Modula Flexibox

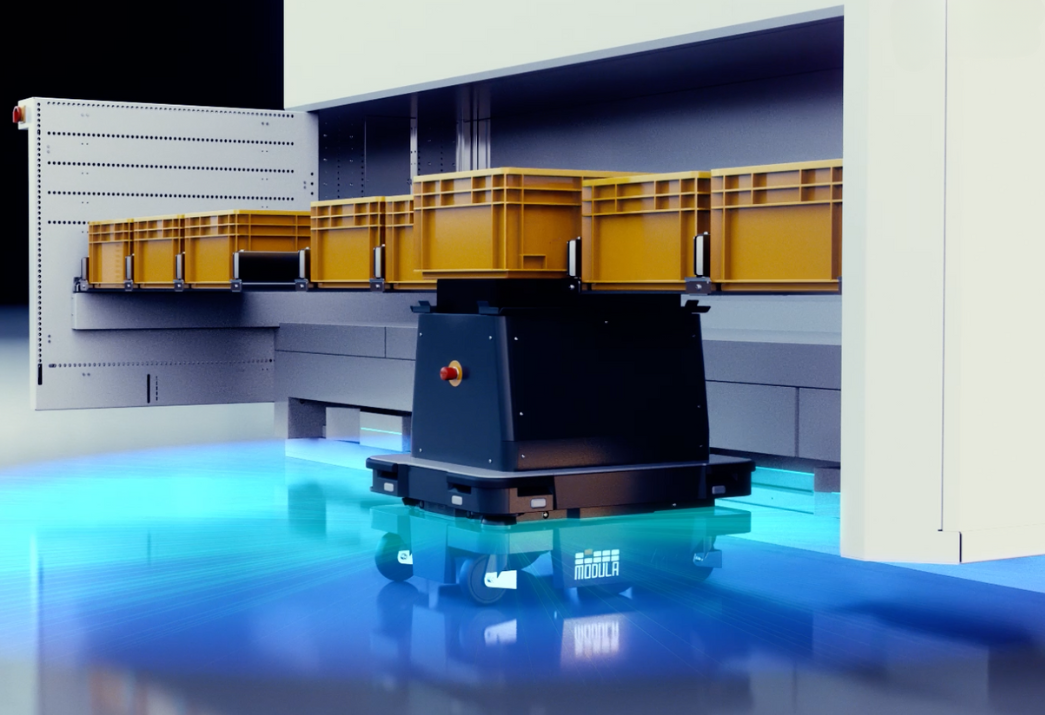

Modula Flexibox is our latest innovative automated solution, designed to combine high picking speed, efficiency, flexibility, and scalability in a single system.

Capable of delivering up to 180 bins per hour, this system significantly reduces cycle movements, optimizes vertical space, and enhances operational flow.

As the newest addition to our product lineup, Modula Flexibox is designed to meet the demands of industries such as retail, e-commerce, automotive, and large-scale distribution. With its high-performance design, it is the ideal solution for managing high order volumes while ensuring ergonomic operations and maximum space utilization.

Why Choose Modula Flexibox

High-Speed Order Fulfillment

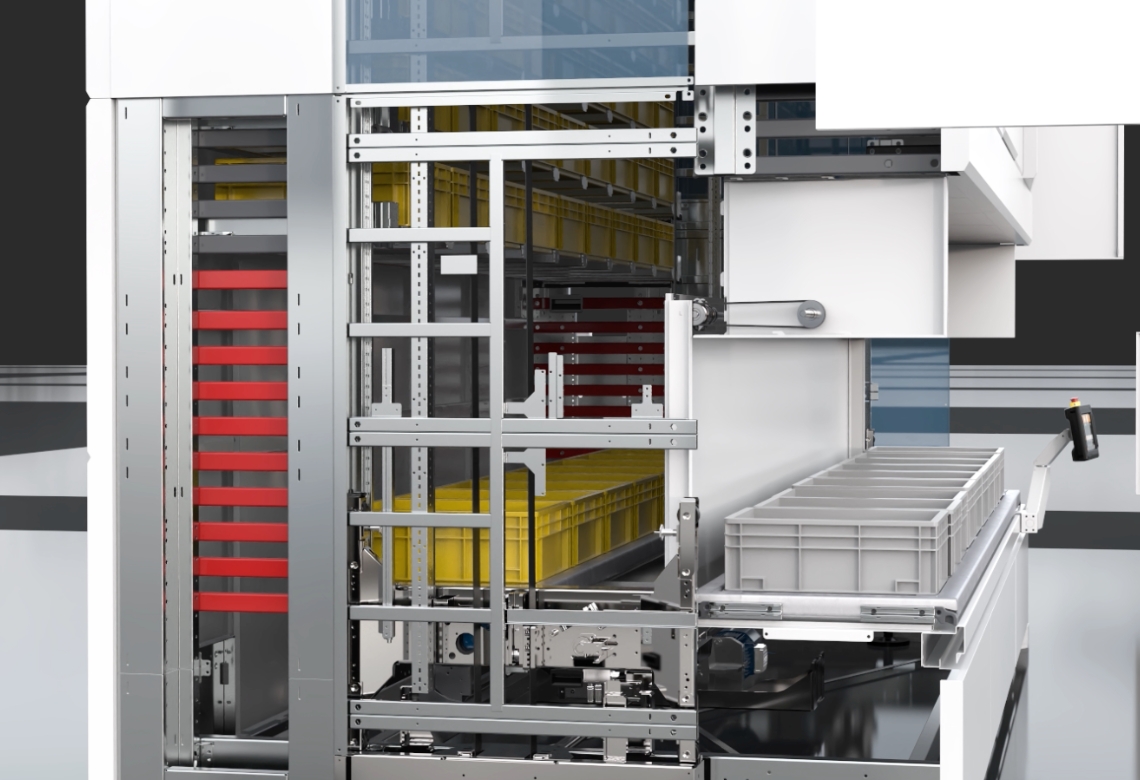

A central elevator with a telescopic fork retrieves up to 9 bins simultaneously, minimizing wait times and allowing multiple order lines to be fulfilled in a single cycle.

Efficient Use of Space

With a compact footprint and the ability to reach heights up to 65′, Flexibox maximizes vertical storage, accommodating hundreds of bins while freeing up valuable floor space.

Flexible and Scalable Design

Flexibox adapts to growing demands with the ability to expand capacity by adding extra trays or increasing the unit’s height or additional units as order volumes grow.

Ergonomic Operation

The picking bay is positioned at an ideal working height, reducing physical strain and improving workplace safety. The Buffer Bay configuration minimizes delays between picks.

Smart and Precise Retrieval

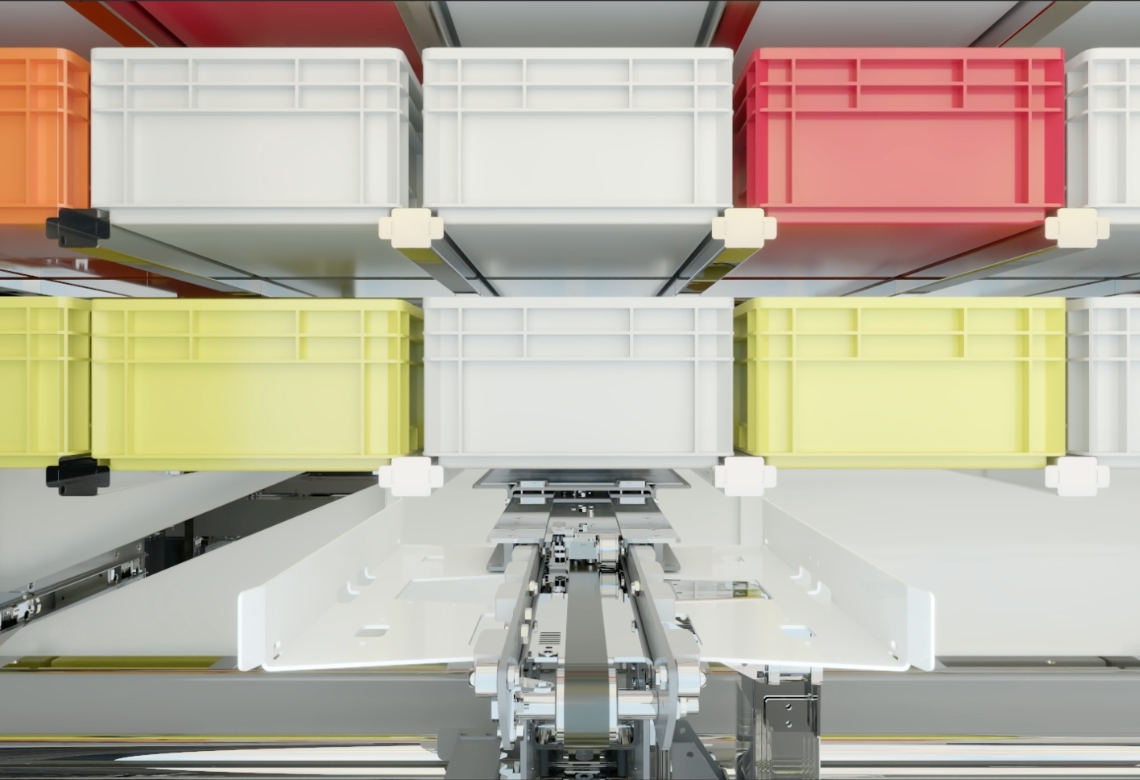

Flexibox’s immediate call feature enables single-item retrieval without moving other bins, ensuring faster, more accurate order picking than conventional systems.

Advanced Technological Integration

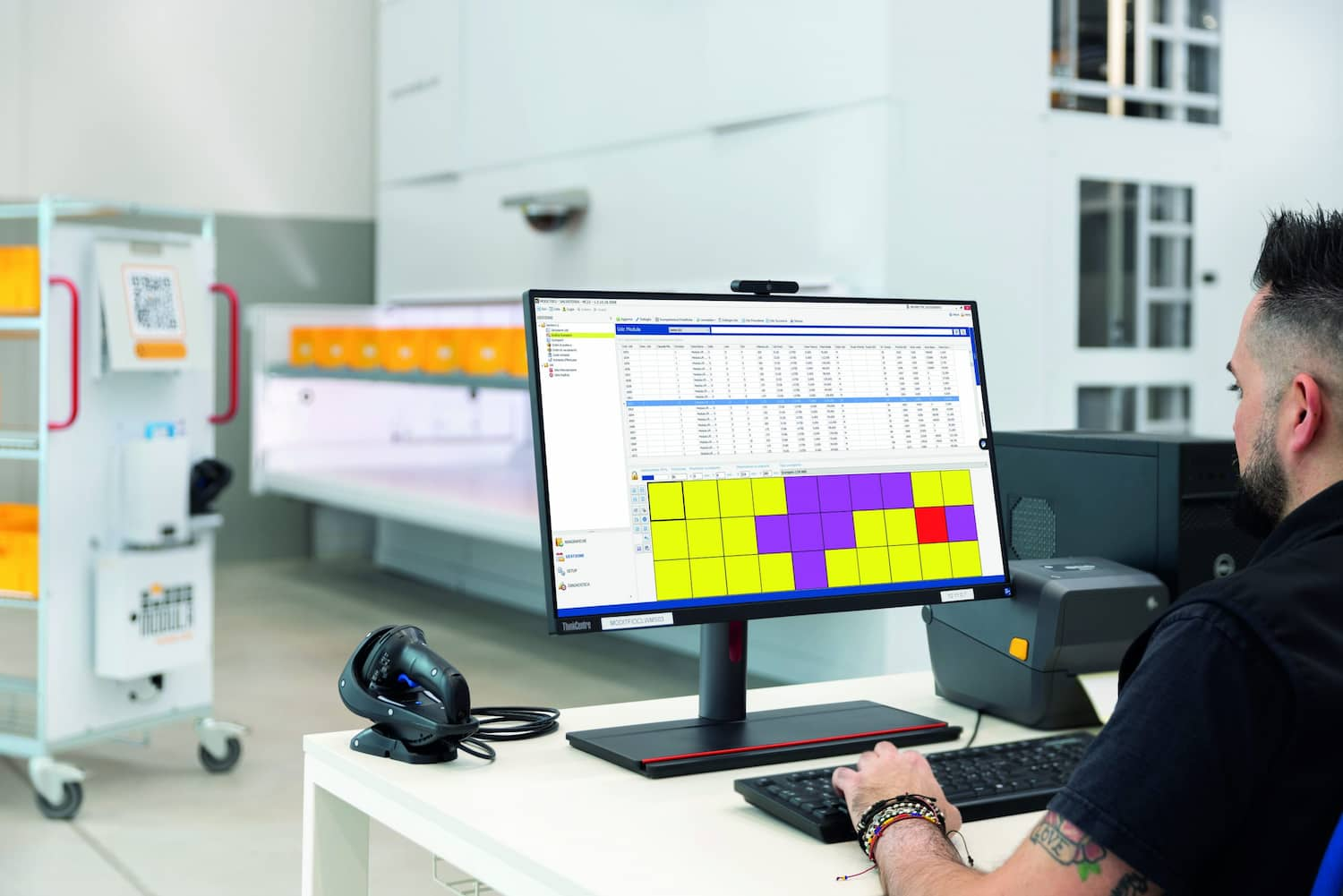

It integrates with our WMS and third-party systems, ensuring compatibility with conveyor belts, AGVs, and AMRs for seamless automation and streamlined workflows.

Modula Flexibox – How Does It Work?

Flexibox is designed for maximum efficiency, featuring a central elevator with a telescopic fork that can retrieve up to nine bins simultaneously. Thanks to the WMS software integration, this advanced system groups multiple order references within a single tray, significantly reducing operator wait times and enabling faster order fulfillment.

When an order is received, Flexibox analyzes all order lines and uses the central elevator to retrieve the required bins. These bins are placed on a service tray delivered directly to the picking bay, allowing operators to complete multiple order lines in a single cycle.

While the current tray is being processed, the system simultaneously prepares the next one, ensuring an uninterrupted workflow and high speed picking rate.

Modula Flexibox – Bay Options & Smart Preparation

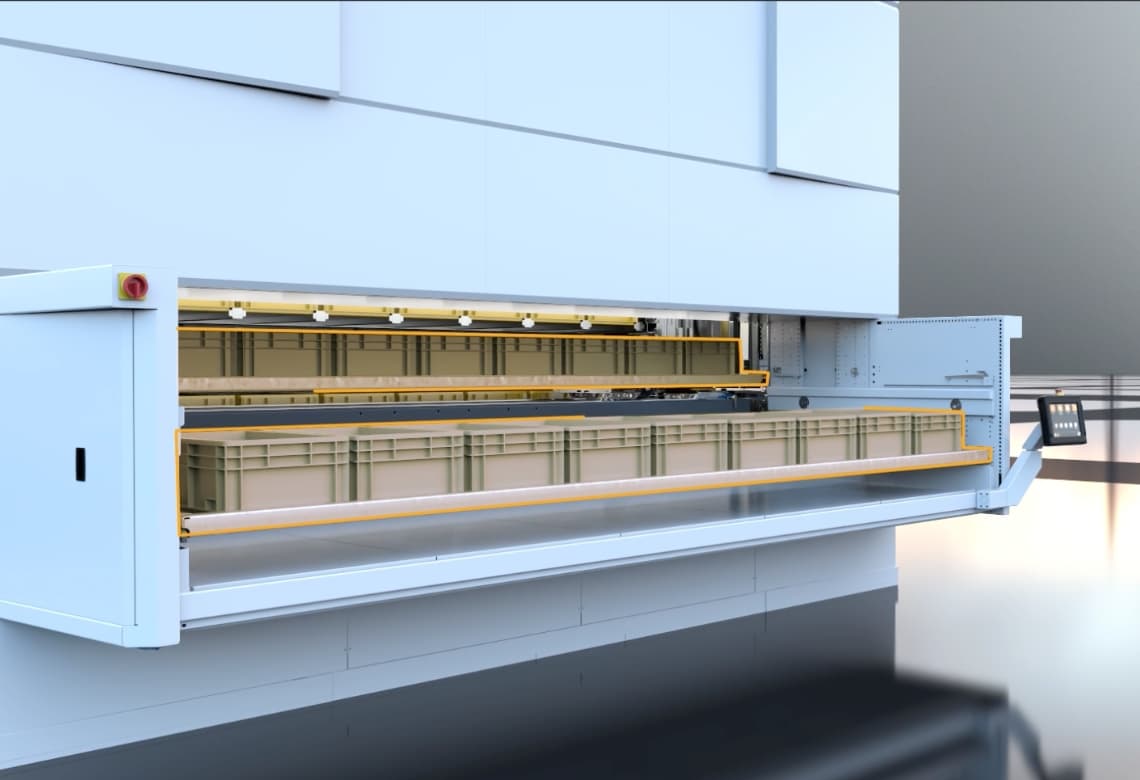

Internal, External, Single or Dual Delivery Bay

Flexibox provides the flexibility to operate with either an internal or external bay, offering single or dual load levels to suit different operational needs. The internal bay is ideal for optimizing floor space, making it perfect for compact environments. In contrast, the external bay focuses on maximizing picking speed .

With a single load level, all picking is performed at an ergonomic height, ensuring operator comfort. The dual load level enhances efficiency and is well-suited for workflows with high demand.

Buffer Bay

The Buffer Bay is designed to enhance ergonomics without compromising efficiency.

In this setup, trays are delivered one at a time to Tray Level 1, ensuring all picking occurs at a comfortable working height. While the operator is working, the system prepares the next tray in the rear column, so it’s ready to be delivered as soon as needed. This continuous flow minimizes waiting times, boosts operational efficiency, and maintains optimal performance without sacrificing ergonomics.

Smart Preparation

Flexibox’s Smart Preparation fully automates order preparation during idle periods. Controlled by the WMS, the system pre-arranges trays in advance using the central elevator, creating “ready-to-pick” trays based on incoming orders. When operators arrive at the bay, the pre-staged trays are immediately available, eliminating waiting times and streamlining workflows.

This ensures maximum efficiency, prevents downtime, and allows Flexibox to operate at full capacity, delivering optimized trays for seamless and productive picking operations.

Modula Flexibox – Unlimited Integrations

Side by Side with our VLM Systems

Flexibox seamlessly operates alongside Modula’s proven Vertical Lift Modules (VLMs) systems, offering a complete storage solution for products of all sizes. Flexibox is ideal for small bins (600 x 400 mm), while VLM systems handle larger items or bulk storage. Together, they create an optimal balance for fast-moving and slow-moving inventory.

Combine it with conveyors, AGVs, and Autonomous Mobile Robots

Flexibox seamlessly connects with conveyors, Automated Guided Vehicles (AGVs), and Autonomous Mobile Robots to fully automate the movement of bins across different warehouse areas. This reduces manual tasks and boosts productivity.

Integration with Put To Light Systems

Flexibox can be combined with put-to-light systems to guide operators to the correct bin locations, enhancing picking accuracy and speeding up order fulfillment.

Flexibox can also integrate with tools like picking carts, picking stations, color-coded picking systems, and wearable technologies, such as smart gloves, providing additional support to operators

Integration with Picking Robots

Flexibox is designed to work seamlessly with robotic picking systems, allowing for fully automated picking operations in high-throughput environments.

Modula Flexibox – Versatility Across Industry

Automotive Industry

Handles a wide range of items, ensuring all parts are easily accessible.

Food & Beverage Industry

Production, processing, and distribution of food and drink products.

Modula Flexibox Technical Highlights

Bin Size

Bin Payload Capacity

Bin Height Range

N. of Bins per tray

Unit Height

Unit Height Increment

Types Of Bay

Number of Bays

Modula Vertical Lift Modules

Modula Vertical Lift Modules (VLMs) are fully automated vertical storage systems that take up a minimum footprint by utilizing the ceiling height available.

These systems allow for large inventory of goods to be quickly accessible while being stored in a safe and secure environment and automatically delivered to the operators, with a simple touch on the user friendly Copilot controller or the scan of the barcode.

Following the Goods-to-Person principle, the VLM delivers the right part to the right person at the optimum ergonomic retrieval height. This feature eliminates the need to search for items. As such, productivity and efficiency are increased while picking errors are drastically reduced.

Modula Warehouse Management Systems