How Do Warehouse Systems Work? [Benefits & FAQs]

The warehouse automation market was valued at approximately $19.2 billion in 2023 and is expected to reach nearly $60 billion by 2030.

In other words, it’s set to almost triple in just seven years. This is fueled by the growing need to keep up with eCommerce demand, labor shortages and the push for greater efficiency.

What does this mean for warehouse managers? It means automation is no longer a “nice-to-have”, but an essential investment to stay competitive.

In this article, we will:

- Share how automated warehouse systems work

- Explore the top benefits of automating your warehouse

- Uncover emerging warehouse trends shaping the future of logistics and supply chain operations

- Discover Modula’s advanced systems and see how they can transform your warehouse

Understanding Warehouse Systems

A warehouse system integrates warehouse equipment, operational workflows and advanced solutions to manage how goods are stored, transported, and tracked within a facility.

But it’s far more than just storage racks and forklifts.

Advanced warehouse systems are designed to support end-to-end logistics, from receiving raw materials to shipping finished goods, while ensuring speed, accuracy and cost efficiency in high-throughput environments.

While the warehouse management system (WMS) is often considered the backbone of warehouse operations, it’s only one crucial part of a larger operational ecosystem.

A WMS helps coordinate data and direct workflows, but its value depends on how seamlessly it integrates with:

- Automated equipment

- Physical infrastructure

- Manual processes

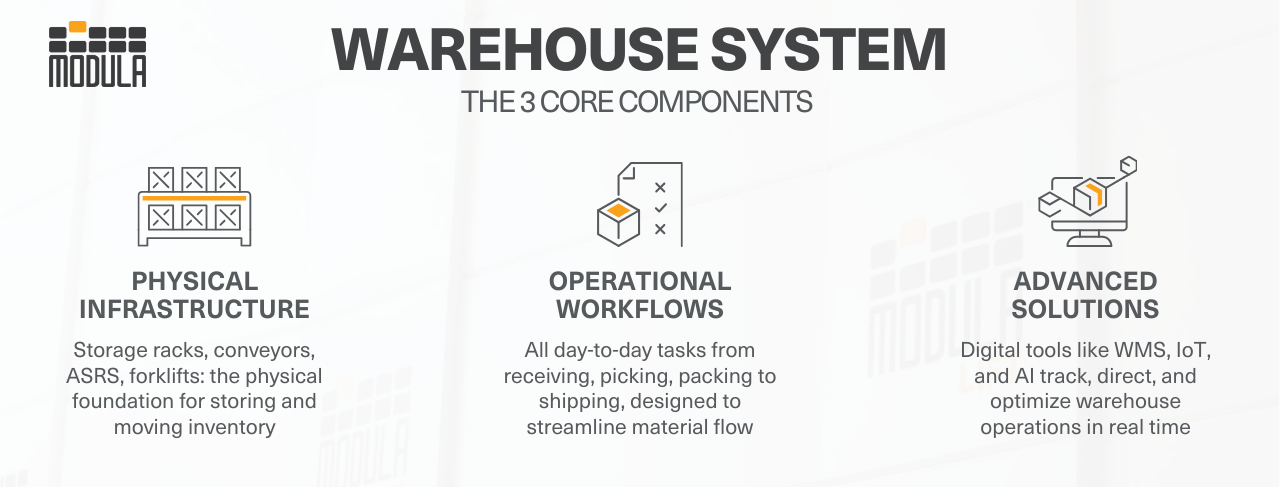

The Three Components of a Warehouse System

Every effective warehouse system is built on three core pillars, each working together to keep operations efficient, accurate and scalable.

Physical Infrastructure

This encompasses all the tangible elements used to store and transport inventory within the facility, including shelving, pallet storage, automated storage and retrieval systems (such as vertical lift modules), conveyors, and forklifts.

Operational Workflows

This encompasses daily tasks that keep the warehouse running smoothly, including receiving goods, storing them, picking orders, packing items, replenishing stock, conducting cycle counts, and shipping orders.

Each step is designed to boost efficiency, reduce delays and maintain inventory accuracy.

Advanced Solutions

Includes the digital tools that drive visibility and control across the warehouse, such as:

- IoT devices

- Robots

- Artificial intelligence (AI)

- Warehouse management systems

- Integrations with enterprise resource planning (ERP) and document management systems (DMS)

Together, these tools deliver real-time visibility, enable predictive analytics, and help warehouse managers make data-driven decisions.

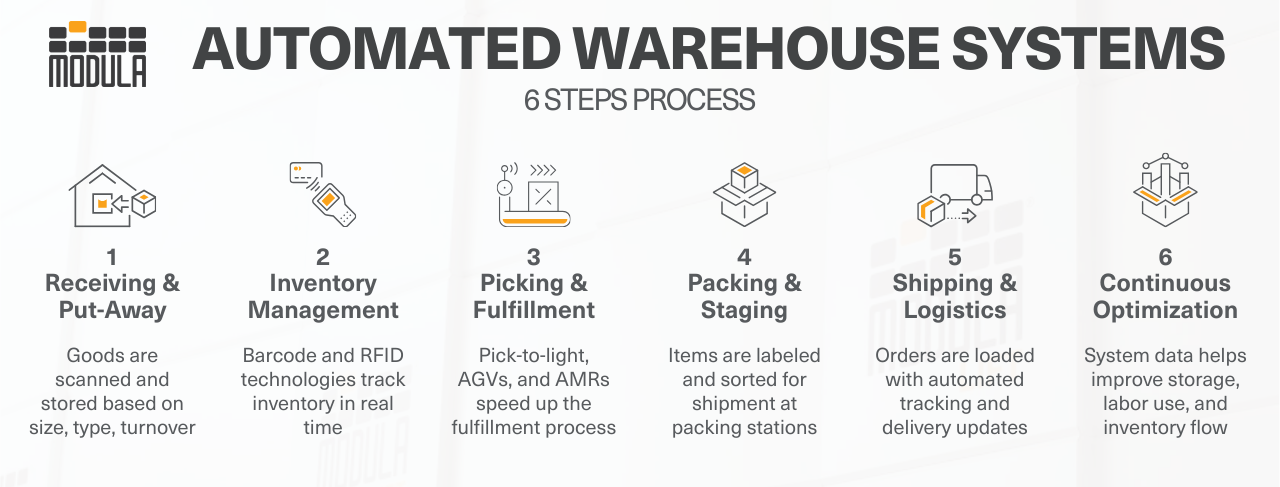

How Automated Warehouse Systems Work

Modern Warehouse systems integrate storage solutions and intelligent software to control and optimize the flow of goods from receiving to shipping.

Instead of managing each stage in isolation, these systems create a connected environment where equipment, inventory data and workflows are fully synchronized.

Here’s how the process typically works:

- Receiving and put-away: Warehouse teams check, scan and route incoming goods to storage locations based on size, product type, or movement frequency. Automated systems like vertical lift modules (VLMs) or ASRS handle storage with speed and precision.

- Inventory management: Warehouse staff can utilize barcode readers, RFID readers and IoT sensors to track inventory instantly. These tools ensure accurate stock levels and help prevent overstocking or stockouts.

- Picking and order fulfillment: When an order comes in, the system generates a pick list and sends it to workers or automated picking tools. Pick-to-light, put-to-light, automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) can help speed up the process and minimize mistakes

- Packing and staging: After picking, teams move items to packing stations, where they scan, label and prep each order for shipment. The system organizes and sorts everything, ensuring it’s ready for pickup by the assigned carrier or shipping priority.

- Shipping and outbound logistics: Once orders are packed and ready, they’re loaded onto trucks at designated docks. The system then updates delivery statuses, shares tracking information and helps coordinate efficient outbound routes.

- Ongoing optimization: As the system collects data on picking speeds, stock levels, errors, and delays, it enables warehouse managers to make informed improvements. They adjust slotting, reassign labor or modify storage strategies to keep operations running smoothly.

Top Benefits of Leveraging Automated Warehouse Systems

Sure, warehouse systems track inventory, but their actual value lies in how they transform your entire operation.

From cutting costs to speeding up deliveries, here’s what they bring to the table:

Secure Inventory

With real-time tracking solutions, such as warehouse management systems, it’s easy to keep track of what’s in stock and exactly where it’s stored.

These solutions not only improve accuracy but also help prevent theft.

Consider the recent Labubus shipment that was stolen from a warehouse in California. The facility lacked proper inventory tracking, making it more difficult to detect and respond to theft.

Lower Costs Across the Board

Labor is one of the most significant warehouse expenses, often accounting for 50-70% of total expenses.

An innovative warehouse system helps you manage this by forecasting labor needs, reducing unnecessary overtime, and assigning tasks more efficiently.

It also optimizes picking routes to eliminate backtracking and prevents incorrect storage, further cutting down on wasted time and labor.

Faster, More Accurate Deliveries

Warehouse systems streamline every step of the order fulfillment process, from order receipt to final dispatch, helping minimize errors and speed up delivery times.

Features like automated pick lists, optimized picking routes and real-time inventory visibility ensure that the right items are picked, packed and shipped without delays.

Scalability

Whether you’re introducing new product lines, expanding into additional facilities, or integrating warehouse automation systems like AMRs or conveyor systems, a sophisticated WMS can support growth without requiring a complete overhaul.

Picture this: you’re heading into the holiday season and planning to deploy robotic picking units to handle the surge in demand.

With built-in automation:

- Setup is fast and seamless

- Throughput increases immediately

- Your team adapts without needing extensive retraining

That’s the kind of agility a future-ready warehouse system delivers.

Improved Workplace Safety

Manual warehouse tasks often involve repetitive bending, lifting of heavy items, and reaching high shelves, which are leading causes of costly employee injuries.

Automated systems handle the strenuous work for your team.

By bringing items directly to the operator at an optimal, ergonomic height, solutions like vertical lift modules reduce physical strain, create a safer work environment, and can lower insurance costs associated with workers’ compensation claims.

6 Emerging Trends in Warehouse Systems

Staying competitive means keeping up with the latest innovations.

The emerging warehouse trends reshaping how facilities operate include:

AI and Machine Learning

AI is no longer just for forecasting, as it’s now driving smarter, faster decision-making across the warehouse.

It’s helping warehouses make more informed decisions on demand, whether that’s adjusting labor schedules, prioritizing urgent orders, or maintaining optimal inventory levels.

It’s a great way to diminish waste, improve efficiency and stay ahead of demand.

IoT Integration

With sensors tracking everything from temperature and humidity to equipment status and item movement, IoT offers you a live view of what’s happening across your facility.

That means fewer stockouts, faster responses to issues and better control over sensitive goods.

Advanced Robotics and Cobots

Technologies like AMRs, robotic arms and drones are taking over repetitive or time-consuming tasks, such as:

- Moving inventory between zones

- Picking and sorting orders

- Scanning stock for cycle counts

- Inspecting hard-to-reach storage areas

This speeds up fulfillment and reduces the physical strain on workers.

Cloud-Based WMS Platforms

Think of a cloud-based WMS as your central nervous system.

It provides teams with real-time access to up-to-date data from anywhere, while enabling faster updates and seamless integration with ERP or eCommerce systems.

It’s beneficial for businesses that run multiple warehouses or manage seasonal volume spikes.

Green Warehousing or Sustainability

Many warehouses are prioritizing sustainability by finding ways to decrease their energy use, waste and resource consumption.

To stay competitive, companies are turning to automation as a practical way to reduce their environmental impact.

Today’s systems are more intelligent and more energy-conscious than ever. Features driving greener operations include:

- Automated lighting that adjusts based on activity or occupancy

- Advanced energy monitoring to track and optimize usage in real time

- HVAC systems optimized for efficiency based on zone activity

- More innovative warehouse layouts that minimize unnecessary movement

- Eco-friendly packaging workflows that cut down on materials and waste

Augmented Reality (AR) for Picking

Vision picking technology equips workers with smart glasses that overlay digital information onto their real-world view.

The AR display can highlight the exact item to be picked, show the quantity, and instantly confirm the selection via a built-in scanner.

This hands-free approach not only boosts accuracy and speed but also significantly reduces training time for new employees.

| Trend | What It Is | Key Impact on the Warehouse |

| AI & Machine Learning | Using intelligent algorithms to analyze data and automate decision-making. | Optimizes inventory, predicts demand, and improves operational efficiency. |

| IoT Integration | Placing sensors on equipment, inventory, and infrastructure to gather real-time data. | Provides a live, transparent view of the entire operation for faster responses. |

| Advanced Robotics | Deploying autonomous systems like AMRs, cobots, and drones for physical tasks. | Speeds up fulfillment, reduces manual labor strain, and increases accuracy. |

| Cloud-Based WMS | Managing warehouse operations through a flexible, accessible, and scalable software platform. | Enables real-time data access from anywhere and seamless integration. |

| Sustainability | Implementing energy-efficient equipment and processes to reduce environmental impact. | Lowers energy costs, meets green initiatives, and improves brand image. |

| Digital Twin Technology | Creating a virtual replica of the warehouse to simulate and test changes. | Allows for risk-free optimization of layouts and workflows before investing. |

| Augmented Reality (AR) | Equipping workers with smart glasses that overlay digital information onto their view. | Enables hands-free, vision-guided picking, which boosts accuracy and speed. |

Discover State-of-the-Art Automated Warehouse Systems at Modula

Modula is the leading provider of automated storage and warehouse solutions that help businesses work faster, save space and stay organized, all while making day-to-day operations more straightforward to manage.

Our warehouse systems include:

1. Vertical Lift Modules

Modula’s Vertical Lift Modules (VLMs) are advanced automated storage systems engineered to maximize vertical space while minimizing floor usage.

These systems optimize cubic storage by extending vertically to the ceiling, ideal for facilities where every square foot counts.

- Modula Lift: Built for speed and strength, the Modula Lift can handle up to 130 trays per hour and carry up to 2,200 pounds per tray. It’s a reliable solution for busy operations that need efficiency and durability.

- Modula Slim: Short on space? The Modula Slim is designed for warehouses with limited space. It offers the same benefits as a VLM, such as improved accuracy, faster picking, and tighter inventory control.

- Modula Next: Think of Modula Next as the next level in smart storage. It combines the space-saving capabilities of a VLM with the precision of a vending machine, providing secure, trackable access to tools, parts, or supplies exactly when needed.

- Modula Pallet: An innovative solution for handling Euro pallets (1,200mm x 800mm) directly from ground level (no forklift needed). It maximizes vertical space while minimizing the risks associated with lifting and storing at heights.

- Modula Flexibox: Our newest automated solution, built to deliver speed, flexibility, and efficiency all in one system. With the ability to handle up to 180 bins per hour, it helps reduce unnecessary movement, maximizes your vertical space, and keeps operations running smoothly.

2. Modula WMS

Modula WMS is a user-friendly inventory management system that works seamlessly with Modula’s automated storage units or can be used independently in traditional warehouse setups.

It seamlessly integrates with most DMS and ERP systems, enabling streamlined tasks such as receiving, picking, and putting items, enhancing accuracy at every step.

3. Modula IoT

Modula IoT brings your warehouse operations into full view.

It connects your Modula systems with the rest of your operation, providing you with the insights you need to stay in control and make faster, informed decisions.

An evolution of our earlier remote monitoring tools, Modula IoT is built for today’s connected warehouses and is available with WMS Premium, Modula Link and Modula Drive.

4. Modula AI Services

We use artificial intelligence to make your warehouse run smarter, faster and more efficiently.

With AI, you can simulate daily operations and make the most of your space, all while staying ahead of the toughest logistics challenges.

Warehouse Systems Explained: Key Takeaways

- Advanced warehouse systems connect all the moving parts that keep operations running smoothly, such as WMS, robotics and IoT

- With better inventory tracking, faster order processing and fewer manual tasks, warehouse systems reduce labor costs and boost overall efficiency

- Trends like AI, robotics, IoT, cloud-based WMS and sustainability initiatives are pushing warehouses to become smarter, faster, and more sustainable.

Warehouse Systems: FAQs

What’s a warehouse management system and do you really need one?

A warehouse management system (WMS) helps you keep track of inventory, organize storage, and streamline everyday tasks such as picking, packing, and shipping.

If you’re juggling spreadsheets or struggling with order accuracy, a WMS can save you time and reduce errors.

How exactly does automation help in a warehouse?

Automation takes over repetitive tasks, such as moving products, storing items, or retrieving orders, so your team can focus on what matters.

It speeds things up, cuts down on mistakes and helps you get more done without needing more space or staff.

What should I think about before upgrading my warehouse system?

Start by examining your current setup: what’s working, what’s slowing you down, and where you want to grow.

Then consider solutions that fit your space and can grow with you, such as automated storage systems or a WMS that integrates with the tools you already use.

Need guidance on warehouse systems?