30 Warehouse KPIs to Track and Measure Performance [+ Each Formula]

Tracking and measuring warehouse key performance indicators (KPIs) allows you to gather insights into all areas of operation. From productivity and efficiency to accuracy and employee safety.

By monitoring the correct warehousing metrics, you can make informed decisions and identify potential issues before they escalate. Moreover, leveraging these insights enables you to optimize your processes and achieve better results.

We’ll share all you need to know about warehouse KPIs, including:

- The most important metrics to track and how to measure them

- The formula for each KPI

- An introduction to our warehousing technologies at Modula

What Are Warehouse KPIs?

Warehouse key performance indicators (KPIs) are metrics that measure a warehouse or distribution center’s effectiveness, efficiency and overall performance.

These KPIs provide valuable insights into different operational aspects, allowing businesses to identify areas for improvement, make informed decisions and optimize their supply chain management processes.

Warehouse KPIs: Benefits

Warehouse Key Performance Indicators (KPIs) offer valuable advantages for optimizing warehouse operations.

Here are the main benefits:

Warehouse Key Performance Indicators (KPIs): Categories

Warehouse Key Performance Indicators (KPIs) track and evaluate performance in specific areas of warehouse operations. Here’s a brief explanation of each category:

- Receiving: Tracks efficiency and accuracy in the receiving process through metrics such as dock utilization, receiving time per unit and receiving accuracy.

- Putting away: Evaluates the effectiveness of placing received items into designated storage locations, using metrics like put-away time, accuracy and utilization.

- Storage: Measures performance and optimization in storage operations, focusing on inventory accuracy, space utilization and carrying costs.

- Picking: Gauges the efficiency and accuracy of the order picking process, with metrics including pick accuracy, rate and travel distance per pick.

- Distribution: Assesses effectiveness in the distribution process, tracking order fulfillment rate, on-time delivery and order cycle time.

- Reverse logistics: Estimates efficiency and accuracy in handling returns and damaged goods, with metrics such as return processing time, rate and disposition accuracy.

- Employee safety: Monitors the effectiveness of safety protocols and practices, measuring accident/incident rate, near-miss incidents and safety training completion rates.

- Labor Productivity – Measures workforce efficiency using metrics such as units per hour, cost per unit handled, and labor utilization rate.

- Equipment & Maintenance – Tracks the performance and upkeep of warehouse machinery with KPIs like downtime, maintenance cost per asset, and mean time between failures (MTBF).

- Sustainability & Energy Efficiency – Monitors environmental impact with KPIs like energy consumption, waste reduction, and CO₂ emissions per unit shipped.

Essential Warehouse KPIs To Track Receiving

Receiving in the warehouse is the process of unloading, documenting, inspecting, conducting quality checks and labeling SKUs. KPIs to measure performance in this area include:

Cost of Receiving Per Receiving Line

Cost of receiving per receiving line is a warehouse KPI that measures how much money is spent on handling and receiving.

By monitoring this KPI, you can gain valuable insights into potential bottlenecks in the receiving process, such as inconsistencies in inventory documentation.

To calculate the cost of receiving per receiving line, divide the total cost of receiving by the total number of goods in each receiving line.

Receiving Efficiency

Receiving efficiency is a warehouse KPI that measures the amount of inventory received per warehouse operator, per hour.

By monitoring this KPI, you can gain insight into how efficient your warehouse is at utilizing manpower during the receiving process.

To calculate the receiving efficiency, divide the volume of inventory received by the number of hours worked.

Receiving Cycle Time

Receiving cycle time is a warehouse KPI that evaluates the time taken to process goods, from the moment they arrive at the warehouse until they are ready for storage or dispatch.

A shorter receiving cycle time is ideal, as it characterizes efficiency in processing incoming goods. An extended receiving cycle time can indicate inefficiencies or bottlenecks in the receiving process, such as labor shortage.

To calculate the receiving cycle time, divide the total time spent in sorting received stock by the total number of items received.

Receiving Accuracy

Receiving accuracy is a warehouse KPI that measures the percentage of accurate receipts. For example, this could include the percentage of accurate orders received vs. purchased orders from suppliers.

By monitoring the accuracy of incoming goods, you can reduce order fulfillment errors, enhancing customer satisfaction.

To calculate the receiving accuracy percentage, divide the actual number of items received by the total number of items expected to be received, then multiply by 100.

Dock Door Utilization

Dock door utilization is a warehouse KPI that measures how many of the total dock doors (an entrance where warehouse operators load and unload inventory from the truck) were used.

By monitoring this KPI, you can identify potential issues in your loading and unloading operations, such as the lack of coordination of incoming and outgoing shipments.

To calculate the dock door utilization, divide the total time dock doors are in use by the total available dock door time.

Warehouse KPIs to Track Putting Away

Putting away is the process of transferring received inventory from the receiving area to the designated storage locations within the warehouse. KPIs to measure performance in this area include:

Put Away Cost Per Line

Put away cost per line is a warehouse KPI that measures the costs associated with storing each line of inventory in the warehouse. Put away costs include labor, material handling and equipment costs.

By monitoring this KPI, you can evaluate the cost-effectiveness of your put away process.

To calculate the put away cost per line, divide the total costs collected during the put away process by the total number of receiving line

Put Away Productivity

Put away productivity is a warehouse KPI that measures the efficiency of the putting away process in the warehouse — transporting goods from the receiving area to their designated storage locations.

By monitoring this KPI, you can measure the efficiency of your putting away process.

To calculate the put away productivity, divide the total quantity of goods put away by the total hours spent on the putting away process during a given time.

Put Away Accuracy

Put away accuracy is a warehouse KPI that measures the correctness of the put away process in a warehouse, which involves moving goods from the receiving area to their correct storage locations.

By monitoring this KPI, you can identify potential issues in the put away process and maintain precise inventory records.

For example, if the accuracy rate is low, you can implement training programs for your warehouse staff to improve their product knowledge and accuracy in identifying storage locations in the warehouse.

To calculate the put away accuracy, divide the number of items that are accurately put away by the total number of items that are put away in a given period. Then, multiply the result by 100.

Put Away Cycle Time

Put away cycle time is a warehouse KPI that measures the amount of time it takes from when goods are received in the warehouse until they are correctly stored in their designated locations.

By monitoring this KPI, you can identify potential bottlenecks in the put away process.

A lower put away cycle time is ideal, as it indicates a more efficient put away process, contributing to faster inventory turnover.

To calculate the put away cycle time, record the start time when a warehouse operator begins putting away a SKU and the end time of the putting away process. Then, subtract the start time from the end time.

Warehouse KPIs to Track Storage

Warehouse storage is the process of classifying and organizing products based on their SKU, size, weight, popularity and storage requirements. KPIs to measure performance in this area include:

Carrying Cost of Inventory

Carrying cost of inventory is a warehouse KPI that calculates the total cost associated with storing inventory over a specific period of time.

Costs include inventory costs, capital costs, labor costs, damage costs and obsolescence costs — the amount lost due to the outdated or obsolete nature of a product, technology or business process.

By monitoring this KPI, you can improve cash flow and make data-driven decisions to maintain optimal stock levels.

To calculate the carrying cost of inventory, divide your inventory holding sum by the total value of inventory, then multiply by 100 to get a percentage of total inventory value.

Storage Productivity

Storage productivity is a warehouse KPI that evaluates the efficiency of the warehouse’s storage processes, measured by the volume of inventory stored per square foot.

By monitoring this KPI, you can increase throughput and reduce material handling and retrieval time.

To calculate the storage productivity percentage, divide the occupied space by the total storage capacity and multiply the result by 100.

Modula is a leading manufacturer of advanced automated storage and retrieval systems (ASRS).

With our horizontal carousels, you can enhance performance and reliability for high-speed order fulfillment, even when your warehouse ceiling height is limited.

Space Utilization

Space utilization is a warehouse KPI that measures how efficiently a warehouse is maximizing its available space.

By regularly monitoring this KPI, you can make informed decisions about the most ideal warehouse layout and storage strategies.

To calculate the space utilization rate, divide the occupied space by the total usable space and multiply the result by 100.

With Modula’s vertical lift modules (VLMs), we can maximize your existing warehouse space by utilizing your available ceiling height, improving storage capacity and efficiency.

Our VLMs only take up a minimum footprint in your warehouse, so you can make the most out of your existing facility.

Inventory Turnover

Inventory turnover is a warehouse KPI that measures the number of times inventory is sold or used in a specific period.

By monitoring this KPI, you can gain insights into your inventory management and sales performance.

To calculate the inventory turnover rate, divide the cost of inventory sold by the average inventory value during the same period.

Inventory to Sales Ratio

Inventory to sales ratio is a warehouse KPI that compares the amount of inventory a warehouse has on hand against its sales.

By monitoring this KPI, you can identify sales trends and make informed decisions about purchasing future inventory.

To calculate the inventory-to-sales ratio, divide the value of the inventory by the value of sales over a given period of time.

Warehouse KPIs to Track Picking

Warehouse picking is the process of selecting and gathering goods from their storage locations within the warehouse based on specific order requirements. KPIs to measure performance in this area include:

Picking and Packing Cost

Picking and packing cost is a warehouse KPI that measures the total cost associated with picking, labeling and packing.

By monitoring this KPI, you can identify areas for improvement and implement changes to reduce costs.

For example, investing in automated warehouse picking systems and automated bagging systems can help you cut costs on picking and packing.

To calculate the picking and packing cost, add the labor costs per order and the total indirect costs, then divide the sum by the total number of orders.

To calculate labor costs, multiply the time spent on picking and packing for each order by the hourly rate of the workers involved. To calculate total indirect costs, add the equipment maintenance, packing materials, labels and packing slips.

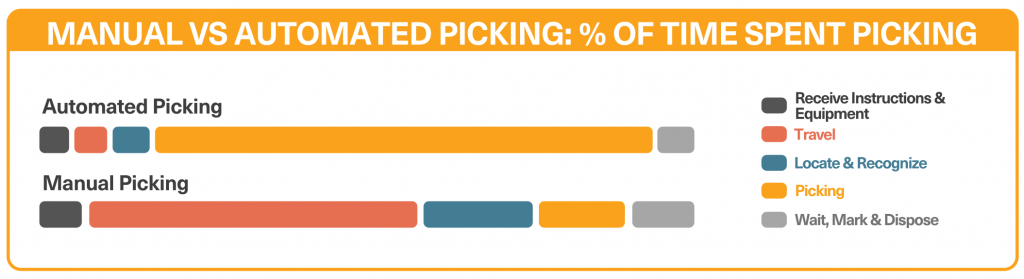

Picking Productivity

Picking productivity is a warehouse KPI that measures the number of order lines picked per hour.

By monitoring this KPI, you can better understand your picking efficiency and identify potential bottlenecks, such as the time it takes for warehouse operators to navigate aisles and pick items.

To calculate the picking productivity rate, divide the total number of order lines picked by a warehouse operator by the total labor hours spent on picking.

Modula’s automated picking systems enhance the picking process by saving time and labor and increasing accuracy and throughput. These systems use smart technology and user-friendly interfaces, along with sophisticated systems to ensure an efficient workflow.

Picking Accuracy

Picking accuracy is a warehouse KPI that measures the precision of picking the correct SKU.

By monitoring this KPI, you can identify picking issues that can cause mispicks. This can help you reduce costly product returns.

To calculate the picking accuracy percentage, divide the number of accurately fulfilled orders by the total number of orders. Then, multiply that number by 100.

At Modula, our picking solutions help your warehouse pickers find inventory faster and process both individual and bulk orders with better picking accuracy.

Labor and Equipment Utilization

Labor and equipment utilization is a warehouse KPI that measures how human resources and equipment in a warehouse is maximized.

By monitoring this KPI, you can effectively schedule and allocate resources, leading to reduced overtime costs and idle time and avoiding the need for excess equipment.

To calculate the percentage of your labor utilization, divide the total labor hours worked by the total available labor hours in the selected time period. Multiply the result by 100 to obtain the labor utilization percentage.

To calculate the percentage of your equipment utilization, divide the total equipment usage hours by the total available equipment hours in the selected time period. Multiply the result by 100 to obtain the equipment utilization percentage.

Picking Cycle Time

Picking cycle time is a warehouse KPI that measures the time it takes to complete the picking process for an order, from the moment the order is received to when it’s ready for shipment.

By monitoring this KPI, you can identify opportunities to improve the efficiency of your picking process. This allows you to reduce order processing time, increase throughput and meet customer expectations for faster order fulfillment.

To calculate the picking cycle time, record the start time when a warehouse operator begins picking an order and the end time of the picking process. Then, subtract the start time from the end time.

Warehouse KPIs to Track Distribution

Warehouse distribution is the process of managing and transporting inventory from the warehouse to its intended destination, such as retail stores, wholesalers or directly to customers. KPIs to measure performance in this area include:

Order Lead Time

Order lead time is a warehouse KPI that measures the amount of time that passes from when an order is received until it reaches the customer’s doorstep. This typically includes the time required for order processing, picking, packing and shipment.

By monitoring this KPI, you can provide valuable insights into your warehouse operations’ efficiency.

To calculate the order lead time, subtract the start time when an order is placed from the end time or when the order is fulfilled.

Perfect Order Rate

Perfect order rate is a warehouse KPI that measures the percentage of orders that are processed, picked, packed and delivered without any errors or delays. This typically includes criteria such as the correct items and quantities, proper packaging, timely delivery and correct documentation.

By monitoring this KPI, you can identify areas where mistakes or delays are occurring so you can implement preventive actions, such as training your employees on proper picking procedures and improving quality control measures.

To calculate the perfect order rate, divide the number of perfect orders by the total number of orders. Then, multiply it by 100.

Back Order Rate

The back order rate is a warehouse KPI that measures the percentage of orders that cannot be fulfilled at the time they are received due to stockouts, which can happen during unexpected spikes in demand.

By monitoring this KPI, you can gain insights into the frequency at which customer orders cannot be fulfilled because of inefficient stock levels.

This allows you to identify inventory management issues, optimize reorder points and improve supply chain planning to minimize backorders and enhance customer satisfaction.

To calculate the back order rate, divide the number of back-ordered units by the total number of units ordered.

With Modula’s Warehouse Management System (WMS), you can monitor the movement and location of products within your warehouse, while gaining complete visibility into your stock levels to meet seasonal demands and prevent stockouts.

Warehouse KPIs to Track Reverse Logistics

Reverse logistics is the process of managing the flow of goods from the customer back to the warehouse, due to product returns, repairs, recycling or disposal. KPIs to measure performance in this area include:

Return Rate

The return rate is a warehouse KPI that measures the percentage of shipped orders that customers return due to incorrect orders or product damage.

By monitoring this KPI, you can identify potential problems in the order fulfillment process, including picking, packing and shipping errors or issues with product quality.

To calculate the return rate, divide the number of returned orders by the total number of orders shipped over a specific period of time, then multiple by 100.

Return Processing Time

Return processing time is a warehouse KPI that measures the time that passes from when a returned product is received in the warehouse until it is processed and ready for resale or disposal.

By monitoring this KPI, you can identify inefficiencies in the returns process, such as improper storage location assignment or lack of proper tracking systems.

To calculate the return processing time, track the total time spent on processing returns during a specific period and divide it by the total number of returns processed in that same period.

Return Processing Cost

Return processing cost is a warehouse KPI that measures the total costs associated with processing returned items from customers.

Return processing costs include the direct costs of labor for inspecting, restocking or discarding items, as well as indirect costs like storage, administrative tasks and even the cost of refunding or replacing the item for the customer.

By monitoring this KPI, you can identify potential areas for cost savings in the returns process. This can include automating warehouse processes and implementing preventative measures, such as performing quality checks, to reduce the rate of returns.

To calculate the return processing cost, add the direct labor costs, additional labor-related expenses, transportation costs and overhead costs. Divide this sum by the total number of returns processed during a specific period.

Return Value

Return value is a warehouse KPI that measures the total cost of goods returned to the warehouse during a specific period.

By monitoring this KPI, you can gain insights into the financial impact of returned items and the efficiency of your return management process. This allows you to assess the profitability of returned products and make informed decisions about your inventory management.

To calculate the return value:

- Calculate the deductions associated with the return process. This can include restocking fees and shipping costs.

- Based on the condition of the returned item, estimate its resale value. This can be done by considering factors such as market demand and depreciation.

- Subtract any applicable fees or deductions from the resale value to calculate the return value.

Return Feedback

Return feedback is a warehouse KPI that measures the feedback provided by customers on returned products. By monitoring this KPI, you can identify recurring return issues.

For example, if your customers consistently mention a specific defect in a product, you can identify the root cause of the defect and take appropriate actions to address it (like working with suppliers or manufacturers to improve product quality).

To calculate the return feedback, conduct customer surveys after product returns and analyze the results.

Warehouse KPIs to Track Employee Safety

Warehouse safety prioritizes the physical and mental well-being of the employees, while ensuring that processes are performed according to safety guidelines and best practices. KPIs to measure performance in this area include:

Accidents Per Year

Accidents per year is a warehouse KPI that measures the number of incidents or near misses that occur in a warehouse each year. This can include minor incidents such as small cuts or scrapes, as well as major incidents like equipment accidents, falls or hazardous material spills.

By monitoring this KPI, you can gain insights into the safety conditions of your warehouse.

If the number of accidents is high, it can indicate the need for hands-on safety training regarding warehouse equipment and a more thorough enforcement of safety protocols in the warehouse.

To calculate the number of accidents per year, add all the accidents recorded in the year.

Time Since Last Accident

Time since last accident is a warehouse KPI that measures the duration since the last reported safety incident in the warehouse. This is usually measured in days, but it can also be measured in weeks or months.

A higher value for time since the last accident is ideal, as it indicates a safer working environment.

To calculate the time since the last accident, count the days between the current date and the date when the last accident occurred.

Time Lost Due to Injury Rate

Time lost due to injury rate is a warehouse KPI that measures the amount of work time lost due to injuries sustained within the warehouse.

A lower rate is ideal, as it suggests a safer working environment and less disruption to warehouse operations. Conversely, a higher rate can indicate potential safety issues within the warehouse.

To calculate the time lost due to injury rate, track the total number of work hours lost due to injuries during a certain period and divide it by the total number of work hours scheduled for that same period. Then, multiply it by 100.

Warehouse KPIs: Key Takeaways

Warehousing requires maintaining a bird’s eye view of your operation’s performance by predicting and monitoring supply chain KPIs related to receiving, inventory control and order fulfillment.

Neglecting to monitor essential KPIs can hinder the effective improvement and refinement of warehouse operations.

Key points to remember about warehouse KPIs include:

- Their essential role in assessing the efficiency and effectiveness of various warehouse processes.

- Accurately tracking warehouse KPIs can lead to significant improvements in operations, cost reductions and enhanced customer satisfaction.

- By regularly reviewing and adjusting based on these metrics, warehouse managers can proactively address challenges and optimize operational performance across the board.

Track Your Warehouse KPIs With Modula Automated Solutions

At Modula, our automated storage and retrieval systems improve employee safety by following the parts to picker’s principle, where our automated warehouse solutions deliver the goods to your warehouse operator’s location.

Our warehouse solutions can boost your warehouse’s organization, picking accuracy and productivity by making better use of space and enhancing productivity.

We offer both vertical and horizontal systems tailored to your space needs, business requirements and objectives.

We also provide warehouse management systems to help you gain complete visibility into your inventory, so you can prevent stockouts and optimal stock levels all year round.