What Is Piece Picking? [+ Best Practices to Utilize in 2024]

As eCommerce continues to surge and the demand for rapid order fulfillment increases, traditional manual picking methods can no longer keep up. This shift is driving the adoption of automation in logistics, with a strong focus on enhancing picking speed and accuracy.

A critical aspect of the order fulfillment process is piece picking — the task of selecting individual items to fulfill customer orders.

While often overlooked, piece picking significantly impacts operational costs, order accuracy, error rates, and overall customer satisfaction. Even small errors in this process can lead to costly mistakes and delays, making it a critical area for improvement.

In this blog, we’ll cover everything you need to know about piece picking, including the various methods and equipment used in piece picking and how to maximize this strategy for your warehouse operations.

We’ll also discuss how integrating the right technology can significantly reduce errors, cut down on labor costs, and increase overall efficiency — key factors in staying competitive in today’s market.

What Is Piece Picking?

Piece picking, or individual item picking, is an order picking strategy where warehouse employees select individual items to fulfill customer orders.

Unlike other picking strategies, piece picking focuses on single SKUs rather than handling boxes or pallets.

Piece picking is an essential function in warehouses, especially in environments where orders consist of a small number of items or when items need to be picked individually rather than in bulk.

Types of Piece Picking Methods

Identifying the best picking methods and strategies for your organization can help optimize picking processes and improve overall order fulfillment.

There are several specific order picking methods that fall under piece picking. Here are the different methods:

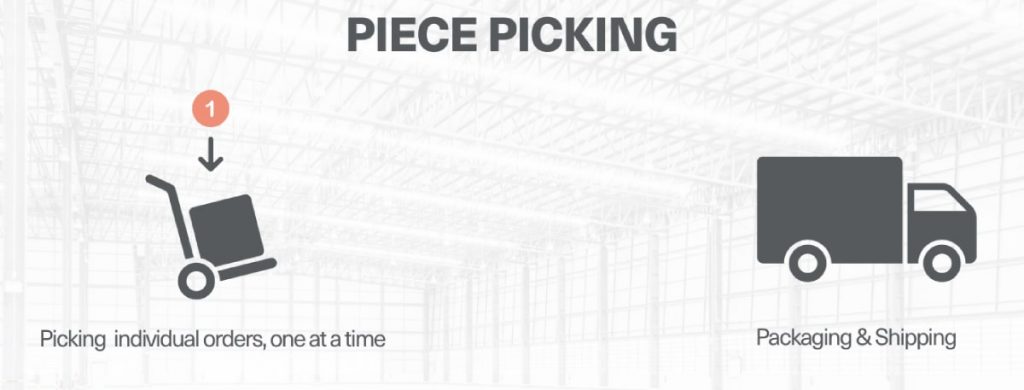

Single Order Picking

Single order picking is a strategy where a warehouse employee manually picks all the items for one specific order, before moving on to the next order.

This picking strategy can be time-consuming if orders are spread across a large warehouse.

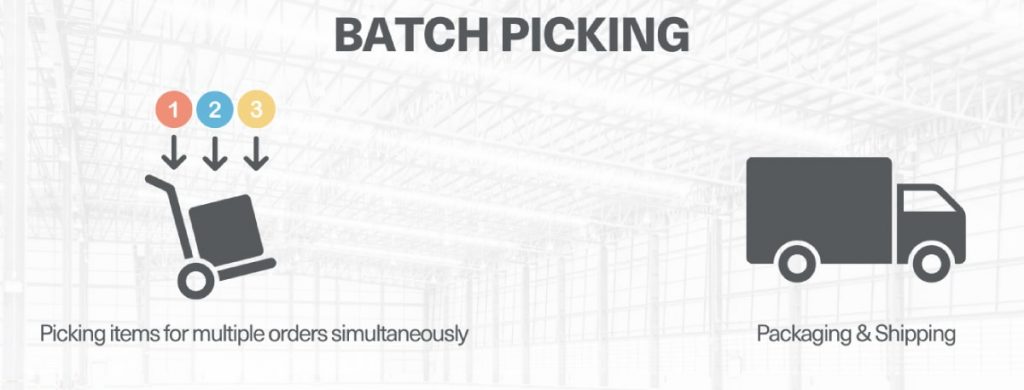

Batch/Multi-Order Picking

Batch order picking is a strategy where a warehouse employee picks items for multiple orders simultaneously. The items are picked together and then sorted into individual orders later.

This approach is particularly effective in warehouses where multiple orders contain the same or similar items.

Picking multiple orders at once reduces travel time across the warehouse and speeds up the process.

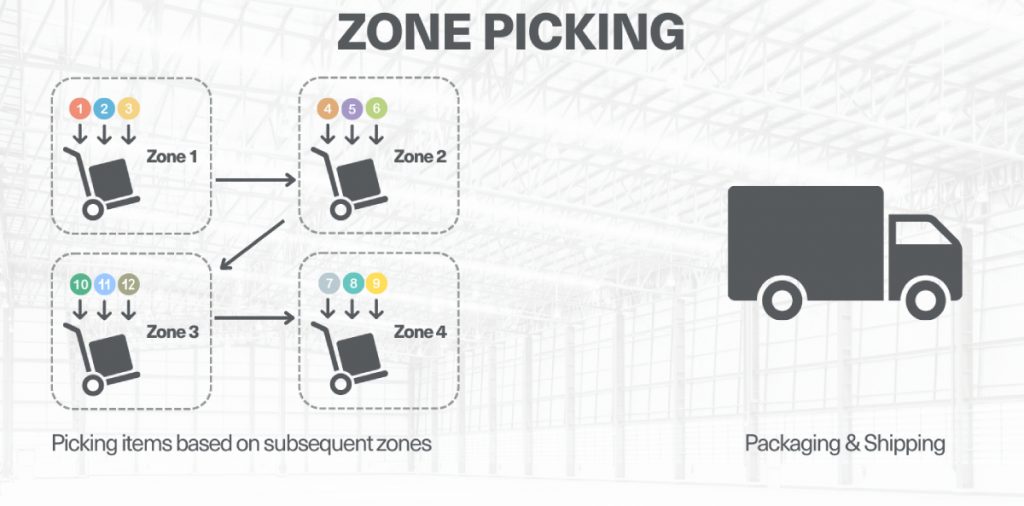

Zone Picking

Zone picking is a strategy where a warehouse employee is assigned to specific zones within the facility and picks items only from their designated areas.

This method can be efficient, particularly when combined with other picking strategies, as it minimizes movement and optimizes picking times.

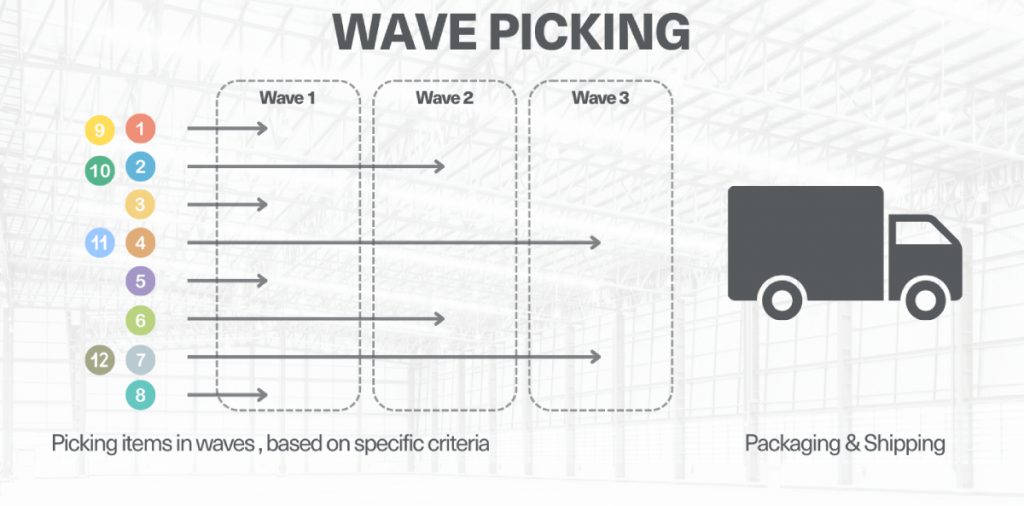

Wave Picking

Wave picking is a type of picking strategy where a warehouse employee picks items in coordinated “waves” throughout the day, based on criteria like shipping destinations or delivery schedules.

A warehouse management system (WMS) schedules and organizes these waves. This method can help improve labor efficiency and the use of resources in the warehouse.

Cluster Picking

Cluster picking is a warehouse picking strategy in which a single picker collects items for multiple orders simultaneously using a multi-compartment cart or trolley.

In this method, the picker travels throughout the warehouse once, picking items for several orders and placing them into different compartments or bins on their cart.

Types of Equipment for Piece Picking

You can choose from different types of piece picking equipment, depending on your business needs and goals.

The common types of equipment for piece picking include:

Pick-to-Light Systems

Pick-to-light systems use illuminated displays at storage locations to guide pickers to the correct items. The light indicates the quantity of the item to be picked, helping to reduce errors and speed up the picking process.

Picking Carts

Picking carts are mobile units that are often equipped with multiple compartments or shelves. They allow workers to collect items for one or more orders simultaneously and transport them easily throughout the warehouse.

The use of pick carts is particularly effective in operations where items are picked manually and need to be transported to a packing or sorting area.

Voice Picking Systems

Voice-picking systems are picking solutions that utilize voice prompts and advanced speech recognition software to communicate picking instructions to employees through headsets.

Warehouse employees receive verbal commands on which items to pick and where to find them, allowing them to keep their hands and eyes free for the task.

Barcode Readers

Barcode readers are handheld devices used to scan barcodes on items or storage locations. These scanners communicate with the warehouse management system (WMS) to track inventory and guide pickers to the correct items

Conveyor Systems

Conveyor systems are used in piece picking to transport items or totes efficiently across the warehouse.

They reduce the need for pickers to manually move items from one area to another, allowing them to focus on picking tasks.

Autonomous Mobile Robots (AMRs)

AMRs are increasingly used in piece picking to automate and enhance the efficiency of the picking process.

These robots can navigate the warehouse independently, transporting items from picking areas to packing stations or even performing the picking tasks themselves.

AMRs are particularly valuable in repetitive or high-volume picking tasks, where they can operate continuously, reduce the need for human labor, and minimize errors.

These robotic solutions can help increase picking speed, reduce physical strain and lower the risk of potential hazards for workers.

Automated Storage and Retrieval Systems (ASRS)

Automated storage and retrieval systems (ASRS) are technologies controlled by computers or robots that store and retrieve inventory in specific warehouse locations.

Automated storage and retrieval systems can typically integrate with various warehouse software solutions, such as Warehouse Management Software (WMS) and Warehouse Execution Software (WES), to help manage and streamline your warehouse operations.

These systems are especially beneficial in large warehouses with a high volume of SKUs, where manual picking can be time-consuming and prone to errors. By automating the retrieval process, AS/RS systems increase picking speed, reduce labor costs, and improve accuracy, making them a key tool in modern, high-efficiency warehouses.

ASRS can help save space, increase picking accuracy and improve efficiency.

Key Benefits of Piece Picking

Piece picking provides a myriad of benefits, from boosting productivity to reducing costs.

- Increase productivity: Warehouse managers can measure order picking productivity using a warehouse KPI known as the pick rate, or the number of goods that are picked per hour. When you plan efficient routes to minimize travel time and set up clear, organized processes, warehouse pickers can work more efficiently.

- Improve picking accuracy: When warehouse pickers focus on individual items, piece picking reduces the likelihood of errors. Collaborative mobile robots also enhance accuracy by guiding employees to the correct pick locations and utilizing barcode scanning to further minimize human error.

- Boost customer satisfaction: Customers appreciate it when their orders arrive on time and without any mix-ups. It is no secret that faster delivery times and accurate orders not only make customers happy, but also encourages them to come back and maybe even leave a great review.

- Reduce costs: The right piece picking method can reduce the number of warehouse pickers needed to fulfill orders. For example, batch picking allows warehouse employees to collect items for multiple orders at once, cutting down on trips through the warehouse. Leveraging automated warehouse technology, like collaborative mobile robots, also lowers labor costs by boosting overall productivity.

Best Practices for Piece Picking

Now that you understand the key benefits of piece picking, it’s time to implement guidelines that will help achieve optimal outcomes in your warehouse picking processes.

Design a Strategic Warehouse Layout

Optimize your warehouse layout to minimize travel distances and streamline the flow from receiving to shipping. Consider implementing zoning strategies to keep high-demand items easily accessible.

For example, place your best-selling products near the packing and shipping areas to reduce pick times and speed up overall order processing.

Leverage Batch and Wave Picking When Needed

Depending on the order volume and characteristics, consider batch or wave picking to handle multiple orders more efficiently.

Both methods can significantly enhance the throughput and accuracy of your picking operations — especially in high-volume environments.

Invest in the Right Piece Picking Technology

Whether it’s utilizing collaborative mobile robots or advanced barcode scanning systems, the right technology can dramatically enhance the efficiency of piece picking.

You can also consider integrating voice-directed picking, wearable devices or automated warehouse pickers to help streamline operations and reduce errors, ensuring that pickers have their hands free and clear instructions readily available.

Store Similar SKUs Together

Storing mixed SKUs in one location can reduce picking accuracy and productivity, as warehouse employees must sift through bins to find the correct color or size of an item. To avoid these issues, store only one SKU per location.

For example, if you separate different colors of the same t-shirt into distinct bins, pickers can quickly locate and retrieve the specific item a customer has ordered without confusion, speeding up the process and reducing errors.

Establish Warehouse Picking KPIs

Optimizing your picking processes is challenging without knowing your current performance. Key performance indicators (KPIs) can help you set performance benchmarks for your inventory management, picking and packing processes.

These insights allow you to recognize ideal outcomes and pinpoint areas for improvement.

In the context of piece picking, align with warehouse KPIs, such as pick accuracy, order cycle time and items picked per hour.

Continuously Improve Processes

Regularly review and analyze picking operations to identify bottlenecks or inefficiencies.

Implement continuous improvement practices and follow the lean warehousing principles to refine your warehouse operations.

Train Your Warehouse Staff

Regularly train your employees in the latest picking techniques and safety practices.

For example, you can provide hands-on workshops that simulate real-life scenarios, interactive online courses covering new technologies and methods or regular safety drills to keep everyone up to date on best practices and emergency procedures.

This training improves efficiency and ensures a safer working environment.

Monitor and Adapt to Demand Patterns

Use data analytics to understand demand patterns and adjust stocking and picking strategies accordingly to meet customer needs more effectively.

When you analyze sales data, seasonal trends and customer purchasing behavior, you can predict future demand more accurately.

For example, you can increase stock levels of high-demand items or reposition them for swift access.

Optimize Your Picking Operations with Modula’s Automated Warehouse Picking Systems

As a top provider of automated warehouse solutions, Modula’s automated solutions optimize warehouses across various industries to boost their picking speed and accuracy.

Our automated picking systems streamline the process by reducing time and allocating labor to more pressing tasks such as quality assurance, while enhancing accuracy and throughput.

With advanced picking aids, user-friendly technology, and smart software, we deliver a seamless and efficient workflow.

Our advanced order picking solutions include:

- Modula Put to Light: The Put to Light System, operating in batch or multi-order modes, significantly increases throughput by allowing simultaneous picking of multiple orders. This system replaces traditional paper-based methods like pick tickets and shipping lists, further reducing errors, improving inventory accuracy and boosting productivity.

- Modula Picking Station: Modula Picking Station is engineered to manage batch and multi-order processes. It can be used individually or in multiple locations as needed, and provides a versatile and precise solution to complete more orders faster. To top it off, its paperless system discards the need for order lists, accelerating the picking process.

- Modula Picking Cart: Modula Picking Cart is the perfect solution for mobile, paperless batch, or multi-order processes. It comes with a put-to-light display and can connect wirelessly to the WMS for optimal route planning.

- Modula Mobile Picking App: Modula Picking App is a user-friendly tool that keeps your operators connected with real-time updates and full control of warehouse processes. Ditch the paper and bulky printouts. Access real-time information directly on your smartphone or tablet, making picking operations seamless and organized.

Discover our automated solutions and connect with our team to understand how we can elevate your warehouse operations.