What Is Lean Warehousing? Benefits, 5S Principles & Best Practices

Lean warehousing addresses persistent challenges in warehouse management by eliminating waste and streamlining operations.

Whether it’s cutting excess inventory, reducing inefficiencies or managing damaged goods, the goal is the same: maximizing value by minimizing waste.

A recent humanitarian logistics guide shows how smarter handling of packaging, expired stock, and end-of-life equipment can significantly improve efficiency, reinforcing lean principles that apply across different industries.

In this article, we will:

- Break down the core principles, benefits and best practices of lean warehousing

- Show you how to implement lean strategies across your warehouse operations

- Introduce you to the advanced automated solutions and inventory management systems at Modula to help you implement a lean approach in your warehouse operations

What Is Lean Warehousing?

Lean warehousing is an approach to warehouse management that eliminates warehouse processes or activities that use resources but do not create additional value, thus reducing waste while boosting efficiency, productivity and customer satisfaction.

This approach was initially developed in automotive manufacturing by Toyota.

Let’s take a manual picking process as an example.

Manual picking requires your warehouse operators to use pick lists and navigate pick locations manually. This can be seen as wasteful. It uses resources, including time and labor, but it doesn’t add any value for customers.

A lean warehousing approach might replace the manual pricking process with an automated solution to eliminate resource waste.

Benefits of Lean Warehousing

Lean warehousing helps you cut waste, streamline operations and get more out of your team on the floor.

Think of it as working smarter, not harder, to boost productivity and efficiency.

Here are some key benefits of adopting a lean approach:

- Raise productivity: Lean warehousing is all about cutting out wasteful processes like overproduction or storing more inventory than you need. By zeroing in on the tasks that actually add value, you can boost productivity and keep operations running smoothly.

- Boost employee safety: Lean warehousing prioritizes workplace safety by utilizing warehouse automation to eliminate the need to reach high and low places, reducing both clutter and unsafe work practices.

- Increase employee morale: Lean principles promote employee involvement and empowerment. When team members are engaged in continuous improvement efforts, retention improves. So does their commitment to the warehouse’s success.

- Cut down on downtime: When your processes are running efficiently, your warehouse keeps moving, and that means fewer delays.

- Reduce the need for more storage space: Instead of moving to a bigger facility, the lean approach allows you to optimize inventory levels and reduce excess stock in your existing warehouse. This in turn, allows you to eliminate the high cost of expanding your warehouse or leasing additional space.

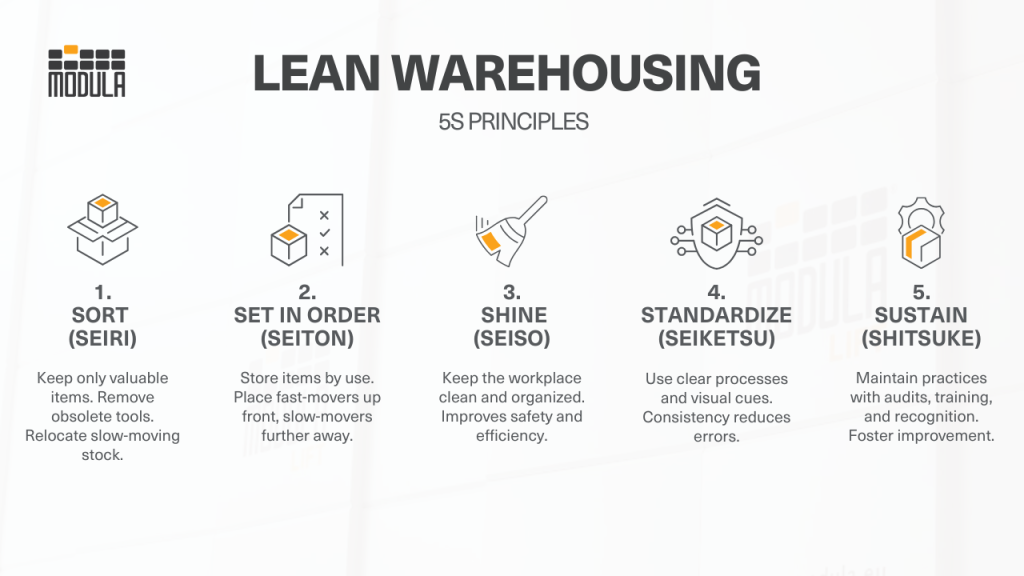

The 5S Principles of Lean Warehousing

The 5S principles are a fundamental part of all lean methodologies, including lean warehousing.

These principles can help you create an efficient, organized, and safe working environment when applied to every aspect of the warehouse operation. From your warehouse design to how goods are picked and packed.

The 5S principles (and their Japanese counterparts) include:

1. Sort (Seiri)

The Sort principle states that each item in the warehouse should be thoroughly assessed to ensure it is valuable. Items that are obsolete, redundant or rarely used should be removed.

To implement the Sort principle, eliminate anything that isn’t used regularly and discard unnecessary items like unused tools and equipment.

If you have slow-moving inventory that has been sitting for a long period of time, put it in a separate storage area to free up space in your working warehouse.

This makes it easier for your warehouse operators to find the items they need, enhancing efficiency.

2. Set in Order (Seiton)

The Set in Order principle states that items should be stored in specific locations based on their frequency of use, ensuring that they are accessible when needed.

The Set in Order principle is implemented by organizing your inventory to make items easy to find and access.

One way to comply with the Set in Order principle is to apply the ABC analysis method, categorizing goods based on their value and turnover.

Store your fast-moving items (category A) in easy-to-access areas near the dispatch area, while keeping your slow-moving items (category C) in less frequently accessed areas, such as mezzanines or in the back corner of the warehouse.

3. Shine (Seiso)

The Shine principle states that a clean and well-maintained warehouse is crucial for promoting safety and efficiency.

To implement the Shine principle:

- Establish a routine for regular cleaning and organizing activities: Make a schedule for sweeping, dusting and mopping floors, wiping down surfaces, and removing debris or trash. Assign responsibilities to specific warehouse employees or hire professional cleaning services.

- Use shelves, racks, totes and bins: Make sure items are stored in an organized and easily accessible manner. Implement labeling systems or barcode scanners to facilitate quick identification and retrieval of goods.

- Optimize your warehouse layout: Minimize congestion and allow for efficient movement of goods. Make sure pathways are clutter-free and that warehouse equipment, such as forklifts and pallet jacks use designated routes to prevent accidents.

4. Standardize (Seiketsu)

The Standardize principle states that consistent processes, procedures, and guidelines should be established and followed to maintain efficiency.

To implement the Standardize principle:

- Documenting existing processes and procedures within the warehouse: This includes workflows, inventory management, order fulfillment, receiving, picking, packing, and shipping processes. Take note of any variations or inefficiencies in these processes.

- Analyzing documented processes and identifying areas where best practices can be established: This involves identifying the most efficient and effective ways of performing tasks, reducing waste, and improving overall productivity. Benchmark against industry standards and seek input from employees who are directly involved in these processes.

- Creating clear and concise work instructions for each task or process: These instructions should outline the step-by-step procedures, expected outcomes, quality standards, and safety precautions. Standardized work instructions serve as a reference point for employees to consistently perform their tasks.

- Providing training for your warehouse staff: Train your staff on the newly established work instructions. Ensure that employees understand the procedures, follow the guidelines, and are capable of performing their tasks according to the standard.

- Utilizing visual cues: Use signs, labels, color-coded indicators or floor markings to visually represent the standardized processes and guidelines. These visual management tools help employees easily identify the correct procedures, locations or materials, reducing errors and promoting adherence to the standard.

5. Sustain (Shitsuke)

The Sustain principle states that the first four S’s (Sort, Set in Order, Shine and Standardize) should be consistently maintained to create a culture of continuous improvement.

To implement the Sustain principle:

- Conduct regular audits: Identify any areas that need improvement and ensure standards are being maintained

- Provide ongoing training: Consistently reinforce the importance of 5S practices and ensure your warehouse operators know how to apply them

- Acknowledge warehouse employees: Reward your staff who maintain high standards to boost their morale and job satisfaction and encourage other operators to follow their lead

How To Implement Lean Warehouse Management

Auditing your warehouse processes is one of the best ways to spot what’s slowing you down and find opportunities to improve.

In fact, a 2025 review of 16 lean warehousing case studies found that regular, structured audits consistently led to efficiency gains in manufacturing environments, proving just how valuable this step can be.

1. Audit Your Warehouse Processes

Auditing your warehouse processes is key to identifying inefficiencies and areas that need improvement in your warehouse.

- Define your objectives: These might include improving efficiency, reducing costs, ensuring safety compliance, enhancing customer service or identifying training needs. Clear objectives will help you focus on the audit.

- Create an audit checklist: Develop a list of areas to examine based on your objectives. This might include inventory management, order picking, packing and shipping, equipment maintenance, space utilization and employee training.

- Gather data: Use different methods to collect information, such as physical inspections, staff interviews, documentation review (like shipping records or safety logs) and data analysis (like order fulfilment times or error rates).

- Analyze the data: Look for patterns that indicate a problem. For example, if there are frequent stockouts of specific items during a certain season, this might indicate inadequate stock of fast-moving items.

- Benchmark your performance: Compare your performance to industry benchmarks, essential KPIs or your own historical data to identify areas for improvement.

- Provide recommendations: Based on your findings, recommend improvements. This might include changes to procedures, equipment, warehouse layout or employee training.

- Present your findings: Prepare a report outlining your findings and recommendations. Then present this to the relevant stakeholders. .

2. Implement Just-in-Time (JIT) Inventory Management

Just-in-time is a type of inventory management that requires you to work closely with suppliers to ensure that raw goods arrive just as production is scheduled to begin.

Implementing JIT inventory management allows you to boost efficiency, eliminate excess inventory and minimize storage costs, goals that are in line with lean manufacturing.

To implement JIT inventory management in your warehouse:

- Collect historical sales data at a granular level (by consumer behavior or SKU, for example) to provide a detailed outline of demand patterns.

- Develop strong relationships with your suppliers and involve them in your planning process. Communicate your demand forecasts with your suppliers and ensure they can meet your requirements in terms of quantity, quality and timing.

- Avoid stockouts with inventory-management software that automatically triggers purchase orders when your supplies reach low levels.

- Implement strict quality control measures, both in your own operations and with your suppliers, to prevent defective products.

3. Train Your Warehouse Employees

Implementing lean warehousing requires that you change processes and restructure employees’ mindsets.

Training warehouse employees is key to ensuring that everyone understands the principles of lean manufacturing and how to put them into practice.

To train your employees on lean warehousing practices:

- Provide a thorough orientation program for new employees. The program might include an introduction to the principles of lean warehousing, for example, along with an overview of your company’s specific processes and procedures, plus a clear explanation of employee roles and responsibilities within the warehouse.

- Offer specific training sessions focused on lean warehousing principles and practices such as the 5S methodology, value stream mapping, waste reduction techniques, visual management and problem-solving tools for continuous improvement.

- Provide hands-on training opportunities for your employees to apply lean concepts such as mock simulations, role-playing exercises or actual work assignments.

4. Utilize Warehouse Automation

Automation can significantly improve efficiency and accuracy in your warehouse.

Automated warehouse solutions include automated storage and retrieval systems, robotic picking systems and warehouse management systems that can boost picking accuracy and speed.

5. Utilize Continuous Improvement (Kaizen)

The lean journey doesn’t end once the initial improvements have been implemented.

Implement scalable systems like modular racking, automated storage and flexible WMS platforms that can evolve with your warehouse as it grows.

Then establish regular review cycles to assess key areas such as workflows, slotting accuracy and pick paths each month or quarter.

Encourage floor staff to flag inefficiencies and share ideas for improvement.

With small, data-driven changes made consistently over time, you’ll create a lean, adaptable operation that stays efficient even as demands shift.

You can sustain a culture of continuous improvement by holding regular team meetings to discuss ideas or hosting formal kaizen events where your team works together to solve particular problems.

Achieve Lean Warehousing With Modula Automated Warehouse Solutions

As a leader in automated storage solutions and warehouse management systems, Modula provides advanced solutions that can enhance productivity, efficiency and picking accuracy — primary goals that align with the lean warehousing approach.

Our automated solutions include:

Modula Vertical Lift Modules

Modula Vertical Lift Modules (VLMs) maximize your existing warehouse space by utilizing your available ceiling height, boosting efficiency and capacity.

Modula VLM models include:

- Modula Lift: Perfect for storing industrial and spare parts; available in a wide variety of capacities and sizes.

- Modula Slim: Ideal for warehouses with limited floor space, thanks to its compact design.

- Modula Next: Instead of opening the entire unit like traditional vertical lift modules, Modula Next opens only the compartment with the item you need. That means more precise, efficient picking and restocking.

- Modula Pallet: Modula Pallet keeps all pallet handling at ground level so you can take advantage of vertical space without the risks that come with lifting heavy loads overhead.

- Modula Flexibox: Our latest automated solution combines speed, efficiency and flexibility. It can handle up to 180 bins per hour, helping you cut down on unnecessary movements and make the most of your vertical space.

Our VLMs allow you to:

- Save up to 90% of floor space by taking advantage of your available ceiling height

- Speed up order processing with a throughput of 140 trays per hour

- Increase picking speeds to over 300 lines per hour

- Enhance employee safety by removing the need for reaching high and low areas

- Safeguard your inventory thanks to a secure, enclosed system

Modula Horizontal Carousel

The Modula Horizontal Carousel (HC) is the ideal automated storage solution for facilities where ceiling height is limited.

Our HC allows you to:

- Modify shelf spacing to store different goods

- Boost picking rates to 550 lines per hour per operator

- Achieve complete visibility of stock levels and orders

- Monitor picking operations in real time

- Achieve near-perfect picking accuracy, hitting 99% with our Put to Light Systems and barcode readers

Modula Picking Solutions

Modula picking solutions reduce the search time needed for navigating inventory and boost picking accuracy when handling large or individual orders.

Our Picking Solutions allow you to:

- Improve picking accuracy and speed using light devices that guide your warehouse operators to the right location

- Enhance inventory management with a comprehensive view of your current and forecasted stock

- Further drive order accuracy and efficiency when paired with our advanced automated storage solutions

Modula Warehouse Management System

Modula Warehouse Management System (WMS) enables you to monitor your inventory’s location and movement, giving you full insight into your stock levels.

Our WMS allows you to:

- Experience full inventory visibility

- Monitor and track stock levels and inventory movement

- Enhance accuracy when paired with Modula ASRS

Modula’s advanced storage solutions and warehouse management system allow you to implement a lean approach to your warehouse operations to optimize your storage space, improve your picking accuracy and boost your employee’s productivity and efficiency.

Lean Warehousing Explained: Key Takeaways

- The core principle of lean warehousing is to cut activities that don’t add value, including excess inventory, inefficient workflows and unnecessary movement

- Applying the 5S methodology (Sort, Set in Order, Shine, Standardize and Sustain) keeps your warehouse organized, safe and efficient while driving continuous improvement

- When you integrate automated systems like ASRS, WMS, and picking solutions with Kaizen practices, warehouses can scale efficiently, reduce downtime and stay responsive to changing operational needs

Lean Warehousing Explained: FAQs

What’s the main goal of lean warehousing?

Lean warehousing is all about improving efficiency by cutting out anything that doesn’t add value.

The goal is to streamline operations, improve accuracy and boost responsiveness, all while doing more with less.

How is lean warehousing different from traditional warehouse management?

While traditional warehouse management tends to focus on maximizing storage and throughput, lean warehousing puts efficiency and flexibility first.

It’s about reducing waste at every stage, from receiving to shipping, and constantly improving processes with input from your team.

Can lean warehousing work in automated warehouses?

Yes. In fact, automation and lean principles go hand in hand. Tools like ASRS, WMS and real-time analytics help ensure your technology supports efficient, value-added processes.