Warehouse Storage Solutions for Small Parts [Types + Our Automated Storage Solutions]

From medicine and vitamins to nuts and bolts, small parts storage is an integral part of warehouse operations.

If you’re handling and storing small parts within your warehouse, it’s essential to keep them organized and secure, to ensure you’re maintaining the highest standards of productivity, safety and efficiency.

We’ll share all you need to know about small parts storage, from small parts storage containers to our automated solutions that keep your small parts safe and orderly.

Plus, we’ll share how we’ve helped our clients streamline their small parts storage through our automated storage solutions.

Let’s get started!

Storing Small Sized Products in a Warehouse

What defines a small part? Small parts are lightweight, small units.

Small parts include metal items, such as bolts and nails, plastic items such as bottle caps and bottles, minerals such as stones and rocks, and pharmaceutical goods such as vitamins and medicine.

While small parts might seem easier to store than the larger, heavier products in your warehouse, they are more likely to be misplaced and overlooked due to their size, resulting in messy areas that can be hazardous to your employees, and lead to product loss and employee theft.

Small parts often come in large amounts, which makes proper storage difficult and for employees to count and pick them accurately.

In addition, small parts are expensive — think automotive and small metal components. Due to their size, small parts can easily be stolen and misplaced.

This puts your business at risk of wasting time and money if your employees need to continuously search for missing goods.

Small Parts Storage Containers

From traditional storage containers such as plastic bins and standard shelving, to technologically advanced automated storage solutions, here are the different types of storage containers that house small parts in the warehouse.

1. Plastic Storage Containers

Plastic storage containers are manual storage systems made from high-grade polypropylene and designed to withstand water and oil spills.

Typically, plastic storage containers are stacked on top of each other or mounted on walls, as part of a storage system.

Plastic storage containers come in many different shapes and sizes, allowing for numerous layout options. They represent an economical alternative to shelving and drawer storage for smaller warehouses.

2. Industrial Cabinets and Drawers

Industrial storage cabinets are used in facilities such as automotive repair, machine shops and small parts areas to store equipment and tools in an organized and clean space.

Typically, they have doors to protect and limit access to the stored items, and can be configured with other tools such as desks and workstations.

Great for small parts and smaller tools, they don’t however best utilize the vertical space available and require more footprint to expand the storage capacity.

3. Standard Shelving Systems

Standard shelving is one of the most common and simple systems for storing small parts. This system is often combined with plastic totes or bins to organize and separate items and they can be easily configurated to store different spare parts and tools.

Shelving systems are grouped into two categories: mobile and static shelving.

Static shelving systems are storage solutions that are situated in a permanent location. Typically, static shelving stores lightweight inventory that needs constant replenishment and they can be incorporated into a mezzanine structure to expand the storage capacity.

Unlike static shelving, mobile shelving systems are mounted on rails, eliminating the need for multiple fixed aisles, as the aisles open up only when the operator requests access.

4. Automated Storage and Retrieval Systems

Automated storage and retrieval systems, also called AS/RS or ASRS, are technologically advanced storage and retrieval solutions controlled by computers and robots.

Thanks to automation, automated storage and retrieval systems securely store small parts to prevent product loss and employee theft. In addition, AS/RS retrieve items automatically for your warehouse operators, to help avoid mispicks.

At Modula, we provide automated storage solutions for small parts storage, to help ensure your small items stay organized and secure in your warehouse.

In addition, we offer warehouse management systems that integrate with automated storage systems, to facilitate accurate picking thanks to barcode readers, laser pointers and LED bars.

Small Parts Storage Solutions: A Look at Our Modula Case Studies

From ensuring goods are stored in a secure system to minimizing space demands and eliminating mispicks, our automated storage solutions offer warehouse solutions for companies across industries.

Here’s a glimpse at how we’ve helped our clients organize, automate and streamline small parts storage.

1. Symrise

The challenge:

Symrise, an international perfume and fragrance company, has a laboratory in Park Avenue, New York.

The laboratory needed a storage solution to display 40,000 perfume bottles in a small space, with limited ceiling height. In addition, they needed to monitor inventory and handling, while ensuring the products were safely stored at room temperature levels.

The solution:

Symrise installed two Modula Sintes 1.7 units and 15 licenses of the WMS tracking software and laser pointers. Thanks to these solutions, Symrise laboratory employees can now safely store, quickly identify and easily track 40,000 perfume bottles whenever an order is placed.

Warehouse Picking Operations improved with Modula solution for Symrise [USA] – Cosmetics

2. Rotor Clip

Rotor Clip, a New Jersey-based manufacturer that specializes in industrial springs, needed additional storage and automated retrieval for its small parts.

Due to the items’ high value, Rotor Clip also needed a storage solution that limits access to unauthorized personnel.

The solution:

Rotor Clip installed two Modula vertical lift modules to store small parts in a limited space. Thanks to these modules, operations were streamlined and most importantly, the items were stored in a secure location to prevent loss and theft.

Warehouse Inventory Optimization increases productivity and safety of manufacturer Rotorclip

Modula Automated Solutions for Small Parts Storage

Whether it’s springs and bolts or small plastic bottles and nails, we provide the ideal storage solutions for every possible small item.

At Modula, our automated storage solutions save space, retrieve items quickly and offer a secure location to prevent theft and product loss.

1. Modula Vertical Lift Modules

Our vertical lift modules make use of your warehouse’s available ceiling height to streamline your small parts storage, while keeping items safe from unauthorized parties.

We offer two vertical lift modules:

- Modula Lift, our best-selling vertical lift module, is the ideal storage solution for small and spare goods, for every industry and workplace environment.

- Modula Slim makes the perfect storage solution for warehouses with limited floor area.

The key benefits of our Vertical Lift Modules include:

- Save 90% of warehouse floor space by utilizing available ceiling height

- Boost picking speeds of up to 300 lines per hour or more

- Secure your small parts in an enclosed and ventilated system by taking control of accessibility

- Boost efficiency and save time locating items

- Receive small parts automatically thanks to the user-friendly Copilot controller or a simple scan of the barcode

- Streamline inventory management with documented and monitored picking operations

- Improve employee safety by eliminating the strain of reaching high and low

2. Modula Horizontal Carousels

Our horizontal carousels are the optimal storage solution when your warehouse ceiling height is limited.

The key benefits of our Horizontal Carousels include:

- Track picking operations in real-time

- Achieve 99% picking accuracy with our Put to Light Systems and barcode readers

- Take advantage of picking rates of up to 550 lines per hour for each operator

- Secure small parts with compact and high-density storage areas

- Receive small parts quickly and accurately with Modula’s digital Copilot feature

- Boost efficiency and prevent mispicks with Modula Warehouse Management Systems (WMS) integration

- Provide an ideal working place for your employees by protecting them against potential accidents, decrease physical strain and eliminate unessential travel within the warehouse

Modula HC for the US Market: the New Horizontal Carousel for Efficient Picking

3. Modula Accessories to Improve Handling of Small Parts

Modula offers a variety of add-on options to take further advantage of the capabilities of our automated solutions. These options drive productivity, ease administrative tasks, and enhance the work environment.

When dealing with storing and handling small items and parts, these accessories offer tangible benefits for the users:

Partitions And Dividers:

Thanks to a range of accessories such as side extensions, removable dividers and containers, each tray or bin can be configured as desired to provide an organized, flexible storage solution for items of various dimensions and shape.

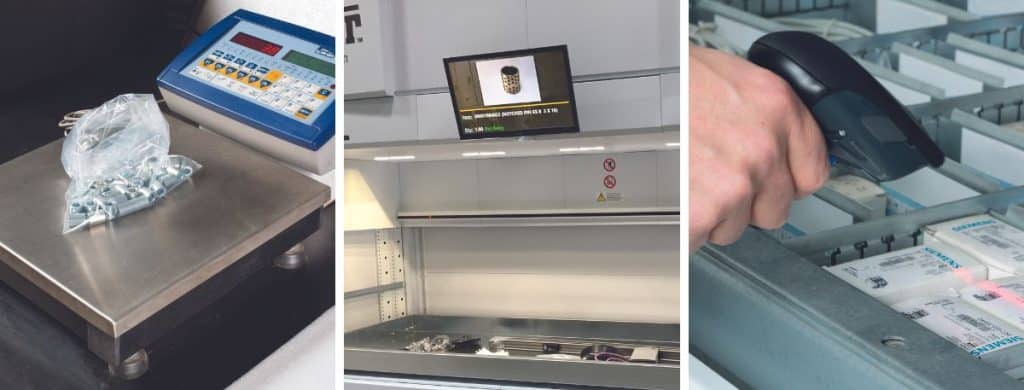

The laser pointer, located at the center of the bay, indicates the precise position of the products in the tray. Adding an order-picking laser pointer is an effective way of boosting production and improving accuracy when picking small items or products.

Laser pointers can be combined with an alphanumeric LED bar that shows the position, code, description and quantity of the item to be picked or placed.

The 24” external picking monitor is another great accessory to simplifying the picking operations of small to medium size items.

Mounted on top of the piking bay, the monitor displays a picture of the item, the order number, and quantity as well as the type of operation. It can also be used to show a larger graphic visualization of the tray layout in addition to the one on the copilot.

The counting scale is the ideal device to pick and replenish small items in large quantities.

With this accessory, users can quickly determine the number of items placed on its platform, based on the unit weight of each individual piece making operations fast and accurate for companies stocking products such as screws, bolts and small parts.

Barcode readers are often used when the items picked from or placed into a warehouse have complex part numbers or are different to distinguish.

The use of barcodes improves picking accuracy and assures correct goods selection by the operators. Barcode readers may also be used to file or confirm orders and for user login purposes.

All these add-ons can be integrated either before or after installation, providing great flexibility.

4. Warehouse Management Solutions

Monitor inventory and boost productivity and accuracy with our warehouse management solutions.

The key benefits of our Warehouse Management Solutions include:

- Access extensive inventory control and visibility

- Increase accuracy and boost retrieval methods, when integrated with our automated storage solutions

- Take better control over inventory management, preventive maintenance and material handling

- Conduct operations in multi- and batch-order modes, without sacrificing quality

5. Modula Warehouse Order Picking Solutions

Our warehouse order picking solutions are perfect for dealing with small parts in multi- and batch orders.

Our Modula Warehouse Order Picking Solutions include:

- Mobile Picking Station to quickly process large orders

- Modula Put to Light to direct your operators to the accurate location on a cart or station to “put” goods

- Modula Picking Cart to transport goods to various areas in the warehouse

- Modula Mobile Picking App to receive updates in real-time and track and manage your manual picking operations from your smart device

Modula presents the new picking solutions to automate and speed up warehouse operations

Wrapping Up on Automated Small Parts Storage

Unlike larger goods, small parts are more prone to misplacement, loss and theft due to their size.

To streamline your small parts storage, invest in automated small parts storage containers that can safely store your small items in a centralized location.

At Modula, our automated small parts storage containers are designed to manage all kinds and sizes of inventory.

Reimagine your small parts storage and utilize your warehouse available space with our automated solutions.