What Will the Warehouse of the Future Look Like? Futuristic Warehouse Models & Technologies

The warehouse of the future is no longer a distant vision. It’s quickly becoming a reality.

From autonomous robots navigating storage aisles to artificial intelligence forecasting inventory needs, technology is transforming warehouse operations at a rapid pace.

These innovations are not just futuristic. They’re a response to today’s business pressures: rising customer expectations, labor shortages, and the need for speed and accuracy in fulfillment.

According to the 2025 MHI Annual Industry Report, 83% of supply chain leaders are adopting robotics and automation, with many prioritizing AI, IoT, and advanced software to build more resilient and responsive operations.

In this article, we explore:

- What the future of warehousing looks like.

- Emerging future warehouse models

- Next-generation technologies and data-backed insights into how the industry is evolving.

We’ll also introduce you to automated warehouse solutions at Modula, designed to help you build a futuristic warehouse that offers increased productivity, safety and organization.

Whether you’re planning a transformation or simply staying informed, this guide will help you understand where warehousing is headed.

What’s Driving the Warehouse of the Future?

The future of warehousing will be driven by a wave of key forces: rising consumer demands, labor and supply chain challenges, and the need for sustainability. These trends are accelerating the adoption of new models and technologies designed for faster, smarter, and greener operations.

Rising Customer Expectations

Same-day deliveries have become standard in many sectors, increasing pressure on warehouses to fulfill orders faster and more accurately. This shift is prompting investment in micro-fulfillment centers, automation, and software that supports real-time inventory visibility and faster picking speeds.

Adoption of Robotics and AI

A significant shift is the growing presence of automation, with robots and automated systems taking over many manual tasks in the warehouse, such as picking, sorting, and packing. This trend is not only about efficiency, but it also addresses labor shortages and helps reduce human error.

According to the 2025 MHI Annual Industry Report, 83% of supply chain leaders are adopting robotics and automation, while 82% are implementing AI, IoT, and other advanced software to build more resilient operations.

Labor Shortages and Workforce Challenges

Labor and talent shortages remain a top concern. MHI reports that 83% of supply chain leaders are adopting robotics and automation, while 82% plan to implement AI technologies within five years.

As warehouses automate, they are also upskilling existing staff and rethinking roles to work alongside technology. Wearables, mobile tools, and user-friendly systems support this shift by improving ergonomics, safety, and productivity on the warehouse floor.

Demand for Sustainability

Technology also plays a critical role in driving green warehousing practices. From optimizing delivery routes to reducing packaging waste, sustainability is becoming a strategic priority. The MHI report emphasizes the role of end-to-end orchestration in enabling organizations to monitor carbon emissions and supplier compliance across the value chain.

The Push for Resilience and Agility

Global disruptions have exposed the fragility of traditional supply chains. In response, 28% of companies now rank supply chain agility and resiliency among their top concerns. Digital solutions, particularly cloud computing (91% adoption) and predictive analytics (87%) are key to enabling agile responses to market changes.

Futuristic Warehouse Models

As warehouse operations evolve, new models are emerging to meet the demands of modern supply chains. The warehouse of the future will prioritize flexibility, automation, and sustainability, enabling faster order fulfillment, smarter inventory control, and a smaller environmental footprint.

These are three warehouse models that will define the future of warehousing:

On-Demand Warehousing

On-demand warehousing, also known as flexible warehousing, is a warehouse fulfillment model that allows companies to rent space and fulfillment services on a short-term or seasonal basis. It enables rapid scalability without long-term leases and is ideal for handling demand surges and expanding into new geographic markets.

It also allows companies to partner with 3PL providers to meet consumer expectations surrounding fast-tracked shipping by facilitating same-day order fulfillment and delivery.

Smart Warehousing

Smart warehousing is a warehouse fulfillment model that uses advanced technologies such as artificial intelligence, Internet of Things, robots and automated storage and retrieval systems to automate manual tasks in the warehouse.

Smart warehouse systems boost productivity and inventory management, while reducing errors caused by manual labor.

Green Warehousing

Green warehousing is a warehouse fulfillment model that utilizes sustainable and eco-friendly practices to reduce the environmental impact of the logistics and supply chain industry.

- Green warehousing practices include:

- Using solar or renewable energy

- Implementing energy-efficient lighting and HVAC systems

- Reducing waste through eco-friendly packaging and smart layout design

- Optimizing space vertically to reduce building footprints and energy use

Green practices are becoming standard features of future-ready warehouses, helping companies meet both regulatory and consumer expectations.

Futuristic Warehouse Technologies

From autonomous robots to warehouse drones, a wide range of technologies is transforming the way modern warehouses operate. These future warehouse technologies are helping facilities improve speed, accuracy, safety, and space utilization, laying the foundation for fully automated, data-driven operations.

Here are some of the most important technologies shaping the warehouse of the future:

Automated Storage and Retrieval Systems

Automated storage and retrieval systems (ASRS) are computer-controlled technologies that store and retrieve inventory from designated storage locations. These technologies improve space efficiency and picking accuracy while reducing the need for manual labor.

AS/RS systems work in conjunction with a warehouse management system (WMS) to identify the correct items to retrieve.

Common AS/RS technologies include:

- Vertical Lift Modules (VLMs)

- Horizontal Carousels

- Unit-loaders and mini-loaders

- Tote shuttles

These solutions are increasingly used to maximize vertical space and improve throughput in high-density storage environments.

Artificial Intelligence (AI) and Machine Learning (ML)

Artificial intelligence (AI) refers to software and systems capable of performing tasks that typically require human intelligence, such as identifying inventory, optimizing pick paths, or analyzing supply chain data. In the warehouse, AI supports tasks like:

- Detecting and preventing picking errors

- Predicting stock replenishment needs

- Optimizing labor and equipment usage

Machine Learning (ML), a subset of AI, enables systems to continuously improve their performance by analyzing large data sets. Over time, ML algorithms can refine forecasting models, reduce error rates, and support proactive decision-making.

Mobile Robots (AMRs and AGVs)

Automatic guided vehicles (AGVs) are computer-controlled and sensor-guided robots that transport items within the warehouse.

AGVs are equipped with wires and reflective markers and move through pre-defined pathways. They require guidance from warehouse operators to function.

On the other hand, autonomous mobile robots (AMRs) are the descendants of AGVs. AMRs are sophisticated robots that utilize artificial intelligence and sensors without needing the guidance of warehouse employees to function.

While both AGVs and AMRs can transport inventory within the facility, AMRs are more advanced robots that can independently navigate the warehouse without pre-defined routes.

Internet of Things (IoT)

Internet of Things (IoT) devices include RFID tags, smart sensors, and connected devices that track assets, monitor equipment, and enable real-time visibility across warehouse operations.

For example:

- Predictive maintenance tools alert teams when equipment performance declines, helping avoid unplanned downtime

- RFID tags help track inventory automatically

- Sensors monitor temperature or humidity for sensitive goods

Augmented Reality (AR) and Virtual Reality (VR)

Augmented reality (AR) is a technology that utilizes 3D modelling and multimedia to integrate images, videos or sounds into the real environment, creating an interactive experience.

On the other hand, virtual reality (VR) is a technology that utilizes machine learning, neural networks and a pose tracking system to create a computer-generated environment.

Unlike virtual reality, which creates a completely digital environment, augmented reality adds to or “augments” your existing environment.

Warehouse Drones

Warehouse drones, also known as unmanned aerial vehicles (UAVs), are aerial robots equipped with cameras and sensors. They can be used for:

- Cycle counting and inventory audits

- Capturing high-resolution images of storage zones

- Accessing hard-to-reach areas safely

Some drones operate autonomously, while others are manually piloted. They help reduce the time and labor needed for manual inventory checks and improve stock accuracy.

How To Build a Warehouse of the Future With Automated Warehouse Solutions

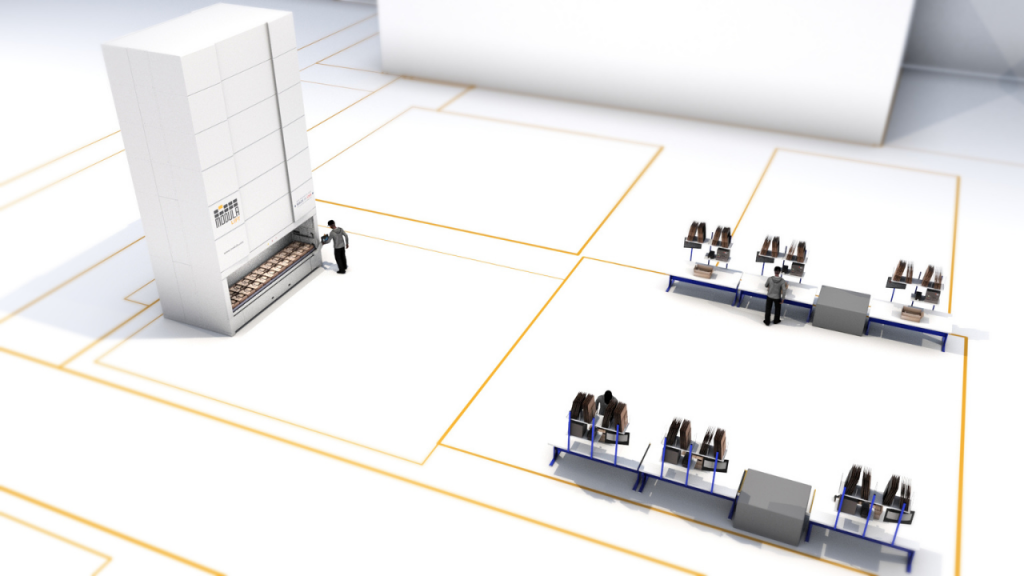

As an industry leader in advanced automated storage solutions and warehouse management systems, Modula transforms warehouses across industries to improve efficiency, productivity, picking accuracy and inventory management.

Our automated warehouse solutions include:

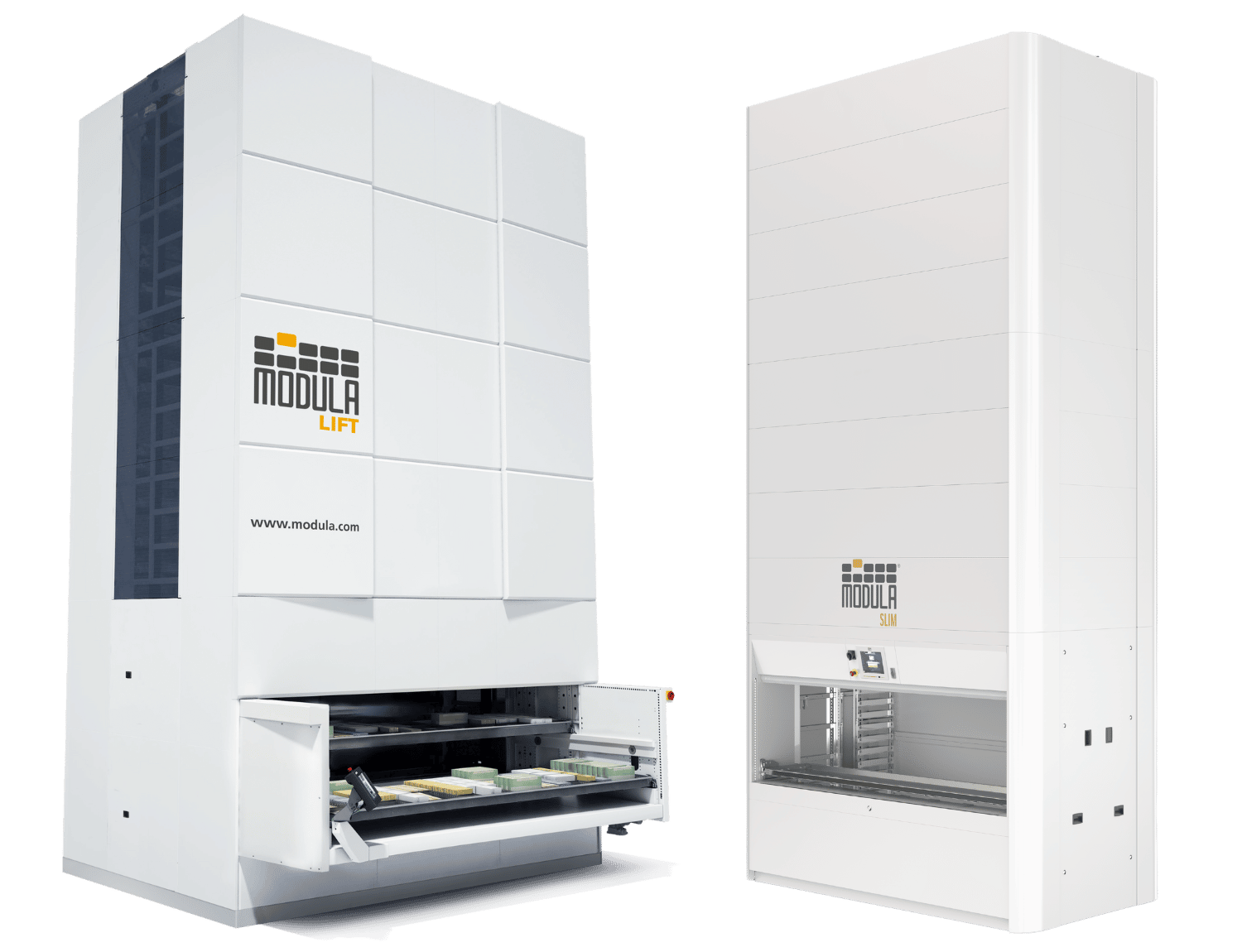

1. Modula Vertical Lift Module

Modula’s Vertical Lift Modules (VLMs) utilize your warehouse’s ceiling height to create more storage and improve warehouse organization.

Our VLM models include:

- Modula Lift: Perfect for spare and industrial parts, available in a wide range of capacities and sizes

- Modula Slim: The ideal storage solution for facilities with minimal floor space, thanks to its compact size

- Modula Next: A cutting-edge automated storage and retrieval system that merges the space optimization of vertical lift modules (VLMs) with the precision and control typically found in industrial vending technology

- Modula Pallet: A breakthrough warehouse solution built to safely manage euro pallets (1,200 mm x 800 mm) directly from floor level, removing the need for forklifts and streamlining material handling

- Modula Flexibox: With the capacity to handle up to 180 bins per hour, Modula Flexibox minimizes unnecessary movements, maximizes vertical storage and streamlines overall warehouse operations

Modula VLMs allow you to:

- Save 90% of your floor space by taking advantage of your ceiling height

- Increase picking speeds to 300 or more lines per hour

- Process batch orders in less time with a throughput of up to 140 trays per hour

- Improve employee safety by automatically delivering inventory to your warehouse operators

- Secure goods in an enclosed system with a reliable locking feature and restricted access

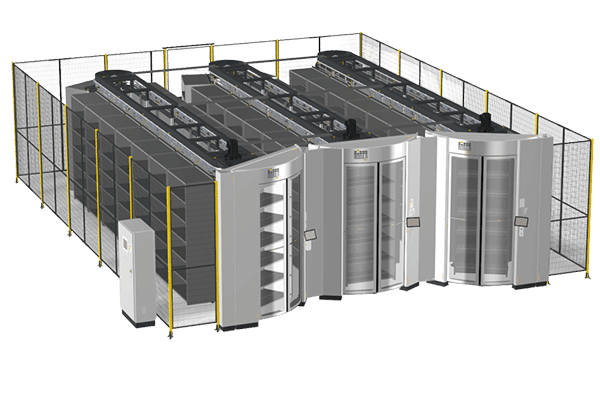

2. Modula Horizontal Carousels

The Modula Horizontal Carousel (HC) is the ideal storage option for warehouses with limited ceiling height.

Modula HC allows you to:

- Skyrocket productivity with picking rates of up to 550 lines per hour for each warehouse employee

- Offer the safest working environment by eliminating physical strain

- Adjust shelf spacing to store different sizes of inventory

- Monitor and document picking operations in real time, providing complete traceability of stock levels and orders

- Experience 99% picking accuracy with our barcode readers and Put to Light Systems

3. Modula Picking Solutions

Modula picking solutions minimize the search time required for locating inventory and boost picking accuracy when processing individual or multiple orders.

Modula picking solutions allow you to:

- Boost picking speed and accuracy, thanks to Put to Light devices that help your warehouse operators navigate their way to the correct picking area

- Manage inventory more accurately, thanks to in-depth views of your current and forecasted inventory

4. Modula Web Analytics

Modula Web Analytics is a remote management, support, and analytics platform that enables you to quickly collect data from your Modula vertical lift modules and horizontal carousels, regardless of where they are in your warehouse.

Built-in and turned on around-the-clock, it offers an intuitive online portal for you to manage and track your operations securely from any location and device.

Modula Web Analytics allows you to:

- Track your Modula automated warehouse solutions remotely

- Monitor your warehouse from any location with remote diagnostics, support and resolutions, while implementing predictive maintenance

- Track the status of your warehouse, including unit statistics, energy consumption and equipment health

- Receive real-time notifications about the status of each module

- Get reports on energy consumption, fulfilled orders, completed cycles and tray usage efficiency

Warehouse of the Future: FAQs

What does the warehouse of the future look like?

The warehouse of the future is automated, data-driven, and sustainable. It uses technologies like robotics, AI, IoT, and vertical storage systems to streamline operations, improve accuracy, and respond to dynamic market demands.

What are the main technologies in a future warehouse?

Key technologies include automated storage and retrieval systems (AS/RS), artificial intelligence (AI), autonomous mobile robots (AMRs), Internet of Things (IoT) devices, and warehouse management systems (WMS). These tools improve efficiency, visibility, and scalability.

How does warehouse automation improve productivity?

Automation reduces manual tasks, speeds up picking and packing, minimizes errors, and enables real-time inventory tracking. This leads to faster order fulfillment, lower labor costs, and better overall performance.

Why is sustainability important in the future of warehousing?

Sustainable warehousing reduces energy use, emissions, and waste—supporting environmental goals while also lowering operational costs. It’s becoming a competitive differentiator as customers and regulators demand greener supply chains.

How can businesses prepare for the future of warehousing?

To prepare, companies should invest in scalable automation, adopt a flexible warehouse model, implement data-driven systems, and partner with solution providers that offer modular, future-ready technologies like Modula.

Wrapping Up on the Warehouse of the Future

The warehouse of the future combines advanced automation, sustainable practices, and flexible operating models to meet today’s and tomorrow’s logistics challenges. These facilities are designed to be more efficient, safer for workers, and responsive to evolving consumer expectations.

With Modula’s automated warehouse solutions, you can move toward a future-ready operation that:

- Maximizes space through vertical storage

- Increases picking speed and accuracy

- Reduces reliance on manual labor

- Improves inventory visibility and management

According to the 2025 MHI Annual Industry Report, 90% of supply chain leaders are investing in automation this year alone. Staying competitive means not only meeting customer demand, but also staying ahead of it through smart, scalable technologies.