What Is Consignment Inventory? [Best Practices & FAQs]

In the industrial environment, maintaining operational efficiency while maintaining healthy profit margins is paramount for businesses relying on complex machinery.

One strategic approach that’s gaining traction among manufacturers and their clients is the inventory consignment model.

We’ll share everything you need to know about consignment inventory, including how it works and best practices.

Plus, we’ll introduce you to automated warehouse storage solutions and warehouse management systems at Modula which can help you maximize your inventory management strategy.

What Is Consignment Inventory?

Consignment inventory is a supply chain model in which the manufacturer (consignor) places spare parts and tools at the client’s (consignee) site and retains ownership of the inventory until the client uses it.

This approach ensures the client can immediately access parts for maintenance and repairs without the upfront costs of maintaining a large inventory.

How Does Consignment Inventory Work?

Consignment inventory operates under a collaborative partnership between two parties: the manufacturer and the client.

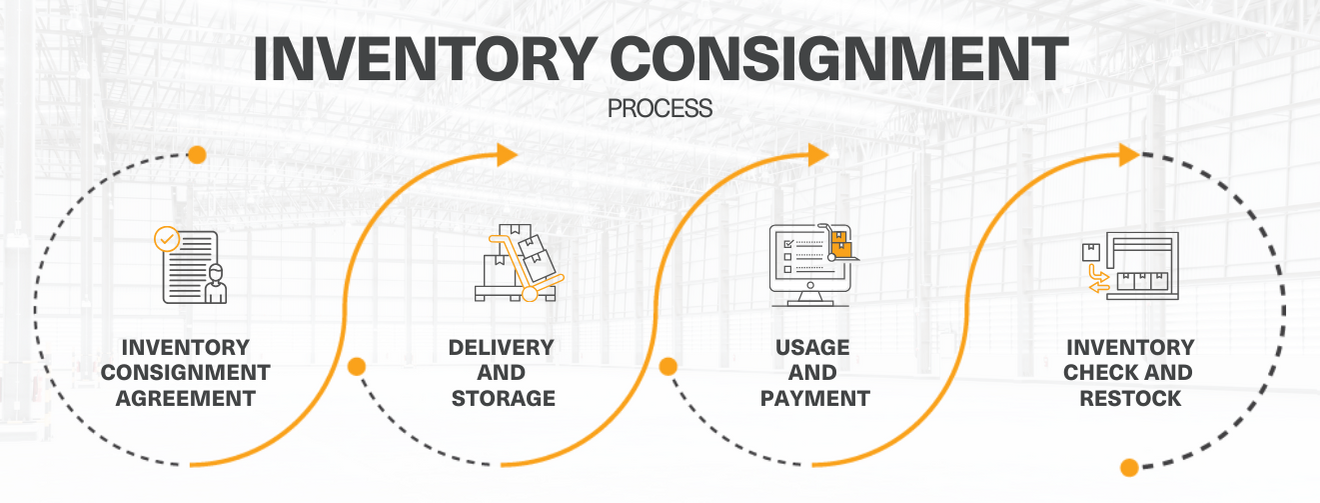

Here’s how this supply chain model works:

- Agreement: The manufacturer (consignor) and the client (consignee) agree upon a consignment arrangement for spare parts and tools. This agreement typically outlines the types and quantities, pricing, storage conditions, and the responsibilities of each party in managing and utilizing the inventory.

- Delivery and Storage: Following the agreement, the manufacturer supplies the spare parts and tools directly to the client’s site. The client is responsible for managing the consigned inventory, ensuring that it is properly stored. This allows the client to have immediate access to the inventory where and when they need it.

- Usage and Payment: Even though the inventory is stored at the client’s site, the consignor retains ownership of the items. When a part or tool is needed for maintenance or repair, the client retrieves it from the consigned inventory and pays the manufacturer for the cost of this item. This arrangement ensures the client is only paying for what they need and use.

- Inventory Replenishment: The manufacturer may use a warehouse management system to keep a real-time check on stock levels at the client’s site and supply more parts as needed to maintain predefined inventory thresholds. This ensures the client has always the necessary parts and tools on hand.

Examples of Consignment Inventory

Examples of consignment inventory between a manufacturer and a client can span across various industries, highlighting the versatility and benefits of this supply chain model.

Here are some examples:

Aerospace Manufacturer

An aerospace company can store key engine components on consignment at an airline’s maintenance hub. This ensures that aircraft can be serviced promptly, reducing the time aircraft are out of service.

Automotive Parts Manufacturer

An automotive manufacturer places a consignment inventory of robotic arm components at their client’s factory.

This arrangement ensures that production lines run with minimal interruption, maintaining high productivity levels. In addition, an automotive parts manufacturer can place essential spare parts and tools at a car dealership or repair shop.

The dealership uses these parts for customer repairs and maintenance, paying for each part only after it is used. This ensures the dealership always has the right parts on hand without the need for significant inventory investments.

Energy Sector

A turbine manufacturer provides consignment stock of spare parts to a power generation company. This ensures that any maintenance can be performed quickly to avoid disruptions in the power supply.

Agricultural Machinery Manufacturer

Consider a manufacturer of agricultural machinery that implements a consignment inventory with its farming clients.

The manufacturer places essential spare parts at the client’s site, allowing immediate repairs during critical planting or harvesting seasons. This arrangement ensures that farmers can maintain operational efficiency without the need for significant upfront investments in spare parts.

CNC Machines Manufacturer

A manufacturer of CNC machines and its client, a precision parts production facility.

The manufacturer provides a stock of critical spare parts – such as cutting tools, bearings, and electronic components – to be kept at the facility. When a part is required for a machine repair, it is immediately available, the facility uses it, and the manufacturer is compensated for that specific part.

IT Manufacturing Company

A manufacturer of IT hardware consigns servers and routers to a data center.

The data center operator uses the equipment as needed, improving their infrastructure without the upfront costs, and pays for the equipment based on usage or upon deployment.

Benefits of Consignment Inventory

Consignment inventory offers different advantages for manufacturers and clients.

Benefits for manufacturers include:

- Improved flexibility in product distribution: Consignment inventory can give manufacturers more flexibility in how they distribute their products. They can gain deeper insights into the client’s usage patterns, facilitating better production planning and inventory management.

- Enhanced customer satisfaction: Manufacturers can improve customer satisfaction by providing value-added services and ensuring clients have what they need to quickly maintain and repair the machinery.

Benefits for clients include:

- Reduced upfront costs: Clients do not have to pay for the inventory until it is sold, which frees up capital for other business needs.

- Reduced downtime: Immediate access to essential parts and tools translates to prompt maintenance and repairs, reducing operational downtime.

Consignment Inventory Best Practices

Consignment inventory best practices include strategies that improve collaboration and efficiency between manufacturers and clients.

These techniques focus on clear communication, effective inventory management and shared responsibilities to ensure a successful and mutually beneficial consignment partnership.

The common consignment inventory best practices include:

Develop a Clear Agreement

Drafting a comprehensive contract that clearly outlines terms is key, as it ensures a seamless partnership between the manufacturer and client.

The contract should outline inventory types and quantities, the consignment period, shipping and returns responsibilities, payment terms, who is responsible for loss or damage and for handling unused inventory.

Ensure an Accurate Inventory Tracking is in Place

Both parties must have a system in place for accurate inventory tracking.

Utilizing a Warehouse Management System (WMS) or similar technology enables real-time monitoring of stock levels, ensuring timely replenishment and minimizing the risk of stockouts.

Require Open Communication

Effective communication between the manufacturer and client is paramount.

To ensure an open communication with your business partner:

- Regularly schedule meetings to discuss inventory levels, sales trends and any potential challenges

- Establish clear and accessible channels for communication, whether through email or calls

- Encourage transparency in sharing information and feedback about product performance and customer feedback

Implement an Efficient Stock Replenishment

The consignor should establish an efficient process for stock replenishment, ideally automated through the use of technology. This ensures that the consignee always has access to necessary inventory, maintaining operational efficiency without manual intervention.

Ensure Quality Control

Maintaining high-quality standards for consigned goods is essential. The consignor must ensure all items sent to the consignee meet specified quality criteria. The client is responsible for managing the consigned inventory, ensuring that it is properly stored.

Automated solutions can help preserve the integrity and value of consigned goods.

Streamlining Consignment Inventory with the Modula Next

Modula Next offers a robust solution for the complexities and specific needs of consignment inventory management.

This system’s design and capabilities directly address the operational challenges of storing, tracking, and managing consigned goods, a necessity for both consignors and consignees.

Here’s a closer look at Modula Next’s features and benefits:

High-Density, Space-Efficient Storage

One of the most significant challenges in consignment inventory management is optimizing storage space without compromising accessibility.

Offering the space-saving and efficiency of Vertical Lift Modules (VLMs), Modula Next makes effective use of vertical space, dramatically reducing the warehouse footprint required.

This allows clients to store a larger inventory within a smaller area, which is particularly advantageous for facilities with limited space. By maximizing storage density, businesses can keep more consigned goods on hand, ensuring they meet demand without the need for additional real estate investments.

Targeted Access for Improved Inventory Control

In consignment models where items stored are not owned by the consignee but by the consignor, security and precision are key aspects.

Modula Next operates on a goods-to-person principle. When an item is requested, the unit retrieves the specific tray where the item is stored and brings it to the picking bay at an ergonomic height.

Unlike conventional Vertical Lift Modules, Modula Next’s shuttering door system opens only the compartment containing the requested item.

This targeted access mechanism ensures operators can access only the designated item, minimizing the risk of unauthorized handling or misplacement of consigned goods.

By restricting access to other items, Modula Next also facilitates accurate tracking of which items are being used, supporting effective inventory management and accurate record-keeping.

Scalability and Customization

Adapting to varying inventory needs over time is a common challenge in consignment agreements.

Modula Next offers scalable and customizable storage solutions that can be adjusted to meet diverse and changing inventory requirements.

Whether the need is to accommodate different item sizes, weights, or types, Modula Next’s modular design enables it to evolve alongside the changing demands of consignment inventory, ensuring a long-term, adaptable storage solution.

Advanced Inventory Management Software

The Modula WMS is an end-to-end inventory solution for your business that can work with our automated storage and retrieval systems (ASRS) or as a stand-alone in traditional warehouses.

Integrated with Modula WMS software, Modula Next provides real-time insights into inventory status, enabling both consignors and consignees to monitor stock levels accurately, anticipate replenishment needs, and make data-driven decisions.

This level of visibility facilitates a more proactive approach to inventory management, ensuring that stockouts are avoided and inventory is always aligned with demand. Consignees can accurately report usage back to consignors, enabling timely replenishment and accurate billing.

Explore Modula Next in Action

To discover more about Modula Next, check out our product video that covers everything from its innovative features, to its practical applications across various industries.

A Quick Recap on Consignment Inventory

In summary, the unique features of Modula Next — particularly its goods-to-person principle and shuttering door system — offer significant advantages for managing consignment inventory.

These capabilities enhance security, efficiency, and accuracy in inventory management, while also promoting safety and ergonomic benefits. For businesses involved in consignment models, leveraging these advanced features can lead to more streamlined operations, stronger partnerships, and improved overall performance.