

Myth 2: Automation Is Only for Large Warehouses

Modern automation is highly scalable and modular. Vertical lift modules and horizontal carousels can be configured for operations of any size, from small stockrooms to large distribution centers.

Many SMBs start with one or two units for high-volume SKUs, reclaiming up to 90% of floor space and boosting picking speed and accuracy without a costly warehouse redesign.

Myth 3: Automation Is Too Complex for Small Teams

As we covered earlier, Modern systems are designed for ease of use. Most operators can be trained in under an hour, and ongoing maintenance is simple with vendor support.

Myth 4: Automation Isn’t Worth the Cost

While the upfront investment is higher than manual storage, most businesses see payback in six to 18 months through labor savings, faster fulfillment and better inventory control.

Myth 5: Implementation Will Cause Weeks of Downtime

Businesses can’t afford to shut down for a major overhaul. That’s why modern automation projects are implemented in managed phases.

A pilot project, like installing a single VLM, causes minimal disruption to your daily operations.

Myth 6: We’ll Have To Change Our Entire Workflow

While some processes will change for the better, the goal of automation is to enhance your existing workflow, not force a complete redesign.

Goods-to-person systems are designed to integrate with your current processes for receiving, packing, and shipping.

They eliminate the least efficient part of your workflow, walking, while keeping the rest of your operation intact.

| THE MYTH | THE REALITY |

| 1. Automation replaces workers. | It supports employees by automating strenuous tasks, allowing them to focus on skilled work like quality control. |

| 2. It’s only for large warehouses. | It’s highly scalable and modular, fitting any size facility and reclaiming up to 90% of floor space. |

| 3. It’s too complex for small teams. | Modern systems are user-friendly and intuitive, with most operators fully trained in under an hour. |

| 4. It isn’t worth the cost. | The ROI is typically fast (6–18 months) due to major savings in labor, space, and fulfillment speed. |

| 5. Implementation causes major downtime. | Implementation is phased and managed, often starting with a pilot project to minimize operational disruption. |

| 6. We’ll have to change everything. | It enhances your current workflow by integrating with existing processes and eliminating inefficient travel time. |

Discover Modula Automated Warehouse Storage Systems

When comparing warehouse automation to manual storage, small and medium businesses need to weigh efficiency, accuracy, and cost-effectiveness.

Modula’s automated storage solutions can help support SMBs tackle space limits and rising labor costs while boosting order speed and inventory accuracy.

Here are our automated vertical lift modules:

- Modula Lift: Our best-selling VLM, offering unmatched versatility to store and retrieve items of all sizes while saving up to 90% of floor space.

- Modula Slim: Space-efficient design perfect for smaller facilities, delivering the same automation benefits in a compact footprint.

- Modula Next: Precision-engineered for the most accurate picking, ideal for high-value or fragile items where zero errors matter.

- Modula Pallet: The safest and most efficient way to store and handle heavy or bulky palletized goods, reducing manual lifting and improving safety.

- Modula Flexibox: High-speed automation capable of processing up to 180 bins per hour, perfect for fast-moving, high-volume environments.

If your facility has low ceiling, our Modula Horizontal Carousel offers an ideal storage solution by moving along a horizontal axis instead of vertically, maximizing floor space while maintaining full accessibility and efficiency.

Manual vs. Automated Warehouse Systems: Key Takeaways

- Automated warehouse systems like Modula vertical lift modules cut walking time, minimize mispicks and accelerate order fulfillment

- By maximizing vertical storage, automation cuts storage footprints by up to 90% and scales with growth, without costly expansions

- While automation has higher upfront costs, most SMBs see payback within six to 18 months through labor savings, improved throughput, and better inventory control

Manual vs. Automated Warehouse Systems: FAQs

What is a service manual warehouse?

A service manual warehouse is a type of warehouse where workers handle inventory management, picking, and replenishment manually, using basic equipment such as pallet jacks, forklifts, and shelving.

When should you upgrade from manual to automated storage?

You should consider upgrading when:

- Order volume is consistently increasing and manual processes can’t keep pace

- Picking errors are leading to high return rates or customer dissatisfaction

- Labor shortages or costs are impacting operations

- Space constraints require more efficient storage utilization

- Your business is scaling and you need consistent and reliable throughput

What are the benefits of an automated warehouse system?

An automated warehouse system uses integrated technologies, such as conveyors, vertical lift modules (VLMs), horizontal carousels, robotic picking arms, and warehouse management systems to store, retrieve and track inventory with minimal human intervention.

Benefits include:

- Faster picking and order fulfillment

- Reduced labor costs and dependency on manual labor

- Higher accuracy in inventory tracking

- Better use of vertical and horizontal space

- Improved workplace safety