Frassinetti Enhances Efficiency with Modula Automation

Case Study Summary

Frassineti srl, a leather goods company founded in 1964, has evolved to offer customized services with cutting-edge technology in pattern making. Facing challenges related to material storage and product traceability, they sought a solution to enhance productivity and efficiency. The traditional method with bulky shelving was impeding their operations.

The Challenge

The outdated storage method made product traceability difficult and hampered productivity. Products were stored on shelves that occupied significant space.

The Solution

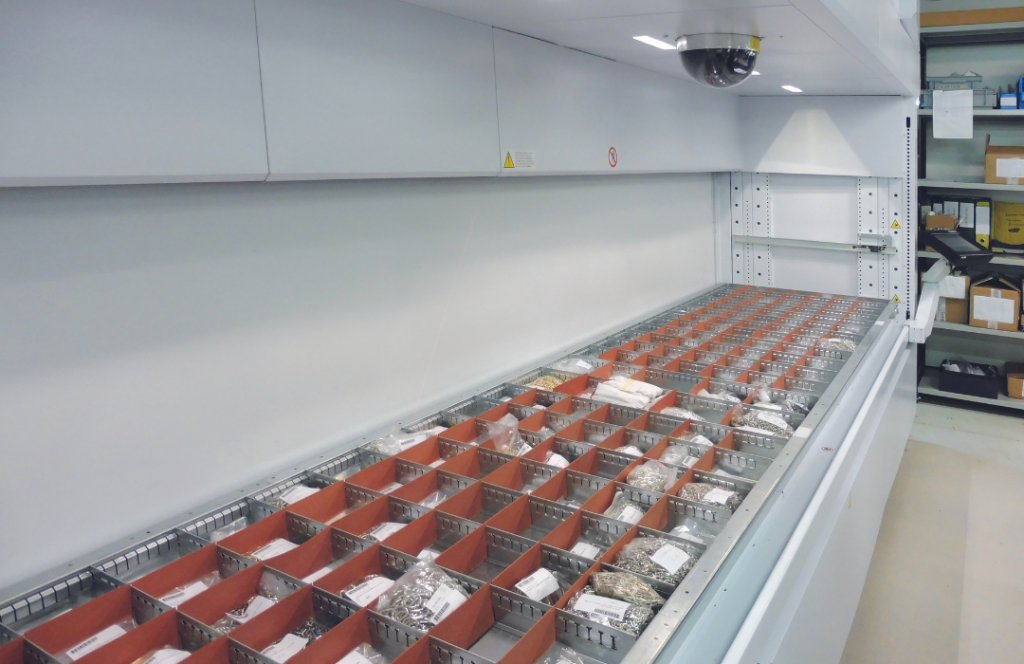

To address these challenges, Frassineti decided to implement 2 Modula Vertical Lift Modules: 1 Sintes 1.7 and 1 Modula Lift ML25D. These installations greatly facilitated operator activities, improved material organization, and enhanced picking efficiency. Additionally, a Laser Pointer was installed in the Modula Lift, increasing product location precision and eliminating errors.