Modula Vertical Lift Modules Benefit Aerospace Companies with Cost Savings and Operational Efficiency

Modula’s Vertical Lift Modules (VLMs) are fundamental in helping aerospace and aircraft suppliers and manufacturers contain costs and prepare for future demand

The aerospace industry has seen dramatic shifts in demand with the onslaught of Covid-19 and its effects on air travel. Manufacturers have laid off employees; small airlines have declared bankruptcy. But industry analysts say that there are opportunities for organizations that can trim costs through efficiencies they may not have already incorporated into their operations.

“Rather than simply focusing on cuts, we believe that OEMs and large suppliers should also make needed investments in the future, in five key areas: using technology as an accelerator, stabilizing the supply chain, streamlining the workforce, focusing on sustainability and making a coordinated pitch for government support,” says consulting firm PricewaterhouseCooper.

Three of those areas — those involving technology, the supply chain, and the workforce — are addressed by switching from a traditional shelf storage system to an automated solution such as the vertical lift modules (VLMs) offered by Modula.

Modula VLMs maximize space and picking efficiency while saving aerospace companies time and money

In any aircraft manufacturing and parts maintenance facility, a disorganized picking and storage process can have a huge financial impact in terms of resources needed and inefficiency costs generated to run the daily operations. Missing parts, a lack of a reliable real-time inventory, picking errors and too much time wasted to locate parts can easily bring high operational costs that were always problematic but are now particularly hazardous to the health of a business. The size of the products and tooling present ergonomic and space claim challenges. Aerospace industries require a large number of parts and components in a wide variety of sizes and weights that are typically needed on short notice. Small and fragile components need to be stored and organized efficiently to be easily and quickly accessible. Large and heavy parts need to be picked and lifted at the optimal working height to guarantee the safety, not only of the products but also of the operators.

The necessity of unquestionable quality assurance, combined with the need to keep cost in check, has already forced many in the aerospace industry to adopt lean inventory and logistics models from the shop floor to the top floor. Designed to meet all these needs, Modula vertical lift modules are already in place in many aerospace facilities across the United States.

Thanks to the enclosed system of vertically arranged trays, the VLMs use the available room height from floor to ceiling. This maximizes any area’s storage potential. Items can be stored in VLMs as tall as 53 feet in a safe and secure unit that automatically delivers them to the operator with a tap on a touchscreen or a scan by a barcode reader. This feature eliminates the need to search for items and ensures that the right part is delivered to the right person at the ergonomically optimal retrieval height.

The result is a work environment that runs more efficiently, so hiring additional workers is not necessary. What’s more, employees are more satisfied with their jobs because previous physical stresses are eliminated. As a result, employee turnover is reduced and worker productivity enhanced.

Virtually any type of parts can be stored in the Modula VLMS: tools, avionic components, engines, cables, hardware, specialized equipment parts, electronic gears, etc. Trays can be organized for items of every type and size. By using partitions and dividers, it is possible to create the exact number of storage locations required in each tray. Configuration settings can be adjusted at any time to accommodate changes in the size or quantity of the stored items.

Easily integrated into existing systems, Modula’s WMS software provides highly accurate inventory management

Moreover, Modula`s VLMs can be easily integrated into any existing local IT system thanks to Modula’s Warehouse Management System (WMS) – a full suite of inventory management software that provides an accurate and continuous exchange of information with minimal impact on the pre-existing procedures. This greatly reduces the risk of human errors. By using the available data to its full potential, Modula`s software solutions offer companies in the aerospace industry improved inventory control and accountability. The user can monitor stock levels in real time and speed up order execution times for both picking and replenishment operations while having the visibility required to make good inventory decisions and reduce costs.

Because the special tools used in aircraft manufacturing and maintenance are expensive, a reliable locking and validation feature plays a key role in an industry that demands precision, safety, and accuracy.

Every unit is password protected, allowing only authorized operators with a personal badge and/or access code entry to operate the machine. All picking operations are monitored and logins are tracked, even down to specific trays, when can help with inventory traceability, Such traceability is valuable in preventing operators from picking the same items or for high valuable aircraft parts to be stolen.

By adopting Modula`s storage and retrieval solutions, aerospace companies can protect their investments and count on a substantial ROI through increased productivity, significant space saving, enhanced security and traceability, and a greater efficiency across all aspects of the aircraft manufacturing and maintenance process.

Benefits at a glance:

- Saving space: Saves up to 90% of valuable floor space compared to traditional storage methods, accommodating for future growth needs

- Full traceability and continuous inventory updates: All picking operations are monitored and documented to offer full traceability of the orders and monitor stock levels in real time

- Secured aircrafts special tools & spare parts: Access can be controlled to keep unauthorized parties away from valuable items.

- Increased productivity and accuracy: In an industry where every minute counts, operators can quickly and easily identify the items needed to be picked or replenished, thanks to simple visual picking aids

- Secured environment for products: Modula units are fully enclosed by an automatic door that prevents goods from being damaged or exposed to dust

- Easy software integration: Modula WMS can be seamlessly integrated with any ERP or host system, further increasing visibility into inventory and supply chain activities

- Stock density optimization: Thanks to a height detection system, the height of each tray is measured as the tray is put away, allowing the densest storage location to be determined in real time and maximizing the storage density within the unit. Trays can be organized for every type/size of stored item

- Ergonomic storage and retrieval workstation: Bulky and heavy aircraft parts are automatically delivered at the ergonomically optimal retrieval height

- Flexible integration & scalable design: The units can be integrated into any existing aerospace logistics system and facility

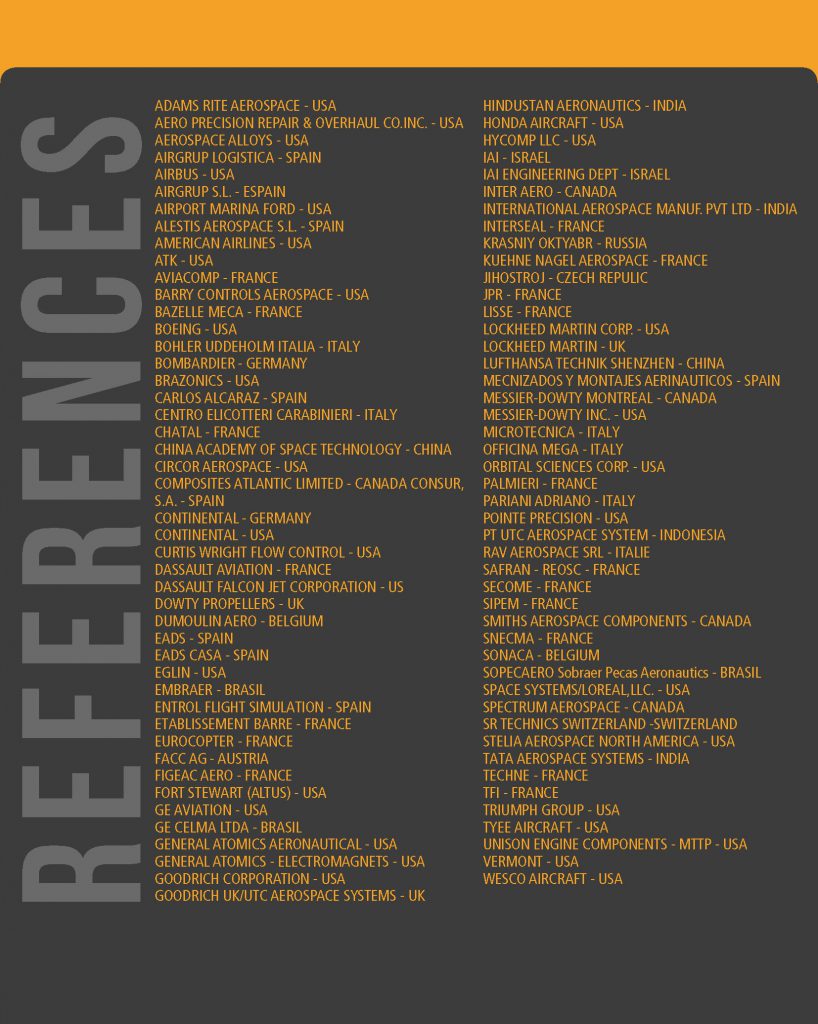

Our references in the aerospace industry: