Automated Storage Solutions for Automotive Parts Departments

From saving valuable floor space to securing parts and ensuring better inventory control, automated automotive storage solutions are an invaluable tool for automotive parts departments.

Our innovative solutions at Modula are designed to significantly improve efficiency, productivity and visibility across your organization — in terms of storage, organization and beyond.

We’ll discuss the five main challenges that automotive dealership parts departments are currently facing and the key benefits of automation, and exactly how Modula solutions can help.

5 Challenges for Automotive Parts Departments

In an automotive dealership, the Fixed Operations Department (Service, Parts, and Body Shop) is critical to the profitable operation of the dealership.

This department is responsible for vehicle maintenance and repair, replacement parts, and body repairs, which provides an ongoing source of revenue for the dealership.

In fact, nearly half of a dealership’s gross profits (49.6%) come from the service and parts department, according to the National Automobile Dealers Association (NADA). However, managing the inventory of the Fixed Operations Department presents several challenges:

1. Inventory Management

With thousands of parts for various makes and models, tracking inventory and ensuring that the right parts are available can be daunting.

As new models are introduced, dealerships must also be prepared to stock new parts and train technicians to repair the latest technology.

2. Increased Demand for Parts

As the average age of vehicles on the road increases, there is a growing demand for repair and maintenance services, adding more pressure on automotive parts departments.

To meet this demand, dealerships must have an extensive inventory of parts available, which can be a significant challenge to manage.

3. Shortages of Parts

Shortages of parts due to supply chain disruptions, backorders, or other factors can lead to lost sales and decreased customer satisfaction.

Dealerships must have strategies in place to manage these shortages and ensure that they can provide customers with the parts they need in a timely and efficient manner.

4. Space Limitations

With limited space in automotive parts departments, dealerships must find innovative ways to store and organize their inventory to maximize space and improve efficiency

5. Protection and Storage of Costly and Delicate Parts

Parts such as engines, transmissions and electronic components can be costly and require careful handling to avoid damage.

In addition, these parts may be sensitive to temperature, humidity, and other environmental factors, which can further complicate their storage and handling.

Benefits of Automated Automotive Storage Solutions

From optimizing floor space to streamlining inventory management, here are the key benefits of automated storage solutions for automotive parts departments:

Modula Automated Storage Solutions for Automotive Parts Departments

As a pioneer in the manufacturing industry, our automated storage solutions are built to help you optimize space, improve picking accuracy, gain inventory visibility, boost productivity and more across your parts department.

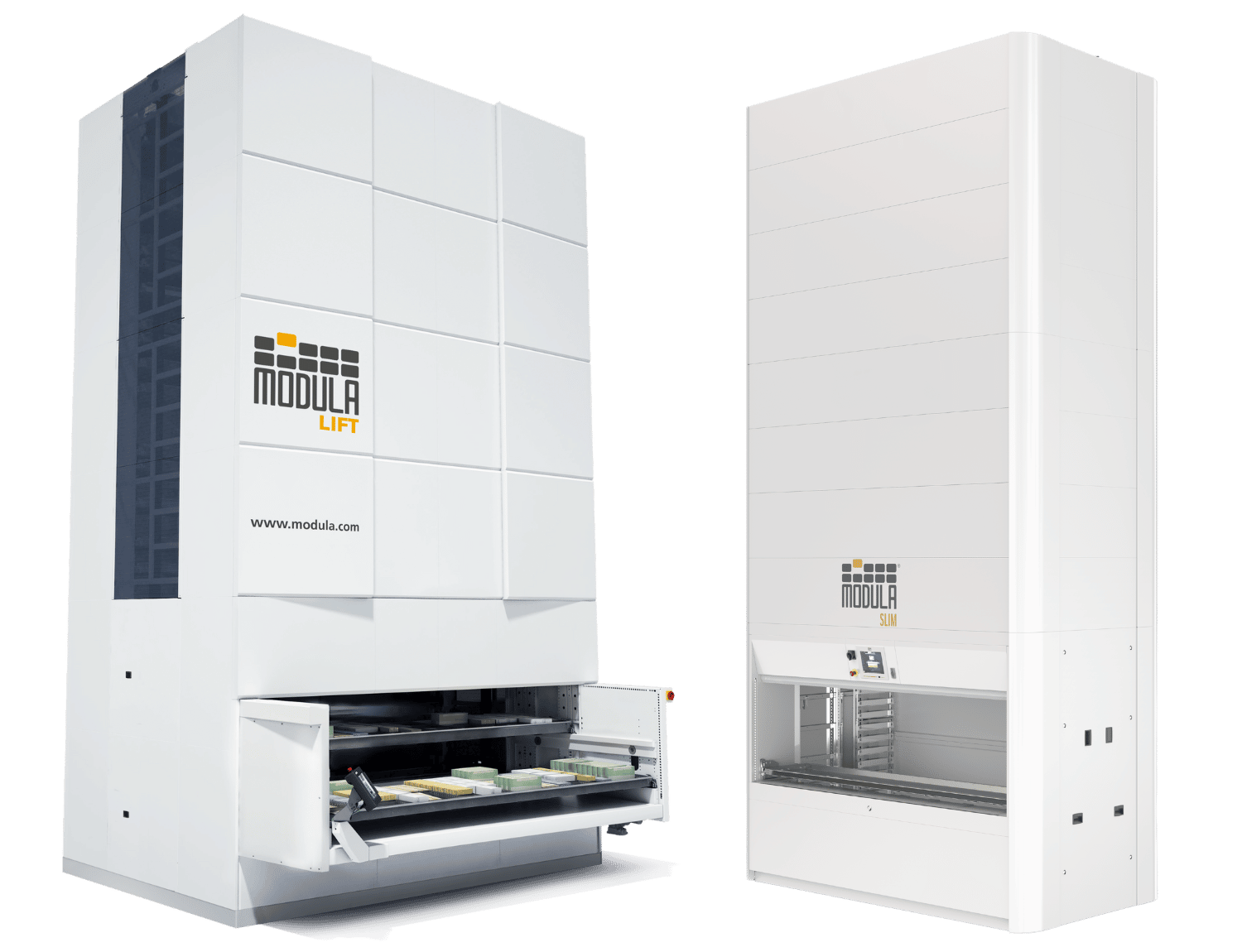

1. Modula Vertical Lift Modules

Modula vertical solutions can reduce space requirements by up to 90%. Our VLMs — Modula Lift and Modula Slim — are fully automated vertical storage solutions that utilize minimal floor space by taking advantage of high ceilings.

Modula VLMs allow you to:

- Process more orders in less time with a throughput of up to 140 trays per hour

- Manage inventory security with a reliable locking and validation feature

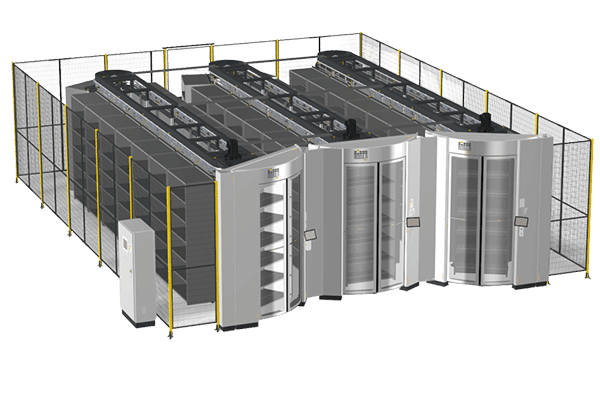

2. Modula Horizontal Carousels

Experience high-speed picking where ceiling height is limited with our horizontal carousel (HC).

The Modula HC allows you to:

- Ensure high-speed picking in a low-ceiling environment

- Gain better productivity thanks to picking rates of up to 550 lines per hour

- Adjust shelf spacing to store different products

- Achieve full traceability of orders and stock levels

3. Controlled Environment Storage Solutions

Modula Climate Control and Modula Clean Room allow you to secure temperate-sensitive car parts in controlled environment storage solution.

Modula Climate Control

Modula Climate Control helps you protect your inventory from temperature fluctuations that can cause corrosion and oxidation.

Modula Climate Control allows you to:

- Control temperature from +2°C to +25°C (+35 °F to +77°F)

- Control relative humidity ≥ 5%

- Access stored inventory with a thermal break panel that can be independently opened outwards

Modula Clean Room

Retain your auto parts’ performance by keeping them dirt- and dust-free with the Modula Clean Room.

Modula Clean Room allows you to:

- Reduce air particles within your storage room to prevent oxidation and corrosion

- Get access to clean room classifications ranging from 6 to 8

- Reduce exposure to contaminants, including dust, dirt, and other debris

- Access your inventory with dual openings

- Comply with ISO 14644-1 standard

- Implement the same advanced technology to all Modula lift modules

4. Modula Order Picking Solutions

Boost order picking accuracy and improve warehousing efficiency with our intuitive picking solutions.

Modula Order Picking Solutions allow you to:

- Boost picking speed by reducing search time

- Provide accurate current and forecast inventory with paperless picking solutions

- Improve picking accuracy with put to light and pick to light devices

- Increase worker satisfaction through computer-aided, easy to understand solutions

5. Modula Software Integrations

In addition, vertical storage systems feature a color touch screen controller that interfaces with most Dealer Management Systems (DMS).

This allows orders to be automatically sent directly from the DMS to the storage unit.

Personnel is no longer required to manually enter order information from parts invoices. This results in a decrease in staffing for the parts department.

Current data exchange partners utilizing the Automotive Package include: CDK Global, Reynolds & Reynolds, Dealertrack Technologies and Karmak.

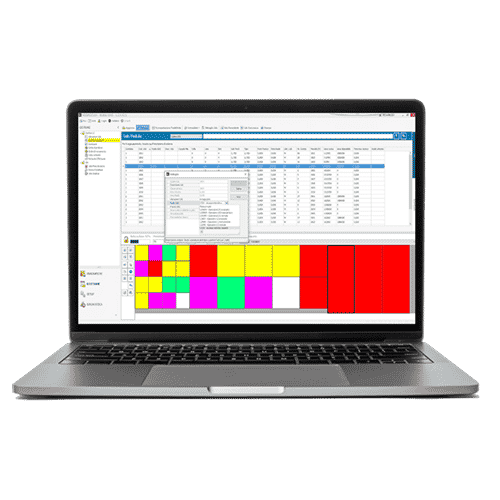

6. Warehouse Management System

Connect warehouse operations with your DMS to monitor inventory levels in real-time.

The Modula Warehouse Management System (WMS) is one of the most advanced and intuitive solutions on the market. From receiving to shipping, gain full visibility into your inventory.

Modula WMS allows you to:

- Monitor stock levels

- Track the location and movement of your inventory

- Track your employee’s activity and set access levels and permissions

- Monitor system performance for predictive maintenance

- Connect and share insights with other systems within your warehouse

- Complete integration with your DMS or ERP system to allow automatic syncing

Modula Case Studies in the Automotive Industry

From car dealerships to commercial vehicle manufacturers, our automated storage solutions allow automotive companies to maximize floor space and ensure inventory is safe.

Here’s a look at how our solutions have helped two automotive companies:

1. Walser Subaru

Walser Subaru is a car dealership and parts/service facility, based in Burnsville MN.

The challenge:

Due to a company expansion, Walser Subaru needed more storage and security for their auto parts. In addition, the company was experiencing picking inefficiencies in the order fulfillment process.

The solution:

Walser Subaru installed two 20-foot Modula VLMs, which were perfect for their warehouse’s high ceilings. With just these two VLMs, the company was able to store more than 75% of all their car parts, protecting the parts with security features while making them accessible for picking.

They also integrated the Modula WMS with their CDK Global Dealer Management System for seamless inventory control.

Walser Subaru is storing over 75% of all their inventory within the two Modula VLM MC25Ds

2. Ford Motor Company

Needing little introduction, Ford Motor Company is a renowned automobile company in the United States, assembling over 1 million vehicles per year.

The challenge:

Ford needed to create buffer storage for different car parts when production lines were temporarily halted.

The solution:

Ford acquired three Modula Lift modules to complement the automated solutions at their plant in Almussafes, Spain.

The Modula VLMs were able to place parts aside for later retrieval when the production line stalled, and deliver parts as needed throughout the manufacturing process.

Integrated with anthropomorphic robot arms and Modula’s WMS, the VLMs enabled the company to run on a six-day-a-week continuous cycle, producing 17,250 engines a week.

Modula VLMs also allowed Ford to optimize floor space, with 260 engine blocks stored in 14 square meters of warehouse space.

Modula realizes a fully Automated Warehouse Solution for Ford Motor Company

At Modula, we can help you save space, keep your automotive parts secure, provide better inventory control and more — all with the goal of increasing efficiency and profitability across your automotive parts department.

Contact our team at Modula to schedule an audit and find out how our automated solutions can benefit your automotive business, from storage to productivity and ultimately, your bottom line.