What Is Buffer Storage? Benefits and How to Automate It in Manufacturing

Efficient material flow is essential to keep production lines running smoothly. When one process slows down or stops, it can create bottlenecks and costly downtime across the entire operation.

That’s where buffer storage comes in.

A production buffer storage provides temporary holding areas between production or warehouse stages, helping balance workflow and absorb short-term fluctuations in demand or output.

When automated, it ensures steady throughput and minimizes manual handling.

In this guide, we will:

- What buffer storage is and how it works in manufacturing

- The benefits of using buffer storage systems

- Share how buffer storage works with automated storage and retrieval systems (ASRS)

- Explore how Modula’s storage solutions can optimize buffering in your facility.

What Is Buffer Storage in Manufacturing?

Buffer storage refers to a temporary holding area used to balance the flow of materials between different stages of production or between production and shipping.

It acts as a cushion that absorbs short-term fluctuations in cycle times or material flow, ensuring that a delay in one stage doesn’t cause the entire process to stop. This keeps operations continuous and efficient.

For example, in a manufacturing line, semi-finished parts can be stored in a buffer while the next workstation completes its task.

Once ready, the buffer releases the items to maintain continuous production and prevent downtime.

How Does Buffering Work in Practice?

The role of a production buffer is to balance connected processes, allowing each to operate independently at its own pace.

In manufacturing: imagine a CNC machine (Process A) feeding parts to an assembly station (Process B). A buffer placed between the two stores components temporarily. If Process A stops briefly, Process B can keep working by pulling parts from the buffer. This ensures continuous production and improves equipment utilization.

In warehousing: a buffer can hold picked items before they move to the packing or shipping area. This helps maintain a steady flow even when picking speed varies, improving order accuracy and throughput.

Buffer storage is also common in warehouses and distribution centers, where it helps temporarily hold goods before order fulfillment or shipping, supporting a steady and efficient workflow.

Buffer Storage vs. Safety Stock: Understanding the Difference

Although they sound similar, buffer storage and safety stock serve different purposes.

- Safety stock protects against external uncertainty, such as supplier delays or unexpected demand increases. It’s extra inventory kept to avoid stockouts.

- Buffer storage protects against internal uncertainty, such as process variations, machine downtime, or unbalanced workflows. It’s inventory held to maintain smooth operations between stages.

How Does Buffer Storage Work With ASRS?

Buffer storage and automated storage and retrieval systems (ASRS) work together to keep production moving smoothly and fulfillment on schedule.

ASRS are fully automated storage and picking systems that store high volumes of raw materials or finished goods in compact footprints.

When used as buffer zones, they ensure materials, parts, or finished goods are always available when needed, even if other processes slow down.

Here’s how they complement each other:

- Temporary holding areas: ASRS leverages buffer zones to temporarily store materials or finished goods before they move to the next step, whether it’s packaging or shipping.

- Optimized space: Unlike traditional buffer zones that take up floor space, automated storage and retrieval systems use vertical storage to hold inventory compactly while still offering fast access.

- Load balancing: If downstream operations slow down, ASRS can hold excess items to prevent bottlenecks and keep upstream processes running without interruption.

- Managing demand spikes: During peak periods, buffer zones help absorb surges by pre-positioning inventory for faster picking and fewer delays.

- Smart sequencing: ASRS prioritizes items in your safety stock based on real-time demand, order urgency or expiration dates, ensuring the right products move at the right time.

To further improve efficiency, you can integrate warehouse management software (WMS), which will:

- Provide real-time inventory quantity reports

- Notify you when products are running low to prevent shortages, or when inventory has reached maximum levels to support first in, first out (FIFO) delivery

- Alert warehouse operators when the buffer stock is ready for delivery

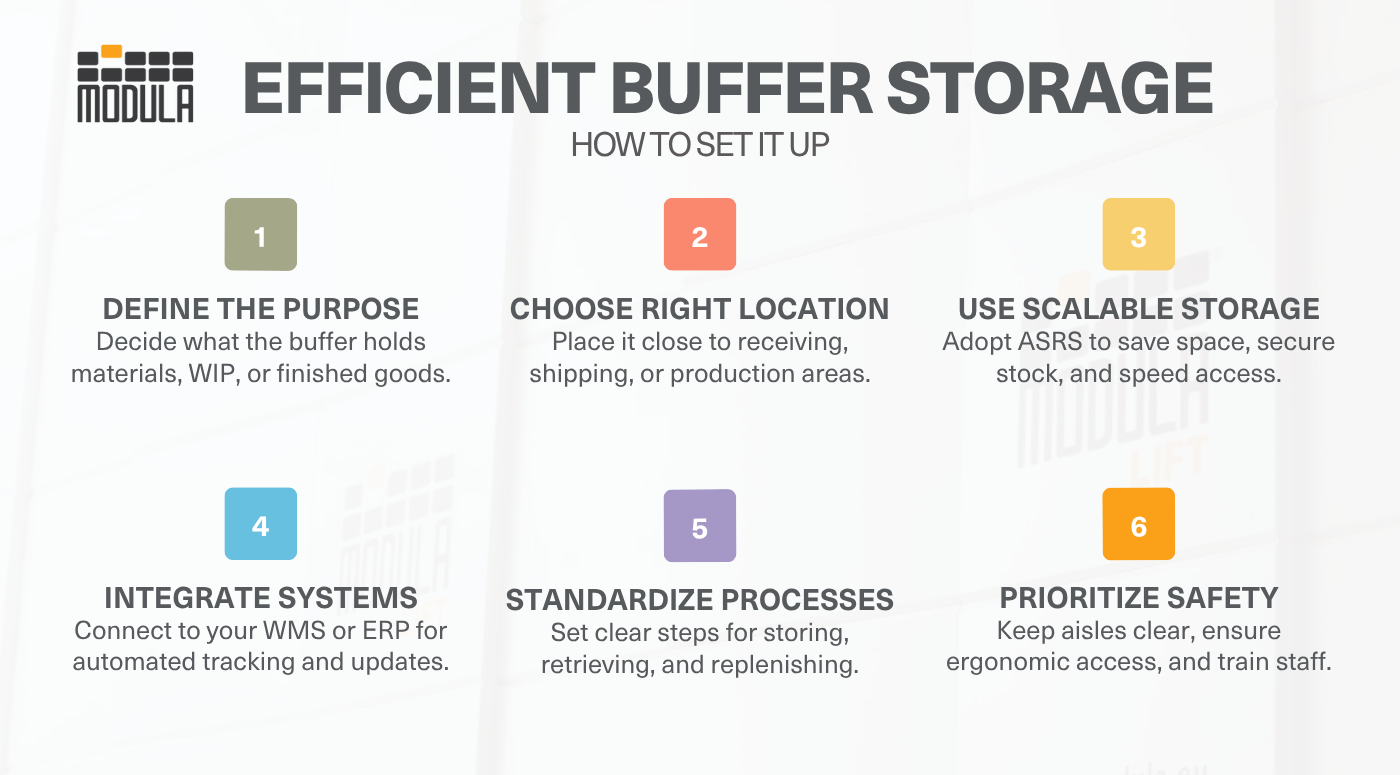

How To Implement an Efficient Buffer Storage Area

Manufacturers, suppliers, and retailers rely on buffer storage to prevent stockouts, keep up with production demands, and meet customer expectations.

An efficient buffer system maintains a continuous flow of materials, minimizes clutter, and keeps production and fulfillment running without delays.

If you’re starting from scratch, or refining your setup, here’s how to build an efficient buffer storage plan that supports flow and flexibility.

Define the Purpose

Start by clarifying what your buffer will hold — raw materials, work-in-progress goods, or finished products.

This will shape the buffer’s size, location, and how quickly items need to be accessed.

Choose the Right Location

Position your buffer near receiving, shipping and along manufacturing lines to keep goods moving efficiently. The closer it is to the point of use, the less handling time and the fewer disruptions to your workflow.

Use Scalable Storage

When inventory levels fluctuate, static shelving can create bottlenecks. Instead, automated storage and retrieval systems (ASRS) like Modula’s vertical lift modules provide flexibility and control by:

- Maximizing vertical space

- Keeping buffer stock secure and organized

- Offering fast, programmable access to stored items

Integrate With Your Systems

Connect your buffer storage with your warehouse management system (WMS) or ERP platform.

This allows for automated stock movements, real-time tracking and inventory replenishment, so nothing gets lost or left behind.

Standardize Your Processes

Clear, documented procedures for staging, storing, retrieving and restocking buffer items are essential because they prevent errors and keep operations consistent across shifts and during peak periods.

Prioritize Safety and Accessibility

Keep aisles and access points free of pallets, carts or loose materials to prevent trips and falls. Ensure employees can reach stored items without bending, stretching or climbing in unsafe ways.

For automated systems, provide hands-on training, post clear operating instructions near control panels and establish emergency stop procedures to support safe, consistent use.

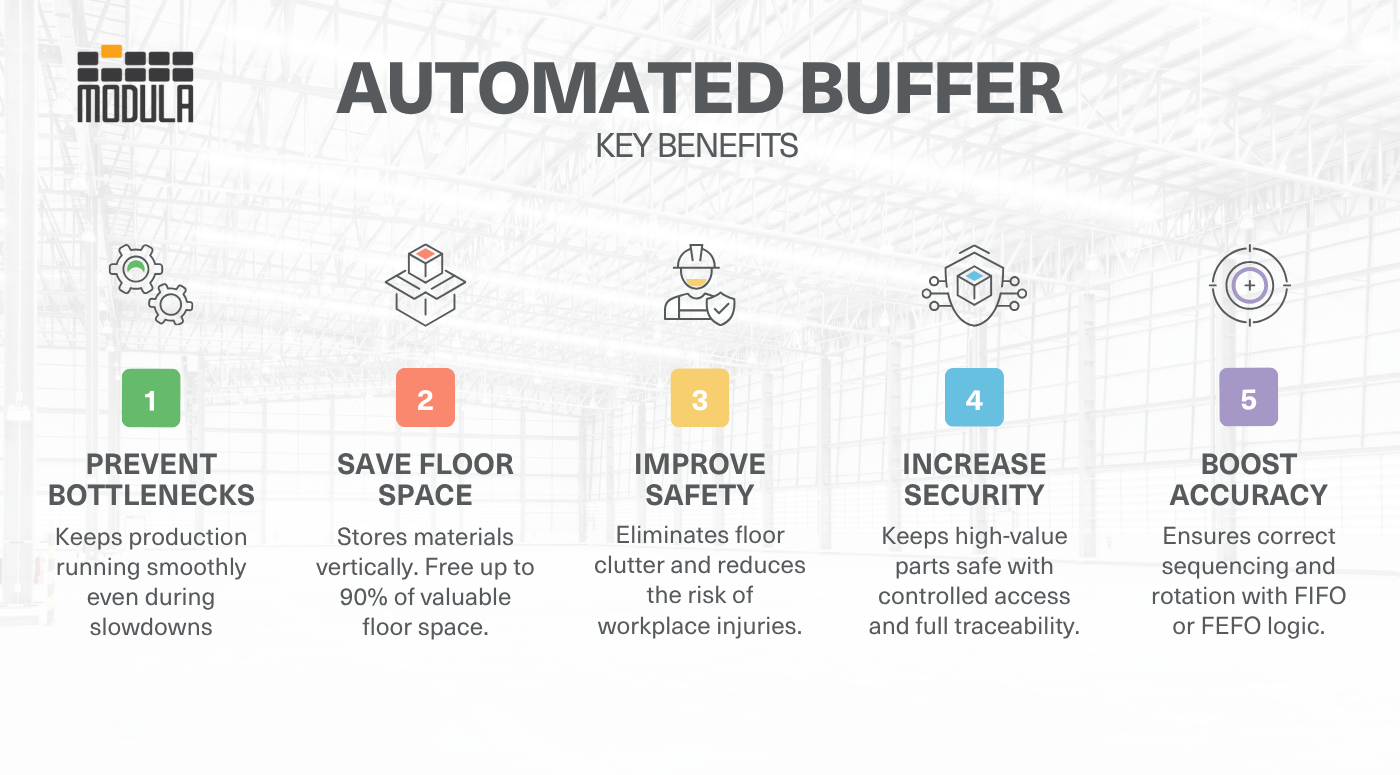

5 Benefits of Buffer Storage Solutions in Production

Buffer storage in production offers a secure, organized space to protect both your products and your employees.

These storage solutions help you reclaim space, avoid picking mistakes and optimize operations.

Wondering if it’s worth it? Here are five solid reasons to consider making the switch.

Preventing Bottlenecks and Downtime

The primary goal of a production buffer is to prevent interruptions in the workflow.

By separating connected processes, an automated buffer ensures that a temporary slowdown at one workstation doesn’t halt the entire production line.

This keeps machines operating at full efficiency and maintains consistent throughput across all stages.

Reclaiming Valuable Floor Space

Traditional buffer areas often occupy large sections of floor space with pallets, carts, or bins.

Automated storage systems, such as Vertical Lift Modules (VLMs), use vertical storage to hold materials compactly and reclaim up to 90% of floor space.

That space can then be repurposed for production lines, assembly areas, or quality control.

Improving Workplace Safety

According to OSHA’s report, the manufacturing sector reports one of the highest volumes of workplace injuries and illnesses across all industries.

A common safety risk comes from cluttered floors, often caused by boxes and goods left waiting for the next stage of delivery.

Using an automated buffer storage system eliminates this hazard by organizing temporary goods in a secure, designated space. This keeps the walkways clear and allows employees to move safely through the facility.

Increasing Inventory Security and Control

Whether you operate an SMB or large enterprise, buffer materials, especially semi-finished or high-value parts, are at risk of damage or theft when stored in open areas.

Automated buffer systems limit access through secure user logins and record every transaction, ensuring full traceability and inventory protection.

Enhancing Accuracy and Rotation

Manual buffers make it difficult to keep items in the correct sequence or track expiration dates.

An automated buffer integrated with Modula WMS automatically enforces FIFO (First-In, First-Out) or FEFO (First-Expired, First-Out) logic, improving process accuracy, inventory rotation, and product quality.

Leading Modula Solutions for Buffer Storage in Warehouse Automation

Managing buffer stock doesn’t have to be a headache. At Modula, we simplify it with automation that keeps your operations running smoothly.

Our automated solutions save space, improve employee safety, prevent mispicks and boost workforce productivity and accuracy.

Modula Vertical Lift Modules

Maximize your buffer storage capacity by going vertical.

At Modula, we offer five advanced vertical lift modules designed to keep inventory accessible, organized, and ready for the next stage in your workflow.

- Modula Lift, our most popular vertical lift module, is the perfect storage solution for industrial goods, components and spare parts for every workplace environment and industry.

- Modula Slim is the optimal storage solution for warehouses with limited floor space.

- Modula Next combines the space-saving power of vertical lift modules with the precision and control you’d expect from an industrial vending machine.

- Modula Pallet stores pallets vertically to help you make the most of your warehouse space, without relying on forklifts.

- Modula Flexibox is our latest solution for eCommerce, retail, automotive and distribution operations, delivering up to 180 bins per hour while minimizing cycle movements.

Our Vertical Lift Modules allow you to:

- Saves up to90% of floor space by using a minimal footprint, taking advantage of the available ceiling height

- Increase picking speeds of 300 lines per hour or more

- Keep your goods safe by securing them in an enclosed system with restricted access

- Receive goods automatically thanks to the user-friendly Copilot controller

- Boost inventory management with monitored and documented picking operations

- Improve safety for warehouse operators by eliminating the need to reach for products

- Accommodate heavy loads without strain

- Reduce employee and operational costs

Modula Horizontal Carousels

If your warehouse ceiling height is limited, our Modula Horizontal Carousels offer the perfect storage solution.

Our Horizontal Carousels allow you to:

- Store more goods with compact and high-density storage areas

- Retrieve items quickly and easily with Modula’s digital Copilot feature

- Integrate with Modula Warehouse Management Systems (WMS) to boost accuracy and productivity

- Promote 99% picking accuracy with our Put to Light Systems and barcode readers

- Utilize picking rates of up to 550 lines per hour for each warehouse employee

- Offer the most ideal working environment by protecting employees against hazards, minimizing physical strain, enabling fast machine stoppage and removing unessential travel around the warehouse

- Monitor picking operations in real-time thanks to automation

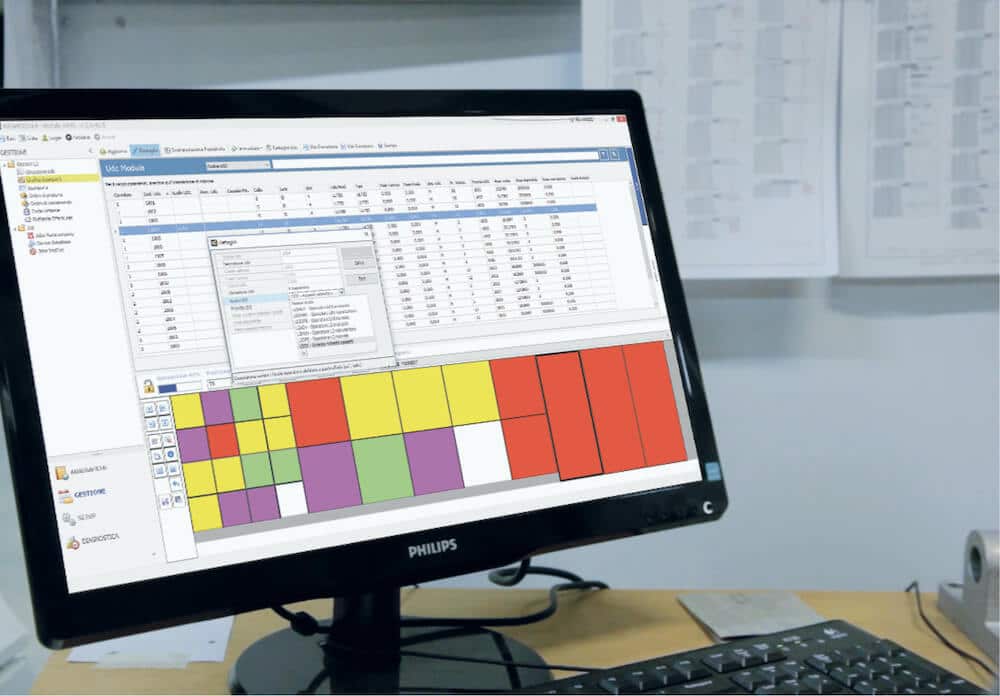

Warehouse Management Solutions

Take your automated storage systems to the next level with our warehouse management solutions to increase accuracy, productivity and efficiency.

Our Warehouse Management Solutions allow you to:

- Access extensive inventory control and visibility

- Boost accuracy when integrated with our automated storage solutions, as well as retrieval methods including picking and shelving

- Gain better control over managing inventory, materials handling and preventive maintenance guidance

- Operate in batch and multi-order modes without compromising productivity and quality for larger than usual orders

Modula Warehouse Order Picking Solutions

Easy to install and navigate, our order picking solutions are ideal for boosting your safety stock management when dealing with multi- and batch orders.

Our Modula Warehouse Order Picking Solutions include:

- Modula Put to Light to guide your warehouse operators to the accurate location on a station or cart in which to “put” the items

- Mobile Picking Station to process large quantity orders in less time

- Modula Picking Cart to move retrievals to different locations within your warehouse

- Modula Mobile Picking App to manage your manual picking operations from the touch of your smartphone or tablet

Buffer Storage: Key Takeaways

Buffer storage plays a bigger role than most give it credit for. It helps you stay ahead of unexpected demand, protects your products and makes smarter use of your warehouse space, all without slowing down your flow.

- Buffer storage can help manufacturers and warehouses absorb demand spikes, avoid stockouts and maintain a continuous production and fulfillment flow

- ideal for holding raw materials, work-in-progress items, or finished goods that are waiting to move to the next step, whether that’s assembly, packaging or shipping

- From vertical and horizontal storage systems to WMS integration and guided picking tools, Modula provides a complete suite to automate and optimize buffer storage at scale

Buffer Storage: FAQs

What is a buffer?

A buffer is simply a temporary space where materials or products are held before moving to the next step.

It helps keep things running smoothly in a warehouse by preventing delays between product phases.

What does a buffer do?

A buffer keeps your operations flowing. It acts like a cushion, holding materials so that if one part of the process slows down, the rest doesn’t have to stop and wait.

What is buffer storage in production and what is it used for?

In production, buffer storage keeps raw materials, work-in-progress items, or finished goods until they’re ready for the next stage.

It helps avoid bottlenecks and keeps the production line moving.

Why are buffers important?

Buffers are important because things don’t always go as planned. Suppliers run late, machines can stall and demand can spike without warning.