Modula Introduces Modula Next in the US Market

Modula is thrilled to announce the official launch of Modula Next in the United States, marking a significant step forward in automated storage and retrieval technologies.

By combining the space-saving benefits and efficiency typical of VLMs, with the precision and control of industrial vending machines, this innovative system is designed to enhance inventory management and operational efficiency in various industries, particularly where precision picking and handling of high-value items are critical.

Why Choose Modula Next

Modula Next is an innovative solution that combines the compactness of our Vertical Lift Modules (VLMs) with advanced retrieval accuracy. This system is engineered to optimize vertical space, enabling businesses to maximize their storage capacity within a minimal footprint. All this while addressing the critical need for precision and efficiency in modern warehouses and manufacturing facilities.

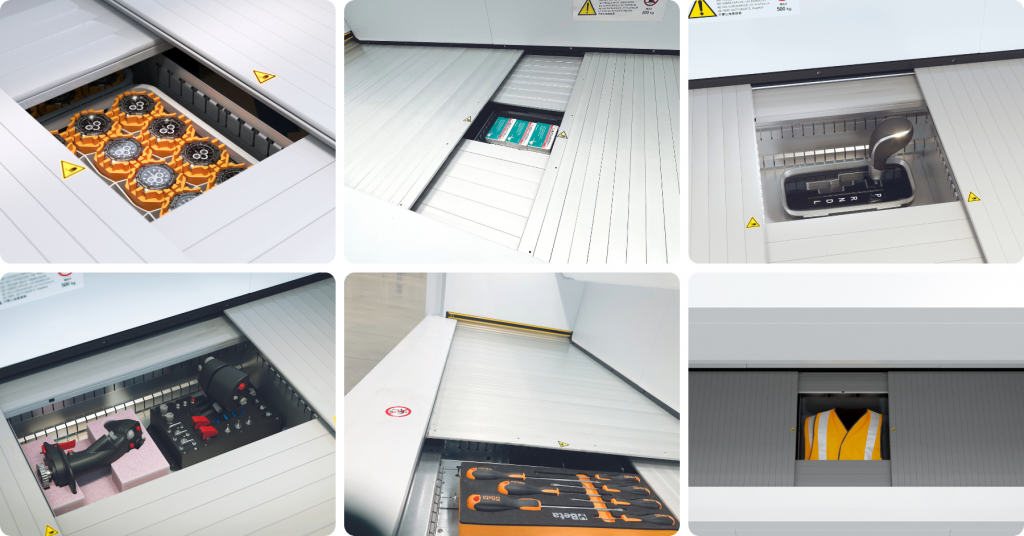

The unit features a sliding shutter door system that allows access to only one specific item and compartment at a time, ensuring unmatched precision in picking and replenishment operations. With its adjustable compartment configurations, Modula Next also offers a flexible scalable solution for a wide range of industrial storage needs.

“Our focus at Modula has always been on innovation and adapting to the evolving needs of our customers,” states David Lind, Sales Director of Modula Inc. “With Modula Next, we’re stepping into new territory that lets us break into different applications and industries. This means we can get even closer to what our customers need, offering tailored solutions that really hit the mark“.

Warehouse Management System; A Complete End-To-End Wms Solution For Your Business

Modula Warehouse Management System (WMS) is a complete inventory management software, designed to operate Modula’s automated storage and retrieval solutions or as a stand-alone software in traditional warehouses (manual areas). As one of the most intuitive and advanced software solutions on the market, Modula WMS seamlessly interfaces with almost all DMS and ERP systems, making processes, such as receiving, picking, and putting away products, faster and more accurate.

How Modula Next Works

Modula Next operates on a goods-to-person principle. When an item is requested, the unit retrieves the specific tray where the item is stored and brings it to the picking bay at an ergonomic height.

Unlike conventional Vertical Lift Modules, Modula Next’s shuttering door system only opens the compartment containing the requested item. This targeted access ensures that operators can only access the designated item, adding a significant layer of security. This feature is especially crucial when managing costly or sensitive materials, or in applications where picking accuracy is paramount, as it eliminates the potential for errors or access to other products stored in that tray.

Modula Next can also be programmed to open multiple compartments or even the entire tray. This flexibility allows for adaptable operations based on specific operational needs, offering a balance between security and accessibility.

Modula Next: Key Features and Advantages

- Smart System Combination: Modula Next marries the high-density storage capability of VLMs with the controlled dispensing precision of industrial vending machines.

- Innovative Design: The sliding shutter doors provide controlled access to one item or compartment at a time, ensuring precise handling.

- Flexibility and Customization: Its adjustable compartment configurations cater to a broad spectrum of industrial storage needs, accommodating various item sizes.

- Versatility Across Industries: Modula Next is suitable for sectors such as manufacturing, healthcare, retail, aerospace, automotive, and more, especially where secure and precise inventory management is crucial.

Modula Next is an innovative solution that combines the compactness of our Vertical Lift Modules (VLMs) with advanced retrieval accuracy

Safety for your Operators and Products

With advanced safety features, including safety light barriers and emergency stop buttons, Modula Next ensures a secure operating environment. These features, coupled with its space-efficient design, offer an unmatched solution for modern storage challenges.

Applications Across Industries

The precision, flexibility, and capacity of Modula Next make it an ideal choice for industries requiring stringent inventory control and quick access. From manufacturing to healthcare, and aerospace to retail, its benefits cater to a diverse range of sector needs.

Special Applications

- Consignment Inventory Management: Offers efficient service and precise tracking, enhancing supplier-client relationships.

- Storing Personal Protective Equipment (PPE): Ensures quick, secure access to essential safety gear, maintaining compliance and equipment quality.

- Dispensing Kitted Components: Improves task-specific efficiency by securely storing and dispensing complete kits.

- Securing Sensitive or High-Value Items: excels in managing high-value items, providing unmatched security and traceability. Its targeted access control and enhanced inventory security features make it an indispensable tool for industries handling valuable or sensitive materials.

Explore Modula Next in Action

To learn more about Modula Next, check out our product video that covers everything from its innovative features, to its practical applications across various industries.

Connect with Our Team to Discover More

Have questions or want to discuss how Modula Next can fit into your operations? Reach out to our team. We’re here to help you explore the best solutions for your storage and retrieval needs