Modula Introduces Flexibox: A New Automated Solution for High-Speed and Flexible Order Fulfillment

Franklin, Ohio – March 2025

Modula Inc., a leading manufacturer of automated storage and retrieval solutions, officially launches Flexibox, a high-speed, scalable, automated storage solution designed to boost order fulfillment efficiency and flexibility across various industries.

Modula Inc., a leading manufacturer of automated storage and retrieval solutions, announces the official launch of its latest innovation: Modula Flexibox.

Unveiled at ProMat 2025 in Chicago, IL, Flexibox is now available to businesses aiming to boost their order fulfillment operations with high-speed picking and scalable automation.

Tailored for the retail, e-commerce, automotive, and distribution industries, Flexibox allows companies to streamline warehouse operations with minimal upfront investment and without disrupting existing workflows.

How Flexibox Works

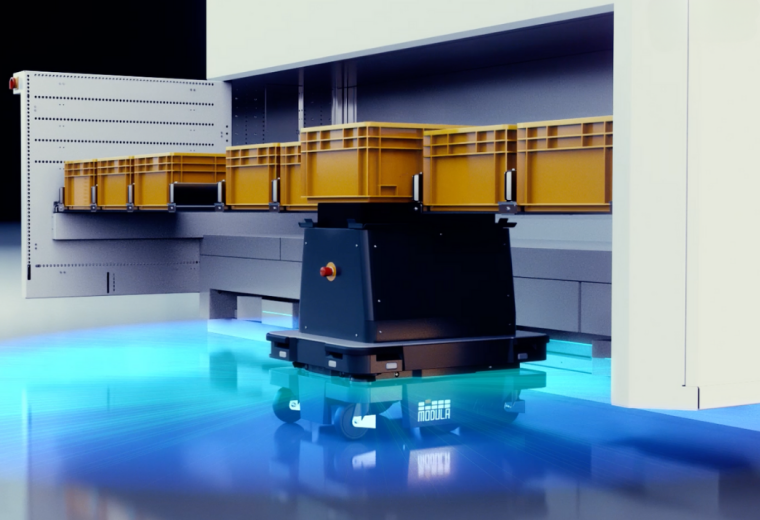

Built on Vertical Lift Module (VLM) technology, Flexibox is designed for maximum efficiency and features a central elevator with a telescopic fork capable of retrieving up to nine bins simultaneously.

Integrated with advanced WMS software, it groups multiple order references within a single tray, accelerating order fulfillment and minimizing operator wait times.

When an order is received, Flexibox analyzes all order lines and retrieves the required bins using its central elevator.

It places these bins on a service tray and directly delivers it to the picking bay, enabling multiple order line completion in a single cycle.

While operators process one tray, the system simultaneously prepares the next one, ensuring an uninterrupted workflow and maintaining a high-speed picking rate.

Flexibox provides flexibility with internal and external bay configurations, available in single or dual delivery levels to meet diverse operational needs.

The internal bay optimizes floor space, making it ideal for compact environments, whereas the external bay maximizes picking speed. A single delivery level offers ergonomic picking at an optimal height, while the dual delivery level boosts efficiency in high-demand workflows.

With Smart Preparation, Flexibox automates order processing during idle periods by pre-arranging trays in advance. Controlled by the Warehouse Management System (WMS), the system reduces waiting times and optimize workflows by preparing “ready-to-pick” trays based on incoming orders.

In addition, Flexibox maximizes vertical storage and frees up valuable floor space by reaching heights of up to 65 feet and accommodating hundreds of bins.

What Sets Modula Flexibox Apart?

Flexibox is designed to meet the growing demand for faster, more efficient order fulfillment, making automation accessible to businesses of all sizes.

“Flexibox represents a major step forward in high-speed order fulfillment,” said David Lind, Sales Director of Modula Inc. “Designed to adapt to the ever-changing needs of modern warehouses, it allows businesses to automate efficiently, scale flexibly, and increase picking throughput without major infrastructure changes.”

Modula Flexibox Key benefits:

Modula’s Legacy of Innovation

The launch of Flexibox marks the latest milestone in Modula’s ongoing commitment to developing solutions that meet the evolving needs of modern warehouses.

“With Flexibox, we are providing a dynamic solution that addresses modern warehouse challenges,” said Orfeo Finocchi, CEO of Modula Inc. “It is designed to be scalable, efficient, and seamlessly integrated into existing operations, ensuring companies can meet growing demands without the burden of costly overhauls or long downtimes.“

Over the past few years, Modula has introduced several groundbreaking technologies:

- 2021 – Modula Climate Control and Clean Room for specialized temperature and environment-sensitive applications.

- 2022 – Modula Horizontal Carousel and an updated version of the Modula Lift.

- 2022-2024 – Modula Next for ultra-precise picking and Modula Pallet for safe, ground-level pallet handling.

What’s Next?

For those who couldn’t attend the initial product showcase, Modula is offering live webinars, on-site visits, and additional demo opportunities to demonstrate the capabilities of Modula Flexibox. Businesses interested in high-speed, flexible automation are encouraged to explore how this solution can enhance their operations.

About Modula

Modula is a leading manufacturer of automated storage solutions, designed to optimize space and improve picking and storage operations for any industrial sector or environment.

Modula’s vertical lift module (VLM) line maximizes the storage potential of high-ceiling facilities by securing items in enclosed units up to 54 feet tall.

Our horizontal carousels are ideal for low-ceiling environments and those seeking maximum throughput. For both solutions, automated delivery significantly boosts productivity and saves operators from unnecessary bending, walking, and reaching for parts.

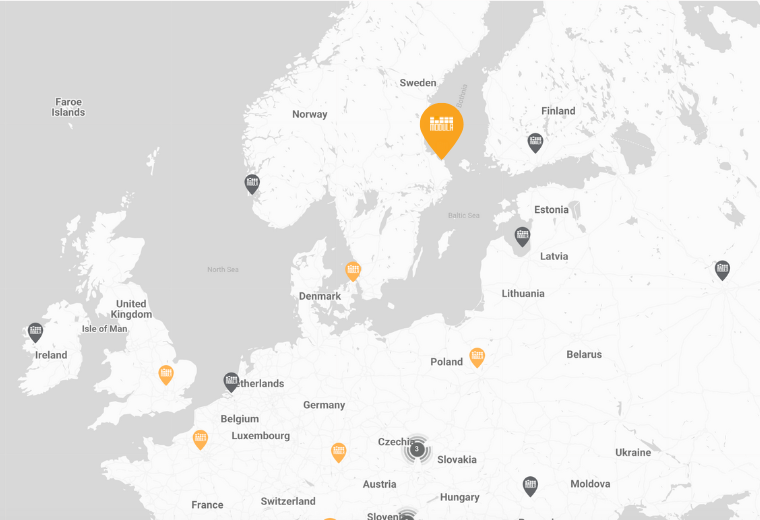

Today, Modula counts on more than 30,000 customers around the world and four production plants in Italy, the US (Lewiston, Maine & Franklin, Ohio), and China.

Additionally, Modula has a network of twelve subsidiaries (located in France, UK, Spain, Poland, Denmark, Germany, Sweden, India, Singapore, Australia, Colombia, and Mexico) and more than 100 authorized dealers worldwide.

This guarantees a local presence to clients, allowing the company to serve all markets in a personal and timely manner.