What Is Order Picking? Methods & Solutions for eCommerce

Demand for warehouse order picking software is picking up fast; it’s projected to grow from $12.41 billion in 2025 to $17.79 billion by 2030.

That’s 7.49% growth each year, showing just how quickly demand for smarter, faster fulfillment is accelerating.

It’s a clear sign that faster, smarter fulfillment is becoming a top priority.

For customers, it’s all about speed and convenience. But behind the scenes, warehouses are dealing with growing complexity; managing high return rates, tighter shipping windows, and increasing order volumes.

The pressure isn’t letting up. That’s why optimizing warehouse operations, especially order picking, isn’t just a nice-to-have capability anymore. It’s essential to staying competitive and keeping pace with demand.

Here’s a sneak peek at what we’ll dive into:

- The process of order picking in a warehouse

- Optimal warehouse picking strategies you can leverage

- The best Modula order picking software (including order picking robots) you can use to complement your strategy and further improve picking accuracy, speed and efficiency

Order Picking in a Warehouse Explained

Warehouse order picking is the process of retrieving specific items from storage to fulfill a customer order.

Think of it as a critical step that occurs before packing and shipping.

To speed things up and reduce errors, many warehouses now rely on order picking software to streamline the process.

From picker robots to voice-picking technology, these tools help operators quickly and accurately locate the right SKUs in the inventory.

When done right, warehouse picking can significantly minimize mispicks and keep your customers happy by ensuring orders are correct and delivered on time.

Warehouse Order Picking Market in the U.S.

The warehouse order picking market is heating up fast across the U.S. As customer expectations around speed and accuracy continue to climb, retailers and logistics teams are turning to smarter order picking software to keep up.

These tools help streamline fulfillment and make sure the right products get out the door as quickly as possible.

Let’s talk about what’s steering the market these days:

- eCommerce Growth: In 2024 alone, the market was projected to hit $1.18 trillion in revenue; a huge leap from just a few years earlier. By 2029, experts expect eCommerce revenue to grow by another $655 billion, continuing its steady upward climb. This continued growth is driving demand for smarter, more scalable solutions, like those offered in eCommerce warehouse automation to keep fulfillment operations fast, accurate, and efficient.

- Automation Adoption: It’s no wonder more and more warehouse operators are turning to automation to speed up response times and make order fulfillment faster and more efficient.

- Same-Day Expectations: Same-day delivery is changing the way warehouses operate, pushing teams to pick faster, track inventory in real time, and optimize fulfillment from end to end.

- It has quickly become the norm in the U.S., with big names like Amazon, Target (via its Target Circle 360 membership), and Costco all offering it to keep up with rising customer expectations.

Types of Warehouse Picking Strategies

To optimize picking processes and, in turn, the entire order fulfillment process, it’s important to find the picking methods and strategies that work best for your organization.

Some go-to picking strategies you’ll want to consider include:

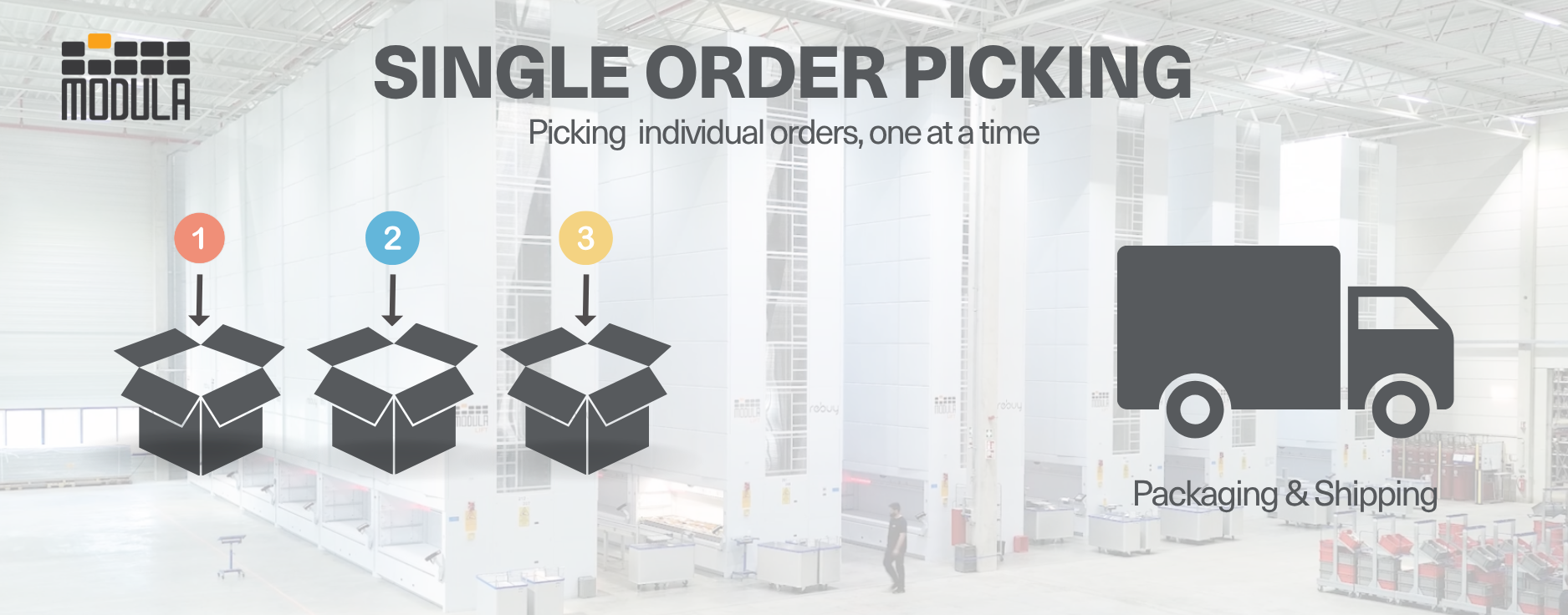

Single Order Picking (or Discrete Picking)

Single order picking, or discrete order picking, is a strategy in which a warehouse employee manually picks a single order.

In this method, a picker receives printed pick lists and travels through the warehouse to manually collect each item on the list for a specific order.

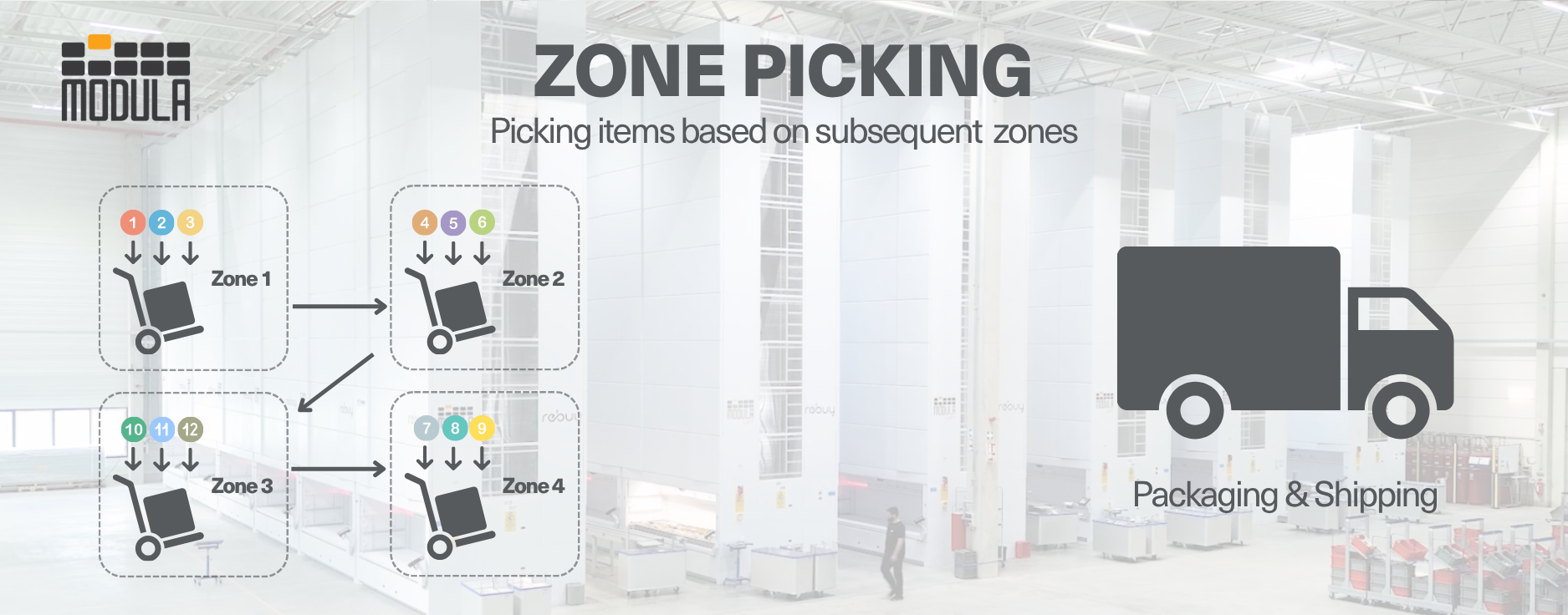

Zone Picking (or Pick and Pass)

Zone picking, or pick and pass, is a picking strategy in which the facility is divided into several zones and pickers are assigned to specific areas.

Each warehouse employee is responsible for gathering goods within their designated zone and passing the order to the next zone until all items in the order are picked.

Batch/Multi-Order Picking

Batch picking is a picking strategy in which a warehouse employee collects multiple orders simultaneously during a single pass through the facility.

In this method, orders with similar items or destinations are grouped together. For instance, all orders containing a specific type of electric component, or all orders destined for the same city.

Without order picking software, managing batches is complex. However, smart software can instantly group identical items from 50 different orders into one pick mission, saving hours of walking time. The picker then retrieves all items for these grouped orders in one journey around the facility.

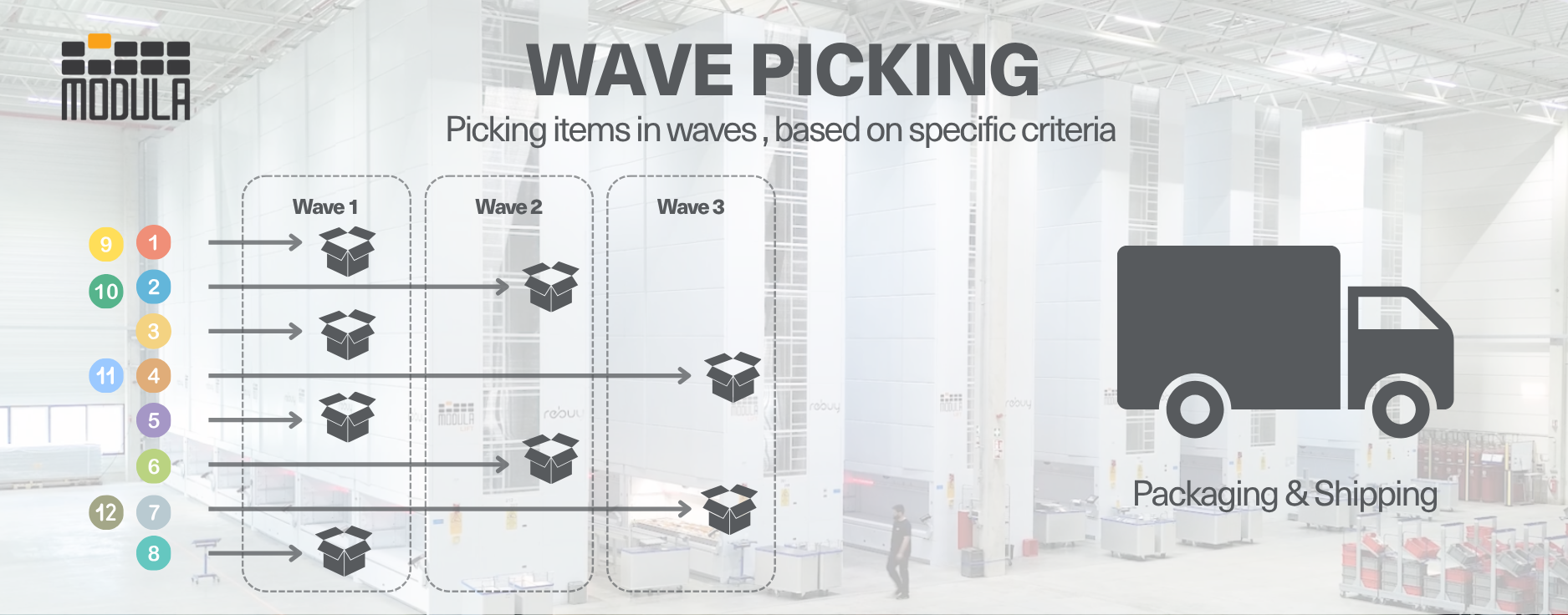

Wave Picking

Wave picking is a strategy that groups orders and picks them in waves throughout the day based on specific criteria, such as delivery schedules or shipping destinations.

In this method, a warehouse management system (WMS) schedules and organizes the waves, ensuring high-priority shipments are processed first.

Warehouse employees collect items for a batch of orders during each wave, which allows for a more organized and efficient use of labor and warehouse resources.

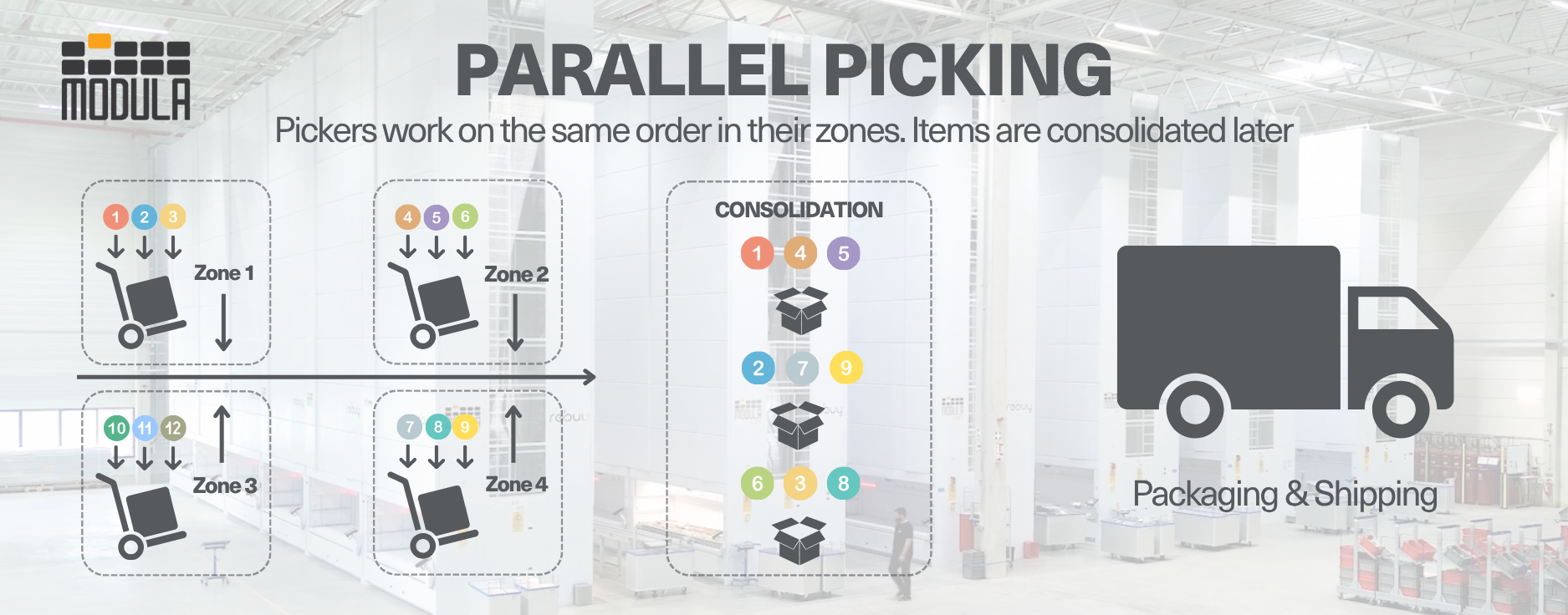

Parallel Picking

Parallel picking is a picking strategy in which multiple warehouse employees work simultaneously on picking partial parts of the same order.

In this method, an order is divided into smaller parts or sections, and each picker is responsible for collecting items from their assigned section of the warehouse.

For example, if a phone accessory kit consists of different items stored in different parts of the facility, one warehouse employee will be responsible for collecting earphones from one section while

another employee collects a phone case from a different area.

After picking all parts of the order, warehouse employees consolidate them at a central location before packing and shipping.

Cluster Picking

Cluster picking is a picking strategy in which a warehouse employee picks items for multiple orders simultaneously using a multi-compartment cart or trolley.

In this method, the picker travels throughout the warehouse once, picking items for several orders and placing them into different compartments or bins on their cart.

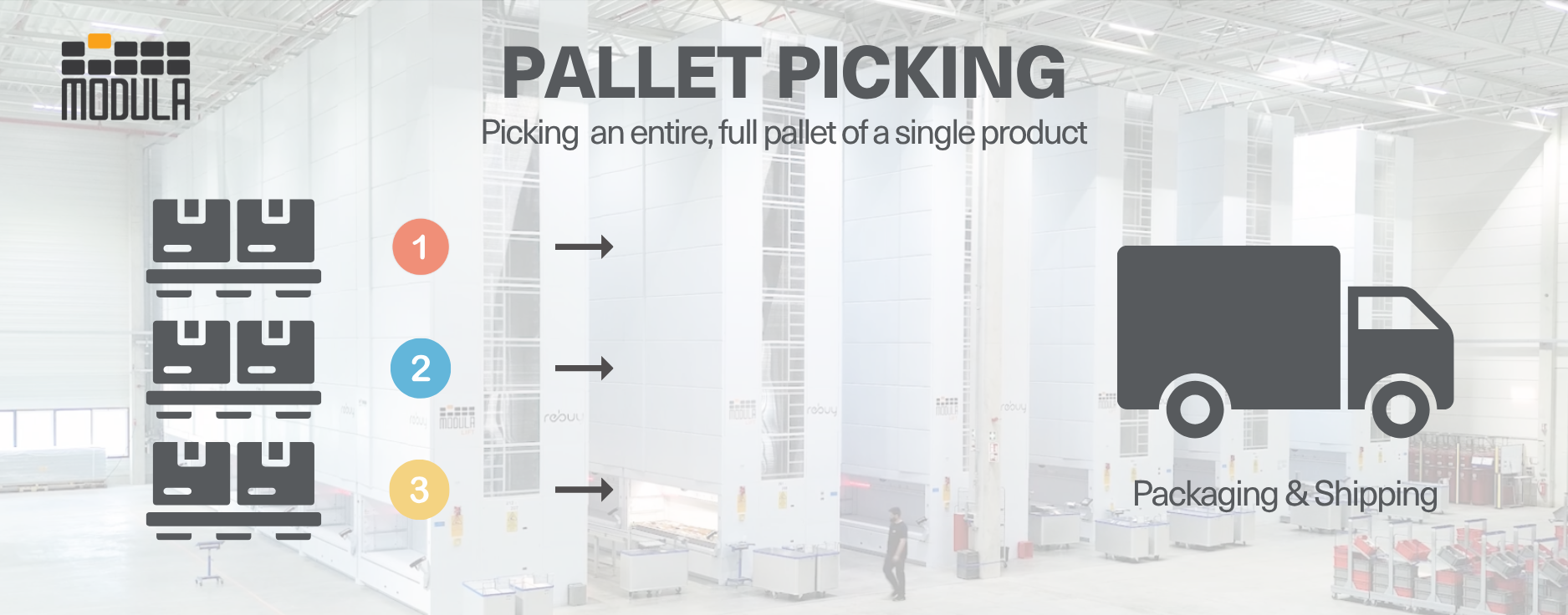

Pallet Picking

Pallet picking is the process of moving full pallets of products, usually for storage or shipping. It’s commonly used when items need to be transported in bulk.

Once picked, the pallet is brought to the dock, labeled for shipping and loaded onto a trailer headed to its destination.

Combined Warehouse Picking

Some warehouse operations combine picking methods to improve efficiency and adapt to varying order types or warehouse layouts.

For instance, employees might use a combined zone and batch picking approach, collecting multiple orders from their designated zones.

Comparison of Order Picking Strategies

| Order Picking Method | How It Works | Best For | The Modula/Software Advantage |

| Single Order Picking | A single picker collects all items for one order at a time. | Small warehouses with low volume of complex orders. | WMS ensures the picker takes the shortest path, reducing walking time. |

| Zone Picking | Pickers stay in a specific zone; orders move from zone to zone. | High-volume facilities with complex orders spanning many zones. | Automation moves goods between zones so pickers never leave their station. |

| Parallel Picking | Multiple pickers work on the same order simultaneously in different zones. | Complex, multi-part orders where sequential picking is too slow. | Software synchronizes the final consolidation, ensuring all parts arrive at packing together. |

| Batch Picking | A single picker collects items for multiple orders in one trip. | Operations with many small orders (e.g., e-commerce). | Modula VLMs present items for multiple orders instantly; software guides sorting. |

| Cluster Picking | Picker uses a multi-bin cart to pick and sort into specific order bins. | High-volume, small-item picking to avoid bottlenecks at packing. | Put-to-Light on the cart visually shows exactly which bin to put the item in. |

| Wave Picking | A WMS schedules orders into “waves” based on shipping times. | Large-scale operations coordinating with strict shipping schedules. | Software automatically prioritizes waves based on carrier pickup times (e.g., FedEx cutoff). |

| Pallet Picking | Picker retrieves a full pallet using a forklift or pallet jack. | Bulk distribution and moving large quantities of a single SKU. | WMS tracks pallet locations in real-time to minimize forklift travel distance. |

| Combined Picking | A hybrid strategy using multiple methods (e.g., zone and batch). | Complex operations handling both bulk and e-commerce orders. | Modula WMS manages the complexity, routing each order type to the correct workflow automatically. |

Top Automated Order Picking Systems and Software

There’s more than one way to make warehouse picking faster and more efficient.

Automation brings a whole toolbox of solutions, from robotics that handle the heavy lifting to smart order picking software that keeps everything running smoothly.

These systems help guide workflows, cut down on mistakes, and optimize pick paths on the fly.

Some of the top automated order picking systems out there include:

Collaborative Robots

Collaborative robots, or cobots, are advanced warehouse robotics designed to work alongside warehouse employees to enhance efficiency and productivity.

These automated order picking robots are equipped with sensors and built-in safety features for seamless collaboration.

When paired with order picking software, cobots become even more effective. In many warehouses, cobots handle tasks like palletizing, as well as picking and packing orders, all while staying in sync with broader fulfillment systems.

Pick to Light Systems

Pick to light systems are assisted picking technologies that guide warehouse operators with visual picking instructions.

This system uses alphanumeric LED displays and buttons at storage locations to guide workers through light-assisted tasks like picking, sorting and assembly.

When integrated with order picking software, pick-to-light becomes even more efficient, syncing real-time order data with visual cues to streamline workflows and keep fulfillment running smoothly.

Voice-Picking Systems

Voice-picking systems are picking systems that utilize voice prompts and advanced speech recognition software to communicate picking instructions to warehouse employees through headsets.

Powered by order picking software, these systems deliver real-time verbal commands, telling workers exactly which items to pick and where to find them.

Since employees don’t need to look at a screen or carry paper lists, they can keep their hands and eyes free.

Heavy-Duty Picking Equipment

Heavy-duty picking equipment consists of warehouse machines that are designed to handle large and heavy inventory, such as boxes of orders.

This type of equipment enhances warehouse operations by boosting efficiency, picking accuracy, safety and productivity.

Heavy-duty warehouse equipment includes:

- Forklifts: Lift and transports heavy loads, especially palletized products

- Reach trucks: Retrieve items from high shelves in narrow aisles

- Order pickers: Lift warehouse pickers to the level of high racks for picking individual goods

- Stackers: Used for stacking and retrieving pallets in stacking areas

Autonomous Mobile Robots (AMRs)

Autonomous mobile robots (AMRs) are sophisticated robots that can independently travel in a warehouse, reducing the need for human intervention.

They use technologies such as machine learning, artificial intelligence and sensors to plan and adapt to their paths instantaneously.

When integrated with order picking software, AMRs can receive task assignments, optimize pick paths, and work in sync with other systems to streamline fulfillment from start to finish.

Automated Storage and Retrieval Systems (ASRS)

Automated storage and retrieval systems (ASRS) are computer-controlled systems that automatically store and retrieve items in a warehouse.

These systems are typically integrated with a WMS, and when paired with order picking software, they can accurately identify which items to retrieve and when, ensuring a smooth, efficient picking process.

This warehouse storage solution includes tote shuttles, mini-loaders, vertical lift modules, horizontal carousels and unit loaders.

As both a storage and picking solution, ASRS works best when connected to smart order picking software that helps coordinate item locations and optimize workflows.

At Modula, we rethink how warehouses move, pick, and perform, using intelligent systems that turn every step of the order picking process into a competitive advantage.

Our order picking software and solutions include:

- Put to Light: Speed up warehouse picking and reduce errors when handling large order batches. Powered by order picking software, this system uses a scanner, LED lights, and an OLED display to guide operators to the correct put location.

- Modula Picking Station: Ideal for batch picking and warehouse consolidation, this station combines Put to Light technology with scan or touch validation, driven by order picking software for greater accuracy.

- Modula Picking App: Manage picking and inventory replenishment from any mobile device. This app connects to your order picking software to give operators real-time visibility and control on the go.

- Modula Picking Cart: A mobile picking solution with shelves, Wi-Fi, battery backup, and Put to Light controllers. Includes five configurable displays and validation tools, all synced with your order picking software to maximize speed and precision.

- Modula Color Guided Picking: A smart, cost-effective alternative to Put to Light. Operators follow color-coded instructions and scan barcodes using standard picking carts, optimized through integrated order picking software without the need for a full system setup.

3 Factors To Examine When Selecting Order Picking Methods and Systems

Before you land on a picking method, take a good look at your space. The warehouse layout and size all influence how efficiently goods can move from shelf to shipment.

Warehouse Size

As warehouses grow larger, so does the complexity of operations, particularly the picking process.

Big-box warehouse space in the U.S. has steadily expanded, reaching 2.9 trillion square feet in recent years.

Larger facilities often benefit from zone or wave picking to streamline workflows. For example, zone picking allows workers to stay within familiar areas, cutting travel time and increasing accuracy.

Type of Inventory

The type of products you’re storing plays a big role in choosing the right picking method. Some items need special handling or storage conditions.

Take perishable goods, for example, like cartons of milk. They need to be picked and processed quickly to stay fresh.

In cases like this, methods like batch picking or wave picking make more sense because they help speed things up from storage to shipping.

Order Volume

Warehouses dealing with high order volumes, especially during peak seasons, can boost efficiency with batch or wave picking. These methods allow teams to handle multiple orders at once, expanding throughput.

For example, during the holiday rush, a warehouse using batch picking might group all orders with the same popular items into one batch, speeding up the entire process.

3 Key Benefits of Choosing the Right Order Picking Method and Software

When your picking process is efficient, getting orders out the door fast and error-free becomes a whole lot easier.

So, why does the right order picking software, method, or solution matter?

Optimize Space Utilization

Certain picking methods, such as zone picking, can help make better use of warehouse space.

This division allows for more organized storage and reduces the distance that workers need to travel to collect items, speeding up the picking process.

Achieve Scalability or Adaptability

As order volumes change or business expands, having an effective picking method enables a warehouse to adapt more easily.

This scalability is essential for handling peak periods, such as holidays or sales seasons, without a drop in service quality.

Meet Customer Expectations

The right picking strategy can notably improve the timeliness of shipments.

Since delivery is a crucial part of the shopping experience for many, logistics companies need to ensure orders are picked, packed and ready for shipment quickly.

How To Improve Order Picking Accuracy in a Warehouse: Best Practices

Once you’ve invested in the right picking systems, the next step is to implement these solutions into your warehouse picking processes.

Warehouse order picking best practices you should implement include:

Optimize Your Warehouse Layout

Arrange your warehouse to streamline the flow of goods, reduce travel time for pickers and ensure easy access to frequently picked items.

For example, you can arrange your warehouse for optimal picking by placing the most frequently picked items near the shipping area.

This minimizes the distance pickers need to travel to collect these items, speeding up the entire picking process.

Use the Correct Equipment

Equip your team with appropriate tools to improve safety and achieve efficiency in the picking process.

This includes using automated storage and retrieval systems to reduce physical strain and utilizing AMRs for picking efficiency.

Implement a Warehouse Management System

Use a warehouse management system (WMS) to optimize picking routes and minimize mispicks. The system analyzes each order and calculates the most efficient path based on item locations.

For example, if someone orders shoes, a jacket, and a backpack, the WMS can guide the picker to start in footwear, then head to outerwear, and wrap up in accessories, taking the most efficient path through the warehouse.

Modula’s warehouse management system is designed to seamlessly integrate with our advanced automated storage and retrieval systems, creating a unified and efficient warehouse management experience and improving overall productivity.

It stands out as one of the market’s most intuitive and advanced software solutions and effortlessly interfaces with nearly all DMS and ERP systems, optimizing processes such as receiving, storing and picking.

Track Your Warehouse Productivity

Regularly monitor and analyze warehouse key performance indicators (KPIs) related to picking, such as picking productivity and picking accuracy, to identify areas for improvement and implement changes when needed.

For example, if your data shows a decrease in picking accuracy, consider adjusting your picking method to reduce errors.

In addition, if productivity metrics are lagging, you can explore introducing automated order picking systems to your employees or reorganizing the layout of your warehouse to optimize the picking process.

Outsource Fulfillment to a Third-Party Logistics (3PL)

If you don’t have the resources or lack the space, consider partnering with a 3PL to expertly handle your warehousing and fulfillment needs, especially if you are scaling operations.

A 3PL can streamline order picking by implementing advanced tech and strategies, like automated systems and optimized layouts, to cut fulfillment time and costs.

Improve the Order Picking Process With Modula’s Order Picking Software and Solutions: Key Takeaways

Efficient warehouse picking is essential for smooth and accurate order fulfillment. While it might seem straightforward, it actually involves several strategic decisions.

The picking strategy you choose, how you measure success, and the technologies you rely on, including order picking software, all play a key role in how quickly and accurately orders make it out the door.

- Strategy Matters: Choosing the right warehouse picking method, such as batch, zone, or wave picking, can make a big difference in how efficiently your team works and how quickly orders are fulfilled

- Automation is Key: Many warehouses are now using automated picking systems to improve fulfillment speed and reduce errors

- Software is the Brain: With the help of a WMS and automation, teams can pick orders accurately the first time, keeping customers happy and operations running smoothly

At Modula, we make your picking process faster and more accurate by adding automation that cuts down on errors and keeps things moving smoothly.

Reach out to our team to discover how our picking solutions can help meet your needs.

Order Picking: FAQs

What is order picking?

Order picking is a critical warehouse process that involves retrieving items from storage, then gathering and preparing them for packing and shipping to fulfill customer orders.

What are the main types of picking strategies available in a WMS?

Warehouse management systems (WMS) typically offer a range of picking strategies tailored to different operational needs.

Some of the most common strategies include:

- Single order picking: A straightforward method where one worker picks one order at a time. It’s best suited for smaller operations or when accuracy is a top priority.

- Batch picking: Multiple orders are picked during a single trip through the warehouse, helping to cut down on travel time.

- Zone picking: The warehouse is divided into sections or zones, with each picker responsible for one area. Orders move through the zones until they’re complete.

- Wave picking: Orders are grouped and picked in scheduled waves based on shipping times, carrier pickups, or workload balancing.

What are the three strategies of picking in a warehouse?

Warehouse operations commonly rely on three core picking strategies: pick and pass, parallel picking, and wave picking.

Each method is designed to boost speed, accuracy, and scalability in order fulfillment. The best fit depends on your warehouse layout, order volume, and overall operational priorities.

What is the key to successfully pulling orders accurately?

Order picking accuracy comes down to different key factors:

- Real-time inventory visibility helps pickers find the right items quickly by showing exactly what’s in stock and where it’s located

- Optimized pick paths guide workers along the most efficient route, cutting down on mistakes and wasted movement

- Clear labeling and smart slotting make it easier to identify SKUs and pick the correct item the first time

- A reliable WMS adds an extra layer of protection by using barcode scanning, alerts, and verification steps to catch errors before they happen

- Consistent training and procedures ensure every team member knows exactly what to do and how to do it right