Top Automated Warehouse Solutions in 2025 [+ Key benefits]

Automated warehouse solutions address a wide range of challenges in the warehousing industry, whether it’s managing higher inventory volumes or eliminating cumbersome processes.

We’ll explore leading automated warehouse solutions, explain how they work and share key benefits of transitioning to a fully automated warehouse.

Plus, we’ll introduce you to our advanced automated warehouse solutions at Modula that can help you transform your order fulfillment process, from start to finish.

What Are Automated Warehouse Solutions?

Automated warehouse solutions are technologies and systems that optimize operations, manage inventory and enhance efficiency and picking accuracy.

Automated warehouse solutions include automated storage and retrieval systems, warehouse robotics, storage solutions and automated picking systems.

What Is a Fully Automated Warehouse?

A fully automated warehouse is a storage facility that utilizes innovations, such as vertical lift modules, warehouse management systems and robots, to perform warehouse operations with minimal to no human intervention.

A fully automated warehouse allows you to improve efficiency, boost picking accuracy, store inventory safely and reduce errors caused by manual labor.

Warehouse Processes You Can Streamline With Automated Warehouse Solutions

Key processes across your entire warehouse can be improved with automated warehousing systems.

Processes that can be automated include:

- Receiving: Barcode scanners, sensors or radio frequency identification (RFID) can help identify and record received goods

- Sorting: Robotic hands and conveyor systems can help sort items based on their SKUs and designated warehouse locations

- Inventory management: Warehouse management systems can help track inventory levels, locations and item movement in real-time

- Storage: Vertical lift modules and horizontal carousels can help optimize warehouse storage

- Picking: Pick to Light systems, Put to Light systems and voice picking can help your warehouse operators accurately pick items

- Replenishment: Warehouse management systems can help monitor stock levels and notify your warehouse operators when inventory needs to be replenished

- Put-away: Autonomous mobile robots can transport received goods to their designated storage locations

- Packing: Automated packing stations can quickly pack items into boxes or containers

- Shipping: Automated label printing and application systems can print and apply shipping labels to packages, then sort them based on carrier or shipping method

- Returns: Inventory management systems and reverse logistics software can help automate the process of tracking returned items

Check out the video below to discover the difference between a traditional and automated warehouse picking system:

Traditional vs Automated Warehouse Picking System

When Is the Right Time To Use Automated Warehouse Solutions?

Deciding when to implement automated warehouse systems depends on several factors that impact their efficiency and return on investment (ROI).

Key considerations include:

- Volume and growth: Consider investing in automated warehouse solutions when order volume grows significantly. For example, if your team struggles to complete orders during peak seasons or consistently fails to meet daily quotas, automation can ensure timely deliveries.

- Manual processes: Automated warehouse solutions, including warehouse management systems and picking robots, streamline operations, reduce manual errors and improve overall productivity.

- Space constraints: Automated warehouse solutions, including vertical lift modules, maximize limited space by utilizing the existing ceiling height.

- Labor costs: Analyzing labor costs and assessing the potential ROI from implementing automated warehouse solutions can emphasize significant savings opportunities. For instance, at Modula, the typical ROI for a vertical lift module or horizontal carousel ranges from six to 18 months.

Key Benefits of Automated Warehouse Systems

Automated warehouse systems offer diverse benefits, including:

- Maximize storage: Warehousing costs in the U.S. are rising. So instead of relocating to a bigger and more expensive warehouse, automated warehouse systems maximize efficiency by utilizing your facility’s existing space.

- Amplify productivity: Automated warehouse storage systems, like vertical lift modules, help speed up the picking process by delivering inventory directly to warehouse operators.

- Increase workplace safety: Automated warehouse systems reduce potential accidents by minimizing or eliminating manual tasks, such as overexertion from accessing inventory in high or low areas.

- Boost picking accuracy: Automated warehouse systems, such as voice picking and Put to Light systems, guide operators to the correct picking location. This allows them to accurately pick orders without manually reviewing pick tickets or paper lists.

- Gain complete inventory visibility: Warehouse management systems provide real-time visibility into stock levels and product movement. This enables better inventory control and informed decision-making for demand forecasts.

How To Automate Your Warehouse

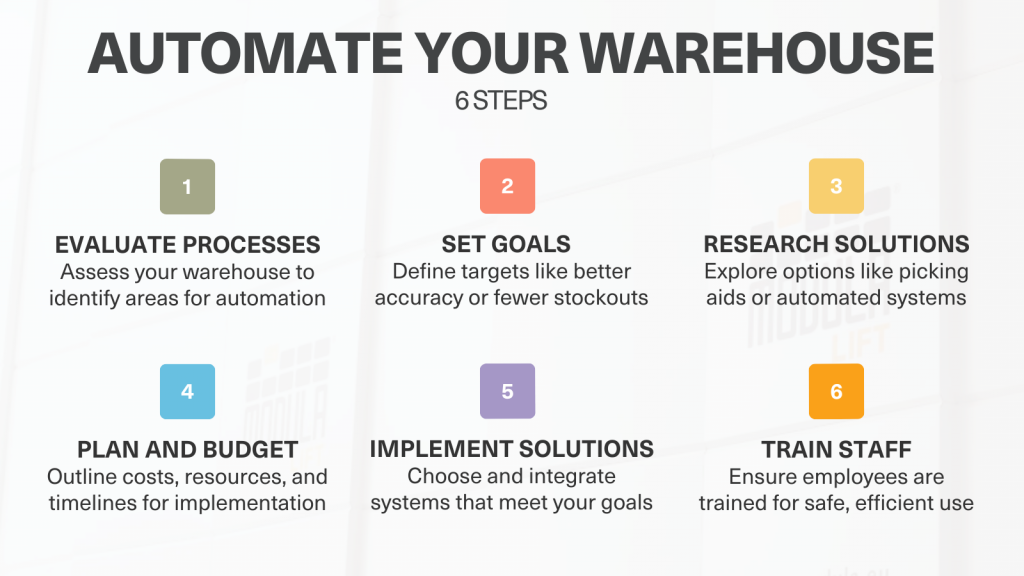

While transitioning to a fully automated warehouse doesn’t happen overnight, a properly planned and strategic approach can help ease the transition and streamline the process.

Here’s how to implement warehouse automation in six steps:

- Evaluate your current processes: Begin by assessing your existing warehouse processes, such as receiving, storing, picking, managing inventory, packing and shipping. Identify areas where automation can lead to improvements.

- Identify goals and requirements: Determine the specific goals and requirements you aim to achieve through automation, such as improving picking accuracy or gaining better visibility into your inventory to reduce stockouts.

- Research your options: Research which automated solutions could work for your needs. For example, voice picking to improve picking accuracy and efficiency, or automated storage and retrieval systems for retrieving inventory in narrow warehouse aisles.

- Create a plan and budget: Develop a budget and implementation plan for your chosen automation solutions, taking into account the required resources, costs and timeline.

- Identify and implement warehouse automation solutions: Determine the solutions that align with your goals and budget, then integrate the new system(s) into your facility based on your plan.

- Train warehouse operators: Make sure employees receive proper training on the new technology and processes to minimize the risk of workplace accidents and maximize the performance of your new solutions.

Discover Leading Automated Warehouse Solutions From Modula

An industry-leading manufacturer of advanced automated storage solutions and warehouse management systems, we help warehouses across industries increase productivity and efficiency across operations.

1. Modula Vertical Lift Modules for Inventory Storage

Modula Vertical Lift Modules (VLMs) optimize your available warehouse space by taking advantage of the ceiling height, resulting in a minimal footprint.

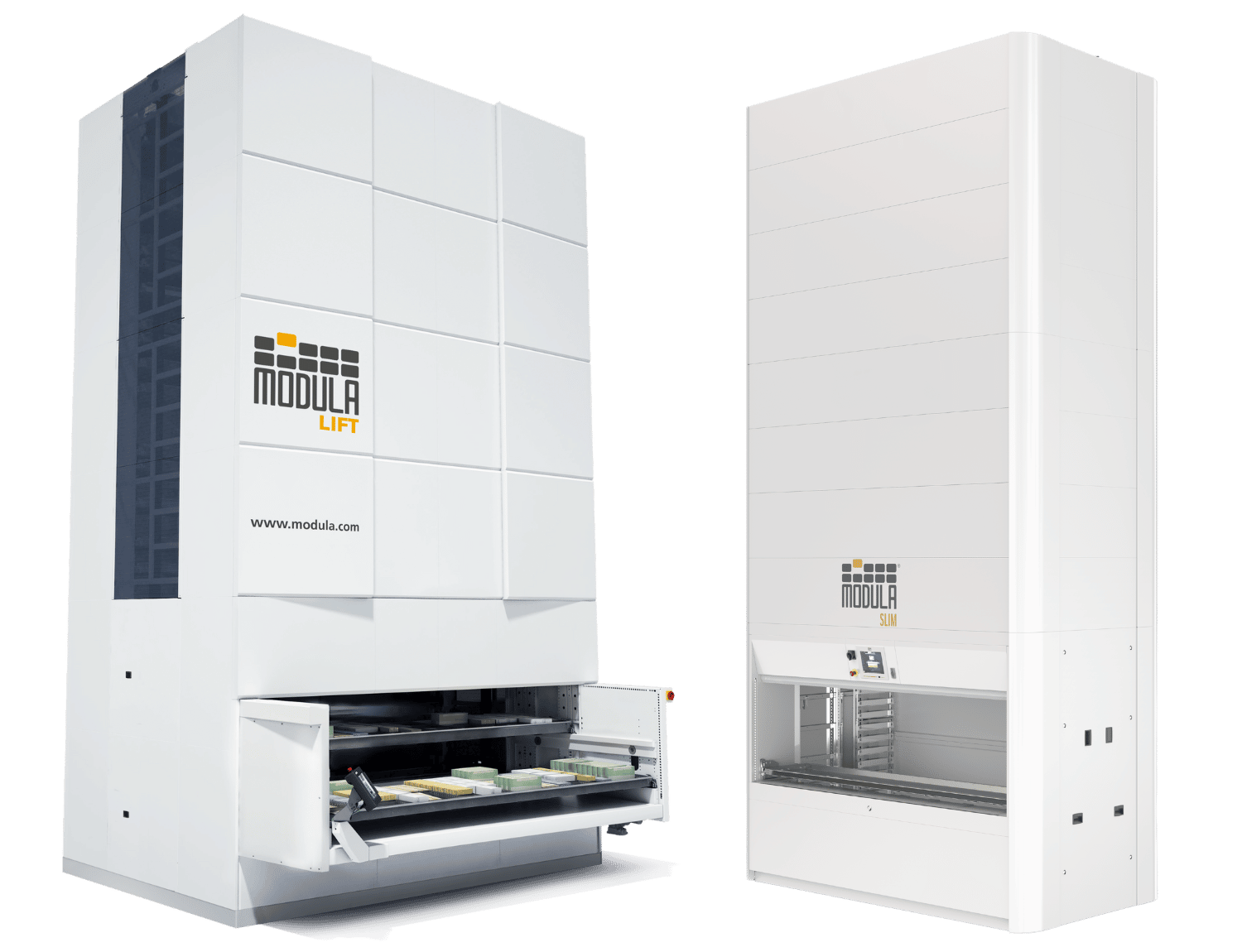

We offer three models:

- Modula Lift, our popular vertical lift module, is the ideal storage solution for components and industrial items across all possible industries.

- Modula Slim offers an optimal storage solution for warehouses with limited floor space.

- Modula Next, an innovative automated solution that combines the space-saving and efficiency of Vertical Lift Modules (VLMs) with all the precision and control of industrial vending machines.

- Modula Pallet, a warehouse solution designed to safely handle euro pallets directly from the ground, eliminating the need for forklifts.

Our VLMs allow you to:

- Conserve 90% of your floor space by utilizing minimal footprint and maximizing the available ceiling height

- Enhance picking speeds to 300 lines per hour or more

- Increase safety for warehouse operators by eliminating the need to reach for products

- Safeguard your goods within an enclosed system with restricted access

- Improve inventory management through monitored and documented picking operations

- Move inventory using the user-friendly Copilot controller

- Handle heavy loads with ease and without strain

- Minimize employee and operational costs

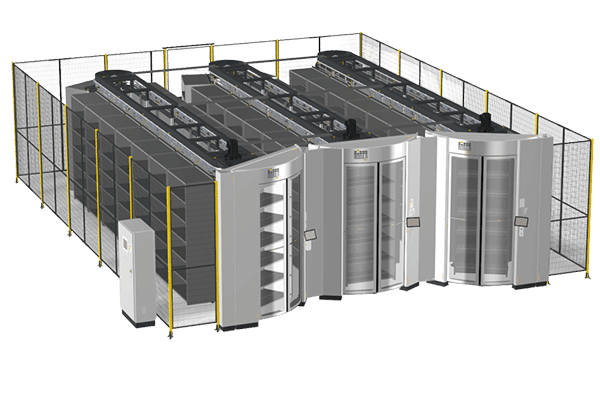

2. Modula Horizontal Carousels for Inventory Storage

The Modula Horizontal Carousel (HC) acts as the ideal storage solution for warehouses with limited ceiling height.

Our HC allows you to:

- Maximize storage capacity with compact and high-density storage areas

- Move inventory easily using Modula’s digital Copilot feature

- Achieve 99% picking accuracy with our Put to Light Systems and barcode readers

- Experience picking rates of up to 550 lines per hour for each warehouse operator

- Provide a safe working environment by protecting your employees from potential hazards, eliminating physical strain, enabling quick machine stoppage and reducing unnecessary travel within the warehouse

- Monitor picking operations in real-time

3. Modula Picking Solutions for Accurate and Efficient Picking

Modula Picking Solutions allow you to reduce the search time for locating inventory and increase accuracy when processing individual or large batches of orders.

Our Order Picking Solutions include:

- Modula Put to Light Picking Solutions utilize a combination of light and digital displays to guide your warehouse operator during the picking process. These solutions can operate as a stand-alone system or pair with our Picking Cart or Picking Station to further achieve efficiency in the picking and putting processes.

- Modula Picking Station houses the totes and bins where inventory is stored. Each bin is integrated with a put to light display, equipped with its own control unit and power supply.

- Modula Picking Cart serves as the optimal picking solution for paperless batch or multi-order processes for warehouse operations that require mobility.

- Modula Mobile Picking App allows your warehouse operators to manage replenishment and picking operations from any device, regardless of where they are in your warehouse.

All of our picking solutions allow you to:

- Boost picking accuracy, thanks to light devices that will guide your warehouse operators

- Eliminate the need to review paper lists or pick tickets

- Improve inventory management by offering an in-depth view of your current and forecasted inventory

4. Modula Warehouse Management System for Inventory Management

Modula’s Warehouse Management System allows you to track the location and movement of inventory within your warehouse, while gaining complete visibility into your stock levels.

Choose from two Warehouse Management Solutions:

- Module WMS Base: Ideal for small warehouse footprints

- Modula WMS Premium: End-to-end inventory and warehouse management solutions

Our Warehouse Management Systems allow you to:

- Enhance inventory control and visibility

- Increase accuracy, when integrated with our automated storage solutions and retrieval methods, such as picking and shelving

- Achieve superior control over inventory management, material handling, and preventive maintenance guidance

- Maintain productivity and quality in both batch and multi-order modes, even when handling larger-than-usual orders

5. Modula Web Analytics for Predictive Maintenance

Modula Web Analytics allows you to consolidate statistical data from your Modula automated storage and retrieval systems (ASRS), regardless of where they are located in your warehouse.

Built-in and on around-the-clock, Modula Web Analytics captures data in an intuitive online portal where you can conveniently and securely monitor and manage your warehouse operations, from any device or location.

Modula Web Analytics allows you to:

- Monitor your Modula automated warehouse solutions remotely

- Manage your warehouse from any location with remote diagnostics, support and resolutions, while implementing predictive maintenance

- Keep track of your warehouse status, including energy consumption, unit statistics, warning lights and alarms

- Monitor the performance and health of each of your Modula units and receive notifications about machine status

- Access comprehensive reports on tray usage efficiency, completed cycles, fulfilled orders and energy consumption

At Modula, our automated storage and retrieval systems are proudly made in the USA, and designed to minimize your storage requirements, significantly increase your productivity and picking accuracy and boost employee safety.