E-Commerce Drives Vertical Lift Module Adoption to Save Warehouse Space

As E-Commerce Drives Increased Demand for Warehouse Space, Companies Turn to Vertical Lift Modules

Decreasing floor space requirements and increasing storage density offset storage demands

As house-bound consumers turn to online shopping during the Covid-19 pandemic, retailers are shifting their supply-chain and distribution models. Some retailers that previously sold most of their items to distant stores are reconsidering their materials-handling operations accordingly. Recent reports describe how this is playing out in the demand for warehouse space:

- While warehouse vacancy rates have been as high as 10% a few years ago, they tightened up considerably in 2019 — down to 4.8%.

- E-commerce itself has jumped to a 20% annual growth rate from the previous 14%.

- Merchants are seeking warehouses in urban settings to be closer to consumers and deliver purchases faster.

- Retailers mistakenly believe that e-commerce warehouse operations require more space than the traditional model of storing items and shipping them to brick-and-mortar outlets.

What does this mean for warehouse managers? It means that warehouse space likely will be in higher demand in the months and years to come. And with higher demand comes higher prices — both to rent and to buy.

So if you’re a warehouse manager whose organization is shifting from a traditional retail model to an e-commerce-driven operation, what should you do? Two words: Go up.

The benefits of vertical lift modules for e-commerce

Reduce floor space requirements up to 90%

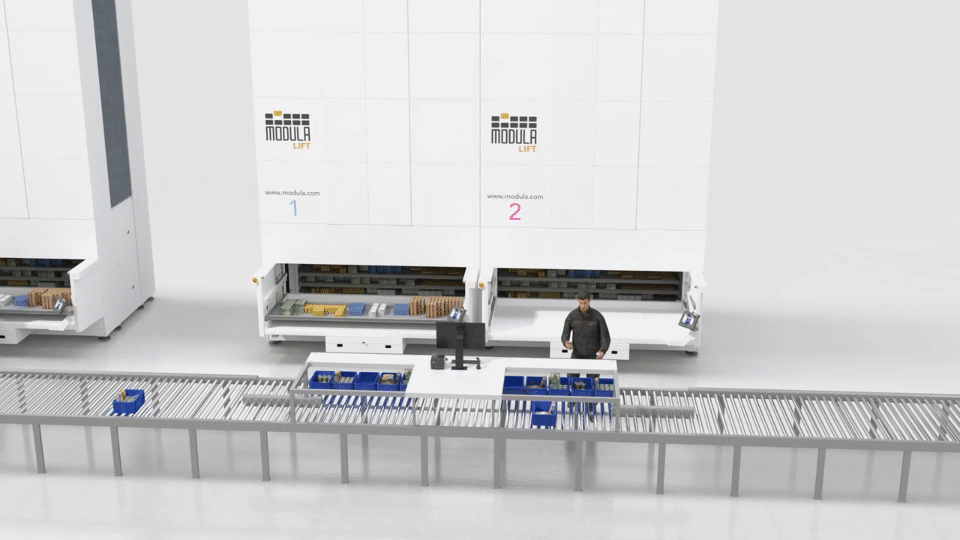

Traditional warehouses are sprawling affairs, with goods stacked on shelves across multiple aisles. Rather than storing items horizontally and thus consuming a lot of square feet, a vertical lift module (VLM) borrows on the concept of a skyscraper. A skyscraper contains a significant amount of office or living space on a small footprint. A VLM does the same with storage.

The reduction in square footage requirements is dramatic. You can reasonably expect to trim the amount of floor space needed up to 90 percent by switching to a VLM from a traditional shelving system. Items that previously were spread across a large warehouse are instead concentrated in space-efficient shelving units inside the VLM.

VLMs also feature variable-height shelving, enabling items of similar heights to be grouped together with a minimum amount of wasted vertical space between shelves. VLMs therefore not only convert horizontal shelving into vertical storage, but they increase the density of shortage as well.

Increase order picking speed as high as 300 lines per hour

That brings up the second major benefit of a VLM in an e-commerce application: They’re quick and efficient.

Rather than a worker scurrying across the warehouse, searching up and down the aisles for the item, the worker stays in place at the VLM and lets the machine fetch what’s needed. That results in a much higher throughput than before.

It’s not unexpected to see productivity as high as 300 lines per hour. And that productivity also includes more accurate picks.

Human error inevitably leads to mispicks. The e-commerce model exacerbates the problem of mispicks because items are shipped to individual consumers, not stores. Not only returns are expensive for e-commerce retailers, as individual consumers grow in their power to elevate or tarnish brands over social media, but quick, accurate deliveries are also more important than ever.

Finally, a VLM makes it easier for an organization to keep track of its inventory. Each time an item is picked, the VLM can provide an electronic update to the corporate ERP and the warehouse management system. Inventory is thus better understood and controlled.

Safety for workers

As workforces have grown more fragile during the pandemic, VLMs have emerged as valuable tools for worker safety. Workers can maintain a proper social distance from each other by remaining in place in front of a bank of VLMs rather than passing each other multiple times a day as they retrieve items from shelves.

Also, VLMs retrieve items and deliver them to workers at an ergonomically correct height. That means no more strain from reaching high above their heads or at their feet to grab each item needed. It makes for a much more pleasant environment for workers, so they’re more inclined to stay on the job. Given the high turnover of warehouse workers, that’s an important consideration.

Modula Vertical Lift Modules for E-Commerce

Modula offers a range of VLMs appropriate for any type of storage facility — from small, space-constrained urban warehouses to large distribution centers. Manufactured locally in the USA, they can be delivered faster than other VLMs and configured in different heights and widths and supplemented with aids that speed the picking process and automate inventory handling and tracking.

Modula’s VLMs allow you to organize your goods in each tray to best suit your order preparation system. For example, you might use dividers to separate inventory based on product qualities such as brand, size, color, price and product type or based on product rotation frequency or lifecycle. In addition, Modula’s software mapping system and highly configurable trays make these types of separations easily accomplished.

Modula VLMs can also enhance security by limiting access to trays and products using dedicated logins and passwords or EKS, BADGE or RFID readers. All product movement is captured, so you’ll see where each item is at any given moment.

For more information, contact Modula