What Is Warehouse Optimization? Benefits, Challenges & Tips

Warehouse optimization is a top priority for companies aiming to boost efficiency, cut costs, and stay competitive.

By implementing strategic warehouse optimization techniques, your organization can immediately experience numerous benefits, such as increased productivity, enhanced customer satisfaction, and improved employee safety.

In this article we’ll explore the benefits and challenges of warehouse optimization, share actionable tips on how to maximize your warehouse operations and explain how our Modula solutions can benefit your business.

What Is Warehouse Optimization?

Warehouse optimization involves managing and enhancing the efficiency of storage, material handling, and distribution within a warehouse. This encompasses everything from layout and design to inventory management, workflow procedures, and technology integration.

The primary goal of optimizing warehouse operations to ensure easy access to goods and flexibility to adapt to changing demands.

Benefits of Warehouse Optimization

Warehouse optimization offers numerous benefits that can significantly enhance the efficiency of your warehouse operations.

Better Inventory Management

Inventory management is a complex task, especially when your business handles hundreds — or even thousands of SKUs.

Manually tracking which items are running low or are overstocked is cumbersome and often leads to errors.

Optimizing your warehouse operations can improve the accuracy and efficiency of your inventory management.

Boost Productivity

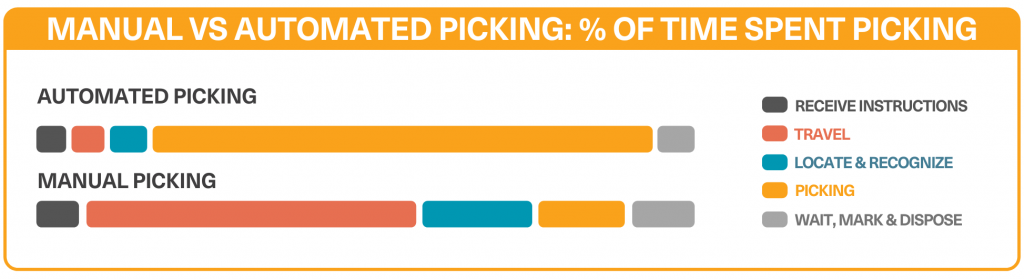

Warehouse optimization enhances productivity by streamlining operations, reducing processing times and minimizing errors.

By organizing inventory better, implementing effective picking strategies, and utilizing automated systems, your operations can manage more transactions faster and with fewer mistakes.

This leads to an efficient flow of goods and quicker response times, which is paramount for meeting production deadlines and keeping operations running smoothly.

Better Employee Safety

Optimizing your warehouse operations can help improve employee safety by reducing the need for work-intensive tasks, such as heavy lifting.

For example, by implementing automated storage and retrieval systems, you can minimize the physical strain on workers. These systems can carry and transport heavy loads, effectively lowering the risk of injuries.

Enhanced Accuracy and Order Fulfillment

Warehouse optimization ensures that the right products are picked, packed, and shipped accurately and efficiently. This leads to fewer errors in order fulfillment, reducing the need for returns or exchanges and improving overall customer satisfaction.

Optimized Utilization of Labor Resources

By streamlining warehouse operations and implementing automation where possible, businesses can optimize the allocation of labor resources. This allows employees to focus on higher-value tasks, such as quality control or customer service, rather than spending time on repetitive manual tasks. It also increases job satisfaction and morale among warehouse staff.

Improved Customer Satisfaction

An optimized warehouse significantly boosts customer satisfaction by ensuring that products are available when needed and reach customers in the expected condition and timeframe. Accurate inventory records prevent stockouts and backorders, while streamlined processes reduce shipping delays.

Moreover, the ability to respond quickly to customer demands and provide reliable service strengthens customer trust and loyalty, which are essential for long-term business success.

Challenges of Warehouse Optimization

Warehouse optimization faces several challenges that can impact operational efficiency and effectiveness including:

- Inaccurate inventory: Keeping precise records is essential, but errors often occur due to manual data entry, misplaced items or outdated systems. Inaccurate inventory tracking leads to stockouts, excess stock, and order fulfillment issues, ultimately disrupting the supply chain.

- Inefficient use of space: Using Warehouse space effectively is crucial as an inefficient layout can result in wasted space, making it difficult to access inventory and move items efficiently. This not only slows down operations but also increases warehouse costs.

- Inefficient picking strategy: Without a well-planned picking strategy, your employees may spend unnecessary time navigating the warehouse, leading to delays in order processing. Inefficient picking can significantly impact productivity and delay shipments.

8 Warehouse Optimization Tips

An optimized warehouse strikes a balance among technology, streamlined processes and proper staff training.

To optimize your warehouse, consider implementing these best practices:

Evaluate Your Existing Warehouse Setup

Begin by conducting a detailed assessment of your warehouse layout, innovations and employees.

Are your employees constantly bumping into each other due to the facility’s layout? Do you have unused space in your facility? Do your employees understand how to use smart warehouse technologies?

By implementing this strategy, you can identify opportunities to reorganize your warehouse, invest in new equipment or upgrade your warehouse racks and shelving systems.

Minimize the Number of Touch Points

Reducing touchpoints in your warehouse operations can help streamline processes, reduce labor costs, decrease the likelihood of errors, and reduce the time it takes to move items from receiving to shipping.

To minimize touchpoints in your warehouse:

- Implement cross docking: Bypass the storage process by directly transferring incoming goods from receiving to outbound shipping docks.

- Adopt drop shipping: Collaborate with suppliers to ship products directly to customers, eliminating handling steps in the warehouse.

- Choose the right picking methods: Implement batch picking, zone picking, or wave picking to reduce the moving and handling items during order fulfillment.

Take Advantage of Warehouse Technology

Incorporate robotics into your warehouse operations to automatically store, transport and retrieve goods, leading to faster processing times and fewer human errors.

You can also leverage automated storage solutions, such as Vertical Lift Modules (VLMs) and Horizontal Carousels (HCs) to maximize your current storage, improve picking accuracy and reduce retrieval times.

These systems organize and deliver items directly to your warehouse operator, minimizing physical strain and enhancing efficiency by reducing the need to walk and search for products.

At Modula, our VLMs are the perfect automated vertical storage solutions that can accommodate parts and components of any size and dimension in your facility.

By maximizing your high ceilings, VLMs can significantly reduce the space needed for storage.

If your facility has a low clearance, our HCs provide a safe and efficient way to store inventory in a centralized space.

Organize Your Inventory Based on Product Velocity

Organizing goods based on their product velocity is key, as it makes picking faster, reduces travel time for workers, and cuts handling costs.

Product velocity, also known as inventory velocity, measures how quickly a product moves from concept to market.

It serves as a warehouse key performance indicator (KPI) for product management and operations teams, highlighting the efficiency and effectiveness of the product development process.

To organize products based on their velocity:

- Identify high-velocity goods: Use sales data and inventory turnover rates to identify your most frequently sold items.

- Designate prime locations: Assign high-velocity items to easily accessible locations to minimize picking time. For example, place high-velocity inventory close to packing and shipping areas.

- Leverage warehouse slotting: Organize similar high-velocity items together to streamline the picking process and reduce travel time for pickers.

Leverage Lean Manufacturing Techniques

Originating in the manufacturing sector, lean manufacturing focuses on achieving more with less.

Incorporating lean warehouse techniques can help reduce the time spent on non-value-added activities, such as redundant data entry or unnecessary movement of goods.

For example, if your warehouse employees spend a lot of time walking back and forth to a distant printer to print out labels, consider relocating the printer closer to the packing station or adopting mobile printing solutions.

This change reduces wasted steps and saves time, allowing your employees to focus on more productive tasks.

Automate Your Shipping Routing

Order Fulfillment is a crucial warehouse activity to optimize, as it helps make sure that your customers receive their orders as expected.

Instead of depending on your employees to direct shipments to the correct collection areas, your business can employ order routing automation tools, such as warehouse management systems (WMS), to streamline the process.

This ensures that the right products reach the right place at the right time.

Use a Warehouse Management System (WMS)

A warehouse management system (WMS) centralizes data and automates different labor-intensive and error-prone tasks like receiving, picking, kitting and inventory management.

This solution can help optimize your processes and provide a single source of data, eliminating the need to guess or cross-reference multiple systems to understand warehouse activities.

Additional benefits of Modula’s WMS include:

- Keep records of unique identifiers, item movement and stock levels

- Track order processing, shipping and delivery

- Set up location codes and labels to track product movement within your warehouse

- Allocate tasks to your employees, set access levels and monitor user activity

- Connect and share data with other systems through data entry or file imports and exports

At Modula, our Warehouse Management System (WMS) seamlessly integrates with our advanced Automated Storage and Retrieval System (ASRS).

It is customized to enhance operations, providing an easy-to-use interface for straightforward management and real-time inventory tracking.

Invest in Employee Training

Your warehouse operations are only as efficient as your employees. If your staff isn’t properly trained, they won’t perform tasks to their fullest potential.

To ensure your employees can manage your warehouse operations:

- Provide comprehensive training: Offer detailed training programs that cover all necessary skills — from inventory management to safety protocols.

- Regularly update training materials: Make sure your training materials are updated to reflect new technologies and processes.

- Use mentorship programs: Pair less experienced staff with veteran employees for hands-on learning and support.

A Quick Recap of Warehouse Optimization

To sum up, warehouse optimization is the process of enhancing the efficiency and effectiveness of storage, handling and distribution operations within a facility.

At Modula, our advanced automated solutions enable faster order processing, improved space utilization and enhanced workplace safety.

Contact our team to see how we can adjust our technology to your needs. Our experts are more than happy to provide customized advice and solutions for your warehouse.