Modula at Fabtech 2025: Advanced Retrieval & Storage Automation for Metalworking

- Event: FABTECH 2025

- Location: McCormick Place, Chicago, IL

- Dates: September 8-11, 2025

- Visit our team: Modula booth #A5706, North Hall

Modula at Fabtech 2025

From September 8 to 11, 2025, Modula will be exhibiting at Fabtech, North America’s largest event for metal forming, fabricating, welding, and finishing, held at McCormick Place in Chicago. You’ll find us at Booth #A5706 in the North Hall.

This year’s edition is expected to be the largest in Fabtech history, with over 1,500 exhibitors and more than 850,000 square feet of technology displays. With new features like the Job Shop Pavilion, dedicated to small and medium-sized manufacturers, FABTECH2025 promises to be an essential destination for companies navigating today’s rapidly evolving production landscape.

Automation for the Future of Metal Manufacturing

As a returning exhibitor and proud sponsor of the Automation Track, Modula is ready to support the industry’s growing demand for smarter, safer, and more efficient processes.

On display at our booth will be two of our flagship automated storage systems: the Modula Lift (Double Bay) and the Modula Next, which made its official debut at Fabtech 2024.

Modula Next

Modula Next is an innovative automated storage and retrieval solution that combines the space-saving efficiency of traditional VLMs with the precision and control of industrial vending systems. When an item is requested, the unit retrieves the tray and presents it at an ergonomic height. What sets Modula Next apart is its unique shuttering door system, which opens only the specific compartment containing the requested item—ensuring unmatched accuracy during both picking and replenishment. This level of control is especially valuable in environments where traceability, security, and precise inventory management are essential.

Modula Next

Modula Lift

Modula Lift remains one of the most versatile solutions for manufacturers looking to improve space utilization and workflow. Available in a wide range of sizes and load capacities, it’s ideal for storing heavy or bulky items like tooling, dies, and raw materials. The Double Bay configuration includes access points on both sides of the unit. This allows businesses to dedicate one bay to replenishment and the other to picking, effectively separating these tasks to boost throughput and streamline operations. Alternatively, it can serve two work zones or departments simultaneously, adding flexibility to complex production environments.

Both systems are designed to solve real-world challenges faced by companies in the metalworking industries, challenges related to space constraints, inventory control, workflow efficiency, and operator safety.

Why Visit Modula at Fabtech 2025?

Don’t Miss Modula at Fabtech 2025 – Booth #A5706 | North Hall

Fabtech 2025 is more than just a showcase, it’s an opportunity to engage directly with our team, discuss your specific challenges, and see how Modula solutions can be adapted to your operations. Whether you’re a job shop or a large-scale manufacturer, we’re here to help you make the most of your space, time, and resources.

Modula’s participation at Fabtech 2025 is your chance to explore the latest in automated storage and retrieval designed with the needs of the metalworking industry in mind.

Fabtech 2025: Registration

We’re happy to have you attend as our guest! Register here for your free expo pass

We look forward to welcoming you in Chicago!

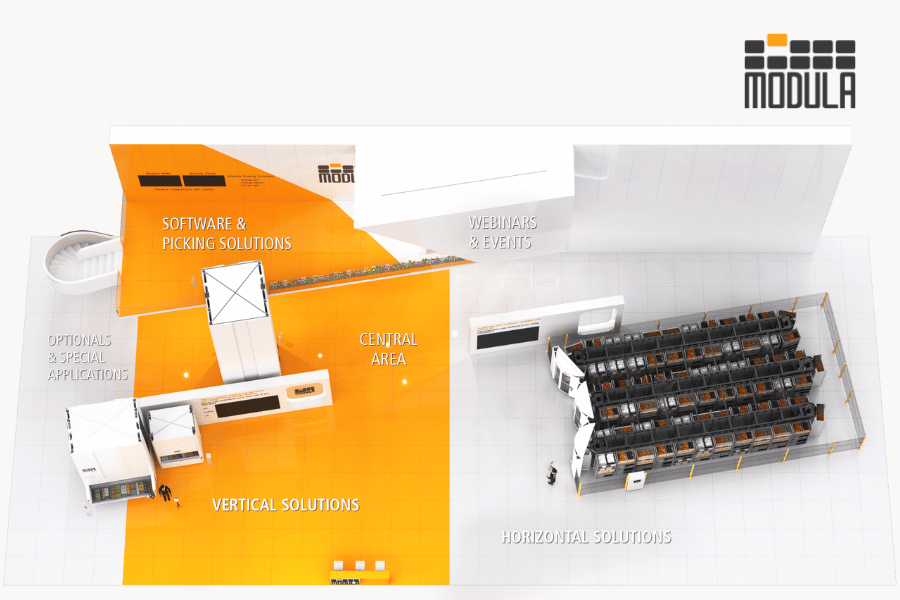

Virtual Booth

Experience the latest on automation and material handling, even if you’re unable to attend the trade shows in person. You can check out our automated storage solutions by visiting our virtual booth from the comfort of your own desk

Subscribe To Our Newsletter

Stay informed about our upcoming events, news, and more. Learn more about automation and material handling. You can easily unsubscribe at any time using the links provided in every email.