Modula at PACK EXPO 2025: Smart Automation for Packaging & Processing

- Event: PACK EXPO

- Location: Las Vegas Convention Center, Las Vegas, Nevada, USA

- Dates: September 29 – October 1, 2025

- Visit our team: Modula Booth #SU-27079 (South Upper Hall)

- Learn more: https://www.packexpolasvegas.com/

Modula at PACK EXPO 2025

PACK EXPO Las Vegas 2025 is the largest packaging and processing show in North America, bringing together more than 2,500 exhibitors and 40,000 professionals looking for cutting-edge solutions to boost productivity and efficiency. For manufacturers and distributors in industries like food, beverage, pharmaceuticals, and consumer goods, packaging plays a critical role in speed, accuracy, and traceability.

Modula will be exhibiting at the 2025 edition to present how automation can support these needs, whether it’s by increasing throughput, making better use of space, or reducing errors during kitting, assembly, and order fulfillment. As a trusted partner to companies across logistics and manufacturing, we’re excited to showcase how our solutions can streamline packaging operations.

See Modula Flexibox in Action At PACK EXPO 2025

At this year’s show, Modula will be demonstrating its latest innovation: the Modula Flexibox, an ultra-high-speed vertical solution specifically designed for handling standardized bins.

Unlike traditional vertical lift modules, Flexibox retrieves up to 9 bins in a single cycle, reaching up to 180 bins per hour. It’s ideal for operations that manage a high volume of small parts and need to get them to the packaging line or into a kit fast.

Whether it’s caps, nozzles, labels, leaflets, or other components, Flexibox can dramatically reduce retrieval times, improve operator efficiency, and keep your production lines moving without interruption.

How Modula Automation Transforms Packaging and Processing

Visit Modula at PACK EXPO 2025 – Booth #SU-27079

If you’re planning to attend PACK EXPO Las Vegas, make sure to stop by the Modula booth for a live look at Flexibox in action. Our team will be there to answer your questions, demonstrate key workflows, and explore how automation can help you optimize your packaging, storage, and order handling operations.

Attend PACK EXPO as our Guest

We’re happy to have you attend as our guest! Register here for your free expo pass

We look forward to seeing you in Las Vegas!

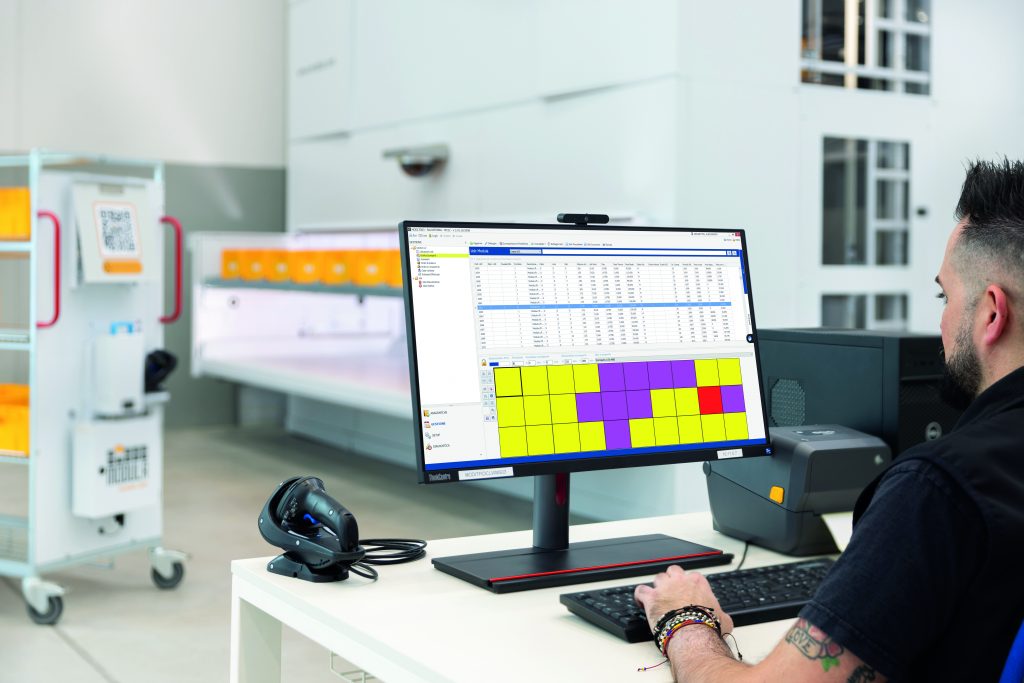

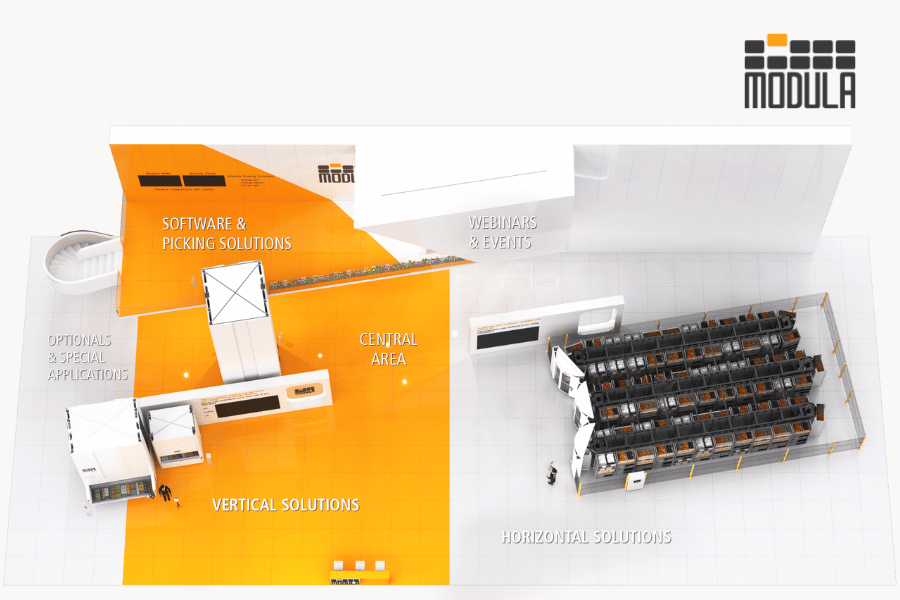

Virtual Booth

Experience the latest on automation and material handling, even if you’re unable to attend the trade shows in person. You can check out our automated storage solutions by visiting our virtual booth from the comfort of your own desk

Subscribe To Our Newsletter

Stay informed about our upcoming events, news, and more. Learn more about automation and material handling. You can easily unsubscribe at any time using the links provided in every email.