Integration with MiR’s Autonomous Mobile Robots (AMRs)

Modula’s Vertical Lift Modules (VLMs)

Modula’s vertical lift modules (VLMs) are fully automated high density vertical storage systems that take up a minimum footprint by taking advantage of high ceilings.

Items can be stored up to 53 feet high in a safe and secure unit that automatically delivers them to an operator with a click on the user-friendly copilot or scan of a barcode.

No more time wasted searching for items, the right part is delivered to the right person at the optimum ergonomic retrieval height.

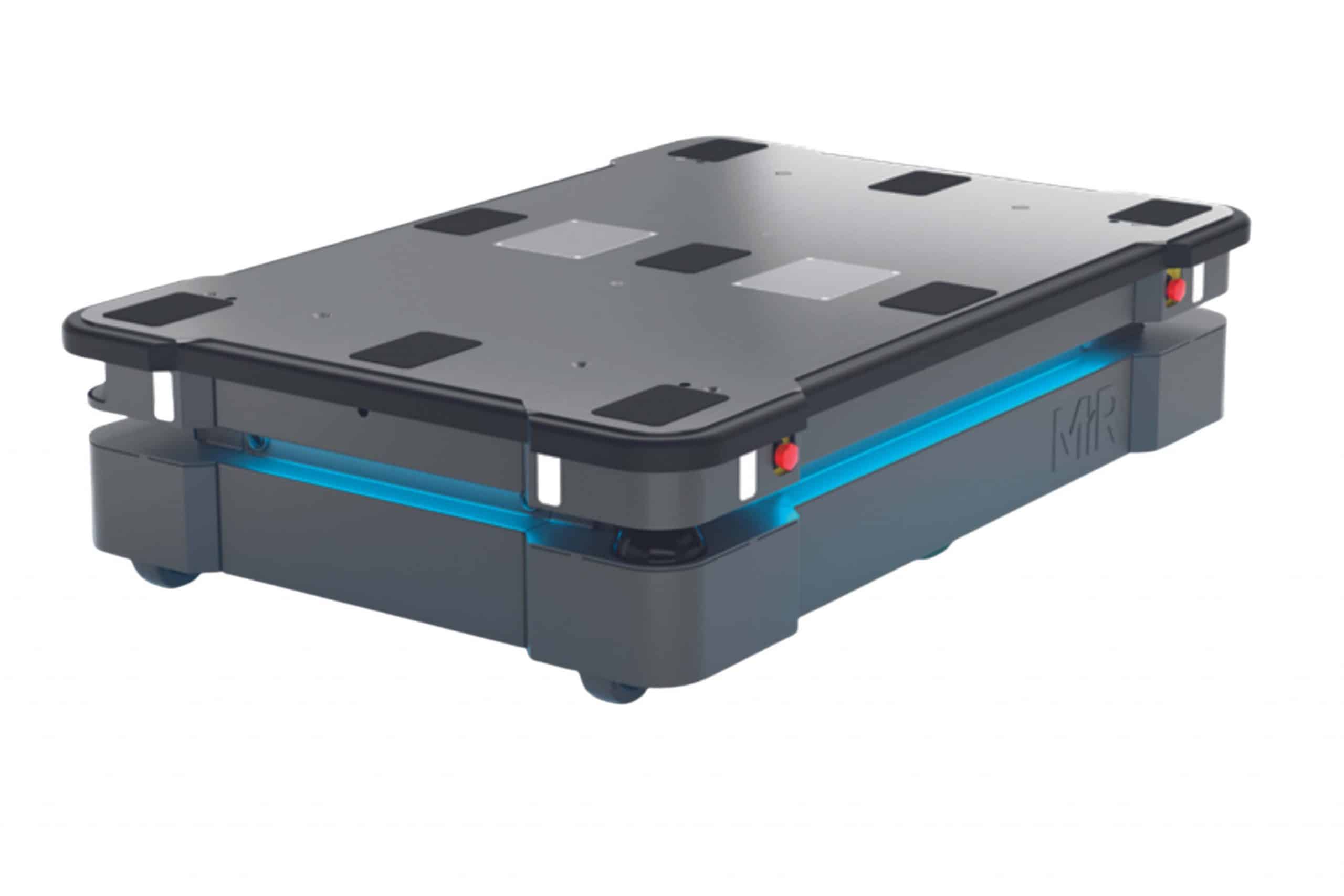

Autonomous Mobile Robots

Autonomous Mobile Robots, known as AMRs, are intelligent robots that can move around an environment independently and perform tasks efficiently while taking the fastest possible route.

AMRs can navigate their way through a warehouse without the need for a human operator, thanks to their advanced sensors, artificial intelligence software, and digital mapping of the warehouse enabling them to know where they are at all times.

Picking & Handling Automation with Modula & MiR

Semi-automated picking of single items

The picking process is carried out manually by an operator who picks products from the Modula VLM and then places them directly into totes or bins on the robot.

The mobile robot then transports the items to the next picking zone or to the consolidation area once the order is completed.

Semi-automated picking with picking carts

To fulfill multiple orders at the same time, companies may rely on a mobile put-to-light system, such as a picking cart.

Thanks to a special “hook-top module”, the AMR can hook onto the picking cart and deliver it easily and safely to where it is needed.

Fully automated picking of single items

The AMR can be equipped with a robotic arm. Once the robot arrives, it docks by scanning the QR Code in front of the bay. The arm picks the item directly from the tray and places it into a tote or bin atop the MiR.

Once the picking is complete, the robot is ready to deliver the item to its destination.

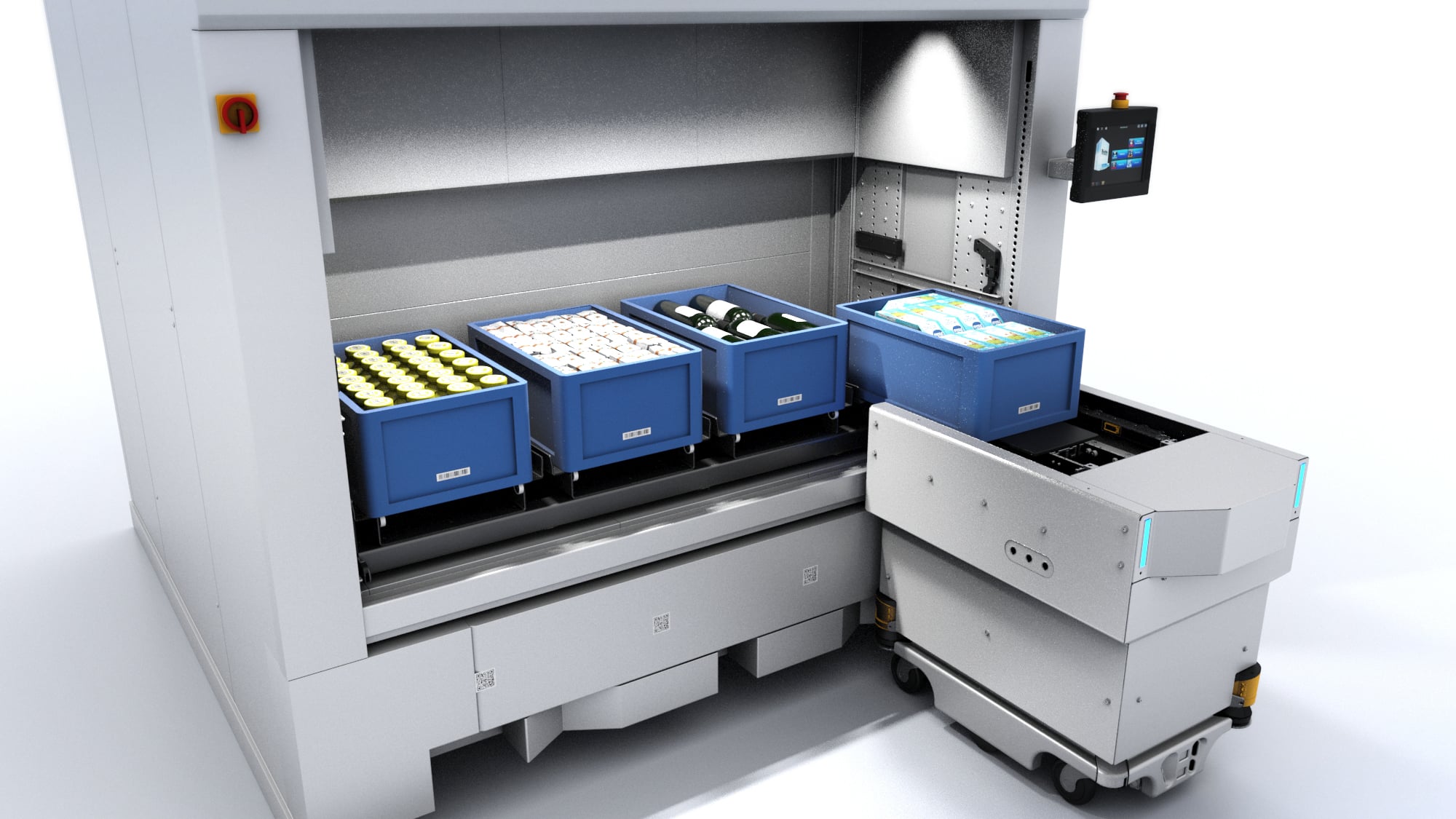

Fully automated case picking

The robot is equipped with a customized “top module” that lifts, picks, and places totes or bins directly from/to the VLM tray.

The VLM moves the required tray into position as the MiR heads in its direction. The robot arrives, docks by scanning the QR code in front of the bay, picks up or places the material, and confirms the end of the operation.

Fully automated solutions for pallets

AMR can also automate the transportation of pallets and heavy loads throughout a facility. The Robot can pick up, transport, and unload pallets directly from Modula’s VLM without any human intervention.

Thanks to this solution, businesses can increase employee safety while optimizing the handling of heavy materials.

How a Manufacturer Transformed Their Operations with Modula X Mir’s Solution

Amer SpA develops and designs AC and DC motors, gear motors, steering systems, and drive systems for vehicles. The company sought a way to fully automate the material handling in its production facility to maximize efficiency in the face of changing manufacturing operations. An innovative solution involving a Modula vertical lift module, AGV robots, and integrated software allowed Amer to accomplish its goal.

Modula Robotics Integrations

Modula Robotics Integrations

Modula’s products can be seamlessly integrated with various types of robots to further automate logistics processes.

Modula Robot Interface

Modula products can seamlessly interface with anthropomorphic robots to automate repetitive tasks and improve productivity

Want to improve the performance of your picking and storage operation?

Run at peak efficiency 24/7 with our integrated automation solutions.