Discover Modula Automated Storage Solutions at MODEX 2026

- Event: MODEX 2026

- Location: Georgia World Congress Center

- Dates: April 13-16, 29026

- Visit our team: Modula Booth – Level 1 — B15713

Modula at MODEX 2026

The supply chain and manufacturing industries are constantly evolving, and MODEX 2026 is the premier event to discover what is next. Taking place from April 13-16, 2026, at the Georgia World Congress Center in Atlanta, MODEX gathers industry leaders and professionals to explore the latest innovations in material handling, logistics, and supply chain technology.

Whether you are looking to overcome labor shortages, maximize your floor space, or increase your order fulfillment speed, warehouse automation is the key. This year, Modula will be at Booth #B15713 to showcase how our cutting-edge Automated Storage and Retrieval Systems (ASRS) can transform your order fulfillment.

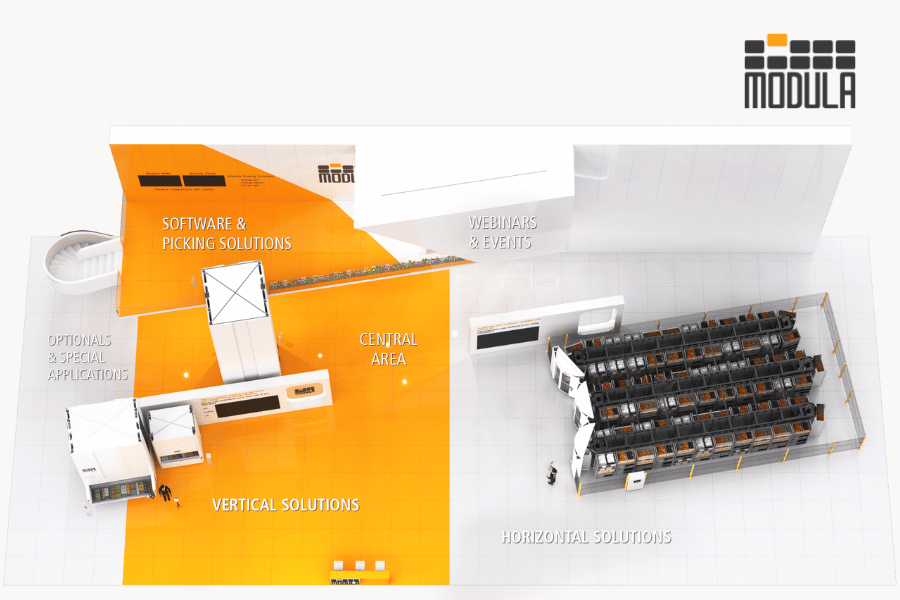

See Modula’s Core Technologies Live At MODEX 2026

At our booth, we will be running live demonstrations of our most popular and dynamic storage solutions, allowing you to see their speed and accuracy firsthand:

The Modula Lift (Double Opposite Bay): Experience the benchmark in vertical storage. By taking advantage of high ceilings, the Modula Lift allows you to recover up to 90% of your floor space. It is a true workhorse, featuring robust trays capable of handling payloads up to 2,200 lbs (990 kg) without strain. At MODEX, we will be showcasing our Modula Lift equipped with a double opposite bay configuration (dual delivery). This setup is designed for maximum throughput: while an operator is picking items from the first bay at a perfectly ergonomic height, the VLM is already retrieving the next tray and delivering it to the second bay. The result is a continuous workflow that eliminates waiting times, reduces physical strain, and boosts picking speeds up to 300 lines per hour..

The Modula Flexibox: Designed for extremely fast-moving industries, the Modula Flexibox is our high-speed automated storage bin system. Capable of processing up to 180 bins per hour, it features a central elevator with a telescopic fork that can retrieve up to nine bins simultaneously. These bins are placed on a service tray and delivered directly to the picking bay, allowing operators to fulfill multiple order lines in a single cycle. With smart order preparation and buffer bay configurations, the Flexibox ensures zero waiting times, making it the ultimate solution for high-volume environments like e-commerce, retail, and automotive

Modula Flexibox – our high-speed automated storage bin system

Exploring Next-Level Automation: The Integration Zone

While our automated storage systems are powerful standalone solutions, they are also designed to be the foundation of a fully connected warehouse. At Booth #B15713, we will feature a dedicated area highlighting our robotics integrations.

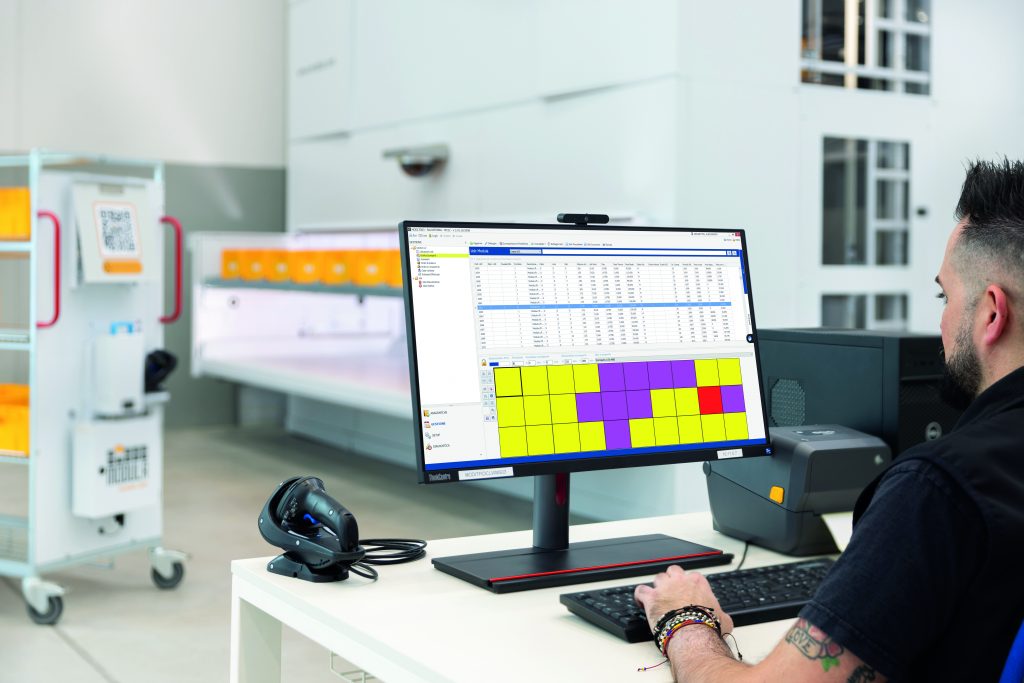

Visitors can learn how seamlessly Modula products interface with advanced robotics. The key to this smooth synergy is our native software integration: the Modula WMS software interacts natively with the industrial robotics software installed on AMRs, robots, or cobots (collaborative robots). This ensures quick installation and optimized material handling operations without the need for complex or costly structural modifications.

Modula Robotics Integrations

Join Modula at MODEX 2026

Our team of material handling experts will be available throughout the show to discuss your specific warehouse challenges and help you design a system that meets your exact needs.

Register here for your free expo pass. We look forward to seeing you in Atlanta!

Virtual Booth

Experience the latest on automation and material handling, even if you’re unable to attend the trade shows in person. You can check out our automated storage solutions by visiting our virtual booth from the comfort of your own desk

Subscribe To Our Newsletter

Stay informed about our upcoming events, news, and more. Learn more about automation and material handling. You can easily unsubscribe at any time using the links provided in every email