Modula Revamps the Diamond Phoenix Carousel to Meet Evolving Market Needs

Now called the Modula Horizontal Carousel New Generation, the new model features enhanced safety barriers, a stronger framework and updated user controls

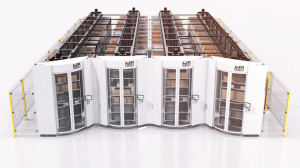

LEWISTON, ME – October 31, 2020: Modula USA, the leading manufacturer of automated picking and storage solutions, today announced the release of the Modula Horizontal Carousel New Generation (HC). Building on a 30-year legacy with the strengths of the well-regarded Diamond Phoenix carousel, the Modula HC adds new technology and features and is ideal for situations in which high-speed picking takes place in low ceiling environments.

Horizontal carousels are automated storage systems on which bins rotate horizontally on an oval track and deliver parts to an operator. This is far more efficient than traditional warehouse operations in which workers rove among static shelving to retrieve items. By installing a Modula HC, a warehouse can dramatically boost its throughput — as high as 500 lines per hour. Because the HC condenses storage in its tightly packed bins rather than on shelves, warehouses can save a significant amount of floor space as well.

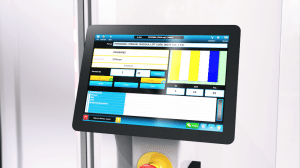

When combined with the Modula Warehouse Management System (WMS) and order retrieval aides such as barcode readers and batch pick stations, the Modula HC vastly improves materials handling accuracy and inventory control. In addition, the carousel now features safety barriers and doors to further protect operators during production.

“These carousels are made in the United States and offer all the best features and durability of the Diamond Phoenix line,” said Modula Engineering Manager Phil Lessard “But we’ve added key safety enhancements and computerization details in the software upgrades that make what was a great product, even better.”

The Modula HC is available in a variety of configurations and can be installed into either a production or distribution setting to support high-speed batch picking, maximize space, reduce labor time costs, and improve accuracy and inventory control.

Other new Modula HC features include:

- Simplified, user-friendly operator interface and inventory control software

- Optimized picking software to minimize operator movement

- Increased storage density

- Automatic doors and perimeter guards on all models

- Stronger foundation with a solid 304 stainless steel framework

- Easier integration with other Modula solutions

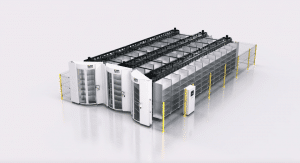

- Single or dual 3-horsepower drives for increased speed of inventory management and high-capacity live lines

- Inverted drives are available to accommodate limited ceiling height

“We’ve built on 30 years of experience with the Diamond Phoenix, and integrated the latest design and technology from our vertical lift modules to create the most advanced horizontal carousels on the market,” Lessard said.

The Modula HC enters the market among Modula’s other automated storage solutions, including a line of class-leading vertical lift modules (VLMs). Tied together with advanced warehouse management software, the automated storage and retrieval systems are ideal for helping businesses of all sizes meet today’s demands for high production, accuracy, and real-time inventory management. They also provide a better working environment through ergonomic design and reduce costs by dramatically trimming floorspace requirements. To learn more about the Modula HC, click here.

About Modula:

Modula designs and produces automatic storage systems that dramatically boost productivity and accuracy, reduce storage spaces requirements, and enhance worker safety and job satisfaction. We have launched our warehouse designer tool to help companies plan new installations and the analysis of existing ones.. The only U.S. manufacturer of vertical lift modules, Modula also offers horizontal carousels, warehouse management software, and a host of accessories that make order picking quick and easy. Established in 1987, Modula has nine branches worldwide, a network of 100 distributors, and factories in the United States, Italy, and China. More information can be found at modula.us.