Taglermaq Enhances Logistics Efficiency and Accuracy with Modula VLMs

Taglermaq Case Study Summary

Taglermaq, based in Santiago, Chile, is a leading provider of logistics solutions and machinery for the food industry and other sectors. With over 30 years of experience, they specialize in high-precision machinery for packaging, processing, inspection, and storage. To streamline its operations and improve warehouse logistics, Taglermaq turned to Modula Vertical Lift Modules (VLMs). By replacing traditional shelving with Modula VLMs, the company achieved a significant reduction in space usage while also improving order accuracy, speed, and safety for its operators.

The Challenge

Taglermaq faced the challenge of managing a growing inventory in a space-efficient way. Previously, the company relied on a traditional RF-based picking system, which was time-consuming and required auxiliary equipment such as lifts and ladders. This process not only consumed valuable floor space but also created inefficiencies, with picking routes taking 15 to 20 minutes per order. The company sought a solution that would improve storage capacity, reduce order preparation time, and ensure high accuracy in order fulfillment while minimizing risks for operators.

The Solution

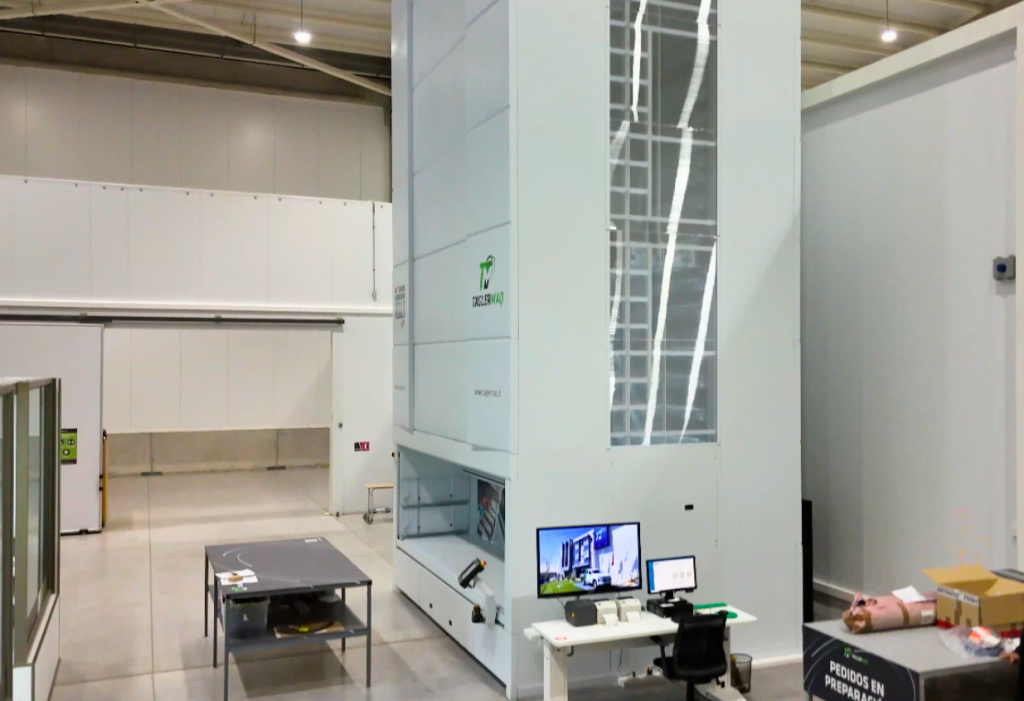

To address these challenges, Taglermaq implemented a Modula Lift ML25D, standing at 38 feet (11.6 meters) high. The unit was tailored to meet the company’s space and operational needs, providing a high level of flexibility and scalability. With Modula, Taglermaq has been able to store over 1,076 square feet (100 square meters) of inventory in just 150 square feet (14 square meters) of floor space, maximizing vertical storage and reducing the need for additional shelving.

The Modula system has also greatly enhanced the accuracy of order picking. Unlike the previous RF-based system, which required 15 to 20 minutes to prepare a single order, Modula enables Taglermaq to process 10 orders in just 20 minutes without the need for auxiliary equipment. The system is fully integrated with Taglermaq’s processes, ensuring accurate inventory tracking and streamlined logistics.

In addition to space optimization and faster order fulfillment, Modula VLMs provide multiple safety features that improve operator safety by eliminating the need for ladders and other support equipment. The system’s user-friendly interface and precision in tracking orders have increased operational efficiency, allowing for higher customer satisfaction.

Key Benefits of the Taglermaq Case Study:

- Space Optimization: Modula VLMs reduced storage space by efficiently utilizing vertical storage, allowing Taglermaq to store over 1,076 square feet (100 square meters) of inventory in just 150 square feet (14 square meters) of floor space.

- Faster Order Fulfillment: Order preparation times were reduced from 15-20 minutes per order to 20 minutes for 10 orders, improving overall productivity and reducing the need for auxiliary equipment.

- Increased Accuracy: The Modula system significantly improved order accuracy, ensuring that every order is 100% complete, thanks to precise inventory management.

- Improved Safety: By eliminating the need for ladders and lifts, Modula VLMs reduced the risks of injury for operators.

- Scalability and Flexibility: The Modula VLMs provide scalable solutions that can adapt to the company’s growing needs, improving both operational efficiency and customer satisfaction.