Warehouse Technology for Beginners: Top 12 Automated Solutions

Warehouse technology is the solution to the many challenges within the warehousing industry, such as inefficient space utilization, cumbersome processes, inventory issues and workplace safety concerns.

In this blog, we’ll explore the top 12 warehouse technologies, explain how they work and share the key benefits of utilizing these innovations in your warehouse operations.

Plus, we’ll introduce you to our top-rated automated warehouse solutions at Modula that can help you reimagine your order fulfillment process, optimize storage space and boost productivity across your warehouse.

What Is Warehouse Technology?

Warehouse technology is a term that refers to a variety of advanced systems and equipment used in warehousing facilities to boost productivity and efficiency.

Warehouse technologies help optimize different warehouse processes, such as receiving and storage, inventory management, picking, packing and more.

Top 12 Warehouse Technologies [+ Modula Solutions]

New warehouse technologies are revolutionizing operations within warehouses across the globe. From mobile robots and drones to warehouse management systems, these innovative tools are driving efficiency, productivity and accuracy in the warehouse.

Warehouse Management Systems

Warehouse Management Systems (WMS) are scalable software solutions that manage and control the day-to-day operations in a warehouse.

WMS enables the centralized management of tasks such as tracking inventory levels and monitoring stock locations and movement.

The Modula WMS is a comprehensive software used for managing inventory, tracking stock levels in real time, monitoring product movement and more. It can manage your automated storage and retrieval systems or act independently in traditional, manual warehouses.

Assisted Picking Tools

Assisted picking tools, also known as pick assist technologies, are a type of warehouse technology that helps warehouse employees find and pick the correct SKUs in the correct quantities for each order.

Assisted picking tools include pick-to-light systems, voice picking tools and automated picking robots.

These warehouse technologies reduce picking errors and increase warehouse efficiency.

At Modula, our order-picking solutions are easy to install and operate. They’re designed to boost picking efficiency and accuracy across your warehouse.

Mobile Robots (AGVs and AMRs)

Automatic guided vehicles (AGVs) are sensor-driven, computer-controlled robots that transport goods within the warehouse. They follow pre-set paths using wires and reflective markers, reducing the need for manual material handling.

On the other hand, autonomous mobile robots (AMRs), are more sophisticated robots that can operate in dynamic environments without the need for fixed tracks or infrastructure. AMRs utilize artificial intelligence and sensors, operating independently without human supervision.

While AGVs and AMRs both transport inventory, AMRs are more advanced robots as they can navigate the warehouse without relying on pre-determined paths.

Warehouse Drones

Warehouse drones, or unmanned aerial vehicles (UAVs), are aerial robots that can perform various tasks in the warehouse, such as inventory management, goods transportation, monitoring, and facility maintenance.

Equipped with cameras and sensors, warehouse drones can help collect inventory data, such as inventory location and stock levels. They can be manually controlled by operators or programmed to navigate autonomously, depending on the specific requirements of the task at hand.

Automated Storage and Retrieval Systems (ASRS)

Automated storage and retrieval systems (ASRS) are computer-controlled technologies that store, organize and retrieve goods in the warehouse.

This warehouse technology includes innovations such as vertical lift modules, horizontal carousels, unit-loaders, mini-loaders and tote shuffles.

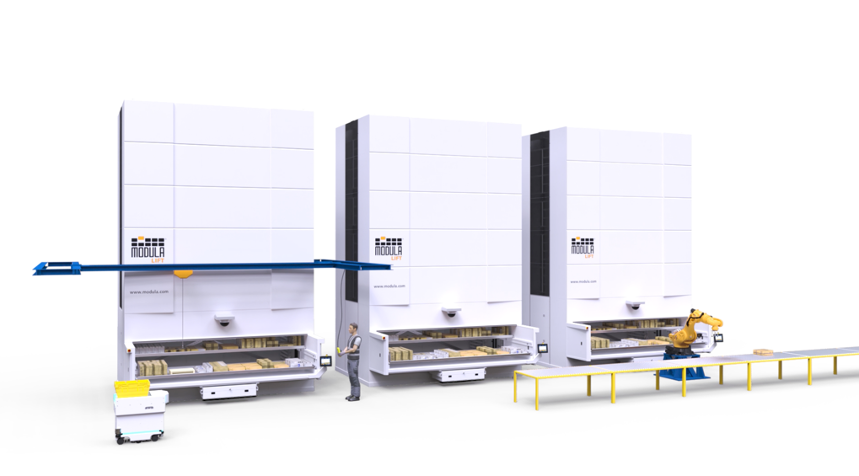

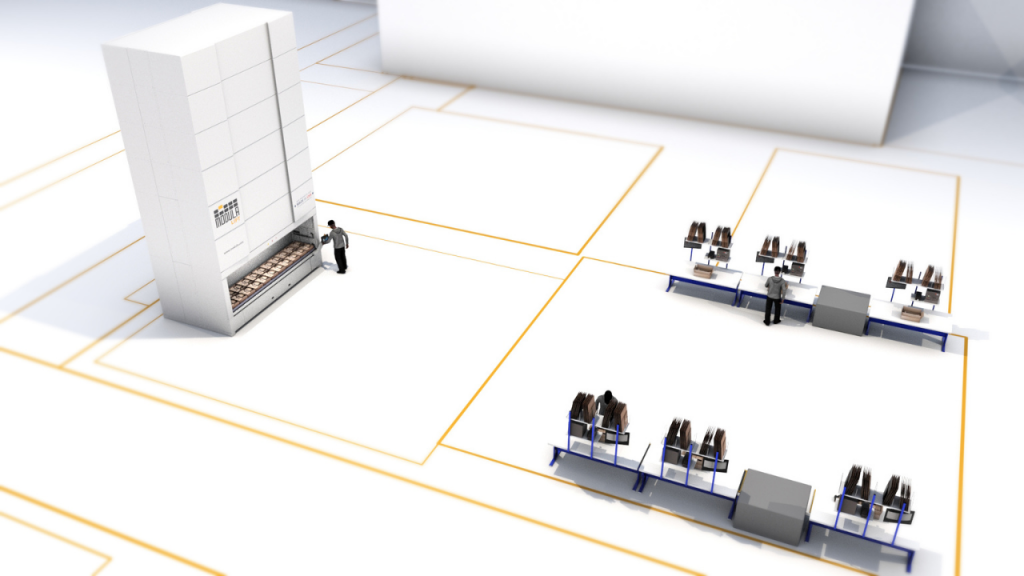

At Modula, our automated storage and retrieval systems reimagine your warehouse operations by maximizing your existing warehouse space, safely storing your inventory and automatically retrieving goods to eliminate the need for your warehouse operators to reach high and low areas.

Modula ASRS include vertical lift modules for warehouses with high ceilings and horizontal carousels for environments with low ceilings.

Predictive Analytics

Predictive analytics uses historical data, statistical algorithms and machine learning techniques to identify the likelihood of future outcomes.

Here’s how predictive analytics can be applied in your warehouse:

- Inventory management: Predictive analytics can be used to forecast demand for different products, helping warehouses manage their inventory more efficiently and prevent overstock or stockouts.

- Preventive maintenance: By monitoring usage data from warehouse equipment, analytics can help schedule timely maintenance based on predefined thresholds or operating hours. This approach reduces unplanned downtime and keeps systems running reliably.

- Demand forecasting: Predictive analytics can provide insight into future sales trends, helping you plan for peak seasons and manage resources accordingly.

The Modula Web Analytics gathers statistical data from all of your automated storage and retrieval systems, regardless of their location. The always-on platform captures all data and presents it in a user-friendly online portal, allowing you to monitor and manage operations from any device, anywhere in the world.

Internet of Things (IoT)

Internet of Things (IoT) devices help track inventory and oversee equipment conditions, including temperature.

IoT devices include wearables, RFID tags, and sensors. Wearables, for example, include smart gloves that are equipped with sensors to capture and transmit data about manual handling activities.

They can track hand movements and grip strength when your warehouse operators carry inventory, allowing them to identify potential ergonomic issues.

On the other hand, RFID tags and smart sensors are attached to inventory to track their location, reducing misplacement.

In addition, IoT devices allow real-time monitoring of warehouse equipment so you can schedule predictive maintenance and reduce the likelihood of costly downtime.

Artificial Intelligence (AI) and Machine Learning (ML)

Artificial intelligence (AI) involves the development of systems or machines that can perform tasks that typically require human intelligence. In warehouse operations, AI can enable robots or computers to perform tasks such as transporting, picking and packing items.

By preventing mispicks, monitoring inventory and packing orders, AI can help reduce costly product returns and enhance warehouse efficiency and accuracy with minimal human help.

On the other hand, machine learning (ML), a subset of AI, allows machines to learn from data and improve their performance over time.

They analyze data to identify patterns and make informed decisions or forecasts, requiring little human input. As ML algorithms process more data over time, they adapt and improve their performance, increasing their accuracy.

3D Bin Packing

3D bin packing technology is an algorithmic approach used for packing inventory into boxes or bins, taking into consideration the three-dimensional size of both the items and their packaging to optimize space.

3D bin packing can also be integrated with your WMS, Enterprise Resource Planning (ERP) Systems and Transport Management Systems (TMS) to further automate the packing process.

This technology ensures that the smallest possible boxes are used for shipping, reducing packaging costs and minimizing your warehouse’s carbon dioxide footprint.

Automated Document Insertion

Automated document insertion utilizes automated systems that place documents such as packing slips, invoices, return forms promotional materials into packages.

This technology is programmed to match the correct document with its package, based on details such as the order number or the customer’s information.

This type of warehouse technology improves productivity and efficiency, so your warehouse operators can focus on more pressing tasks that require human intervention.

Inventory Scanning Technology

Inventory scanning technology is used to electronically track and manage inventory details, such as stock levels and item location.

Types of inventory scanning technology include:

- Barcode scanners: This is the most common type of inventory scanning technology. Goods are equipped with barcodes that can be scanned to quickly identify the SKU.

- RFID scanners: Radio Frequency Identification (RFID) utilizes electromagnetic fields to automatically identify SKUs and track tags attached to products.

- Mobile scanners or handheld terminals: These portable devices combine a barcode scanner or RFID reader with a mobile computer. They allow your warehouse employees to scan items and update inventory records on the go.

Blockchain Technology

Blockchain technology is used in supply chain and logistics operations. The blockchain is a decentralized digital ledger, where transactions are recorded in a way that’s transparent, secure, and unalterable.

Here’s how blockchain can benefit your warehouse operations:

- Traceability: Blockchain provides complete visibility and traceability of inventory as it moves through the supply chain, from the point of origin to the customer’s doorstep.

- Inventory management: Every transaction related to the inventory, whether it’s incoming or outgoing, can be logged in the blockchain, allowing for accurate inventory management.

- Auditability: The unchangeable nature of blockchain records makes auditing processes more transparent. Blockchain can easily provide proof of where a product was at a certain time, who handled it and where it was delivered.

- Smart contracts: Blockchain can be used to create smart contracts, which are automated contracts with self-executing terms. This can help automate certain warehouse processes, like making payments once conditions in the contract have been fulfilled.

- Reduce paperwork: Since blockchain records are digital and automatically updated, they can significantly reduce the paperwork and manual record-keeping typically associated with warehouse operations.

How To Implement Warehousing Technology

The benefits of automation in warehousing include increased productivity and accuracy, cost savings and more.

Here’s a step-by-step process on how to implement smart technology into your warehouse:

- Identify your warehousing needs: Do you need to speed up order processing? Do you need to track inventory more accurately? Do you need to reduce mispicks? Once you define your needs, research technology designed to address those specific issues.

- Choose the technology: Identify which warehouse technologies will solve your current issues, whether warehouse management system (WMS), automated storage and retrieval systems (ASRS), radio frequency identification (RFID) tags, barcode scanners or autonomous mobile robots (AMRs).

- Develop an implementation plan: Include your project objectives, timeline, resource allocation, budget, risk assessment, and communication strategy.

- Train your staff: Train your staff on how to use the new technologies by conducting training sessions and creating user manuals that serve as how-to guides.

- Implement a pilot run: Instead of going full scale from the get-go, consider conducting a pilot implementation in a specific area of your warehouse so you can troubleshoot problems and make necessary adjustments before rolling out the plan completely.

- Monitor and assess: After conducting your pilot testing, continuously monitor the performance of the new technology and evaluate its impact on your processes to help you identify any additional training that might be needed.

- Perform improvements: Based on your evaluations, make the necessary adjustments to optimize the use of technology within your warehouse.

Benefits of Warehouse Technology

Warehouse technology provides a wide range of benefits that can improve overall operations, leading to a more efficient and safer work environment.

Key benefits of implementing warehousing technologies include:

Warehouse Technology at Modula

As one of the leading pioneers in advanced storage solutions and warehouse management systems, we specialize in automated warehouse solutions that help you save warehouse space, boost picking accuracy and efficiency and improve worker safety.

We help improve the internal logistics of all warehouses of all sizes and across industries, with a commitment to innovation that is evident in our high-tech manufacturing standards, allowing us to deliver valuable solutions to our global customers.

Our warehouse technologies at Modula include:

- Vertical lift modules

- Horizontal carousels

- Order picking solutions

- Warehouse management system

- Modula Cloud platform

Key Takeaways on Warehouse Technology

Warehouse technology is transforming the industry by revolutionizing how inventory is managed, how space is utilized and how employees work.

Overall, warehouse technology is transforming warehouses into more efficient, data-driven, and adaptable operations, driving improved productivity, cost savings, and customer satisfaction