Smart Parts Storage Solution for Truck Dealers

Managing inventory is key to maintaining a competitive edge in the automotive industry, as it directly affects a truck dealership’s ability to provide quick and efficient service to its customers.

When inventory is managed properly, parts needed for vehicle repairs or customer purchases are readily available, leading to faster turnaround times and ultimately, satisfied customers.

This is where smart parts storage systems can come in handy.

We’ll share all you need to know about the benefits of smart parts storage solutions for truck dealers and introduce you to the leading automated vertical storage system at Modula.

A Truck Dealer’s Parts and Services Department in Relation to Revenue

The parts department plays a significant role in the overall profitability of a dealership. In fact, according to the National Automobile Dealers Association (NADA), the parts and services department accounts for approximately 49.6% of a dealership’s gross profit.

A profitable parts department should be a priority regardless of the success of new vehicle sales, as part sales are less dependent on market conditions and often have higher margins compared to new vehicle sales.

In addition, a truck dealership’s parts and services department provides an opportunity to build relationships with customers, ensuring repeat business and customer satisfaction, which are important for the dealership’s long-term sustainability and growth.

With the constant changes in the market and fluctuating customer demands, the parts and services department can help keep a truck dealership afloat.

Benefits of a Vertical Lift Module (VLM) as a Parts Storage Solution for Truck Dealers

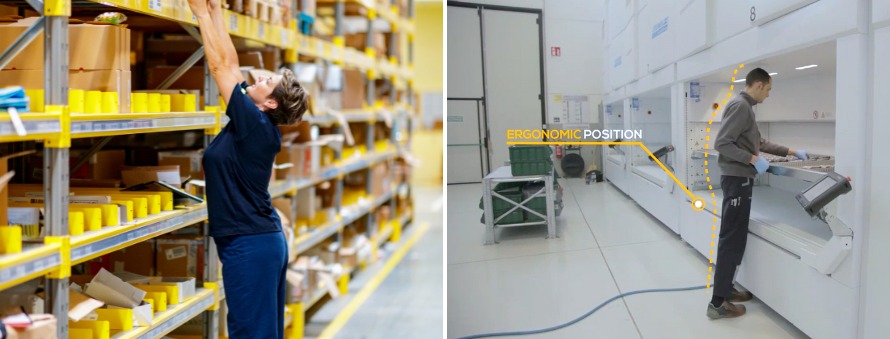

By utilizing vertical space and automating item retrieval, a vertical lift module (VLM) within a vehicle parts department boosts productivity, reduces picking errors and ensures quick access to parts with safety in mind.

Increased storage capacity of parts

Truck dealerships that have implemented automated vertical storage systems in their parts department have significantly increased their storage capacity, saving around 85% of floor space compared to traditional storage racks, such as static shelving.

In fact, a 20-foot-tall vertical lift module only requires about 140 square feet of floor space. Within this footprint, vertical lift modules can store the same number of parts that would require approximately 80 to 85 automotive-type shelving bays.

Improve Picking Accuracy

Accuracy and speed in picking operations are key aspects of a truck dealer’s operation, as they can directly influence customer satisfaction.

Picking accuracy ensures that the right parts and components are selected and delivered to the customers, minimizing errors and preventing costly mistakes.

Speed is equally important — the faster the parts are picked, the quicker the repairs can start. This also increases the efficiency of the car dealership’s service department and improves the customer experience, as vehicle downtime is minimized.

With Modula Vertical Lift Modules (VLMs), truck dealerships can get better control of their inventory, improve picking accuracy (by automatically receiving items with a simple touch on the Copilot console) and significantly reduce the time required to get parts to salespersons and service technicians.

Boost Inventory and Employee Safety

Vehicle parts come in different shapes and sizes, which can present ergonomic and space claim challenges. Engines are large and heavy, while small parts, such as automotive nuts and bolts, can be misplaced without a proper storage system.

With Modula’s VLMs, you can manage your parts inventory. Large and heavy parts can be organized, stored, picked and lifted at the optimal working height, preventing potential workplace hazards.

Small parts can be safely stored in vertical lift modules, thanks to a locking and validation feature. Paired with laser pointers and the Modula Warehouse Management System (WMS) — a comprehensive inventory management software — small parts can also be quickly identified and tracked.

Modula vertical lift modules offer a tray load capacity of up to 2,200 lbs per tray for all models, regardless of tray width or depth, allowing inventory to be stored safely.

Improve Productivity

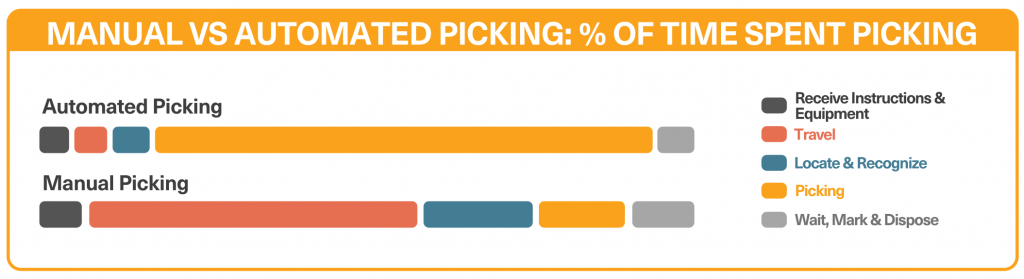

Vertical lift modules automatically deliver parts to the picker at an ergonomic height, reducing the need for the picker to reach high and low or search the facility. With the Modula VLM, the travel time for parts retrieval is reduced by up to 70% compared to static shelving.

Improve Inventory Accuracy With Direct DMS Integration

In addition to saving floor space, inventory accuracy can be improved with automated vertical storage systems, as manual order entry inputting from invoices can be eliminated.

Automated vertical storage systems feature a visual and colored touchscreen. The unit’s touchscreen controller visually indicates item picking and stock locations to reduce picking errors.

The Modula WMS to Distributor Management System (DMS) integrations enable orders to travel automatically from the DMS to the Modula WMS, then to the Modula automated storage systems.

The Modula automated storage system then receives the advanced notification of changes to partner DMSs, allowing real-time updates.

Modula Case Studies in the Truck Dealership Industry

Pacific Coast Heavy Duty Truck, a top Volvo and Mack Dealer in Chilliwack, British Columbia, sought a more efficient way to manage their small auto parts inventory. To address this challenge, they installed a 31-foot-tall Modula vertical lift module. The implementation resulted in an impressive 80% space recovery, significantly expanding their storage capacity.

The Modula Warehouse Management System proved invaluable, providing real-time part availability information when their existing DMS couldn’t deliver accurate data. This streamlined operations and enhanced efficiency. The integration of the Modula system drastically reduced search times for products and improved inventory tracking.

Overall, the adoption of the Modula vertical lift module enabled Pacific Coast Heavy Duty Truck to operate more efficiently, and optimize their space, ensuring smoother workflows and better customer service.

Why Truck Dealers should implement vertical storage solutions

Optimizing storage space and efficiently managing storage is important in ensuring your truck dealership part and services department, as it directly impacts the overall productivity, customer satisfaction and profitability of your business.

To recap, vertical lift modules (VLMs) allow you to:

- Save on floor space: Reduce existing parts storage areas by approximately 85%, allowing you to store more parts, add more service bays or have a larger showroom.

- Increase employee productivity: Retrieve items faster, instead of navigating warehouse aisles to look for the right SKU

- Improve picking accuracy: Reduce mispicks and ensure the right parts are delivered to customers

- Boost inventory accuracy: Ensure stock levels are high enough to cater to consumer needs

- Increase employee safety: Eliminate climbing, bending or reaching high and low storage areas to retrieve parts

- Protect inventory: Safeguard goods with controlled restricted access and barcode verification

From commercial vehicle manufacturers to car dealerships, businesses across the automotive industry utilize Modula automated storage and retrieval systems (ASRS).

Explore more of our automated storage solutions for automotive dealership parts departments.