Complete Guide to Warehouse Management Systems (WMS)

A warehouse management system (WMS) is a software solution that offers a comprehensive view of your inventory and helps manage every aspect of warehouse operations, from receiving to distribution.

It provides a wide range of benefits: from boosting picking accuracy by assigning optimal picking routes, to tracking inventory in real time and improving overall efficiency.

In this guide, we’ll cover everything you need to know about WMS systems:

- What they are and how they work

- The role of a WMS in warehouse operations

- The differences between WMS and inventory management systems

- The types of warehouse management systems

- How Modula’s advanced WMS can help optimize your facility

What Is a Warehouse Management System (WMS)?

A warehouse management system (WMS) is a software platform designed to help companies monitor, organize, and optimize warehouse processes. It integrates with technologies like barcode scanning, RFID, cloud computing, and ERP systems to streamline workflows and improve accuracy.

Consider it the control tower of your warehouse: it supervises and coordinates receiving, put-away, storage, picking, packing, and shipping, while also enabling data collection and analytics.

In fact, one of the main strengths of a WMS lies in its ability to integrate with other business management systems, such as Enterprise Resource Planning (ERP) and Document Management System (DMS) systems, to control or respond to requests that take place along the supply chain.

With U.S. retailers losing an estimated $1.2 trillion each year due to stockouts and overstocking, the need for efficient WMS warehouse systems has never been more pressing.

Warehouse Management System vs. Inventory Management System

While both a Warehouse Management System (WMS) and an Inventory Management System (IMS) deal with inventory, they serve different purposes within the supply chain.

A WMS is designed to manage warehouse processes from end to end: receiving, storing, picking, packing, and shipping. It provides visibility into inventory movement, helping operators make informed decisions on where to store products, how to optimize space, and which stock to pick first (e.g., based on expiration dates). It also helps manage labor productivity and integrates seamlessly with other platforms like ERP, DMS, and transportation systems, enabling a connected and efficient workflow.

An IMS focuses solely on maintaining accurate stock records. It tracks product quantities, sales, orders, and deliveries, regardless of item location. It is often used alongside POS or e-commerce systems. While IMS tools assist with demand forecasting through historical data and trends, they typically don’t manage warehouse operations or guide operator workflows.

Another key difference lies in integration capabilities. An IMS is often a standalone solution that supports basic inventory tracking, while a WMS is a comprehensive platform that connects with various technologies, such as ERP, transportation management, and order systems, to create a fully synchronized warehouse environment.

| FEATURE | WAREHOUSE MANAGEMENT SYSTEM (WMS) | INVENTORY MANAGEMENT SYSTEM (IMS) |

| MAIN FUNCTION | Manages all warehouse operations: receiving, storage, picking, packing, shipping | Tracks stock levels, orders, and deliveries |

| INVENTORY CONTROL | Real-time inventory visibility with item movement tracking and advanced inventory strategies (e.g., ABC classification) | Monitors SKU levels and sales trends |

| OPERATIONAL SCOPE | Optimizes labor efficiency, space utilization, and picking paths | Focuses on keeping accurate stock records and ensuring item availability |

| SYSTEM INTEGRATION | Integrates with ERP, DMS, transportation systems, and automation technologies | May integrate with POS or ERP but is often more limited in operational connectivity |

| DECISION SUPPORT | Assists operators in deciding where to store or retrieve items, manage FIFO/FEFO, and optimize labor | Supports purchasing decisions, replenishment planning, and demand forecasting |

| ROLE IN THE WAREHOUSE | Acts as the operational brain of the warehouse | Often the first step in inventory tracking, but is limited in managing full warehouse operations |

How Does a Warehouse Management System Work?

Here’s a step-by-step overview of how a WMS typically works:

- Warehouse operators record received goods in the WMS: When goods arrive, operators scan barcodes or RFID tags to log each item’s quantity and location. This ensures real-time inventory updates, accurate documentation, and full traceability from the moment goods enter the warehouse.

- The WMS assigns optimized storage locations: The system analyzes item-specific factors such as size, weight, and frequency of access. It then instructs warehouse staff where to store each item, often placing high-turnover SKUs near picking or shipping areas to boost efficiency.

- The WMS continuously tracks inventory: As goods are moved, picked, or sold, the WMS updates stock levels, locations, and statuses in real time. This gives warehouse managers complete visibility and helps prevent stockouts, overstocking, or misplaced items.

- The WMS generates digital picking lists: When an order is received, the system uses stored inventory data to create a digital picking list. This list guides the operator along the most efficient route, reducing travel time and improving order fulfillment speed and accuracy.

- The WMS updates inventory after order processing: Once items are picked, packed, and shipped, the WMS automatically deducts them from stock. This keeps inventory data accurate across all systems and prevents delays in replenishment.

- The WMS generates reports: The WMS compiles data on all warehouse activities, from receiving to shipping, and turns it into performance reports. These insights help improve KPIs such as space utilization, labor productivity, picking accuracy, and inventory turnover.

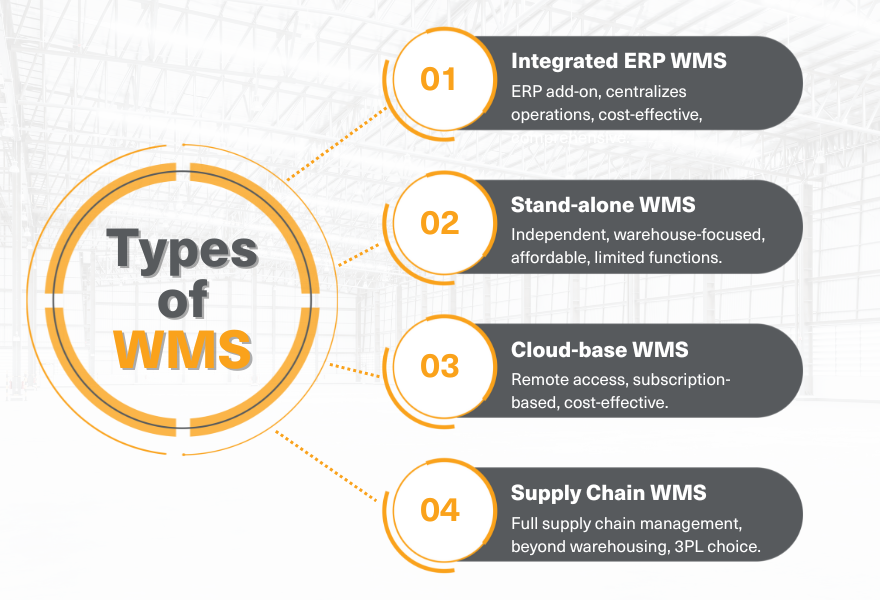

Types of Warehouse Management Systems

There are several types of warehouse management systems (WMS) available, each offering distinct capabilities depending on your business goals, size, and infrastructure. The most common WMS systems include:

Integrated WMS

An integrated WMS is a type of solution that is typically an add-on of an existing ERP system.

It’s a comprehensive software system that integrates core business processes and functions, such as finance and accounting, customer relationship management and project management.

By using a centralized WMS system, businesses can gain a unified view of their operations, streamline workflows, and reduce the cost of managing multiple disconnected tools. This makes it ideal for organizations looking for full system integration across departments.

Stand-alone WMS

A stand-alone WMS is a software solution focused exclusively on warehouse functions like inventory control, order picking, and reporting. Unlike integrated systems, it doesn’t connect with ERP or other business platforms unless manually integrated.

While it lacks advanced features for areas like accounting or order processing, its simplicity and affordability make it an attractive option for small businesses or startups that need to get warehouse operations under control quickly.

Cloud-based WMS

A cloud-based WMS is hosted on a remote server, meaning it can be accessed via the internet from any location. It’s usually offered as a subscription service and maintained by a third-party provider who handles software updates, backups, and technical support.

This type of WMS system offers scalability, flexibility, and low upfront investment, making it ideal for growing companies or businesses with multiple warehouse locations.

Supply Chain Module WMS

A supply chain module WMS is part of a broader supply chain management system. It not only handles warehousing activities but also integrates with functions like vendor management, sourcing, manufacturing, and transportation.

This type of WMS provides end-to-end supply chain visibility and coordination, allowing companies to make data-driven decisions and optimize resources in real time. It’s commonly used by third-party logistics (3PL) providers and enterprises with complex supply chains, often alongside other WMS platforms for specialized warehouse needs.

Benefits of a Warehouse Management System

A warehouse management system (WMS) brings numerous benefits that go beyond simple inventory tracking. Whether standalone or part of an integrated system, WMS software supports warehouse efficiency, security, and strategic planning.

Modula’s WMS for Advanced Inventory Visibility

At Modula, we provide automated storage solutions and warehouse management systems that are designed to optimize space and improve picking and warehouse inventory management operations across a wide range of industries.

Modula WMS is our intelligent and complete end-to-end solution for your business, built for operating Modula’s automated storage and retrieval systems. It can also be used for traditional and manually operated warehouses as a stand-alone software.

As one of the most advanced and user-friendly solutions available in the market, it works well with most Document Management System (DMS) and ERP systems. It simplifies daily warehouse tasks, such as receiving, picking, and storing, by making them faster and more accurate.

Our WMS gives you real time control and a bird’s eye view of your warehouse tasks, thanks to a user-friendly PC interface.

Setting up is easy. All you need is a main computer that will act as the warehouse server and additional computers for your staff to access the system.

After installation, the WMS is ready for use and can smoothly connect with any type of corporate ERP system.

Check out the video below to see the Modula WMS in action:

What Is the Modula WMS Used For?

The Modula WMS can manage each SKU or product code with accuracy by connecting it to a specific compartment within the Modula unit’s trays. Each compartment, divided with partitions and dividers, becomes a traceable location that the WMS can monitor in real time.

Thanks to its simple integration, from each of these compartments, the WMS can manage and retrieve different information related to warehouse inquiries, such as:

- Maturity and expiration dates

- Storage, validation, and product status

- Item location, movement history, and quantity on hand

Each action, whether picking or putting away, is logged and tied to the item’s unique identifier, ensuring full traceability even when multiple SKUs share a compartment.

The Modula WMS is also designed to handle complex warehouse operations efficiently. Whether you’re managing inventory counts or consolidating orders, the system can automate time-consuming processes. When paired with robotic peripherals and accessories, it enhances productivity further by reducing manual input.

For example, the Modula WMS can manage on-the-fly order consolidation using tools like a picking cart. This means items from a single order can be grouped together during the picking phase itself, without needing extra consolidation steps afterward.

The Modula WMS allows you to:

- Track and monitor individual SKUs, their movement, and current stock levels

- Improve order handling, prioritize tasks, and monitor order status

- Manage item locations, create custom location codes, and print labels

- Assign and control user roles, access levels, and task responsibilities

- Track system performance, generate alerts and reports, and analyze operational data

- Integrate and exchange data with other systems through direct input or file transfer

Key Advantages of Modula’s WMS

Here’s what you can expect when you implement Modula’s WMS in your warehouse operations:

Manage an Entire Storage Facility With a Single Modula WMS License

With Modula’s Warehouse Management System (WMS), companies can efficiently oversee and control all current and future Modula products using just one license, regardless of model, size, capacity or individual functions. In addition, the Modula WMS system can also manage manual areas.

Gain Full Control Over Multiple Storage Systems Located in Different Company Areas

Whether you have several Modula units spread across various departments or locations, the WMS gives you full visibility and control. For example, you can simultaneously manage:

- Raw materials and parts in production

- Assembly parts or consumables

- Semi-finished or pre-assembled products

- Finished goods for testing or shipping

- Spare parts

Each Modula unit can be operated independently based on the specific logic and processes of each department, while still being coordinated through a centralized WMS. This ensures accurate, streamlined operations across all units—no matter their function or location.

Integrate the WMS Easily With ERP Systems

Modula’s WMS system is designed for seamless integration with your chosen ERP, WMS or DMS, providing efficient management of orders and inventory between the existing ERP and Modula’s automated storage systems.

There are three common ways to set up this integration:

- Data exchange through Web service (Rest API)

- File exchange (xml, csv, text files)

- Data exchange via ODBC (intermediate database)

The choice of the data exchange method depends on several factors, including the client’s preference, the pre-existing warehouse management system, and familiarity with protocols. Selecting the most suitable method ensures smooth communication and optimized operations.

Install the WMS Easily in the Warehouse

Modula WMS has been designed to be simple and intuitive, even for individuals without specific IT skills. As a result, the learning curve is faster.

After importing and defining the master data and product locations, operators can access the control panel at any time and manage operations easily and efficiently.

Beyond standard functions, the WMS offers detailed reporting for individual machines or the entire system. With just a few clicks, you can analyze space utilization, track operations performed, detect errors, and uncover optimization opportunities.

Manage Individual Items or SKUs in an Accurate and Timely Manner

Modula’s WMS offers precise control over individual items or SKUs. Operators can accurately track and monitor the movement of each item within the warehouse, ensuring efficient picking, packing, and shipping processes.

Each SKU can be managed with different logic, considering quantities and specific units of measurement. For example, an item can be handled in packs of 6, 12, or more, and counted in various units depending on specific needs.

This flexibility allows companies to efficiently control and manage products like water or food, which can be counted as pallet units, individual pieces, or packages based on storage and picking requirements.

With Modula’s WMS, companies can streamline their warehouse operations and optimize inventory management, leading to smoother workflows and increased productivity.

Manage Inventory as a Whole

Modula WMS software offers the ideal solution to keep track of stock levels and create a comprehensive record of the whole inventory in a warehouse.

Operators can access the location, status, and quantity of materials stored in the warehouses at any given moment. All picking and replenishment operations, along with their histories, are also easily accessible with just a few simple steps.

In addition, the WMS can generate precise and organized reports based on individual references or entire groups of locations.

For manual checks, operators can request information through the console. The process is quick and efficient: the Modula unit receives the information inquiry as if it were a regular order and presents the tray with the requested items. The operator can then count the products, confirming quantities and stock levels.

Ultimately, with Modula WMS software, companies can efficiently manage their entire inventory from a unified platform.

The system provides comprehensive insights into stock levels, order statuses and replenishment needs, empowering warehouse managers to make data-driven decisions and optimize inventory control, ultimately reducing holding costs.

At Modula, our easy-to-install and operate WMS provides you with real-time data, helping your organization take control of your supply chain.

WMS (Warehouse Management System): FAQs

What is a WMS?

A warehouse management system (WMS) is software that helps coordinate inventory movement and warehouse operations. It supports tasks like receiving, picking, storing, and shipping, offering better visibility and control throughout the facility.

What’s the difference between a WMS and an Inventory Management System (IMS)?

A WMS manages physical workflows inside the warehouse, such as how goods are stored, picked, and moved. An IMS tracks inventory levels, SKUs, and product data, often supporting sales or purchasing functions. While both systems handle inventory, a WMS focuses on operations; an IMS focuses on records and counts.

What is the difference between a WMS, an ERP, and an Inventory Management System (IMS)?

These three systems often work together, but they have different roles:

1. A WMS handles warehouse operations: how inventory moves and where it’s stored.

2. An IMS focuses on tracking stock levels and item data across locations.

3. An ERP is a broader system that connects departments across the business, including finance, HR, purchasing, and sometimes warehouse modules too.

How does a WMS help improve delivery times?

A WMS reduces delays by streamlining warehouse processes. Faster picking, better inventory accuracy, and fewer errors mean orders can be processed and shipped more efficiently, improving on-time delivery performance.

Can a WMS be used with an ERP system?

Yes. Modula WMS integrates easily with most ERP, DMS, and order management systems using APIs, file exchange, or databases. This ensures real-time data sync between platforms and helps avoid duplicate entries or manual updates.

Does Modula WMS work only with Modula systems?

Yes. While it’s built to manage Modula’s automated storage systems, it can also be used to manage traditional warehouse zones and manual storage areas from the same interface.

Is a WMS suitable for smaller warehouses?

If you’re dealing with inventory inaccuracies, delayed shipments, or growing order volumes, it’s worth considering a WMS. It’s also valuable when introducing automation or expanding into multiple warehouse zones.

Which Modula products work with Modula WMS?

Modula WMS is compatible with all Modula units, including Modula Lift, Modula Slim, Modula Pallet, and Modula Flexibox. It also supports accessories like picking carts, put-to-light systems, and barcode readers.