14 Types of Warehouses + How To Find the Right Warehouse Type

From smart warehouses and climate-controlled facilities to fulfillment centers and hazmat warehouses, there are a wide range of warehouse types used across industries.

Finding the right facility for your business will depend on your operational needs, plans to scale and budget.

We’ll explain the different types of warehouses, including their key roles in the supply chain and tips on how to find the one that’s right for you. Plus, we’ll share Modula automated warehouse solutions to help you create the ideal facility for your business needs and goals.

14 Types of Warehouses

Each warehouse type offers distinct features and benefits, regarding storage, distribution and other factors.

The 14 types of warehouses include:

Smart Warehouse

A smart warehouse is a facility that utilizes automated warehouse solutions, such as advanced robotics, artificial intelligence (AI) and data analytics to improve efficiency and productivity across the organization.

Government and Military Warehouse

A government warehouse is a facility that is owned and operated by a government agency.

This type of warehouse stores inventory for local offices, schools and hospitals, including emergency kits for natural disasters and fire outbreaks.

A government warehouse provides centralized inventory to monitor stock and effectively distribute products to organizations — including charities, like Feeding America.

On the other hand, a military warehouse stores equipment, supplies, provisions and ammunition for military operations and training exercises.

Distribution Center

A distribution center, also known as a distribution warehouse, is a facility that stores products and then distributes them to retailers, wholesalers or directly to consumers.

This warehouse also provides additional order fulfillment services, such as packing orders and managing product returns. A distribution center is typically owned by third-party logistics (3PL) companies.

Climate-Controlled Warehouse

A climate-controlled warehouse is a storage facility that closely monitors and regulates temperature and humidity levels to ensure that perishable and temperature-sensitive goods are protected, such as food, medicine and cosmetics.

This warehouse is essential for industries, such as food pharmaceuticals and cosmetics, ensuring product quality and preventing spoilage or degradation.

Bonded Warehouse

A bonded warehouse is a facility that stores imported goods under the supervision of customs authorities.

This type of warehouse allows businesses to temporarily store goods without immediately paying the required customs duties and taxes until the products are released. Inventory can stay in a bonded warehouse for five years.

Consolidated Warehouse

A consolidated warehouse, also known as a shared warehouse, is a facility that stores goods from different suppliers or manufacturers into a single shipment before being distributed to other destinations.

It serves as a central hub for receiving, sorting and consolidating products. Startups or small-scale businesses often utilize a consolidated warehouse to save money on warehouse costs, such as warehouse rent, storage, security systems and hiring.

Private Warehouse

A private warehouse, also known as a proprietary warehouse, is a facility that stores inventory from a single company.

A private warehouse is often used by businesses that need a high degree of control over their warehousing operations, such as large manufacturers or wholesalers, so they can keep a close eye on inventory levels, production lines and shipping.

Public Warehouse

A public warehouse is a facility that is leased to businesses on a contract basis.

Unlike private warehouses, which are owned and operated by the business that uses them, public warehouses are operated by third-party companies that specialize in warehousing and distribution services.

A public warehouse provides businesses with flexibility in terms of space utilization. Businesses can rent as much or as little space as they need, depending on their inventory levels and seasonal demands.

This flexibility allows them to adapt to changing storage requirements without the long-term commitments and costs associated with owning or leasing a warehouse.

Fulfillment Center

A fulfillment center is a facility that is specifically designed and used for processing orders from eCommerce businesses.

When a customer places an order online, the fulfillment center is responsible for picking, packing and shipping packages to the customer.

A fulfillment center provides comprehensive inventory management services, such as inventory tracking, stock rotation and replenishment, allowing real-time visibility into inventory levels.

Cooperative Warehouse

A cooperative warehouse is a facility that is owned and operated by a group of businesses that share storage and distribution resources.

A cooperative warehouse is often used by farmers or winery owners (who can conveniently store their products in a shared space) to help them cut costs on inventory storage.

Cross-Docking Warehouse

A cross-docking warehouse is a facility that sorts unloaded goods from a truck or trailer. Goods are then immediately loaded into outbound vehicles for delivery, with little to no storage in between.

A cross-docking warehouse reduces the need for storage space and cuts down on the time that goods spend in the warehouse, leading to significant cost savings while speeding up delivery times.

Hazmat Warehouse

A hazmat warehouse, also known as a hazardous materials warehouse, is a facility that safely stores and manages hazardous materials or dangerous goods.

These hazardous goods can include flammable, corrosive and toxic substances that pose a risk to health, safety, property or the environment if not properly stored and managed.

Reverse Logistics Warehouse

A reverse logistics warehouse is a facility that handles the process of moving goods from the customer back to the distributor due to product returns, recalls or repairs.

A reverse logistics warehouse allows businesses to improve customer satisfaction (through efficient return management) and reduce their environmental footprint by recycling and properly disposing of returned goods.

Manufacturing or Production Warehouse

A manufacturing warehouse is integrated within a manufacturing facility. It serves as a storage space for raw materials, components, work-in-progress inventory and finished goods that are part of the manufacturing process.

This type of warehouse supports the efficient flow of materials to the production line and facilitates timely delivery of finished goods to distribution centers or customers.

Why Choosing the Right Warehouse Type is Important

Choosing the right warehouse type is key for achieving optimal operational efficiency and meeting customer expectations.

Here are two reasons why choosing the right warehouse type is important:

It Has an Impact on Supply Chain Efficiency and Customer Satisfaction

Your warehouse serves as a link in the supply chain where inventory is stored, managed and distributed. The warehouse type you choose directly impacts the speed and accuracy of order fulfillment, inventory management and product delivery.

By selecting a warehouse that aligns with your business needs, you can ensure efficient stock replenishment, minimize order processing times and improve overall supply chain responsiveness.

It Has Cost and Operational Implications

Choosing the right warehouse type can significantly impact your bottom line, as different warehouse types come with varying cost structures, lease terms and service offerings.

Assessing your business requirements and considering factors such as storage capacity needs, inventory turnover rate, proximity to suppliers and customers and specialized storage requirements allows you to develop a strategic warehouse management plan that optimizes resources and operations.

When you choose a warehouse type that aligns with your operational needs, you can optimize costs related to storage space, labor, transportation and inventory management — leading to improved operational effectiveness, reduced overheads and improved financial performance.

How To Find the Right Warehouse Type for Your Business

Selecting the right type of warehouse for your business can help ensure efficient operations and optimal productivity. Here are key steps to help you make the right choice:

- Define your needs: Understanding the specific storage requirements of your inventory is the first step in identifying the right type of warehouse for your business. Your warehousing needs will depend on the type of goods you are managing. Do you need a climate-controlled environment for perishable inventory? Or maybe a hazmat warehouse for flammable products?

- Consider size and scalability: Your warehouse should accommodate your existing inventory and also have the ability to scale as your business grows. In addition, a scalable warehouse allows you to adapt to changes in consumer demands. For example, a public or cooperative warehouse can offer flexibility in terms of scaling up or down based on consumer demand.

- Check the facility’s amenities: Ensure that the type of warehouse you select has the amenities you need to properly store your inventory. For specialized needs, look for warehouses offering additional services, such as cross-docking or reverse logistics. If you’re storing temperature-sensitive products, check the facility’s temperature control and humidity control storage systems.

- Consider warehouse costs: Consider the costs that come with each warehouse type. While a private warehouse might offer more control, it can be more expensive to set up and maintain. Public warehouses or cooperative facilities can be more affordable, as they allow businesses to share the costs of warehouse space and equipment.

Modula Automated Warehouse Solutions To Build a Smart Warehouse

As an industry leader in advanced storage solutions and warehouse management systems, Modula helps warehouses across industries reimagine their operations to boost productivity, efficiency and inventory management.

Modula’s automated warehouse solutions include:

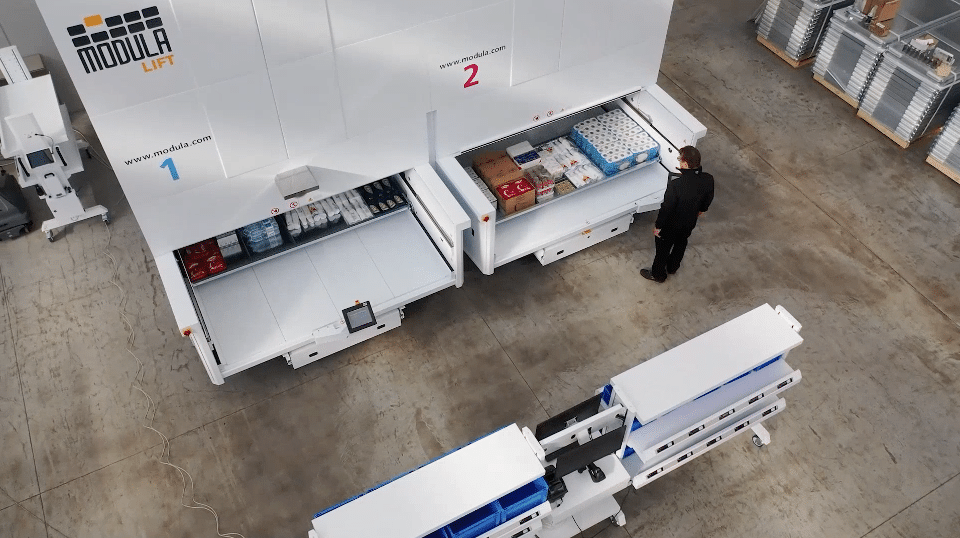

Modula Vertical Lift Module

The Modula Vertical Lift Module (VLM) can help optimize your warehouse space by utilizing your ceiling height.

We offer three models:

- Modula Lift: A versatile storage solution for industrial parts, offering various capacities and sizes.

- Modula Slim: A compact storage solution suitable for warehouses with limited space.

- Modula OnePick: A fully automated storage solution that requires no human intervention.

Modula VLMs allow you to:

- Conserve 90% of floor space by taking advantage of your ceiling height

- Process up to 140 trays per hour

- Speed up picking to 300 lines per hour or more

- Enhance worker safety by removing the need to reach high and low for products

- Secure your inventory with a locked and enclosed system with restricted access

Modula Horizontal Carousel

The Modula Horizontal Carousel (HC) is the ideal automated storage solution for spaces with low ceilings.

The Modula HC allows you to:

- Adjust shelfs to accommodate various inventory

- Get a bird’s eye view of stock levels and orders

- Increase picking speed to 550 lines per hour, per employee

- Keep real-time track of picking operations

- Achieve a picking accuracy of 99% when combined with Modula Put to Light Systems and barcode scanners

Modula Order Picking Solutions

Modula picking solutions can help your warehouse operators navigate inventory faster while ensuring picking accuracy.

Modula order picking solutions allow you to:

- Boost picking accuracy and speed, thanks to light devices that guide operators to the correct pick location

- Increase order accuracy and efficiency when combined with Modula’s advanced automated storage solutions

- Better manage inventory with a detailed view of existing and predicted stock

Modula WMS

The Modula Warehouse Management System (WMS) is a comprehensive inventory management software that serves as the backbone for operating Modula’s automated storage and retrieval solutions.

The WMS is also capable of functioning independently as a standalone software in traditional warehouses, including manual areas.

Modula WMS can seamlessly integrate with nearly all Document Management Systems (DMS) and Enterprise Resource Planning (ERP) systems, optimizing warehouse processes like receiving, picking and storing products.

Designed with user-friendliness in mind, the Modula WMS offers an easy-to-navigate PC interface that grants you real-time monitoring and control over your warehouse operations.

Modula Cloud

Modula Cloud is a remote management platform that allows you to gather data from your Modula vertical lift modules and horizontal carousels, no matter their warehouse location.

This around-the-clock platform provides a user-friendly online portal, allowing you to securely manage and track your operations from any place or device.

Modula Cloud allows you to:

- Remotely oversee your Modula automated warehouse solutions

- Manage your warehouse from anywhere through remote diagnostics, support, resolutions and predictive maintenance

- Monitor your warehouse status, including unit stats, power use and equipment health

- Obtain reports on power use, completed orders and cycles and tray usage efficiency

Modula Automated Warehouse Solutions To Build a Climate-Controlled Warehouse

Take your material handling to another level and safely store inventory that is sensitive to temperature and humidity changes with Modula’s smart solutions.

Modula Climate Control

Modula Climate Control is a VLM that is designed to manage humidity and temperature for your inventory, preventing fluctuations due to changing environmental conditions.

This temperature-controlled VLM maintains fixed humidity, temperature and air movement within contained spaces, ensuring safe storage for perishable goods.

Modula Climate Control allows you to:

- Set and maintain temperature from +2°C to +25°C (+35 °F to +77°F)

- Set and control humidity levels of ≥ 5%

Modula Clean Room

Modula Clean Room is a VLM built for managing inventory in clean room conditions.

Ideal for electronic companies and warehouses storing parts that are sensitive to dust, Modula Clean Room shields components from dust, dirt and other debris.

Whether it’s components for semiconductor manufacturing or dust-sensitive cable wiring, Modula Clean Room meets class 7 and 8 requirements and adheres to ISO 14644 standards.

Key Takeaways on Warehouse Types

A warehouse is more than just a facility for storing inventory. From distribution centers to cross-docking facilities and beyond, each warehouse type plays a key role in the order fulfillment process.

At Modula, our advanced storage solutions and warehouse management system allow you to build your ideal warehouse so you can optimize your storage space, improve your picking accuracy and boost productivity and efficiency across your organization.