Introducing Modula-AMR-ROEQ: Fully Automated Tote Picking System

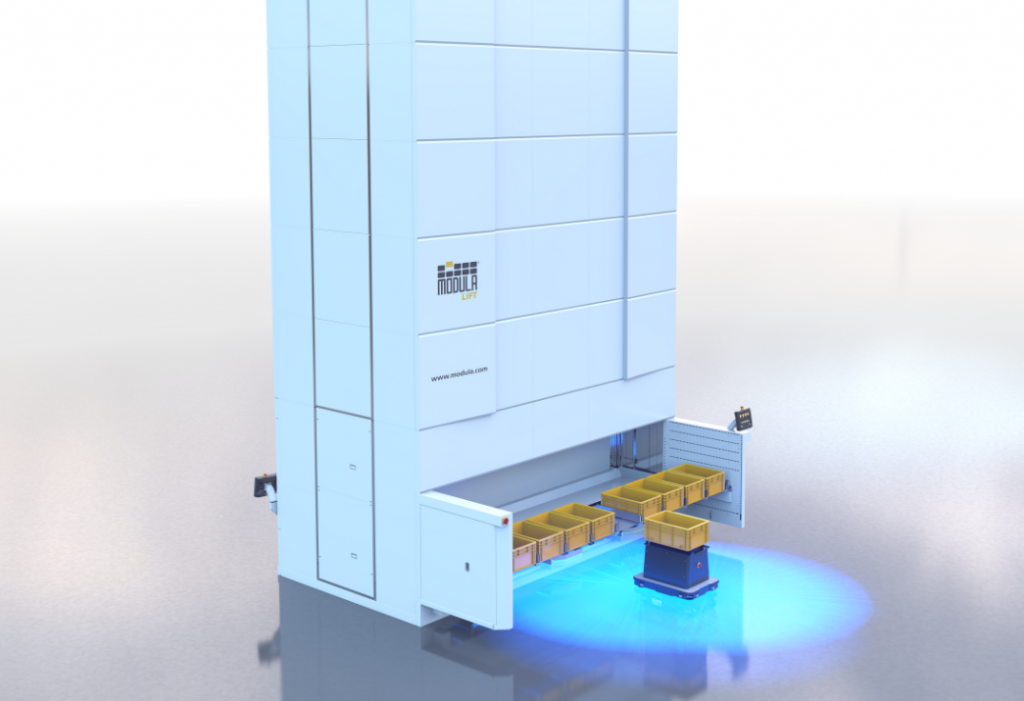

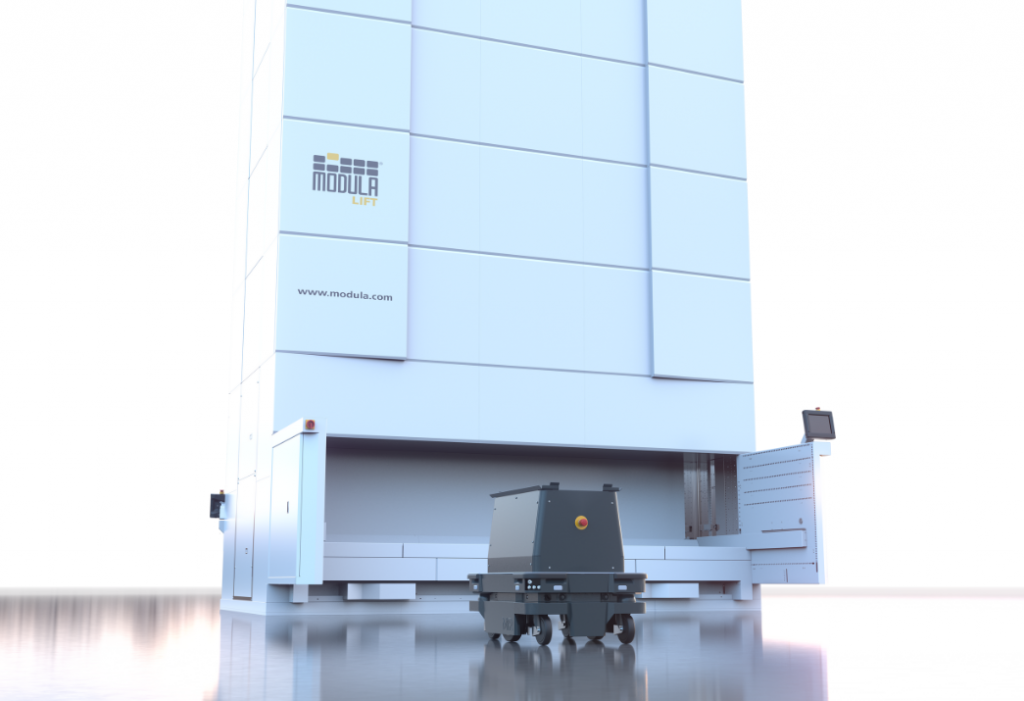

Modula is advancing warehouse automation with the new Modula-AMR-ROEQ solution, developed in partnership with MiR and ROEQ. This innovation combines the proven capabilities of the Modula Lift with the autonomous functionality of AMRs (Autonomous Mobile Robots), creating a fully automated tote picking system that eliminates the need for manual intervention.

How the Modula-AMR-ROEQ Solution Works

The Modula-AMR-ROEQ solution builds on Modula’s previous automated tote picking system, which used a more complex and costly technology. In that system, the AMR had a customized top module to lift, pick, and place bins directly from/to the VLM tray.

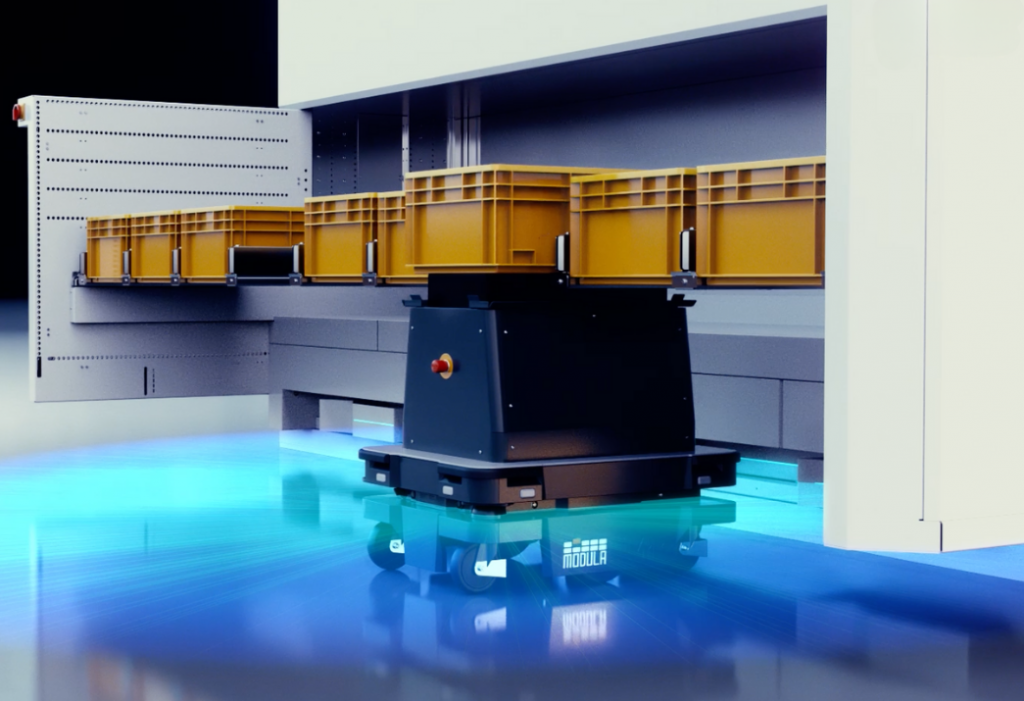

The new solution is simpler, more cost-effective, and allows multiple AMRs to work simultaneously, increasing throughput. It features a specially designed tray in the Modula Lift with interlocking supports to securely hold multiple bins. The AMR, equipped with a ROEQ bay, autonomously approaches the Modula Lift to perform picking and replenishment tasks. The efficient lifting mechanism moves each bin from underneath, enabling easy removal and placement without manual handling.

This setup streamlines totes retrieval and storage, improving efficiency and reducing human error. Totes can be managed individually or in groups, with up to nine totes handled at once per bay. Multiple AMRs working in parallel ensure high throughput, making this solution a significant step towards fully automated warehouse management.

Applications and Benefits of the Modula-AMR-ROEQ Automated Tote Picking System

The Modula-AMR-ROEQ solution can be utilized across various industries, including e-commerce, manufacturing, and distribution centers. By automating tote picking, warehouses can significantly improve their efficiency while reducing labor costs and operational errors. This flexibility allows businesses to adapt to changing demands and optimize their workflows, ultimately improving customer satisfaction through faster and more accurate order fulfillment.

Advantages of a Fully Automated Tote Picking System

The Modula-AMR-ROEQ solution is a major advancement in warehouse automation. By combining vertical storage with autonomous robotics, it enables fully automated tote picking, reducing manual labor while boosting efficiency, accuracy, and productivity. The ability for multiple AMRs to operate simultaneously ensures high throughput, making this a versatile solution for warehouses of all sizes and industries.