eCommerce Warehouse Management Systems [Benefits & Challenges]

The eCommerce market has grown fast, tripling in size over the past five years. And by 2040, it’s expected that nearly 95% of all purchases will occur online.

What does this mean for the average American eCommerce warehouse?

Well, it signals more orders to process, tighter shipping timelines, higher customer expectations, and a greater need for systems that can scale, automate, and keep operations running smoothly around the clock.

To make that happen, an eCommerce warehouse management system becomes a necessity.

In this guide, we will:

- Explain what an eCommerce warehouse management system (WMS) really does

- Cover the top benefits of using an eCommerce WMS

- Discuss the challenges in eCommerce warehousing and how Modula can help your operations

eCommerce Warehouse Management System Explained

An eCommerce warehouse management system (WMS) is a software platform built specifically to handle the high-volume demands of online retail.

While traditional warehouse systems focus more on general inventory control, an eCommerce warehouse management software is designed to keep up with:

- Rapid order turnover

- Instant inventory updates

- The need for speed and accuracy in every step, from picking to packing to shipping

It’s what helps online retailers stay efficient, even during peak seasons or flash sales.

Top Benefits of Using an eCommerce Warehouse Management System

Think a warehouse management system just keeps track of inventory? Well, it does more than that.

From cutting costs to speeding up fulfillment, here’s what an eCommerce warehouse management system actually brings to the table.

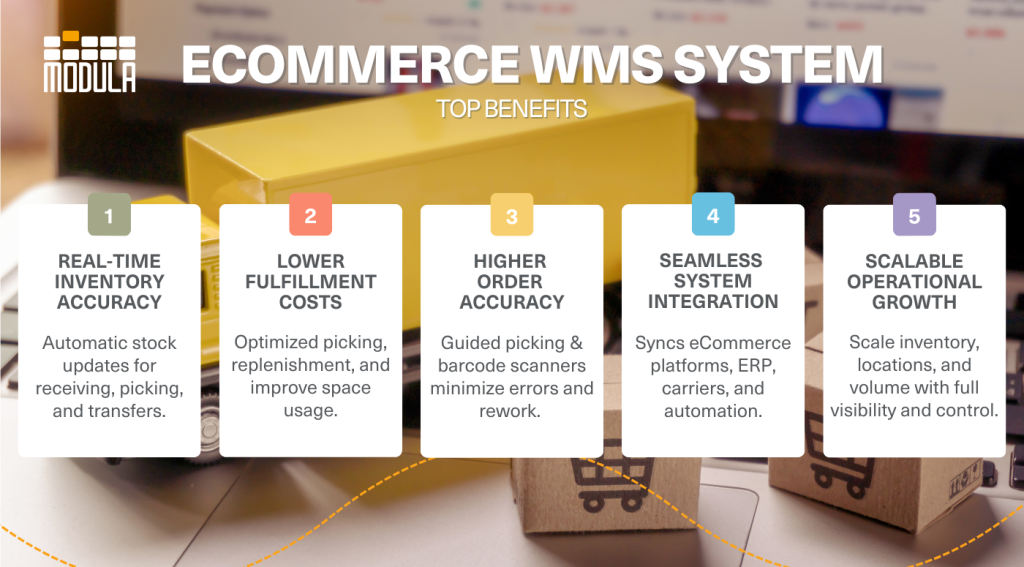

Inventory Accuracy in Real Time

Keeping accurate track of inventory across multiple sales channels is a major challenge.

An eCommerce warehouse management system solves this by giving you instant visibility into everything, like what’s coming in, what’s going out, and what’s moving between zones.

Every time a product is received, picked, or restocked, the system updates automatically. And when you pair it with tools like RFID, barcode scanners, or IoT sensors, you can get accuracy levels of 99% or higher.

Why it matters: When your stock data is reliable, you don’t need to overstock “just in case,” and you’re less likely to run into issues like stockouts, overordering, or unnecessary markdowns.

Lower Fulfillment and Operating Costs

Running a warehouse is expensive, but a smart eCommerce warehouse management system helps cut those costs in different ways.

It can optimize picking and packing, optimize inventory replenishment, and make sure workers are assigned to the right tasks at the right time.

The system can also help you make better use of your space.

For example, Modula WMS integrates seamlessly with vertical lift modules (VLMs) to maximize floor-to-ceiling capacity, telling the machine exactly where to store items to save the most space.

Here’s how it plays out: Companies that use AI-powered eCommerce warehouse management systems features have seen picking speeds jump by as much as 30%, and they’re cutting labor costs by up to 20% in the process.

Better Order Accuracy and Fewer Returns

Let’s face it: picking errors are costly. Each mistake leads to extra labor, refunds, or returns, and more importantly, it damages the customer experience.

Around 24.5% of online orders are returned, compared to just 9% in stores, often due to wrong items or mismatched expectations. That’s nearly one in four orders coming back.

A warehouse management system for eCommerce can help minimize those errors by integrating with tools like voice picking, barcode scanners, or vision-based systems that guide workers through the process.

Plus, these tools collect performance data along the way, so you can spot where issues are happening and fix them before they become trends.

The bottom-line impact: Just a small boost in accuracy can lead to big savings in shipping costs, restocking time, and return handling.

Seamless Tech Integration

An efficient warehouse management system for eCommerce doesn’t work in a silo, it works well with others.

It connects with your:

- Online storefronts (like Shopify, Amazon, or Magento)

- ERP systems

- Carrier software

- Automation tools

That means you can sync inventory across channels, automate carrier selection based on real-time rates, and keep all your data flowing between systems with minimal manual work.

For example: With a carrier integration, your eCommerce warehouse management system can automatically pick the cheapest or fastest shipping option based on the order details, saving time and cutting warehouse costs without lifting a finger.

Room To Grow (Without the Growing Pains)

As your business grows, your warehouse has to grow with it or at least get a lot smarter.

Whether you’re adding SKUs, opening a second location, or bracing for peak season, a cloud-based eCommerce warehouse management system can scale with you.

It gives you historical and real-time data to help you plan for demand, adjust workflows, and stay flexible.

And here’s the big picture: U.S. eCommerce logistics growth includes rapid expansion in warehousing and fulfillment, which means more complexity to manage and higher customer expectations to meet.

An advanced eCommerce warehouse management system helps you stay ahead of both.

The bottom line?

Businesses with scalable eCommerce warehouse management systems report fewer fulfillment delays during peak periods, smoother 3PL onboarding, and better control across multiple warehouse locations.

Top Challenges in eCommerce Warehouse Operations

Running an eCommerce warehouse isn’t just about moving inventory. It’s also about keeping up with nonstop orders, constant returns, tight labor, and rising customer expectations.

Let’s break down what’s really slowing teams down in the warehouse.

Massive Order Volume and Minimal Pick Time Per Order

Most online orders are simple: a handful of SKUs per shipment. But when you’re processing thousands of those a day, complexity adds up fast.

What seems like “just a few picks” turns into hours of labor and miles of walking if your workflows aren’t optimized.

Why it matters: Without smart routing, batch picking, or warehouse automation, pick rates stall, labor costs rise, and you hit your throughput ceiling, especially during major peak sales events (we have our eye on you, Black Friday!)

Outdated Inventory Data Leads to Overselling

Online shoppers take “Available” at face value. If your site says it’s in stock, they expect it to be ready to ship.

If inventory data isn’t updating instantly across all channels, you risk overselling which leads to cancellations, refunds, and lost trust.

The fix: An eCommerce warehouse management system connected to tools like RFID, barcode scanners, or IoT sensors ensures inventory accuracy stays above 99%, even during high-volume days.

Returns Management Slows Down Order Fulfillment

In eCommerce, returns come with the territory. In fact, the average return rate hit 16.9% in 2024, according to the National Retail Federation and Happy Returns.

If your warehouse isn’t set up to handle reverse logistics efficiently, it drags down the whole operation.

What it means: You’ll need dedicated return zones, automated workflows, and system-level tracking to get returned items processed, restocked, or disposed of fast.

Labor Shortages Limit Throughput and Consistency

Hiring and retaining warehouse staff is a growing challenge. And during seasonal surges, onboarding temps quickly (and effectively) becomes a bottleneck.

Without workforce optimization tools or automation to absorb the pressure, your operation becomes inconsistent. Think slower picks, more errors, and missed delivery targets.

Inefficient Use of Space Increases Pick Time

As you expand your product catalog, space gets tighter. If you’re relying on static racking or horizontal layouts, you’re burning through square footage and forcing pickers to walk further than they should.

An expert tip: High-density storage systems like vertical lift modules (VLMs), combined with slotting optimization software, can reclaim up to 75% of wasted space and cut pick time significantly.

Shipping Costs Cut Into Already Thin Margins

Consumers want fast shipping, but they don’t want to pay for it. Meanwhile, last-mile delivery is one of your most expensive line items. Balancing customer expectations with profitability is tougher than ever.

Here’s how to stay ahead: A WMS with built-in rate shopping and carrier integration can automatically pick the best shipping option, based on cost, zone, and SLA, without slowing down fulfillment.

How Modula Supports eCommerce Warehouse Management

At Modula, we help eCommerce warehouses move smarter.

Whether you’re dealing with tight space, nonstop orders, or the pressure to ship faster, our systems are built to keep up.

Our automated storage and retrieval systems (ASRS), including vertical lift modules, deliver six big wins for fulfillment teams.

FEATURE / KPI | STANDARD WMS (MANUAL WAREHOUSE) | MODULA WMS + AUTOMATED STORAGE |

| Picking Method | Person walks to shelf (Walk & Pick) | Item comes to person (Goods-to-Person) |

| Picking Speed | 50-70 lines per hour | Up to 300+ lines per hour |

| Inventory Accuracy | ~95-98% (Human error risk) | 99.9% (Active guidance & shutters) |

| Space Utilization | High floor usage (Static shelving) | Saves up to 90% floor space (Vertical density) |

| Training Time | Weeks (to learn layout) | Minutes (Visual aids & simple interface) |

| Scalability | Hard (Must rent more space/hire more people) | Easy (Add a module or tray vertically) |

That means more space, faster picking, fewer errors, better inventory control, stronger security, and room to grow.

Space Optimization for a Wide Range of Inventory

Modula systems help warehouses make the most of their vertical space, accommodating everything from small gadgets to oversized products in a single high-density solution.

This frees up valuable floor space and supports future growth without needing to expand the facility footprint.

Inventory Accuracy and Real Time Visibility

Thanks to visual picking aids and neatly organized storage, it’s easy for operators to find exactly what they need.

That means quicker picks, fewer mistakes, and fewer returns eating into your bottom line.

Enhanced Product Security

Modula’s enclosed units feature automatic doors that protect stored items from damage, dust, and unauthorized access.

Combined with advanced inventory tracking, these features help prevent loss, theft, and misplacement, especially important in high-turnover eCommerce environments.

Advanced Inventory Management

Modula integrates with ERP and WMS systems to ensure live inventory visibility.

This helps maintain accurate stock levels, decrease overselling, and improve the overall reliability of your eCommerce logistics operation.

Modula WMS is trusted by eCommerce businesses of all sizes to simplify inventory tracking, sync data across channels, and keep fulfillment running smoothly, even during peak demand.

Operational Flexibility

Whether your team is operating manually or using automation, Modula offers the flexibility to scale up or down as needed.

This is ideal for businesses that face seasonal spikes or need to run 24/7 fulfillment centers without interruptions.

Quick, Scalable, and Cost-Effective Implementation

Modula’s automation solutions are designed for fast deployment and easy scalability.

Whether you’re relocating, expanding, or reconfiguring your warehouse layout, the system adapts to your needs, so you can stay agile in a competitive market.

Faster Order Picking and Fulfillment

Modula systems are designed to speed up fulfillment without sacrificing accuracy.

With built-in visual picking aids, guided workflows, and ergonomic access, operators can quickly identify and retrieve the right items, cutting down on errors, returns, and pick time.

A big part of that efficiency comes from Modula’s high-density vertical lift modules (VLMs).

These systems store a wide variety of SKUs, from small items to oversized products, by utilizing vertical space instead of traditional horizontal racking.

By bringing items directly to the operator, VLMs eliminate wasted travel time and streamline the entire picking process.

eCommerce Warehouse Management System: Key Takeaways

Running a successful eCommerce operation requires speed, accuracy, and the ability to adapt instantly.

As order volumes increase and fulfillment expectations tighten, relying on spreadsheets or basic inventory tools is no longer enough.

An advanced eCommerce warehouse management system gives you the control you need to scale.

At Modula, we’re here to help you make that happen.

- As order volumes increase and fulfillment expectations tighten, an eCommerce warehouse management system is critical to managing inventory in real time

- An advanced eCommerce warehouse management system should connect effortlessly with your online storefronts, ERP, carrier systems, and automation tools

- Whether you’re dealing with space constraints, seasonal surges, or nonstop returns, Modula’s automated storage solutions and WMS integration give eCommerce warehouses the tools to move faster, scale smarter, and stay in control

eCommerce Warehouse Management System: FAQs

What is a WMS software for eCommerce?

A WMS software for eCommerce is a specialized platform built to manage everything that happens inside an eCommerce warehouse, from inbound inventory to outbound shipments.

Unlike traditional systems, it’s designed to keep up with the high volume of online orders, where speed, accuracy, and real-time visibility aren’t just nice to have. Rather, they’re essential.

What makes a warehouse for eCommerce different from a traditional warehouse?

A warehouse for eCommerce is designed to handle a high volume of individual orders with precision and efficiency.

Unlike traditional warehouses that focus on bulk storage and pallet-based shipping, eCommerce operations process a large number of small, itemized orders daily, often across multiple channels.

This is why many eCommerce warehouses now rely on automated storage and retrieval systems (ASRS) to manage the intense pace of picking and packing single items.

What should I look for in a WMS for an American eCommerce warehouse?

The right WMS for an American eCommerce warehouse should integrate with major carriers, storefronts, and ERP systems.

It should support slotting, order prioritization, real-time inventory sync, and flexible workflows that scale with seasonal demand.

Prioritize systems with strong U.S.-based support, iron-clad security, and compliance with local fulfillment standards.

Have more questions about eCommerce WMS?