Modula Vertical Lift Modules

Modula Vertical Lift Modules

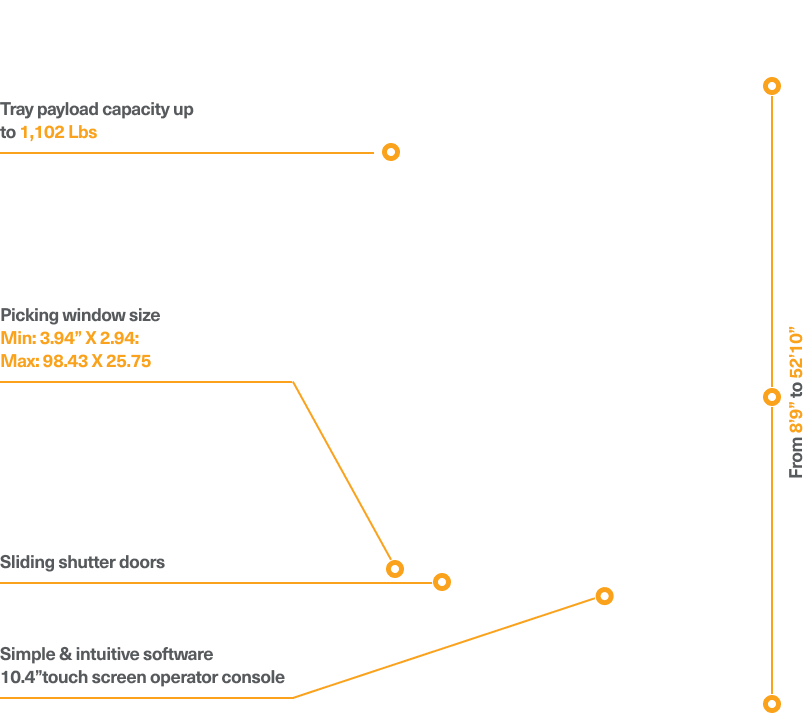

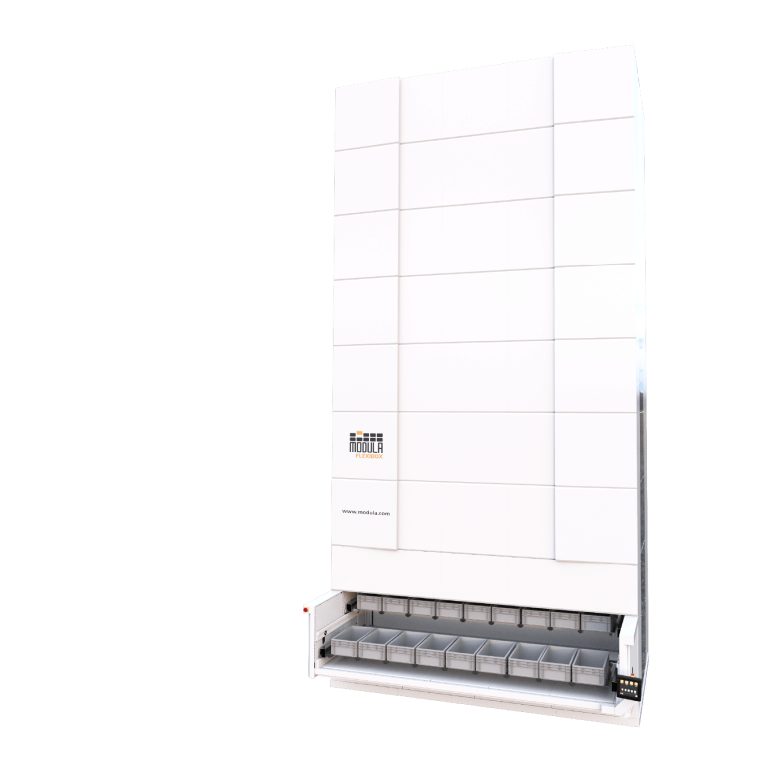

Modula Vertical Lift Modules (VLMs) are fully automated vertical storage systems that take up a minimum footprint by utilizing the ceiling height available.

These systems allow for large inventory of goods to be quickly accessible while being stored in a safe and secure environment and automatically delivered to the operators, with a simple touch on the user friendly Copilot controller or the scan of the barcode.

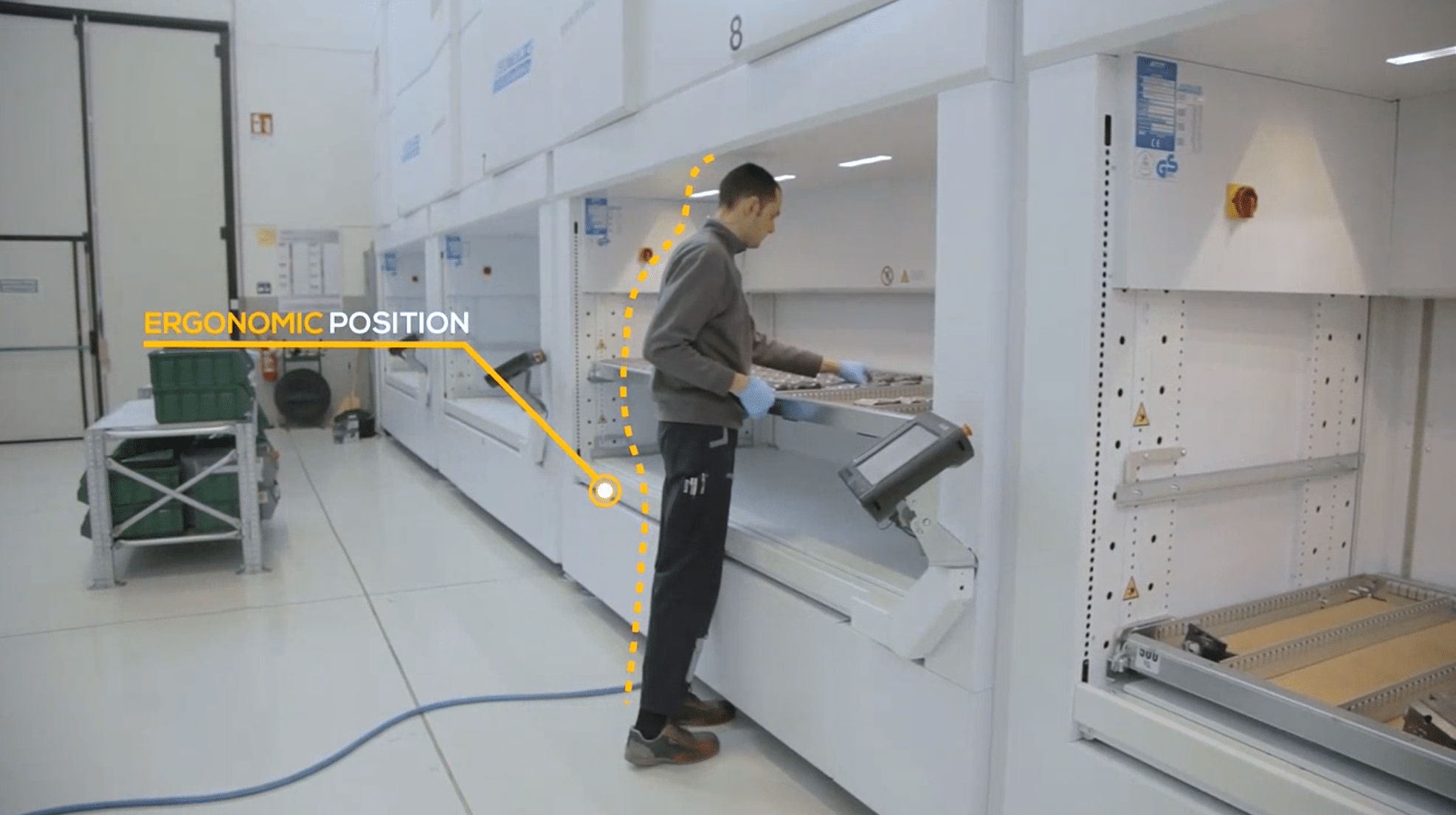

Following the Goods-to-Person principle, the vertical lift module delivers the right part to the right person at the optimum ergonomic retrieval height. This feature eliminates the need to search for items. As such, productivity and efficiency are increased while picking errors are drastically reduced.

Vertical Lift Modules Features & Benefits

Saves Space & Reduces Operations Cost

Saves up to 90% of valuable floor space compared to traditional storage methods and makes space available for future growth needs.

Increases Productivity and Accuracy

Vertical lift modules automatically deliver items to the operator with a simple touch on the Copilot console or a scan of a barcode. This feature drastically reduces handling times, both in picking and replenishing, as there is no walking back and forth to find and retrieve goods.

Process More Orders in Less Time

Operators can process even complex orders in the shortest possible time and with the highest quality level, even during peak workload times, as they don’t have to wait between jobs when retrieving parts.

Industry studies have shown that vertical storage solutions can increase workforce productivity by up to 85% because one worker is able to handle the same volume of work previously performed by multiple operators.

Stock Density Optimization

A height-detection system determines vertical dimensions of items as the tray is put away, calculating adjustments in real time to maximize storage density within the unit.

Designed with Worker Ergonomics and Safety in Mind

Following the parts to picker’s principle, these automated storage systems deliver the items to the fixed operator’s location where the picking operations take place. Walking time for parts retrieval is reduced up to 90% when compared to static shelving.

Security & Inventory Control

A reliable locking and validation feature plays a key role in many industries. Every unit is password protected, allowing only authorized operators with a personal badge and/or access code entry to operate the machine.

All picking operations are monitored and log-ins are tracked even down to specific trays, depending on the chosen level of security.

Flexible Integration & Scalable Design

Thanks to our partitions and dividers, you can create the exact number of storage locations required, and their configurations can be adjusted at any time to accommodate changes in the size or quantity of your stored items or seasonal demands.

The modular design of the VLM ensures almost unlimited flexibility. The height can be modified and adjusted to optimize the unit for the ceiling height by adding or removing modules. If you change locations or move to a different site, your Modula VLM can be quickly adapted to the new height requirements.

The Modula Lift can extend over different floors with access openings on the front and rear, allowing operations on multiple levels simultaneously. The units can also be installed outside of buildings to further expand storage space.

Available Modula VLM Models

Modula Warehouse Management Systems

Want to improve the performance of your picking and storage operation?

Maximize the performance of every inch of your floor space with Modula Vertical Lift Modules.