Upgrading Public Transportation with the Bipartisan Infrastructure Plan: How Modula ASRS Fit In

The recent passage of the Bipartisan Infrastructure Law isn’t just good news for the nation’s roads and bridges — it’s a game-changer for public transportation.

With $505 billion specifically allocated to create and upgrade facilities and infrastructures, transit authorities across the United States can now modernize their systems, improve efficiency and enhance accessibility.

In this article, we’ll cover how Modula’s automated storage and retrieval solutions (ASRS) can help transit authorities capitalize on this opportunity and effectively tackle their operational challenges.

The Bipartisan Infrastructure Law Explained

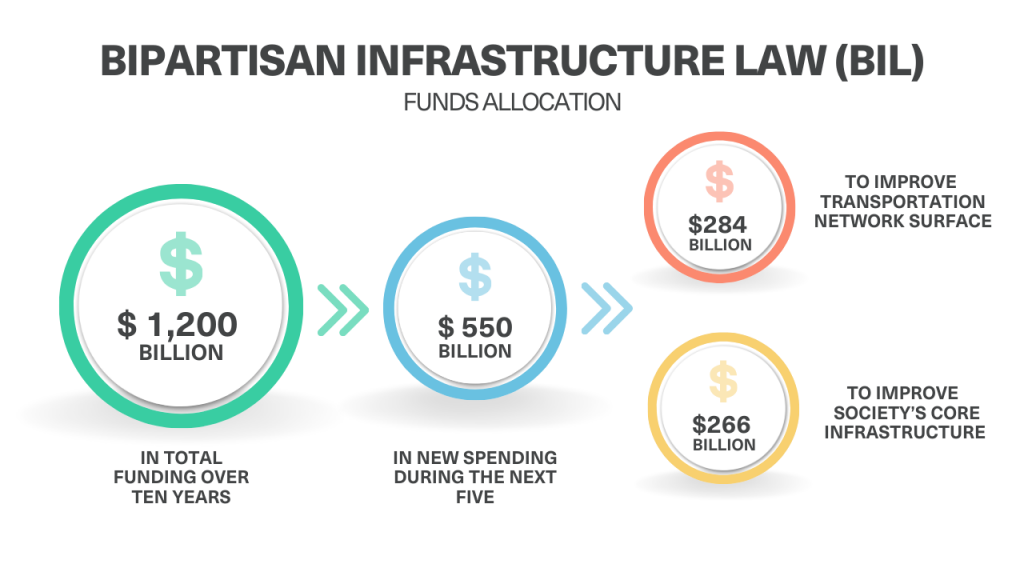

The Bipartisan Infrastructure Law (BIL), officially known as the Infrastructure Investment and Jobs Act (IIJA), is a U.S. infrastructure bill that aims to significantly revitalize and modernize the nation’s infrastructure.

Signed into law on November 15, 2021, The Bipartisan Infrastructure Law allocates approximately $1.2 trillion in funds, with a substantial portion dedicated to transportation infrastructure, including public transit, roads, bridges, rail systems, and more.

The BIL stands as one of the most significant investments in American infrastructure in decades, with a focus on upgrading and repairing existing infrastructure and laying the groundwork for future innovations and improvements.

The Bipartisan Infrastructure Law – Priority Investments

The Bipartisan Infrastructure Law designates funding for a comprehensive array of sectors with a particular focus on two principal categories:

- Core Infrastructure — Focused on critical foundational elements, this category covers upgrades to the power grid, expansion of broadband internet access, improvements to water supply systems, and efforts in environmental resilience and remediation. These investments are essential for modernizing and securing the infrastructure that supports daily life and economic activity.

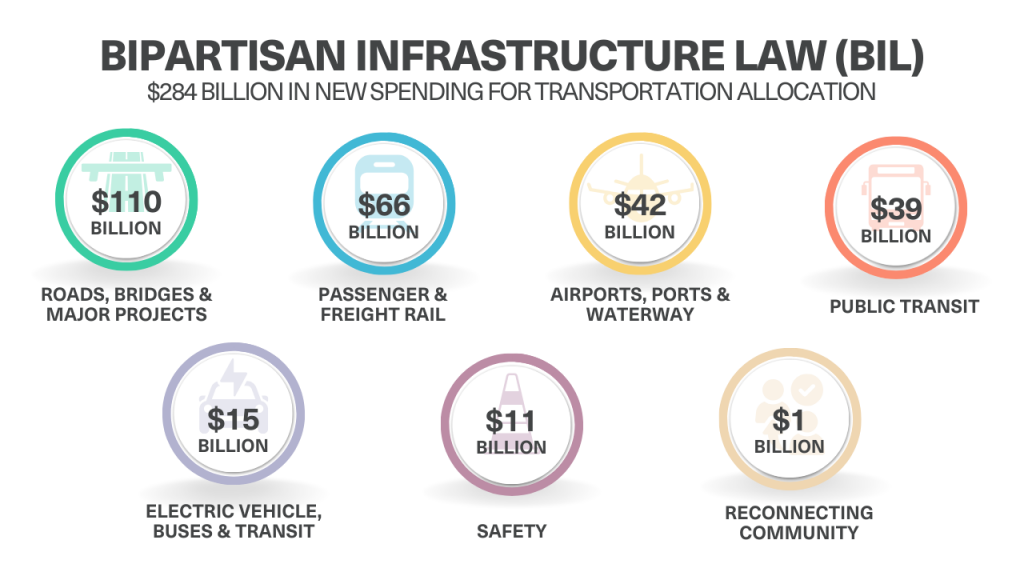

- Transportation Infrastructure — This category involves significant enhancements across various sectors. It includes upgrading roads and bridges, modernizing passenger and freight rail systems, and improving airports, ports, and waterways. Additional investments support public transit expansions, the development of electric vehicle infrastructure, initiatives aimed at transportation safety, and projects that reconnect communities. The infographic below details how the $284 billion allocated for new transportation spending is distributed among these diverse categories.

Navigating Challenges: The Road Ahead for Transit Agencies

Addressing Space Constraints and Operational Inefficiencies

One primary challenge for transit authorities is limited space, especially in urban areas, as cities are densely populated with buildings, roads and other structures.

From the construction and expansion of facilities to the efficient operation and storage of vehicles and equipment, this constraint impacts various aspects of the public transportation infrastructure.

Expanding facilities is often expensive and impractical. In urban areas, the cost of land can be prohibitively high, making expansion projects too pricey and sometimes unfeasible.

This financial barrier can prevent necessary upgrades and expansions that would otherwise support increased capacity and improved services.

In addition to the high costs of acquiring land, urban areas also face the challenge of complex zoning laws and regulatory hurdles, which can significantly hold up or even prevent the development of new infrastructure.

With limited space, efficiently organizing and storing buses, trains and maintenance equipment can become a challenge. This can lead to delays in maintenance operations, slower response times for repairs, and ultimately, more downtime for vehicles that could be serving passengers.

Scaling Efficiency with Modula ASRS

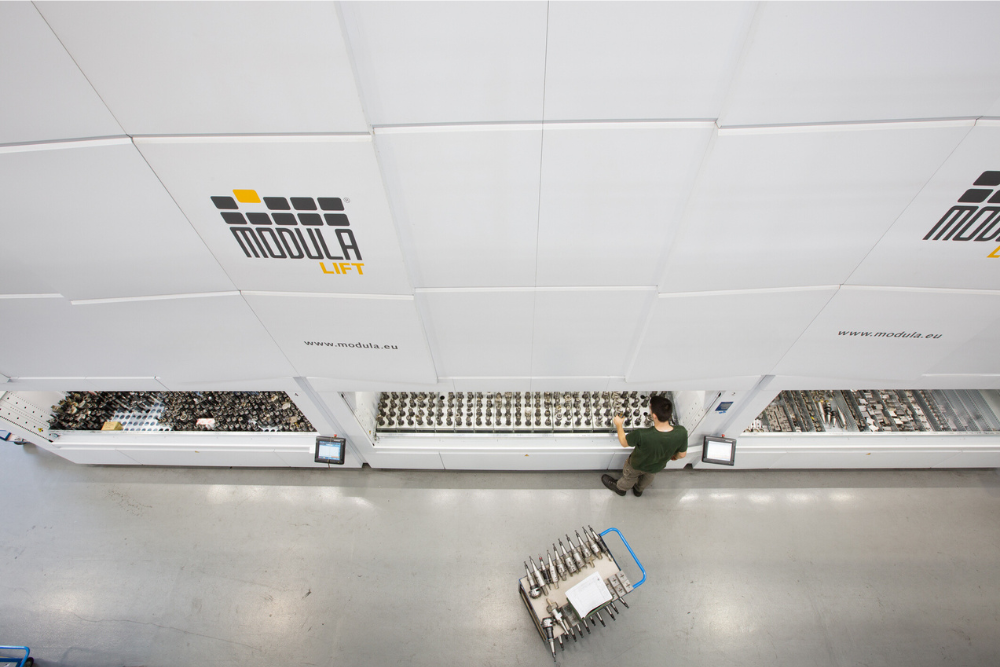

Modula Automated Storage and Retrieval Systems (ASRS) can provide a modern solution to maximize storage efficiency and operational productivity.

Vertical Lift Modules (VLMs) for example, take advantage of vertical space, which is often underutilized in many facilities.

By extending upwards, VLMs create a dynamic storage solution that can be tailored to the specific height restrictions of any urban area.

This vertical expansion allows for a significant increase in storage capacity without the need for additional floor space, making it an ideal solution for transit agencies constrained by the dense urban landscape.

The automated nature of these systems means that items can be retrieved with minimal manual effort, reducing the time and physical space required for inventory management.

Horizontal Carousels, on the other hand, optimize storage differently. These systems utilize a series of bins or shelves that rotate along a track, bringing items directly to the operator.

This method minimizes the need for personnel to move around searching for items, thus reducing the physical footprint required for storage operations.

For transit agencies, this can translate into more efficient use of limited ground space, allowing for smoother and more rapid access to necessary parts or equipment.

In addition, Modula’s ASRS solutions automate the storage and retrieval process, ensuring that specific parts are easily accessible when needed. This reduces the time technicians spend searching for items, accelerating maintenance processes and reducing vehicle downtime.

Transitioning to Modern, Eco-Friendly Fleets

Transitioning to modern, often larger vehicles like zero-emission buses presents several logistical challenges that go beyond just the acquisition of the vehicles themselves.

These eco-friendly buses typically demand more space due to their size and the infrastructure needed to support them.

This can include larger parking areas for these vehicles when they aren’t in use, expanded storage facilities for new, often larger, and more complex spare parts unique to these modern buses.

Such a shift requires comprehensive planning to ensure that all aspects of vehicle operation, from storage to maintenance, are promptly addressed without compromising efficiency or service quality.

Adapting Storage for Tomorrow’s Fleet with Modula ASRS

As public transit moves towards larger, eco-friendly fleets, managing space and parts becomes increasingly challenging.

ASRS can significantly condense the amount of floor space needed for parts storage through their ability to store items vertically or in compact, rotating modules.

These automated solutions are designed to accommodate a wide range of items, from small, delicate parts to larger, bulkier components, making them highly suitable for the diverse inventory associated with modern, eco-friendly transportation.

Moreover, these systems are inherently flexible, offering the ability to adjust storage capacity and configuration with minimal disruption.

This inherent flexibility means that as transit agencies expand or update their fleets, these storage solutions can seamlessly adapt to meet evolving requirements.

Maintaining Speed and Reliability in Service

Public transportation relies on punctuality and reliability.

In fact, according to the American Public Transportation Association, Americans board public transportation 34 million times each weekday, making public transportation an essential service for millions of people daily.

This high level of usage underscores the critical role that efficient, timely and reliable transit systems play in supporting the day-to-day activities of a significant portion of the population, whether it’s commuting to work or attending school.

Consequently, having quick access to critical maintenance supplies and spare parts is key to preventing delays and ensuring smooth operations.

This accessibility can help with both preventative maintenance, which reduces the likelihood of breakdowns, and swift repairs to reduce downtime.

Efficient maintenance is also important for keeping services on schedule and prolonging the lifespan of the transit fleet, which in turn contributes to the cost-effective management of transit systems.

This allows savings to be reinvested in more improvements and expansions.

Finally, consistent on-time services encourage the use of public transit as a reliable alternative to private vehicles, improving public perception and potentially leading to increased ridership and support for future investments in transit infrastructure.

Keeping Transit on Time with Automated Solutions

Modula’s VLMs and Horizontal Carousels efficiently utilize available space by organizing spare parts and maintenance supplies in a way that makes them easily accessible. This is crucial for rapid retrieval during maintenance, directly impacting the ability of transit vehicles to stay on schedule.

The automated nature of these systems significantly reduces the time and effort needed to locate and retrieve inventory items.

On the software side, Modula WMS provides a detailed inventory overview, allowing transit agencies to monitor stock levels, locations, and replenishment needs accurately.

This precision can help prevent shortages of parts and ensure that maintenance can be conducted without delay, maintaining the reliability of public transit services.

Modula Cloud extends these capabilities, enabling remote inventory management.

This cloud-based approach ensures that even off-site personnel can make informed decisions about inventory levels and distribution, facilitating proactive maintenance scheduling and quick responses to unexpected repair needs.

This minimizes disruptions and maximizes the vehicle’s lifespan.

Supporting American Manufacturing

The Bipartisan Infrastructure Law emphasizes Buy American provisions, requiring that materials and products used in infrastructure projects are sourced from the United States.

This focus is an integral part of the legislation, designed to support and strengthen domestic manufacturing, create jobs, and stimulate the U.S. economy

For public transit and other infrastructure projects, the Buy American provisions mean that agencies must prioritize vendors and products that meet these domestic sourcing requirements.

This includes everything from construction materials for infrastructure projects to the components used in public transportation systems.

Compliance and Efficiency through Domestic Manufacturing

Modula’s commitment to manufacturing their automated solutions in the United States aligns perfectly with this initiative.

Modula’s ASRS are manufactured in the U.S., making them eligible for Buy American Act preferences in government contracts.

This can be a significant advantage for public transportation agencies looking to comply with the Act and potentially secure funding for infrastructure projects.

Moreover, Modula’s US-based production delivers shorter lead times, allowing agencies to promptly tackle crucial needs and prioritize efficiency upgrades.

This translates to quicker implementation of ASRS, resulting in faster improvements in equipment maintenance, operational performance and passenger service.

Real-World Impact: Case Study

Modula helps optimize operations and efficiency at Metro — the Los Angeles County Metropolitan Transportation Authority.

LA Metro Improves Storage Safety and Efficiency with VLMs

Facing facility expansion challenges and a need for an automated storage solution, Metro found their answer in Modula VLMs.

The installation of a Modula Lift MX50 delivered impressive results, including:

- 540 square feet of storage on only 96 square feet

- Reduced storage footprint by 82%

- Increased picking accuracy and speed

- Improved worker safety

- Complied with Buy American requirements

By addressing their specific needs for space optimization, efficiency and safety, Modula VLMs helped Metro enhance their operations and deliver better service to their community.

Watch the full video case study at Los Angeles County Metropolitan Transportation Authority:

Seizing the Opportunity

With transit authorities eager to modernize and the infrastructure plan providing substantial funding, Modula’s solutions can help address specific needs like space constraints, efficiency and Buy American compliance.

This positions Modula as a valuable partner in the nationwide push to improve public transportation.

Ready to explore how Modula VLMs can help your transit authority take advantage of the Bipartisan Infrastructure Law?

Contact us today to obtain a comprehensive audit. During this process, we will carefully review your current operations and identify areas where our innovative solutions can be easily applied to improve efficiency, productivity and accuracy.