Artemiranda Transforms Art Supplies Distribution with Modula

Artemiranda Case Study Summary

Artemiranda, a family-run business founded in 1922, specializes in distributing art supplies globally. The company has grown to serve over 130 countries with a catalog of 37,000 references. To streamline its logistics and support its expanding online operations, Artemiranda integrated four Modula Vertical Lift Modules (VLMs). This decision has enabled Artemiranda to manage its large inventory with greater efficiency, achieving fast order fulfillment and ensuring top-notch customer service.

The Challenge

Artemiranda faced significant challenges managing its expansive inventory in a fast-paced, global distribution environment. The company needed a solution to streamline its picking process, optimize space, and reduce errors. All while maintaining the flexibility to handle both small and large product orders. The warehouse had previously relied on traditional shelving and manual operations, which were increasingly inadequate for the growing order volumes and the need for rapid delivery.

The company also needed a system that would allow them to quickly consolidate orders and accurately fulfill shipments, ensuring timely delivery to customers worldwide. The high number of references and the hybrid nature of their business—combining both art supplies and bulkier items—required a flexible, scalable solution that would streamline both picking and replenishment.

The Solution

In response to these challenges, Artemiranda adopted four Modula Vertical Lift Modules (VLMs), including two Modula Lift MC25D units and two Modula Lift ML50D units, each standing at 6.7 meters tall. These units were installed to optimize space and improve picking accuracy.

Modula’s advanced WMS (Warehouse Management System) integration allowed Artemiranda to optimize picking operations, reduce errors, and increase productivity. The WMS tracks inventory in real-time and coordinates warehouse movements, ensuring that orders are prepared quickly and accurately. The VLMs’ features, such as the alphanumeric LED bar, laser pointer, and external picking monitor, guide operators to the correct products and improve picking efficiency.

Orders are prepared by selecting items from the Modula VLMs, while bulkier or slower-moving items are retrieved from the manual warehouse.

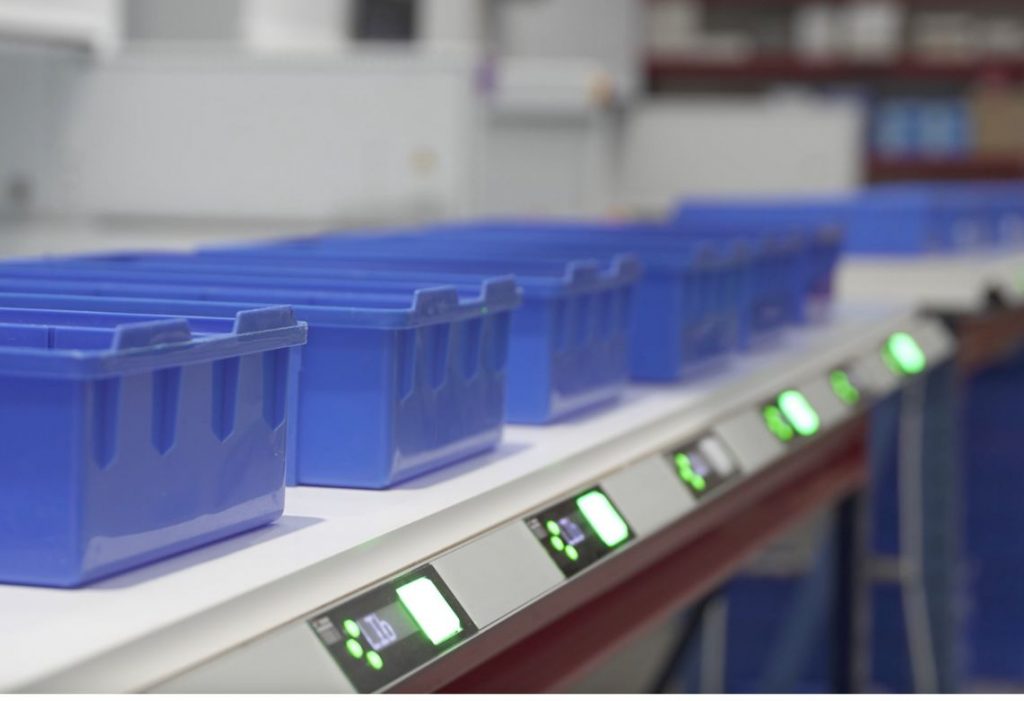

The company has also implemented a Put to Light system, which enables the preparation of up to 24 orders simultaneously, improving efficiency, especially when common items are shared across several orders. With this setup, Artemiranda processes 10 lines every minute and a half with a total of 1,500 to 2,500 order lines daily, ensuring that customers receive their orders quickly. 97% of orders placed before 1 p.m. are shipped the same day.

Key Features of the Artemiranda Case Study:

- Space Optimization: Four Modula VLMs, including two MC25D and two ML50D units, helped Artemiranda reclaim valuable warehouse space, improving storage efficiency and reducing operational costs.

- Improved Picking Accuracy: Features such as the alphanumeric LED bar, laser pointer, and external picking monitor guide operators to the correct items. This reduces errors and enhances accuracy.

- Real-Time Inventory Management: Modula’s integration with Artemiranda’s WMS system ensures up-to-date stock tracking and efficient inventory management.

- Enhanced Productivity: The system supports the processing of 1,500 to 2,500 order lines daily, significantly improving picking speed and reducing labor costs.

- Fast Delivery: Orders placed before 1 p.m. are dispatched the same day, ensuring timely delivery to customers worldwide, with customers in the Iberian Peninsula receiving their orders within 48 hours.

- Scalability: Artemiranda plans to add two more Modula Lift units in 2025, continuing to scale operations and maintain efficient fulfillment.