Modula Pallet

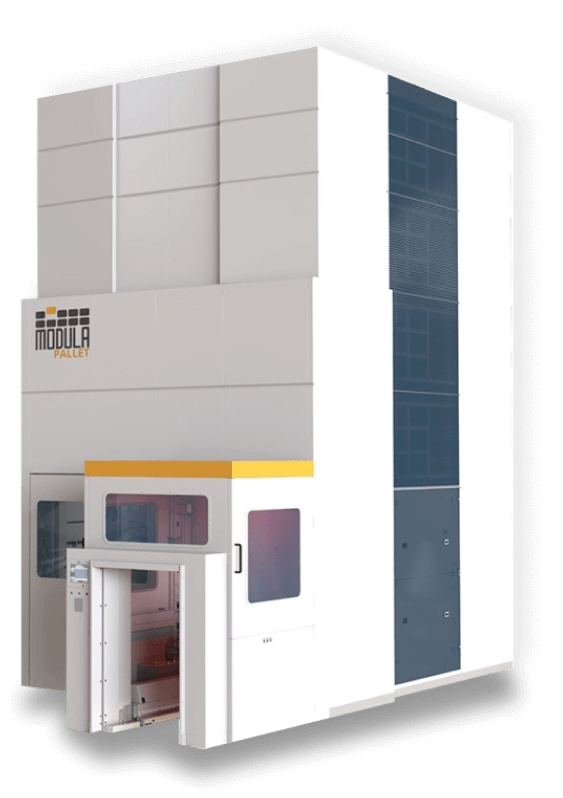

The Modula Pallet is an innovative warehouse solution designed to safely handle euro pallets (1,200mm X 800mm) directly from the ground, eliminating the need for forklifts.

This system keeps pallet movements at ground level, optimizing vertical space and reducing the risks linked to lifting and storing at height.

Serving as an efficient buffer storage, Modula Pallet’s flexible design supports piece picking through a side window bay. It also accommodates mixed storage, including pallets, bulk products and depalletized goods.

Why Choose Modula Pallet

Efficient Use Of Space

Maximizes warehouse space by storing pallets vertically, freeing up valuable floor space for other operations.

Ground-level Pallet Handling

Safe and easy handling of pallets without the need for forklifts, reducing risks and improving efficiency.

Piece Picking

Access goods directly from the side window of the loading bay without retrieving the entire pallet, to enhance speed and ergonomics.

Storage For A Mix Of Products

The dual bay allows for efficient mixed-mode storage, with one bay for pallet storage and another for depalletized or single items.

Advanced Technological Integration

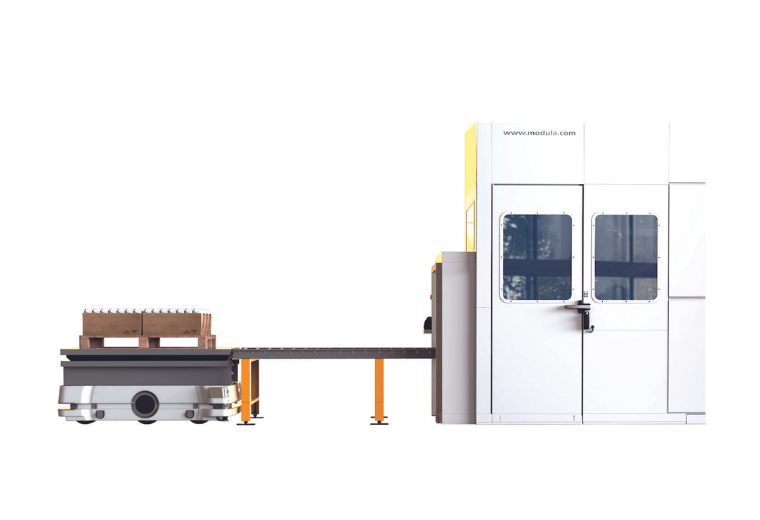

Modula Pallet is designed to integrate with AMRs, AGVs, and roller conveyors through Modula WMS for fully automated process.

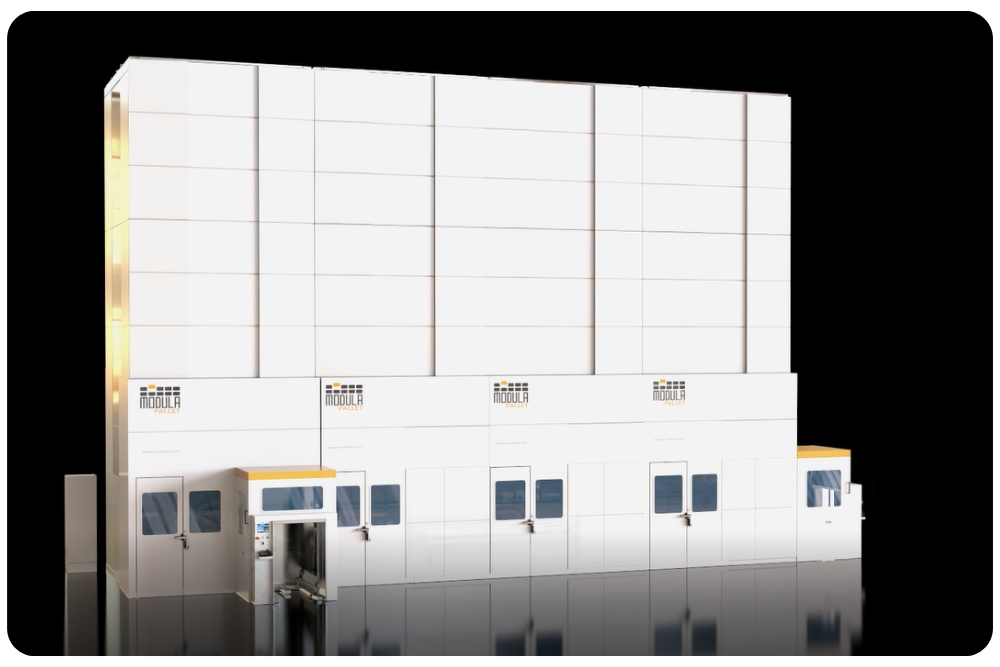

Combine Multiple Units

Install multiple units side by side and use a single bay, with an internal shuttle moving loads between units to optimize space.

Modula Pallet

Ground-level Handling

Modula Pallet enables safe and easy handling directly from the ground, eliminating the need for forklifts.

Keeping all pallet movements at ground level reduces the risks connected to lifting and storing pallets at height, such as injuries from falls or strains, and damage to goods or equipment.

Efficient Use Of Space & Optimized Stock Density

Modula Pallet is equipped with a loading bay that measures the weight and height of incoming pallets to determine the optimal placement and ensure balanced loads.

Piece Picking

Modula Pallet allows operators to access goods directly from the side windows of the loading bay without retrieving the entire pallet.

This feature facilitates piece picking, enabling quick and precise access to individual items. It enhances speed and ergonomics, making the picking process more efficient.

Ideal Buffer For Inventory

Modula Pallet acts as a temporary storage solution in receiving and shipping areas. It provides space for incoming and outgoing goods, ensuring efficient workflow.

Efficient Storage For Diverse Products

Modula Pallet offers a flexible storage solution for warehouses managing diverse inventory types.

It features a dual-bay design: one bay for pallet storage and another for depalletized or single items such as bulk materials, packaged goods and boxes. This configuration maximizes storage space and simplifies the management of both pallets and individual items within a single system.

Single Point Of Access For Multiple Units

Install multiple Modula Pallet units side by side and use a single loading bay.

An internal shuttle moves loads between units, allowing you to pick and place pallets from one central point. This setup optimizes storage efficiency and simplifies pallet management.

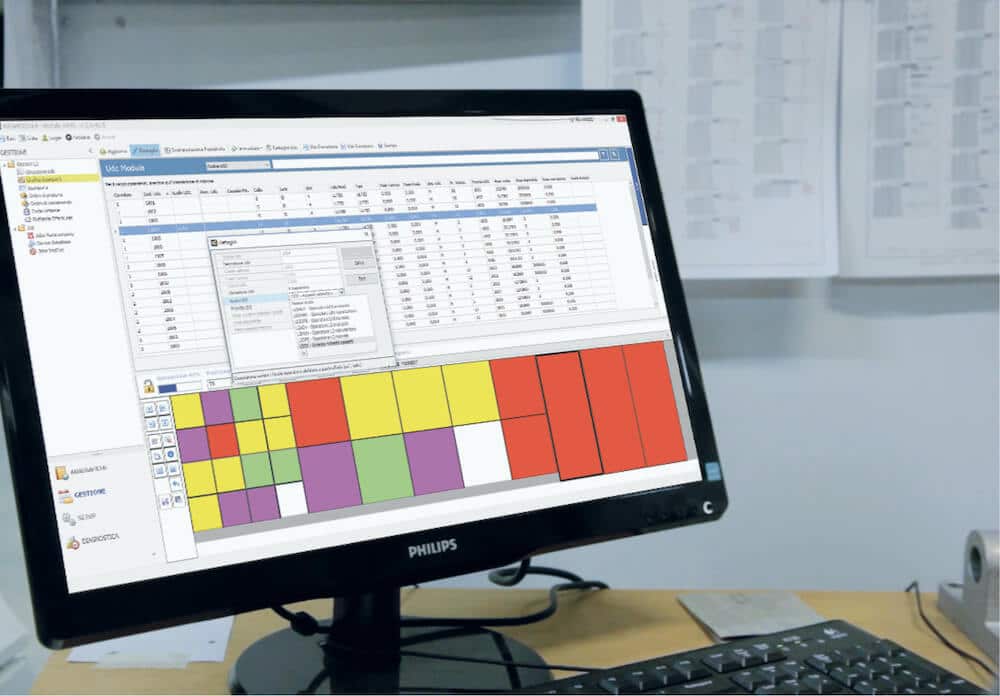

Unlimited Integration With Modula WMS

Modula Pallet is modular and smart, easily integrating with AMRs, AGVs and roller conveyors through the Modula WMS software.

This setup enables fully automated management, boosting efficiency and minimizing the need for manual intervention.

Modula Pallet Facilitates Versatility Across Industry

High Value Items

Ideal for dispensing medical supplies and pharmaceuticals securely.

Aerospace & Automotive

Ideal for dispensing medical supplies and pharmaceuticals securely.

MRO (Maintenance & Repair)

Ideal for dispensing medical supplies and pharmaceuticals securely.