Warehouse Organization Ideas: From Quick & Easy Fixes To Structural Upgrades

The rapid expansion of eCommerce has significantly increased the demand for warehouse space.

By 2025, US businesses will require an additional 330 million square feet of warehouse space to accommodate this growth.

Warehouse managers must invest in smart warehousing technologies and advanced storage solutions to manage larger inventories effectively.

Here are 10 organizational strategies for warehouses, ranging from simple fixes to major structural changes, that can save up to 90% of your existing space.

Why Invest In Warehouse Organization? 3 Scientific Reasons

Numerous studies have confirmed the correlation between our physical and mental wellbeing and our living or working environment.

Let’s look at the research and case studies that show how issues in warehouse organization affect employee satisfaction, productivity, and consequently, revenue.

Employee Satisfaction

A review published by Public Health England showed that a disorganized physical environment hinders creativity and can lead to job dissatisfaction.

The same review found that improving your employees’ physical environment can even reflect on your employer brand. In their case study, they write:

“[The company] reported that they made better use of the workspace which reduced costs and generally raised the brand image.”

Besides motivation, well-organized warehouses are safer as they reduce the risk of workplace injury.

Better warehouse organization improves your employees’ safety and motivation, lowers your turnover rates and even increases the chances of attracting top talent.

Productivity

Princeton University Neuroscience Institute conducted a study to demonstrate how clutter influences the ability to concentrate and process information.

The research showed that clutter overburdens the brain with stimuli and distracts attention from the task at hand.

Another study conducted by the National Institute of Mental Health used functional Magnetic Resonance Imaging to examine the effects of visual clutter on brain function.

Research has shown that disorganized spaces can diminish brain responsiveness and performance. How does this impact employee productivity?

Employees working in cluttered spaces are more likely to make mistakes, work more slowly and tire quickly, all of which directly reduce productivity.

Return on Investment (ROI)

While some warehouse organization ideas and solutions may take a substantial amount of effort or investment to implement, they are likely to more than make up for it by sealing the above-listed revenue leaks and increasing efficiency.

Investing in a healthy and safe warehouse environment as well as employee satisfaction pays off, often in a few months.

How To Organize A Warehouse

Once you identify your reasons to improve your warehouse organization, it is time to act. To determine the scale of the work ahead and the steps to take:

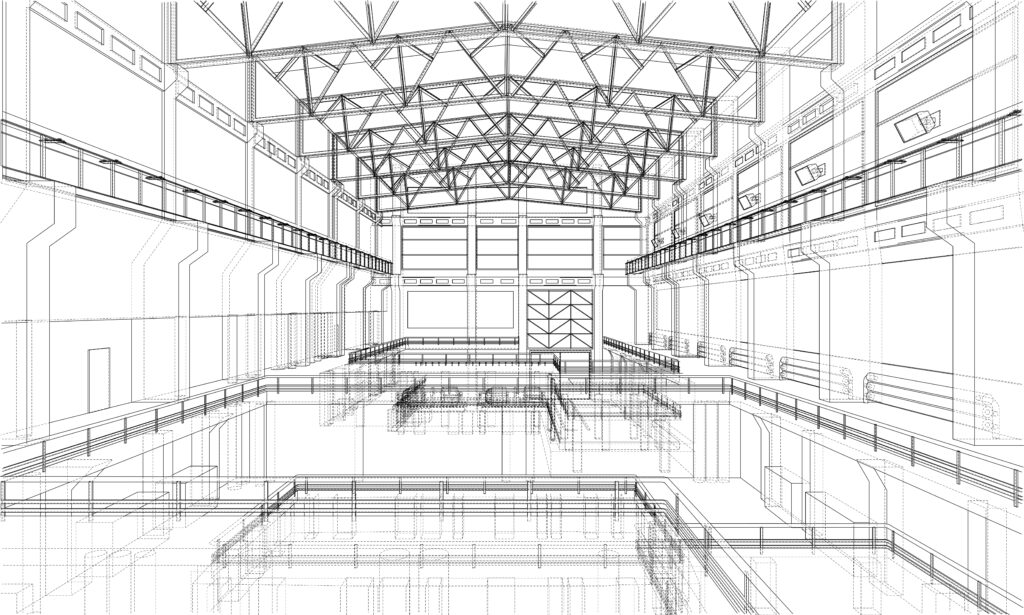

Study Your Floor Plans

Evaluate the space you have against the space you need. Is clutter the result of special constraints or utilization?

Also consider the flow among your rooms, including hallways and all the nooks and crannies.

Your goal is to guide the people and the goods seamlessly through their stations, so try to identify any obstacles to their movements, or possible segmentations to reduce collisions.

Think Horizontally And Vertically

To maximize the utilization of available space, observe your warehouse horizontally and vertically.

- Do you have any dead corners or empty slots?

- Are your shelves wide and tall enough to accommodate the items without excessive empty space?

- Do your shelves run up to the ceiling or stop mid-way?

- If you were to run your shelves all the way up, what type of assistance would your employees require to handle the top-shelves?

- What kinds of goods would be able to store there (maximum weight capacity)?

Interview Your Teams

Your employees are the best source of warehouse optimization insights. Ask them to identify their pain points as well as share ideas for improvement.

Visit Other Warehouses

Learn from your peers and competitors. From the most advanced warehouse organization technology to small hacks, your peers can provide a wealth of ideas and inspiration.

Consult Experts

Modula has been a global leader in developing innovative warehouse organization solutions. Our experts are here to provide guidance and solutions to your storage requirements.

10 Easy-To-Implement Warehouse Organization Tips For Quick Gains

If you need quick and easy fixes to organize your warehouse space, here are 10 tips to get you started.

Assign Container Types To Categorize Inventory

Delegate container types to help your warehouse employees classify inventory, gain real-time visibility into your stock and expedite retrieval and restocking processes.

Assign container types by arranging inventory in appropriately sized and material-specific boxes or containers. Additionally, choose waterproof storage if necessary.

For example, for bulk items like grains or powders, utilize sturdy, airtight containers that protect against both moisture and pests.

Develop a Detailed Labeling System

Develop a comprehensive labeling framework to instantly identify each item’s SKU.

To do this, include the product name, quantity and the expiration date (if applicable) on each box or container. You can also implement barcoding to track stored goods.

Create a Shelving Hierarchy

Designing a structured racking layout in your warehouse can help maximize space, enhance workflow efficiency and reduce retrieval times, increasing overall productivity and safety.

To create a shelving hierarchy, place frequently used packages and supplies within easy reach. This eliminates the need for bending or stretching. In addition, position low-demand items further back in your shelving plan.

Amplify Warehouse Organization and Employee Safety With Signage

Enhance warehouse organization and safety with clear signage to help employees quickly locate items and follow safety protocols.

Implement both paper and electronic signs, similar to those in large retail stores, to guide teams to the correct aisles and stations in large warehouse spaces.

You can also use signage to highlight potential hazards, such as slippery floors and obscured stairs.

Hand Out Maps

Distribute maps to help your staff efficiently navigate the premises. Draw inspiration from large shopping malls that use welcome boards with floor plans to locate specific stores.

Place maps at each unit’s entry point and email PDF versions to your workforce to minimize productivity loss caused by employees getting lost.

Ensure Warehouse Organization Is Every Team Member’s Responsibility

Make warehouse organization a collective responsibility. Conduct regular training sessions to remind employees, especially new hires, of the importance of maintaining an organized space.

Emphasize the benefits, including enhanced safety, a healthier work environment and increased job satisfaction, to encourage consistent participation and foster a culture of accountability.

Run Regular Warehouse Organization Audits

Conduct regular warehouse organization audits to improve inventory accuracy, space utilization, workflow efficiency and safety compliance.

Schedule these audits monthly or quarterly, assign task owners and interview employees to further understand operational challenges and identify areas that need improvement.

Implement a Coherent Receiving Process

Are boxes piling up at your facility’s receiving door? Then it’s time to review your receiving process.

Treat incoming inventory with the same importance as outgoing shipments. Assign an employee to manage the receiving process. They should confirm the accuracy and condition of shipments, then quickly store the items in your clearly labeled storage system.

Adopt a Warehouse Management System (WMS)

Implement a warehouse management system to elevate your warehouse efficiency.

A WMS enables warehouse operators to classify and slot inventory, choose appropriate storage methods and track inventory movement.

Keep Aisles Clear

Maintain clear pathways for moving vehicles, like forklifts, to ensure employee safety.

Optimize aisle space for quick navigation without wasting valuable floor space. This reduces clutter and facilitates easier access to stored SKUs.

Structural Warehouse Ideas For Long-Term, Big Gains

To see real change in your warehousing efficiency, you will want to think beyond labeling and maps. Human error and long lead times are some of the largest setbacks in operating large-scale warehouses – ones that storage automation resolves.

In this section, we look at two of Modula’s storage solutions that have helped companies like Audi, Biotec, and Dassault Falcon Jet improve their warehouse organization by

- Eliminate the need for forklifts and weight zeroes

- Maintaining specific temperature ranges

- Browsing 20,000 items to help the operator find just the one they were looking for in one click

Vertical Lift Modules

Modula Lift, for example, can use every inch of a warehouse’s height to optimize space utilization.

The internal trays with a capacity of up to 2,200 lbs keep your goods or spare parts safe from damage or theft and are easily accessible at one click of a button, eliminating the need for expensive gear and strenuous physical effort.

A motorized central elevator moves the tray with the desired items and delivers them to the operator at an ergonomic height while your warehouse stays orderly and clean from piled-up boxes and papers.

Vertical storage systems have numerous advantages. They allow you to save up to 90% of your warehouse floor space.

In other words: you can move into smaller warehouses or nearly double your current capacity.

Moreover, the Modula Lift can store virtually any type of products or parts in different sizes, weights, heights, and volumes. Thanks to the simple inventory management software and the visual picking aids, operators can quickly and easily identify the items needed, dramatically reducing picking errors.

For facilities with smaller footprints, you can rely on the Modula Slim.

The Modula Slim is the industry’s most compact VLM, taking up only 32.29 square feet and with a depth of less than 66 inches. It comes on a pre-assembled base module for quick shipping and can be installed in your facility within 48 hours, easily integrating with your existing inventory management systems.

Horizontal Storage Solutions

Another warehouse organization idea is to implement a horizontal carousel system.

Modula Horizontal Carousel, for example, is suitable for distribution and production areas which include intensive picking or when the ceiling height is insufficient for vertical storage solutions.

Designed to be extremely ergonomic, the Horizontal Carousels can be used in areas with architectural issues and complex geometry. It operates on horizontal rotation; as the operator “calls” a specific item, the carousel locates and rotates it from the depth of its shelf onto the surface.

Horizontal Carousels can be arranged in groups of up to four; as the operator picks the items from one of them, the others move and prepare the subsequent series of items, allowing up to 550 withdrawals per hour per station.

The automated warehouse solutions are completed with Warehouse Software Solutions which operates in real-time and comes with a user-friendly PC interface.

Warehouse processes can be fast, easy and even fun – to the benefit of all: clients, employees and business owners alike!

Recap On Warehouse Organization Ideas

Warehouse organization can do wonders for your productivity, workplace safety, employer brand, and employee turnover.

- Easy, small-scale organizational fixes will bring quick gains in productivity. However, these are only as sustainable as they consistent.

- Structural upgrades such as automated storage systems result in large, long-term gains. While costly, they are sustainable and a nearly bullet-proof solution to your warehouse organization needs.

Find the right warehouse storage solution for your business!