Warehouse Design [Why It Matters, Layouts & Trends]

Warehouse Design: Key Points

Designing an efficient warehouse is more than just organizing racks and workstations. It’s about making the most of your space while optimizing workflows, minimizing costs, and improving overall performance.

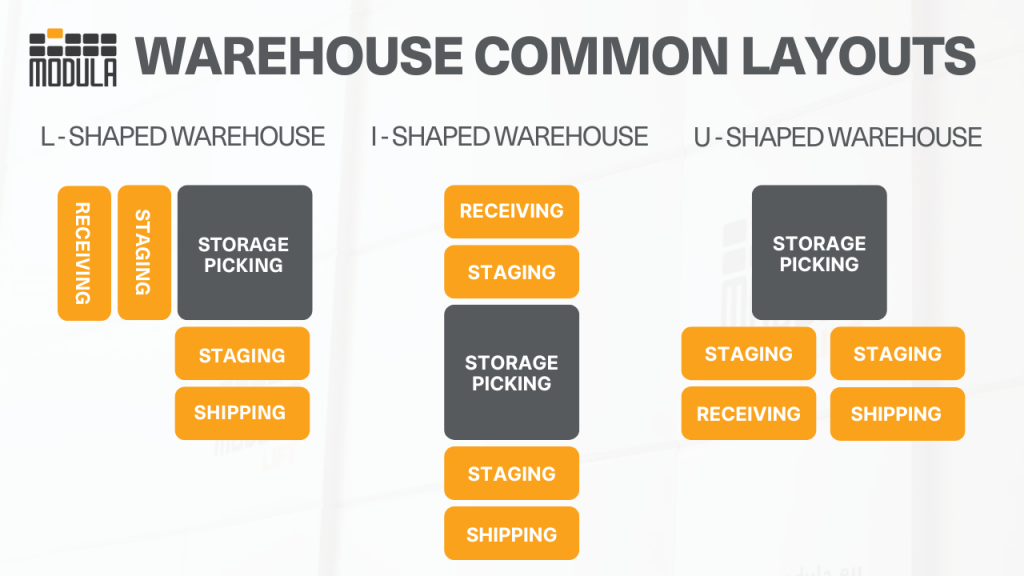

Most warehouses follow one of three common layout patterns: U-shape, L-shape, or I-shape. But layout is just the starting point.

Today, innovations like robotics, dark warehouses, and advanced layout planning tools are reshaping how warehouses operate.

Did you know it costs an average of $7.91 per square foot to operate a warehouse in the U.S.?

With operating costs that high, efficient warehouse design isn’t optional; it’s a necessity.

Warehouse design is important, as it directly impacts how products move through your facility, impacts labor efficiency, maximizes space utilization and ultimately drives your bottom line.

In this guide, we will:

- Why warehouse layout matters

- The most common layout configurations

- Highlight the latest trends shaping warehouse efficiency, such as Modula’s warehouse design software, Modula Plant Designer

Why Good Warehouse Design Matters

A well-designed warehouse goes beyond storage. It directly supports faster order processing, safer working conditions, accurate inventory management and decreasing operating costs.

Optimized Workflow

An efficient layout keeps goods moving smoothly from receiving to storage for optimized picking, packing and shipping. It helps reduce bottlenecks, cut down travel time and improve productivity on the floor.

Maximized Space

As warehouse space becomes more expensive, maximizing both floor and vertical space is critical.

A well-optimized layout boosts inventory capacity without expanding your footprint, helping cut overhead and avoid costly buildouts.

Faster Order Fulfillment

Strategically placing fast-moving items and maintaining clear traffic lanes speeds up picking and packing, essential for eCommerce and just-in-time operations.

Improved Safety

Smart warehouse layouts reduce risk by ensuring clear, properly sized aisles that support safe equipment movement and efficient material handling.

According to OSHA, well-designed aisles help prevent collisions, minimize overexertion from awkward movements, and allow powered industrial trucks to operate safely.

Scalability

A flexible warehouse layout supports future growth by allowing you to reconfigure racking, adjust storage zones or add picking technologies without overhauling the entire space.

Whether you’re expanding product lines, increasing order volume or introducing automation, a scalable design adapts with minimal disruption.

Lower Operational Costs

Smart layouts cut labor by reducing travel time and streamlining picking. Efficient storage, like high-density racking or zone systems, lowers inventory carrying costs. Even small changes can yield lasting savings.

Common Warehouse Layout Patterns

Your warehouse layout significantly influences productivity and efficiency. Most setups include four main areas: dynamic storage, static storage, shipping and receiving.

The arrangement of these zones should align with your facility’s space constraints, throughput requirements and the material handling systems in place.

U-Shaped Warehouse Layout

In a U-shaped layout, the shipping and receiving areas are positioned side by side, allowing for shared use of resources like personnel and warehouse equipment.

This efficient design reduces the need for excessive product handling and supports strong cross-docking capabilities, making it ideal for operations that require speed and streamlined workflows.

Example: A third-party logistics provider (3PL) handling fast-moving consumer goods can use a U-shaped layout to quickly route incoming inventory to outbound docks, reducing storage time and speeding up fulfillment.

L-Shaped Layout

In an L-shaped configuration, the shipping and receiving docks are positioned on adjacent walls of the warehouse.

The design facilitates the storage of inventory between the two zones, frequently extending into the facility’s rear. It offers a practical flow path while maximizing back-end storage capacity.

Example: A regional furniture distributor might use an L-shaped layout to efficiently stage bulky items near receiving, store overflow inventory along the warehouse’s rear aisle and streamline loading operations along the adjacent shipping dock.

I-Shaped Layout

The I-shaped layout enables a straight-line product flow, with goods moving from one end of the warehouse to the other.

Storage sits centrally between the shipping and receiving docks, making this design ideal for high-volume operations that demand efficient movement and maximized central storage.

Example: A high-volume eCommerce fulfillment center might use an I-shaped layout to receive goods at one end, store them centrally for fast picking and ship from the other end for rapid distribution.

5 Warehouse Design Mistakes To Avoid

Designing an efficient warehouse isn’t just about where you put shelves or how much space you have. It takes careful planning to keep operations productive and scalable.

Still, many facilities run into problems that could’ve been avoided. Here are five common mistakes to keep on your radar:

Overlooking Workflow and Product Movement

Ignoring the natural flow of goods, from receiving and storage to picking, packing, and shipping, can create bottlenecks.

Poor layout decisions force workers and equipment into longer, less efficient routes, slowing operations and increasing labor costs.

Misjudging Aisle Widths

Narrow aisles restrict the movement of forklifts and pallet jacks, which increases the risk of accidents and product damage.

On the flip side, overly wide aisles waste valuable floor space. Optimal aisle widths strike a balance between safety and space efficiency, based on equipment type and traffic volume.

Failing To Maximize Vertical Space

Focusing only on square footage while ignoring ceiling height limits storage potential.

Utilize racking systems designed to fit your vertical space, product sizes and picking methods to make the most of every cubic foot.

Inefficient Slotting and Item Placement

Storing fast-moving items far from packing or shipping zones increases travel time and worker fatigue. Without strategic slotting, you risk shipping delays and lower throughput.

Designing Without Scalability in Mind

Layouts that don’t accommodate future growth, new SKUs or automation upgrades often require costly redesigns.

A smart warehouse design should be flexible and modular, allowing you to scale with demand without disrupting operations.

What To Consider When Designing Your Warehouse

Before you map out your warehouse, take these elements into account.

Budget

Your warehouse budget encompasses both startup and operational costs, including the facility itself, equipment, inventory management systems, staffing and recurring expenses like rent and utilities.

Costs can vary widely based on the warehouse’s size, purpose, and level of automation.

As a general benchmark, setting up a mid-sized warehouse typically requires an investment of $500,000 to $1 million, though total budgets can range from $100,000 into the millions for more complex operations.

Flow

Flow refers to the path materials take as they move through your warehouse, from receiving and storage to picking, packing and shipping. An efficient layout ensures a logical, uninterrupted progression that minimizes backtracking and congestion.

When designed properly, good flow reduces handling time, increases productivity and strengthens your overall supply chain performance.

Available Space

Most warehouses range from 10,000 to 100,000 square feet, but your needs depend on inventory volume, storage systems and growth plans.

Build in 20-30% extra space to accommodate future expansion, seasonal demand or automation upgrades.

Employee Requirements

Staffing needs depend on warehouse size, operational complexity and level of automation.

For instance, a facility between 40,000 and 90,000 square feet may require 12 to 25 employees across key roles, such as pickers, packers, forklift operators, inventory coordinators and floor supervisors.

As a general guideline, plan for one staff member per 1,500 to 2,500 square feet. Be sure to factor in peak seasons, which can demand a 25-35% increase in temporary labor to manage surges in order volumes.

Warehouse Regulations

Local warehouse regulations in the U.S. typically address zoning, building codes and safety standards.

Zoning laws often restrict warehouses to industrial or commercial zones and may require 20-50 feet of setback from property lines, depending on local rules.

Building codes, on the other hand, typically mandate fire suppression systems, 20-30-foot ceiling heights, and floor load capacities suited to racking or heavy equipment.

OSHA-based safety standards require at least 10 foot-candles of lighting in storage areas, with adequate ventilation and emergency exits within 200 feet of any location on the floor.

8 Warehouse Design Trends To Watch for

Keep your operations future-ready with eight key trends that are reshaping how warehouses are designed, making them smarter, faster and more efficient.

Robotics and AI Integration

Modern warehouses are being built around automation. AGVs and robotic pickers handle transport, retrieval and fulfillment tasks, reducing labor costs while speeding up operations and improving accuracy.

AI-Powered Inventory Management

AI-powered systems help forecast demand, keep stock levels in check, and automate restocking.

By analyzing real-time and historical data, they help avoid overstock and stockouts, keeping operations running smoothly and efficiently.

IoT for Real-Time Visibility

IoT sensors track inventory, monitor equipment and control environmental conditions. This enables predictive maintenance and tighter quality control, especially in temperature-sensitive operations.

Rise of Dark Warehouses

Dark warehouses, also known as fully automated facilities with minimal or no on-site staff, are gaining traction for high-volume fulfillment.

Designed for 24/7 operation, they use robotics, AI and integrated systems to manage storage, picking and shipping with maximum efficiency and minimal human intervention.

Warehouse Design Software

Warehouse design software helps logistics teams and warehouse managers plan, visualize and optimize their space and operations.

It allows users to create detailed floor plans, map out workflows, assign storage zones and test different layouts, all before making changes on the warehouse floor.

Sustainability and Green Logistics

More warehouses are adopting sustainable design strategies, from installing solar panels and skylights to using energy-efficient lighting and HVAC systems. Green logistics is also influencing site selection, packaging choices, and transportation models to reduce the facility’s carbon footprint.

Flexible and Modular Layouts

Facilities are increasingly being built with adaptability in mind, using modular components, movable partitions, and flexible infrastructure that can be easily reconfigured. These flexible layouts allow operations to adapt quickly to new product types, seasonal peaks, or automation upgrades—without major overhauls.

Micro-Fulfillment Centers and Urban Logistics

With rising demand for same-day delivery, more companies are deploying compact, high-density fulfillment centers in urban areas. These MFCs are designed for speed, relying on automation, smart storage, and proximity to end customers to reduce last-mile costs and improve responsiveness.

Meet the Modula Plant Designer: An Advanced Warehouse Design Software

Modula Plant Designer is a specialized warehouse design tool built to help companies optimize the layout and integration of Modula’s automated vertical storage systems.

Unlike standard design tools, this software is purpose-built to integrate vertical lift modules (VLMs) into warehouse layouts, streamlining operations and making the most of your space.

Benefits include:

3D Layout Visualization

Modula Plant Designer includes 3D visualization tools that let you drag, drop and position Modula units within your facility.

Space Optimization

Modula’s storage systems are designed to make the most of vertical space.

The software enhances this by calculating cubic space savings, demonstrating how VLMs can replace traditional racking and showing how reclaimed floor space can be repurposed for value-added activities

Process Flow Simulation

The tool simulates product flow across storage, picking, packing, and shipping to identify optimal Modula unit placement for reduced handling steps and increased throughput and efficiency.

Automation Integration

Modula Plant Designer supports planning for automation components, including conveyor system connections, integrated picking stations and touchscreen controls and ERP/WMS connectivity.