The Move to Automation: a conversation with the CEOs of Modula and Salvagnini

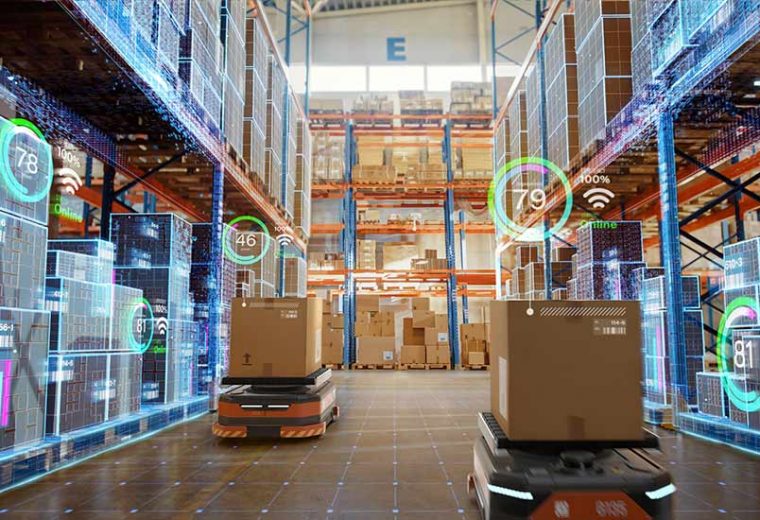

As manufacturers face new and ongoing pressures to boost efficiencies and reduce costs, they turn more and more to automation. Modula and Salvagnini are two of the leading vendors of automated production technology and they currently use each other’s products in their own operations. Modula makes automated storage systems. Salvagnini makes automated systems for processing sheet metal.

We decided to interview the companies’ two North American chief executive officers – Antonio Pagano of Modula and Doug Johnson of Salvagnini America – to get their insights on why a switch to automation is inevitable for most manufacturers, how that switch can benefit organizations, and what’s the proper way to incorporate automation into a company’s operations and overall culture.

How Salvagnini and Modula began using each other’s products

When it initially launched its products in 1987, Modula outsourced much of the production. As it decided to bring more work in-house, the company founder and chairman, Franco Stefani, decided to use automation as much as possible and bought a Salvagnini FMS (a flexible manufacturing system, composed of several integrated machines) to eliminate the manual steps of bending and punching the external panels of Modula vertical lift modules. Seeing the efficiency and quality gains of the Salvagnini units, Modula bought more Salvagnini products to automate additional functions such as punching and laser cutting. When they expanded production from Italy to China and the United States, Modula replicated the production setup in those factories.

Similarly, Salvagnini saw the automation benefits of using Modula’s VLMs in creating their own devices. The United States division concentrates on sales and service but finds significant value in using Modula’s automated storage systems to properly manage their inventory of spare parts and supplies and gain the space-saving design and inventory management that Modula provides.

Every day, 10,000 people are retiring from the workforce, taking an average of 35 years of experience with them. Think of the brain drain. The newer people are going to have to be part of a switch to automation

Doug Johnson, CEO, Salvagnini

The synergy of the Franklin, Ohio, Modula plant

Modula’s new Franklin, Ohio, production facility illustrates how these two companies’ automation technology can be united. The metal parts used in Modula units — the panels, trays, columns, etc. — are manufactured by Salvagnini machines. Integrated software schedules and sequences the punching, laser cutting, and bending operations as part of the fully automated environment.

In turn, Modula VLMs are used to store the parts and machinery tools needed for production, as well as backup parts for servicing if anything goes wrong. The production itself goes faster with the two types of devices complementing each other. Additionally, quality is improved thanks to the consistency of the Salvagnini metal fabrication devices and the material management of the Modula storage units. Operators don’t need to review production lists or respond to unexpected demands. “This software integration allows us to plan in advance and manage potential urgencies” Pagano said.

Johnson said that this combination would potentially be valuable for half Salvagnini’s customers – that is, those that are processing and fabricating metal and installing needed parts in the same operation.

There is a culture [regarding automation] that has to be built, a culture of looking into what you really need and what is good for you. What is a scalable solution? What is something that can grant you flexibility in the future?”

Antonio Pagano, CEO, Modula USA

Why automation is inevitable for North American manufacturers

Large manufacturers adopted automation decades ago, driven by the need to reduce labor costs to stay competitive with foreign producers. Now the need for automation is affecting more and more companies – not just on the production floor but in warehouses storing essential materials. Labor shortages abound. “Every day, 10,000 people are retiring from the workforce, taking an average of 35 years of experience with them,” Johnson said. “Think of the brain drain. And so, when you can find them, the newer people are going to have to be part of a switch to automation.”

Curiously enough, relatively few companies are aware of automated solutions, let alone employing them. Johnson says that when he goes to trade conventions, he’s shocked at how many people have no idea that their type of product existed. Modula estimates that of the 300,000 American companies that could use an automated storage system, only about 10 percent do so

How companies can adopt automation

For many companies, the prospect of automating can seem overwhelming. They know the need exists, but they don’t know where to start and how much of their precious capital should be invested in automated products. Johnson made the point that automation doesn’t have to be all or nothing: “Everybody wants to think about automation in these grand terms. No, automation can begin with a single machine, replacing processes that previously were done manually.”

Pagano said companies need to see automation for the cultural shift it represents as well. In part because automation is not as extensively deployed in the U.S. as the rest of the industrial world. “There is a culture that has to be built, a culture of looking into what you really need and what is good for you. What is a scalable solution? What is something that can grant you flexibility in the future?”

Johnson warned as well that companies need to adequately train their employees to work with automated machines. “You better invest in your people to be able to run this type of technology because it’s not just a matter of pushing a button,” he said. “You have to be able to program it and maintain it.”

Each industry and each customer will have a unique set of needs, both CEOs agreed, so there’s no simple formula that will apply to all organizations. But the focus first should be on processes, not available products, so investments are made prudently.

The future of automation

Automation’s benefits go far beyond addressing labor shortages. With Modula devices, they address the rising costs of manufacturing and warehouse logistics by reducing the need for space and supply chain/operational issues by enhancing material tracking and usage. With Salvagnini devices, the repeatability of an automated operation eliminates the quality issues that arise from manual processes and avoids the potential damage of extensive handling of metal. The high productivity of a panel bender ensures a rapid pay-back too.

For manufacturing in general, Johnson said he imagines further employment of IoT devices and artificial intelligence. He recalled a recent discussion with a customer who envisioned the day in which a simple drawing can be converted to a fully manufactured and delivered product without any human intervention.

We’re not there yet, but odds are that as technology reaches that goal, automation-focused companies such as Modula and Salvagnini will be part of the process.