Avoid Unneeded Warehouse Expansion Choose a Modula Vertical Lift Module Instead

Rather than expanding your warehouse or moving to a new location, consider a Modula vertical lift module (VLM) to greatly reduce needed floor space.

For companies looking to not only boost storage capacity but accelerate their picking processes and better organize parts, a VLM is the most cost effective solution.

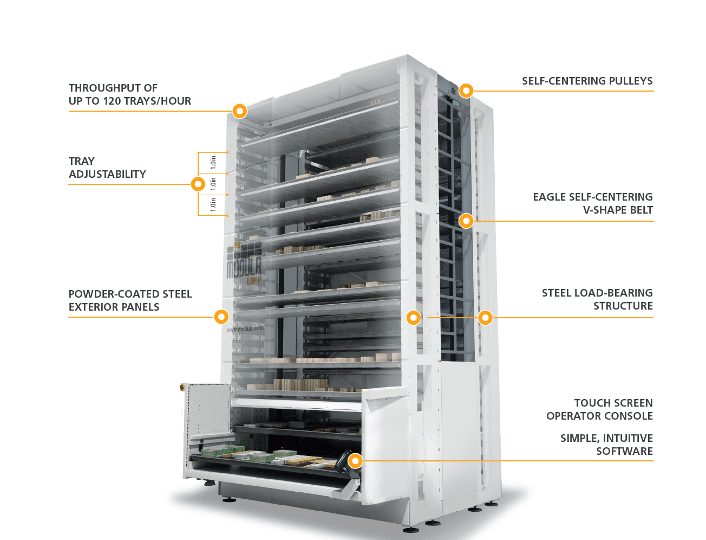

VLMs are fully automated vertical storage systems that take up a minimum floor space area by utilizing the available ceiling height. These systems allow large inventories of goods to be stored in a safe and secure environment, then automatically retrieved and quickly delivered to operators.

No more bending, ladder-climbing or walking long distances to search for and store parts or items. Instead, the parts are brought to operators automatically and delivered at the ergonomically optimum retrieval height. Because of this, productivity and efficiency are increased while picking errors are drastically reduced.

Modula VLMs are some of the most advanced dynamic and flexible solutions available. The modular design of the VLM ensures almost unlimited flexibility. The height can be adjusted to accommodate varying ceiling heights by adding or removing modules. If you change locations or move to a different site, your Modula VLM can be adapted quickly to the new height requirements.

Moreover, thanks to an inventory height-detection system, the height of the contents of each tray is measured as the tray is put away. This allows the densest storage location to be determined in real-time and maximizes the storage density within the unit.

Trays can be organized for every type and size of stored item. Thanks to our partitions and dividers, you can create the exact number of storage locations required, and their configuration can be adjusted at any time to accommodate changes in the size or quantity of your stored items.

Every VLM can be employed as a standalone system utilizing our warehouse management system (WMS) software or as a fully interfaced version to work with your host management system.

Get the most performance out of every inch of your manufacturing floor space with Modula Vertical Lift Modules!

Benefits of Vertical Lift Modules:

- Saves up to 90% of valuable floor space compared to traditional storage methods

- Picking speed up to 300 lines per hour

- Ergonomic storage and retrieval workstation – items are automatically delivered to the optimum ergonomic retrieval height

- WMS software optimizing inventory control management

- Quick return on investment (anywhere from six to 18 months, depending on the overall size of the project)

- Scalable design

- Stores a wide range of part sizes (small, medium, large)

- Provides a safe storage environment for inventory

- Creates new revenue activities by reclaiming otherwise wasted space and labor