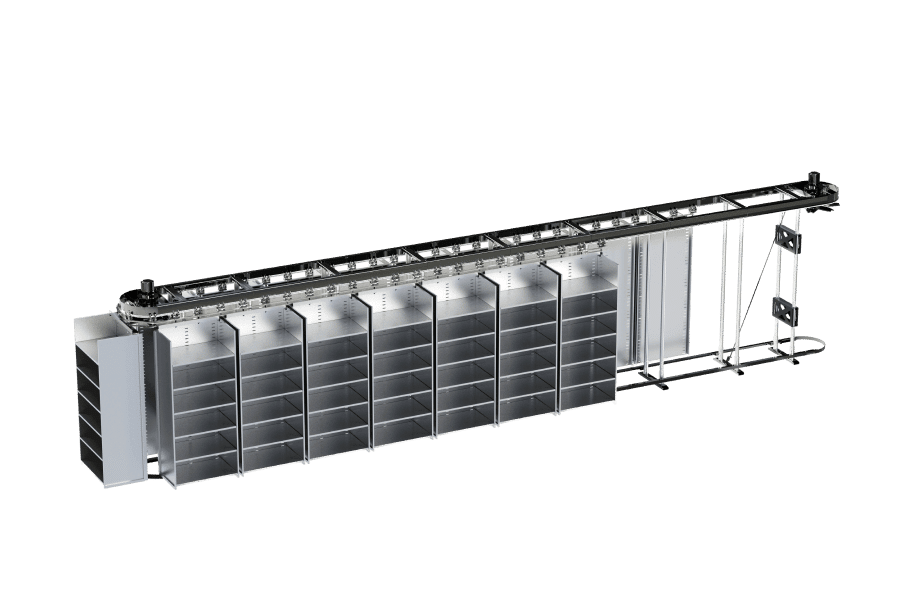

Modula Horizontal Carousel

Modula horizontal carousel (HC) is the ideal solution when you need high-speed picking in a low ceiling environment.

The carousel consists of carriers (bins) mounted on an oval track that rotate horizontally and deliver stored goods to the picker.

In either a production or distribution setting, the HC is extremely effective in saving space, reducing labor costs, increasing throughput and improving accuracy and inventory control.

Modula Horizontal Carousel Benefits

Increased Productivity

Picking Accuracy

Safety & Ergonomics

Traceability and real time inventory

Flexibility for every storage need

Quick ROI

Everything Controlled with User Friendly Interfaces

Main Control Panel

To easily set up and control the carousel, the control panel includes safety features such as an emergency stop button and maintenance lockout key

Full-color Wireless HMI Tablet

Positioned in the picking area, the tablet displays the item details and quantity and highlights the shelf compartments on a graphical diagram.

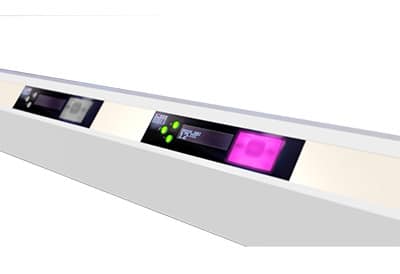

LED Light Bars

The automatic door is equipped with LED light bars to help the operator to locate in the bin the item to be picked

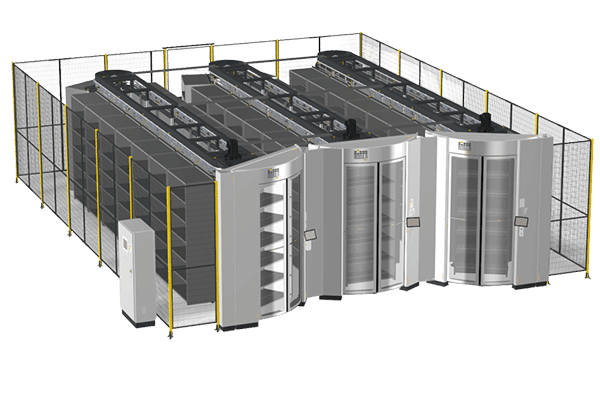

Horizontal Carousels in Pods

Software and pick-to-light technology allows the carousels to work in conjunction with each other and speed productivity.

As the worker picks from one carousel in the pod, the other is pre-positioning the next pick. This minimizes worker downtime and increases throughput. Moreover, horizontal carousels arranged in pods offer great flexibility. With a simple software adjustment, the pods can be easily reconfigured to meet seasonal peaks.

The Modula Horizontal Carousel is offered in in preconfigured groups of two, three, and four carousels per pod.

Faster Order Fulfillment with Batch Picking

Using Modula WMS, an operator creates a batch of orders and fill them all at one time. When the HC presents an SKU for picking, the operator picks the total SKU quantity for all orders.

The batch picking lights, located at each order position, direct the picker to the correct location and indicate the quantity that needs to be placed in each order. By using batch picking, the operator only visits an SKU location one time during picking.

This increases accuracy, reduces picking errors and retrieval time while increasing productivity by up to 65%. The putaway process can be automated much like the picking process in reverse.

Modula Horizontal Carousel Customization Options

Put to Light System

Operating in batch or multi-order modes, the Put to Light System minimizes picking errors, improves inventory accuracy, and boosts labor efficiency.

Batch Picking Station

With WMS and Put to Light devices, this ergonomic picking station provides an intuitive and efficient way to quickly fulfill multiple orders

USB Badge Reader

The USB badge reader is ideal to control user log-ins. The operators use their personal badges to access the machine. This prevents unauthorized accesses

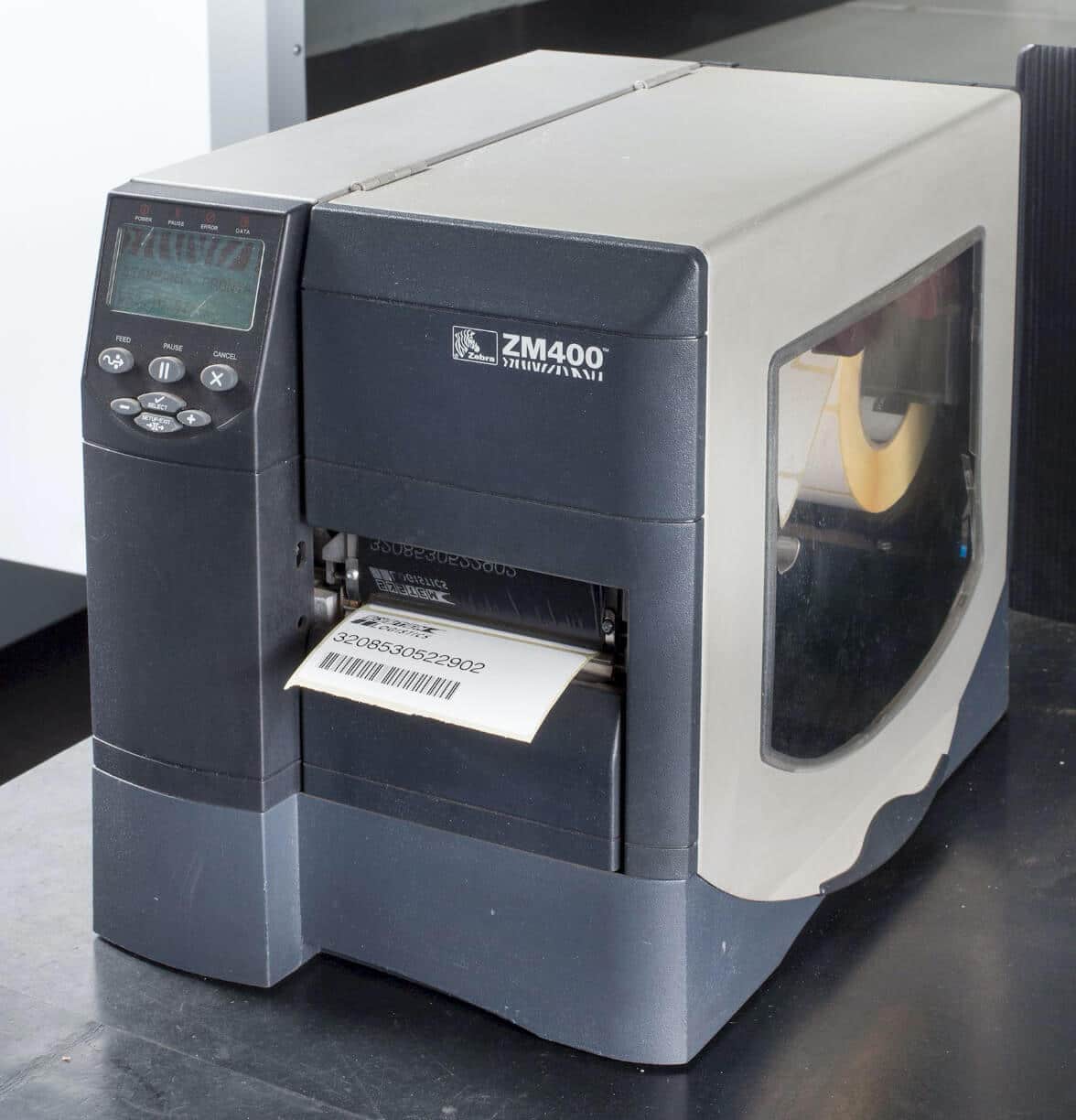

Label Printer

Label printer is a great option to ensure all items are properly labeled in real time, during both picking or replenishment operations.

Barcode Readers

Barcode readers improve picking accuracy and ensure that the correct item is picked. They can also be used to confirm orders or to log into the carousel.

Piece Counting Scale

The Counting Scale is the ideal tool when dealing with large quantities of small items, helping users to quickly select the required quantities.

Modula Warehouse Management Systems

Horizontal Carousel Modules FAQ

What is the ROI on a horizontal carousel or VLM?

Implementing a horizontal carousel warehouse or a vertical lift module into your operation is an investment that can create an effective ROI in as little as six months. This is due to the improved floor space utilization, reduced labor costs, increased picking accuracy, and better inventory control.

How many horizontal machines can be used for one operator?

In times of low throughput, a single operator can operate multiple pods. However, traditionally a single operator would operate a pod of carousels. A pod would be sized to meet the storage capacity and the throughput requirements of the business. Carousel pods of two, three, and four carousels can be handled by a single operator.

How does the picking process work with horizontal carousels in pods?

To speed picking times, horizontal carousels are often used in an integrated workstation called a “pod.” Software and pick-to-light technology allows the carousels to work in conjunction with each other. As the worker picks from one horizontal carousel in the pod, the other carousel is pre-positioning the next pick. This minimizes worker downtime and increases throughput. Moreover, horizontal carousels arranged in pods offer great flexibility. With a simple software adjustment, the pods can be easily reconfigured to meet seasonal peak order times. A pod of four horizontal carousels can operate as one pod with one operator.

Does a horizontal carousel have imbalance issues similar to those on a vertical carousel?

No. Each bin/carrier is independently supported on the Modula Horizontal Carousel and the operation is not affected whether a bin is at its maximum weight or empty. It is recommended to avoid loading the unit to its 1,200 pound (544 kg) maximum capacity regularly because this will cause premature wear.

For which applications is the horizontal carousel a better choice than a vertical lift module?

The biggest factor is the ceiling height in your facility. Choose a horizontal carousel if your ceiling is below 10 feet. For higher ceilings, a vertical lift module is a better choice. But there are other key factors to keep into consideration such as the size and weight of the parts being handled as well as the business cycle and fulfillment requirements.

How does a horizontal carousel compare to a VLM in pick speeds?

Pick speeds vary highly, depending on the distribution of material within the storage system, the line item per order density, and any self-imposed process times, like bagging, tagging, or weigh counting items. Both systems can pick 130-550 items picks per hour if configured to do so. Again, ceiling height should be the main consideration, together with other logistical and operational aspects.

Want to improve the performance of your picking and storage operation?

Maximize the performance of your operations with the high-throughput Modula Horizontal Carousel.