Del Vecchia Spa Improves Picking Efficiency with Modula VLMs

Case Study Summary

Del Vecchia Spa, a renowned distributor of industrial and domestic sewing machines in Italy, encountered challenges related to space utilization and product traceability in their warehouse. The implementation of one Modula ML25D vertical lift module offered an effective solution, enhancing picking efficiency and improving product tracking capabilities.

The Challenge

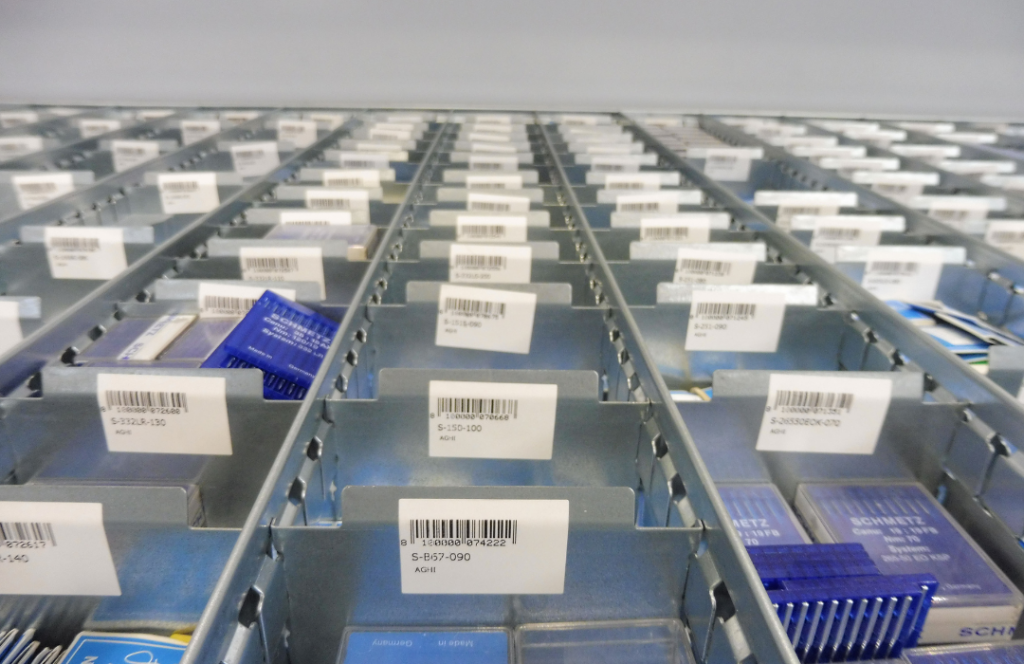

Del Vecchia Spa initially faced difficulties due to traditional shelving systems that occupied a significant amount of space and impeded product traceability. Their existing warehouse setup did not support efficient picking operations, resulting in delays and challenges in managing sewing machine accessories and spare parts.

The Solution

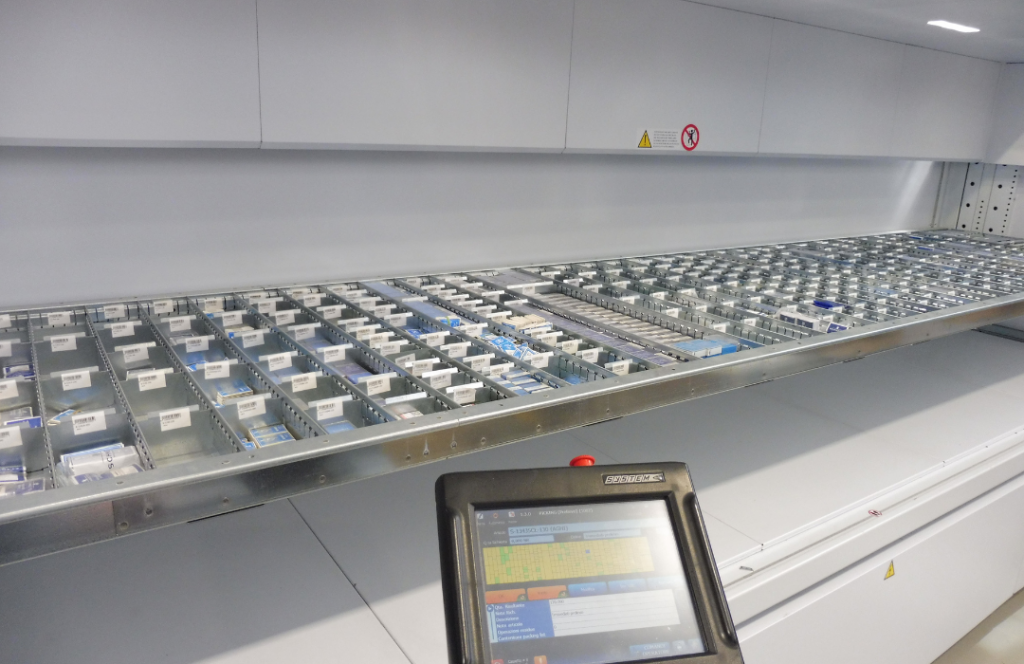

To address these challenges, Del Vecchia Spa opted to install one Modula ML25D vertical lift module. This innovative solution helps minimize the utilization of floor space, while the double internal bay makes it possible to double the picking speed. The unit is equipped with a label printer, enabling them to customize and promptly attach labels to stored materials.

When receiving customer orders, operators input the order information into the Warehouse Management System (WMS), and the tray containing the desired product is automatically delivered at an ergonomic height, based to the goods-to-person principle. During the picking and replenishment processes, the operators input the information through the Copilot console and promptly print labels and apply them to packages and bags to immediately identify the items.

The introduction of Modula into their facility optimized Del Vecchia’s picking process and significantly condensed their warehouse space. This innovative solution effectively resolved concerns related to product traceability.