Modula Put To Light

How Put to Light works

Put to Light Systems, also referred to as ‘scan and sort,” allow you to break large product quantities into individual orders. Light devices indicate the location on a station or cart and the number of items needed for the order.

Each time an item is slotted into the correct position, the user presses a confirmation button to indicate the task is complete.

Designed to Maximize Efficiency

By picking and putting multiple orders, operators save time and don’t need to perform cumbersome manual tasks, such as reviewing pick tickets or paper lists.

Thanks to the integration with the Modula WMS, all operations are monitored, offering a real-time view of order status and inventory.

Pair the Put to Light System with our Picking Stations and Carts

Modula Picking Stations

The Modula Picking Station is ideal for operations with predetermined put positions.

Modula Picking Cart

Need to move retrievals to different locations? Use the Modula Picking Cart – a Put to Light station on wheels.

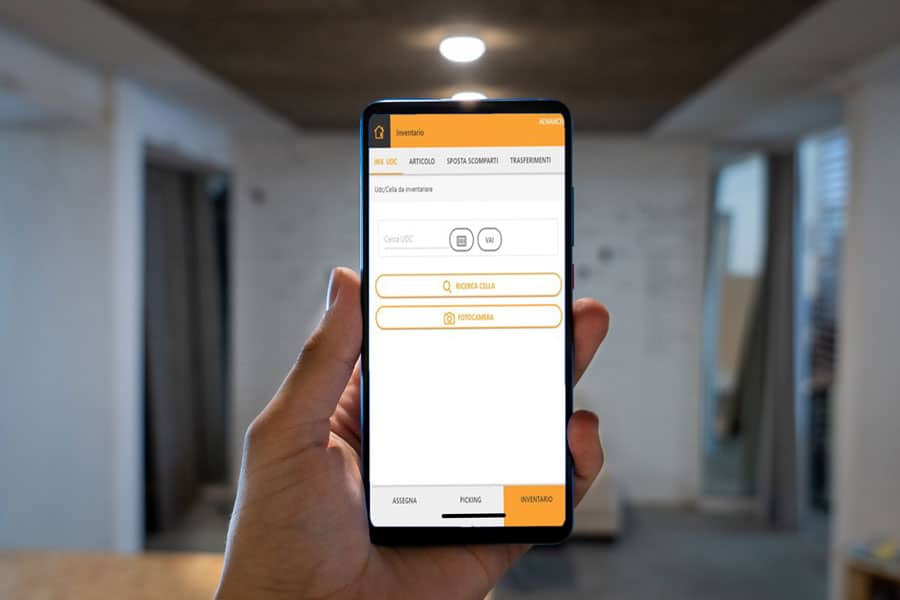

Even more Flexibility with the Modula Picking App

With the new Modula Picking App, operators can freely move around the warehouse while keeping all processes instantly updated and under control.

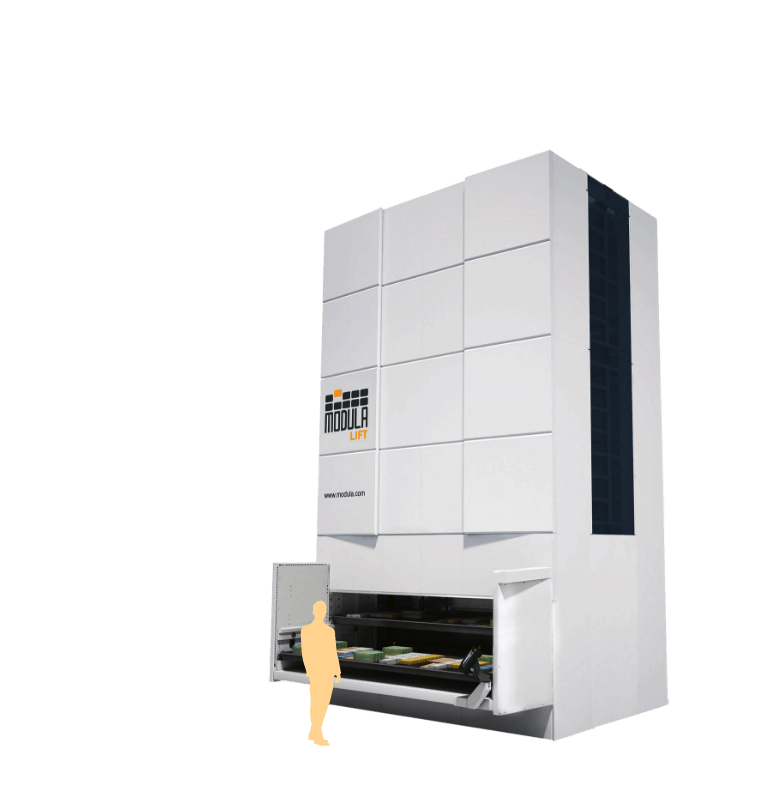

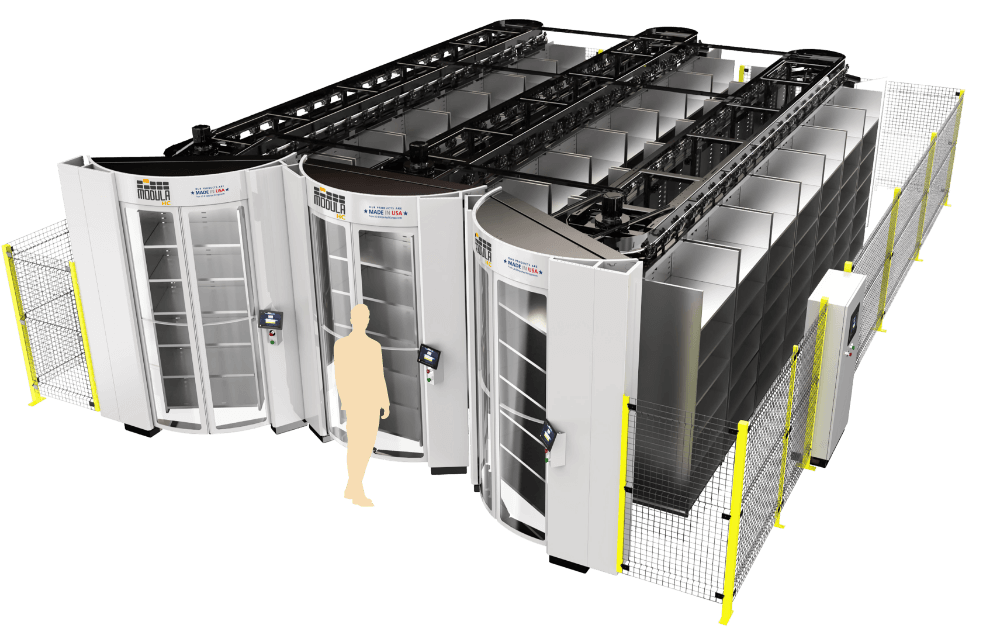

Pair Our Picking Stations with Modula Automated Storage & Retrieval Systems

Boost Your Picking Solutions with End-To-End Inventory and Warehouse Management

Modula Picking Solutions In Case Studies

Subaru of New England, Increases Storage Efficiency with VLMs and put-to-light system

With 9 VLMs and a put-to-light batch picking system, Subaru of New England can process up to 60 orders at a time, with picking rates of over 1,600 lines per day.

Industrial Automation boosts picking efficiency with Modula Lift and Put-to-Light System

With 1 Modula Lift and a put-to-light batch picking system, Industrial Automation increases picking speed and accuracy and continues growing.

GF Machining Solutions keeps up with growing inventory and orders

With 3 VLMs and a put-to-light batch picking system, GF Machining maintains a 99% same-day shipping rate and stores it growing inventory in 50% less space

Want to improve the performance of your picking operations?

Boosting accuracy, efficiency and reliability with Modula picking solutions