Debunking Myths & Misconceptions About Automated Solutions

A recent study found that the global warehouse automation market will nearly double by 2025 and it is expected to be worth $30 billion by 2026.

While most warehouse and distribution centers are interested in automation, many still believe it’s too expensive or risky to implement. Worried about the implications of automating their processes, managers continue to use static storage solutions instead of automated storage and retrieval systems (ASRS), such as vertical lift modules or horizontal carousels.

We spoke with Modula’s Marketing Director, Valentina Cecchi, about myths and misconceptions surrounding automated storage and retrieval systems and how these misconceptions can hold back companies from adapting their operations and remaining competitive.

Here’s what we learned.

Myth #1: ASRS Systems Are Not Flexible

Question: Clients often question the capability of automated storage solutions to handle products of diverse sizes and shapes, fearing a lack of flexibility. From your experience, what types of products can a vertical lift system effectively accommodate, for example? And how versatile is it in managing varying dimensions and shapes?

Answer:

In the world of automated storage systems, Modula’s vertical lift module (VLM) is one of the most dynamic and flexible solutions on the market. I’ve seen a wide range of product sizes and weights stored in this type of unit.

The unit utilizes a height detection system that measures the tallest item on the tray every time it stores a tray in the unit. This capability ensures optimal storage density by determining the most efficient location for each tray in real-time. The VLM’s design allows for trays to be stored and optimized in one-inch increments, providing the best cubic utilization possible.

In contrast, static storage solutions are limited by fixed shelf heights, leading to either wasted space or constraints for taller items.

Modula’s VLM units monitor the weight of each tray to ensure they are properly loaded and compare weight distribution across the entire unit. Static solutions cannot provide this level of visibility. In terms of size, products stored in a VLM can range from paper-thin to as tall as 28 inches and all dimensions in between.

The same flexibility can be found in Modula horizontal carousels.

Before

Before

After

After

Before/after Modula VLM

Myth #2: ASRS Systems Require High Volume to Justify the Investment

Question: Is it true that the financial viability of Automated Storage and Retrieval Systems (ASRS) is primarily limited to high-volume operations? How do ASRS systems perform in settings with lower volumes, particularly in terms of cost-effectiveness, space utilization, and inventory management?

Answer:

The perception that Automated Storage and Retrieval Systems (ASRS) are only cost-effective for high-volume operations is a misconception. While they are beneficial in large-scale environments, their advantages extend to settings with lower volumes as well. ASRS systems, such as Modula VLMs or the Modula Horizontal Carousel, can be particularly valuable for storing any type of products. By compactly storing all inventory, ASRS reduce footprint by up to 85% compared to traditional storage, freeing up valuable space for other uses.

Additionally, these systems provide precise inventory tracking, which is crucial for reducing mispicks or missing items and managing inventory more effectively. All these benefits make ASRS a good investment even in lower-volume scenarios.

Myth #3: ASRS Require Large Spaces and Are Limited to Certain Industrial Settings

Question: Is it true that ASRS are only suitable for large, industrial spaces and not adaptable to smaller or different types of settings like retail or healthcare?

Answer:

Contrary to this myth, modern ASRS technology has evolved to fit various settings beyond traditional industrial environments. Now, they can be tailored for smaller spaces and different contexts, such as retailers, pharmacies, libraries, and supermarkets, where they can facilitate e-grocery logistics and online order fulfillment.

This adaptability makes ASRS accessible and beneficial for a broader range of businesses, not just large-scale industrial operations.

Myth #4: ASRS Installations Are Complex and Can Cause Operational Delays

Question: During the installation of an ASRS, is it necessary for clients to halt their operations? Additionally, what is the typical duration for completing such installations?

Answer:

The installation of automated storage solutions, like Modula’s VLMs, is comparable in duration to static solutions but tends to be less disruptive to client operations. Static solutions often require more space during setup and may cause disruptions within the operating areas. In contrast, Modula VLMs have a compact footprint and need only a fraction of the space, making the process smoother.

Typically, the installation of Modula’s VLM takes about five days per unit, depending on the number of units being installed. After installation, loading the system with parts is quite efficient, facilitated by the unit’s design that brings tray levels directly to the operator, unlike static solutions where stocking involves more manual movement.

Software integration is also very easy since Modula’s software can handle picks from all sides of the unit, or in remote static areas that might be part of the overall picking process. In most cases, installation can be done without interference with ongoing warehouse operations.

For clients who have more concerns about potential disruption, our team can create unique transition plans to minimize any impact the installation process might have during production.

Myth #5: ASRS Are Too Expensive and Have a Long ROI

Question: Automated storage solutions are often seen as expensive with a long return on investment (ROI). How do Modula’s vertical lift modules compare in cost to traditional storage methods? What is the typical timeframe for achieving ROI?

Answer:

Many clients might be pleasantly surprised by how affordable this level of automation really is for them. When people think about automated storage and retrieval systems, they usually envision a big rack supported by mini and unit-load-type cranes. These are very large ASRS systems and can be a much bigger investment in both dollars and time.

However, this isn’t true with vertical lift module (VLM) solutions. We typically observe an ROI within six to eighteen months, varying with project size and ROI parameters. In terms of price, individualVLMs range from $75,000 to $120,000 depending on the overall size and chosen options.

Although the initial investment for a static solution might be less, they require similar implementation times and fail to offer the extensive benefits of automated solutions, such as space efficiency, productivity gains, increased accuracy, and better ergonomics to name a few. This makes this technology a valuable investment for any client, regardless of scale.

Myth #6: ASRS Systems Require Complex Training

Question: Concerns often arise about the impact of automated storage solutions on the labor force and the training requirements for staff. What effects have you observed on the workforce with the implementation of these solutions? What kind of training is needed for employees to effectively use these systems?

Answer:

In my experience with clients, the impact on the labor force from automated solutions has been really positive, contrary to some concerns.

Regarding training, like any new system, automated storage solutions do require an initial learning phase. This is comparable to the training needed in traditional facilities where employees learn to navigate multiple shelves or drawers. For automated VLMs, operators quickly adapt to the user-friendly automated interface. The units are equipped with a color touchscreen controller, enabling easy and efficient product picking.

We’ve noticed that employee retention significantly improves with automated systems. Employees no longer need to walk long aisles or climb stairs and ladders, and the physical strain of reaching and bending is greatly reduced. Once operators are fully trained, efficiency increases, allowing more picking per hour per operator. This allows clients to maintain their picking levels with fewer staff or increase output with the same workforce, showcasing the positive impact on labor utilization.

Myth #7: ASRS Lack in Scalability

Question: How scalable are Automated Storage Systems? Specifically, can these systems be effectively adapted and expanded to meet the evolving needs of a business, whether it’s experiencing growth, diversification, or changes in inventory types and volumes?

Answer:

Automated storage systems are highly scalable and versatile, making them suitable for businesses of various sizes and types. They are designed to adapt to changing needs, whether it’s due to business growth, diversification, or shifts in inventory requirements.

For instance, the height of a vertical lift module can be adjusted to different facility heights by adding or removing modules. Trays, equipped with partitions and dividers, can be customized for any type or size of stored item. Their configurations can be easily modified to accommodate new product types or changes in operational strategies.

Their modular nature ensures that they remain a valuable asset even as a business evolves.

Myth #8: ASRS Software May Not Integrate With Existing ERP Systems

Question: Is there a risk that automated storage solutions might not integrate well with existing software management systems? Specifically, can Modula’s VLM software seamlessly work with a client’s current inventory management software?

Answer:

Absolutely. Modula offers a comprehensive range of software solutions designed to align with various inventory management systems. Clients can choose either a standalone system using our Warehouse Management System (WMS) software or a fully integrated version with their existing management system. We create and manage our software in-house, allowing us total control over its development and features.

Our software is designed for easy interfacing, using shared SQL tables or SAP iDocs when necessary, aiming for simplicity and seamless integration. This ensures smooth inventory information flow through the system. Our software enhances the existing system by handling all picking activities at the machine level and providing real-time updates back to the host system, making inventory management more efficient and responsive.

This video shows how Modula’s Vertical Lift Modules operate.

Do you have more questions about ASRS? Get in touch with our team to learn more about how automated storage and retrieval systems can improve your operations.

Experience the Benefits of Automated Warehouse Solutions With Modula

Modula is the pioneer provider of advanced storage solutions and inventory management systems. Our automated storage solutions can help you transform your warehouse operations.

Our systems can help you:

- Make the most out of your warehouse space

- Boost picking accuracy to nearly 99%

- Achieve fast and accurate order fulfillment

- Reduce or even eliminate repetitive tasks

1. Modula Vertical Lift Modules

Our vertical lift modules (VLMs) are designed to maximize your warehouse space by leveraging your available ceiling height, while delivering items to your employees at an ergonomic height.

Our VLMs come in two models:

- Modula Lift: Efficiently condenses what would usually take 9,050 square feet of traditional storage into just 150 square feet

- Modula Slim: Ideal for limited space, requiring only 32.29 square feet of floor area

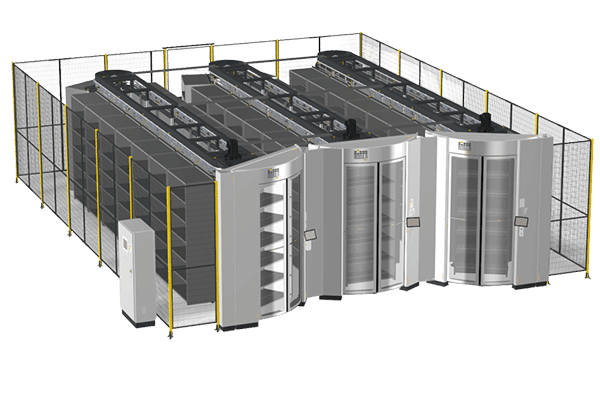

2. Modula Horizontal Carousels

If your warehouse has low ceilings, the Modula Horizontal Carousel (HC) is the perfect solution. It is designed for spaces with limited vertical height and effectively utilizes the width of your warehouse.

Modula’s HC enhances order fulfillment speed and accuracy, allowing you to:

- Gain an impressive picking accuracy of up to 99%

- Manage picking rates of up to 550 lines per hour

- Safeguard your employees from the hazards of moving machinery, thanks to the automatic safety door feature

- Prevent accidents and protect goods against unauthorized access, thanks to the 8′ high perimeter fencing

3. Modula Order Picking Solutions

In addition to storage solutions, we offer picking solutions that can boost your picking speed and accuracy.

Forget labor-intensive manual tasks. Modula’s order picking solutions are user-friendly and simple to implement, optimizing your order fulfillment process.

Modula’s order picking solutions allow you to:

- Enhance picking accuracy using visual aids, such as LED bars

- Speed up picking by minimizing item search time in the warehouse

- Manage inventory better with detailed insights into current and predicted stock levels

4. Modula Warehouse Management Systems

Modula’s warehouse management systems offer complete visibility of your inventory. They are designed to operate with Modula’s automated storage and retrieval solutions. Our WMS seamlessly functions as a stand-alone software even for traditional warehouses.

Modula WMS is considered one of the most intuitive and advanced software solutions available on the market. It effortlessly integrates with nearly all DMS and ERP systems, facilitating smooth inventory and order management.

Modula’s WMS allows you to:

- Track individual SKUs

- Monitor inventory movement and pinpoint their location in your facility

- Manage the entire order fulfillment process, from processing to delivery

- Allocate tasks to warehouse staff, supervise their actions and manage their access rights and permissions

- Create reports and configure alerts

- Conduct data analysis

- Seamlessly integrate and exchange data with other systems using data import/export or manual data entry

Debunking myths and misconceptions about automated storage solutions can help you confidently make the switch to automated warehouse solutions.

At Modula, our solutions range from vertical lift modules to warehouse management systems that can help you see significant improvements in your warehouse management, space optimization and overall operational efficiency.